化工学报 ›› 2025, Vol. 76 ›› Issue (S1): 297-308.DOI: 10.11949/0438-1157.20250089

• 能源和环境工程 • 上一篇

收稿日期:2025-01-20

修回日期:2025-03-25

出版日期:2025-06-25

发布日期:2025-06-26

通讯作者:

何婷

作者简介:何婷(1995—),女,博士,副研究员,heting199503@163.com

Ting HE( ), Shuyang HUANG, Kun HUANG, Liqiong CHEN

), Shuyang HUANG, Kun HUANG, Liqiong CHEN

Received:2025-01-20

Revised:2025-03-25

Online:2025-06-25

Published:2025-06-26

Contact:

Ting HE

摘要:

以醇胺溶液作为吸收剂的化学吸收是目前天然气脱碳领域使用最为广泛的技术,拥有处理量大、循环稳定性好等优点,但是化学吸收剂的再生过程能耗非常高。为降低化学吸收脱碳的能耗,提出了天然气化学吸收脱碳-高温热泵耦合流程,通过高温热泵将气田上的废水余热用于脱碳流程的再生过程,达到节能降碳。利用Aspen HYSYS软件对采用MDEA溶液的脱碳系统进行建模和参数优化。结果表明:经过优化,该套工艺的脱碳率高达95%,系统的单位综合能耗为0.3821 kW·h/kg CO2,相比于常规脱碳系统(单位综合能耗为0.8828 kW·h/kg CO2)降低了56.72%。

中图分类号:

何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308.

Ting HE, Shuyang HUANG, Kun HUANG, Liqiong CHEN. Research on the coupled process of natural gas chemical absorption decarbonization and high temperature heat pump based on waste heat utilization[J]. CIESC Journal, 2025, 76(S1): 297-308.

| 组分 | CH4 | C2H6 | C3H8 | i-C4H10 | n-C4H10 |

|---|---|---|---|---|---|

| 组成/%(mol) | 0.938063 | 0.003600 | 0.000466 | 0.000105 | 0.000108 |

| 组分 | i-C5H12 | n-C5H12 | H2O | H2S | CO2 |

| 组成/%(mol) | 0.000045 | 0.000057 | 0.000510 | 0.000466 | 0.056600 |

表1 原料气的组分设置

Table 1 Component settings for feedstock gas

| 组分 | CH4 | C2H6 | C3H8 | i-C4H10 | n-C4H10 |

|---|---|---|---|---|---|

| 组成/%(mol) | 0.938063 | 0.003600 | 0.000466 | 0.000105 | 0.000108 |

| 组分 | i-C5H12 | n-C5H12 | H2O | H2S | CO2 |

| 组成/%(mol) | 0.000045 | 0.000057 | 0.000510 | 0.000466 | 0.056600 |

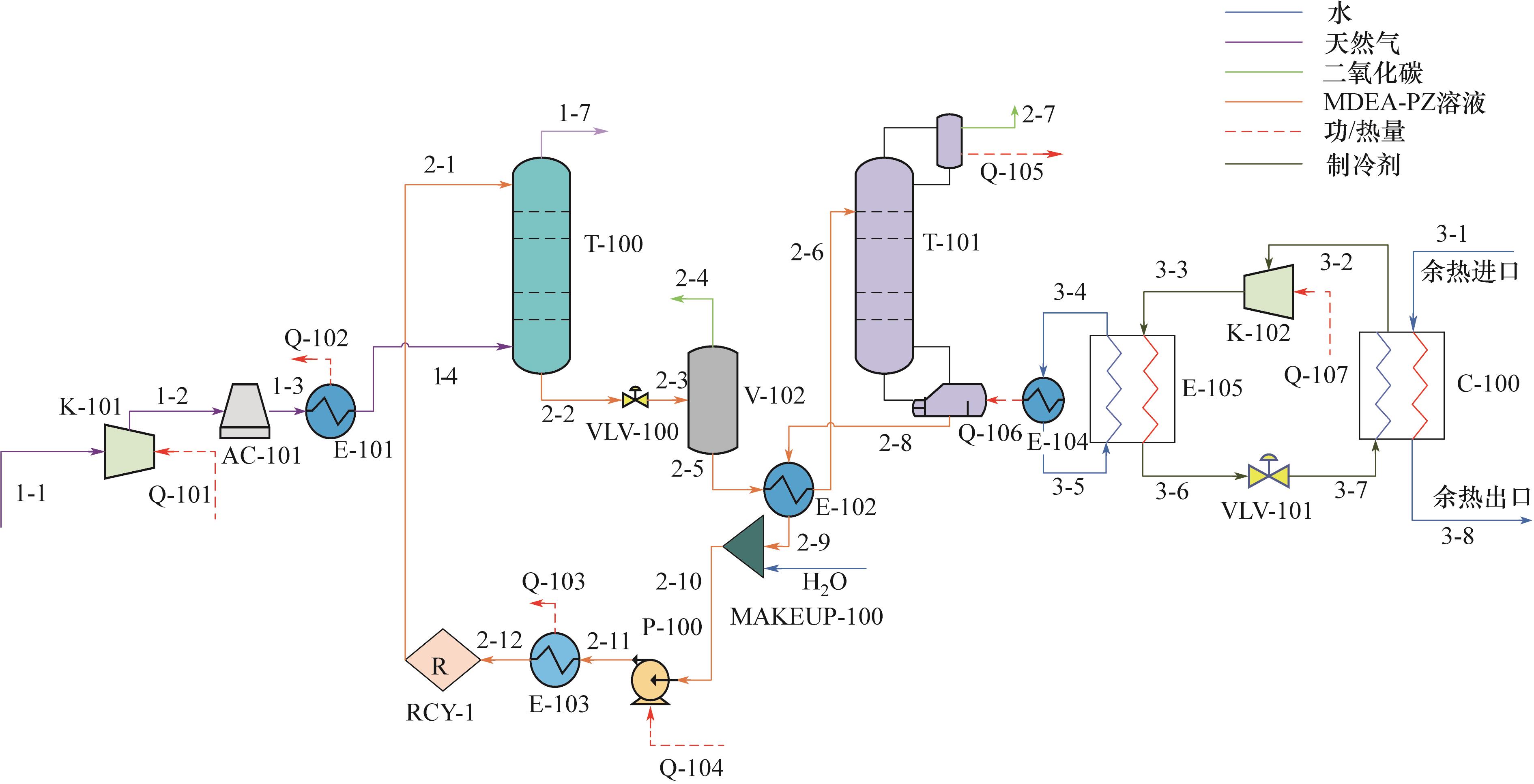

图2 基于余热利用的天然气化学吸收脱碳-高温热泵耦合工艺流程图K—压缩机;AC—空冷机;V—分离器;E—换热器;T-100—吸收塔;T-101—解析塔;VLV—阀门;P—泵;C—蒸发器;MAKEUP—补充;RCY—循环

Fig.2 Process flowchart of natural gas chemical absorption decarbonization high-temperature heat pump coupling based on waste heat utilization

| 流股 | T/℃ | P/kPa | 摩尔流量/(kmol/h) |

|---|---|---|---|

| 1-1 | 25.00 | 2500 | 10364.87 |

| 1-4 | 40.00 | 3700 | 10364.87 |

| 1-7 | 40.13 | 3640 | 9777.00 |

| 2-1 | 40.00 | 3640 | 15031.00 |

| 2-2 | 65.04 | 3700 | 15618.47 |

| 2-6 | 85.00 | 170 | 15618.47 |

| 2-7 | 74.99 | 167 | 738.30 |

| 2-8 | 112.00 | 170 | 14837.30 |

| 3-1 | 80 | 220 | 42708.20 |

| 3-3 | 129 | 1443 | 4157.94 |

| 3-4 | 115 | 166.1 | 1941.00 |

| 3-5 | 115 | 169.1 | 1941.00 |

| 3-6 | 115 | 1433 | 4157.94 |

表2 系统关键参数表

Table 2 System key parameter table

| 流股 | T/℃ | P/kPa | 摩尔流量/(kmol/h) |

|---|---|---|---|

| 1-1 | 25.00 | 2500 | 10364.87 |

| 1-4 | 40.00 | 3700 | 10364.87 |

| 1-7 | 40.13 | 3640 | 9777.00 |

| 2-1 | 40.00 | 3640 | 15031.00 |

| 2-2 | 65.04 | 3700 | 15618.47 |

| 2-6 | 85.00 | 170 | 15618.47 |

| 2-7 | 74.99 | 167 | 738.30 |

| 2-8 | 112.00 | 170 | 14837.30 |

| 3-1 | 80 | 220 | 42708.20 |

| 3-3 | 129 | 1443 | 4157.94 |

| 3-4 | 115 | 166.1 | 1941.00 |

| 3-5 | 115 | 169.1 | 1941.00 |

| 3-6 | 115 | 1433 | 4157.94 |

图3 系统单位综合能耗和单位综合电耗随吸收塔压力的变化曲线

Fig.3 System unit comprehensive energy consumption and unit comprehensive power consumption variation curve with absorption tower pressure

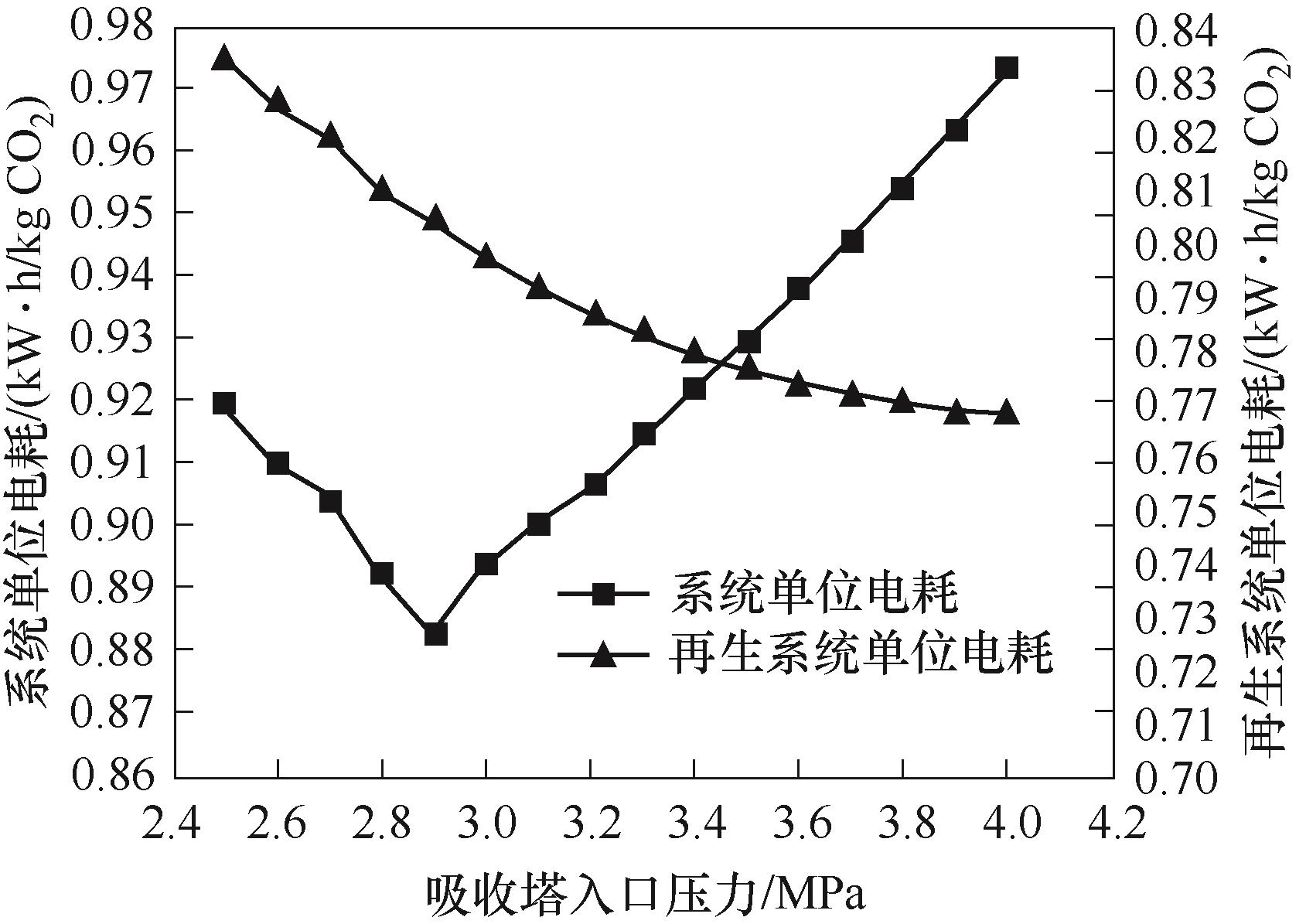

图4 系统单位电耗和再生系统单位电耗随吸收塔压力的变化曲线

Fig.4 The variation curves of system unit power consumption and regeneration system unit power consumption with absorption tower pressure

| 工质 | Tb/℃ | Tc/℃ | Pc/MPa | ρc/(kg/m3) | ODP | GWP | 安全等级 |

|---|---|---|---|---|---|---|---|

| R142b | -9.12 | 137.11 | 4.055 | 446.0 | 0.05700 | 1980.0 | A2 |

| R600 | -0.49 | 151.98 | 3.796 | 228.0 | 0 | 4.0 | A3 |

| R600a | -11.75 | 134.66 | 3.571 | 225.5 | 0 | 20.0 | A3 |

| R601 | 36.06 | 196.50 | 3.375 | 629.7 | 0 | 20.0 | A3 |

| R365mfc | 40.15 | 186.85 | 3.266 | 516.08 | 0 | 890.0 | A2 |

| R1233zd(E) | 18.32 | 165.60 | 3.571 | 476.31 | 0.00034 | 4.5 | A1 |

表3 纯工质相关系数

Table 3 Correlation coefficients of pure workmass

| 工质 | Tb/℃ | Tc/℃ | Pc/MPa | ρc/(kg/m3) | ODP | GWP | 安全等级 |

|---|---|---|---|---|---|---|---|

| R142b | -9.12 | 137.11 | 4.055 | 446.0 | 0.05700 | 1980.0 | A2 |

| R600 | -0.49 | 151.98 | 3.796 | 228.0 | 0 | 4.0 | A3 |

| R600a | -11.75 | 134.66 | 3.571 | 225.5 | 0 | 20.0 | A3 |

| R601 | 36.06 | 196.50 | 3.375 | 629.7 | 0 | 20.0 | A3 |

| R365mfc | 40.15 | 186.85 | 3.266 | 516.08 | 0 | 890.0 | A2 |

| R1233zd(E) | 18.32 | 165.60 | 3.571 | 476.31 | 0.00034 | 4.5 | A1 |

| 工质 | Pk/kPa | Po/kPa | 压缩比 | Tk/℃ | To/℃ | Q/(m3/h) | COP | P/kW | W/(kW·h/kg CO2) |

|---|---|---|---|---|---|---|---|---|---|

| R365mfc | 776 | 196 | 3.959 | 126 | 77 | 430 | 4.02 | 5188 | 0.3850 |

| R601 | 831 | 214 | 3.883 | 130 | 77 | 430 | 4.01 | 5200 | 0.3855 |

| R1233zd(E) | 1443 | 405 | 3.563 | 129 | 77 | 430 | 4.08 | 5115 | 0.3821 |

表4 主要运行参数

Table 4 Main operating parameters

| 工质 | Pk/kPa | Po/kPa | 压缩比 | Tk/℃ | To/℃ | Q/(m3/h) | COP | P/kW | W/(kW·h/kg CO2) |

|---|---|---|---|---|---|---|---|---|---|

| R365mfc | 776 | 196 | 3.959 | 126 | 77 | 430 | 4.02 | 5188 | 0.3850 |

| R601 | 831 | 214 | 3.883 | 130 | 77 | 430 | 4.01 | 5200 | 0.3855 |

| R1233zd(E) | 1443 | 405 | 3.563 | 129 | 77 | 430 | 4.08 | 5115 | 0.3821 |

| 1 | 杨永明. 2019全球主要能源展望报告对比与启示[J]. 新能源经贸观察, 2019(1): 70-83. |

| Yang Y M. Comparison and enlightenment of major global energy outlook reports in 2019[J]. Energy Outlook, 2019(1): 70-83. | |

| 2 | 王旭. 天然气富氧燃烧炉窑碳捕集工艺模拟研究[D]. 武汉: 华中科技大学, 2021. |

| Wang X. Simulation study on carbon capture process of natural gas oxygen-enriched combustion furnace[D]. Wuhan: Huazhong University of Science and Technology, 2021. | |

| 3 | 邬高翔. 天然气净化厂高含CO2尾气捕集工艺技术研究[D]. 西安: 西安石油大学, 2020. |

| Wu G X. Study on tail gas capture technology with high CO2 content in natural gas purification plant[D]. Xi'an: Xi'an Shiyou University, 2020. | |

| 4 | 何婷, 林文胜. 基于余热利用的活化MDEA法脱除CO2的天然气液化系统[J]. 化工学报, 2021, 72(S1): 453-460. |

| He T, Lin W S. Natural gas liquefaction system with activated MDEA method for CO2 removal based on waste heat utilization[J]. CIESC Journal, 2021, 72(S1): 453-460. | |

| 5 | 鲁红志, 范继承, 朱世峰, 等. 化学吸收法与变压吸附法用于水泥厂CO2捕集的对比分析[J]. 水泥, 2023(12): 26-28. |

| Lu H Z, Fan J C, Zhu S F . et al. Comparative analysis of CO2 capture by chemical absorption method and pressure swing adsorption method in cement plant[J]. Cement, 2023(12): 26-28. | |

| 6 | 张伍. 提高MDEA溶液脱碳的单位脱除率[J]. 当代化工研究, 2023(22): 110-112. |

| Zhang W. Improvement of unit removal rate for decarbonization of MDEA solution[J]. Contemporary Chemical Research, 2023(22): 110-112. | |

| 7 | 张凯, 付恩祥, 马士猛, 等. MDEA脱碳工艺在焦炉煤气生产天然气工艺的应用[J]. 化工管理, 2024(5): 141-143. |

| Zhang K, Fu E X, Ma S M . et al. Application of MDEA decarbonization process in natural gas production from coke oven gas[J]. Chemical Management, 2024(5): 141-143. | |

| 8 | 赵钦, 刘芳卓, 张迪, 等. 天然气液化工艺脱碳过程模拟与优化研究[J]. 四川化工, 2024, 27(2): 5-9. |

| Zhao Q, Liu F Z, Zhang D . et al. Simulation and optimization of decarbonization process in natural gas liquefaction[J]. Sichuan Chemical Industry, 2024, 27(2): 5-9. | |

| 9 | 马国光, 王金阳, 张涛. 二氧化碳捕集耦合工艺设计与优化[J]. 低碳化学与化工, 2024, 49(7): 76-83. |

| Ma G G, Wang J Y, Zhang T. Design and optimisation of coupled carbon dioxide capture process[J]. Low Carbon Chemistry and Chemical Industry, 2024, 49(7): 76-83. | |

| 10 | 王宁, 陆诗建, 刘玲, 等. 胺吸收体系中CO2催化解吸再生技术的研究进展[J]. 化工进展, 2025, 44(1): 445-464. |

| Wang N, Lu S J, Liu L . et al. Advances in catalytic desorption and regeneration of CO2 in amine absorption systems[J]. Chemical Industry and Engineering Progress, 2025, 44(1): 445-464. | |

| 11 | 王剑琨, 张媛媛, 唐建峰, 等. 天然气脱碳胺液再生能耗分析[J]. 天然气化工—C1化学与化工, 2022, 47(1): 109-114. |

| Wang J K, Zhang Y Y, Tang J F, et al. Analysis of energy consumption of amine solution regeneration in natural gas decarburized[J]. Natural Gas Chemical Industry, 2022, 47(1): 109-114. | |

| 12 | 陆诗建, 高丽娟, 王家凤, 等. 烟气CO2捕集热能梯级利用节能工艺耦合优化[J]. 化工进展, 2020, 39(2): 728-737. |

| Lu S J, Gao L J, Wang J F, et al. Coupling optimization of energy-saving technology for cascade utilization of flue gas CO2 capture system[J]. Chemical Industry and Engineering Progress, 2020, 39(2): 728-737. | |

| 13 | 蒋洪, 程祥, 陈泳村, 等. PZ活化MDEA乙烷深度脱碳工艺研究[J]. 石油与天然气化工, 2023, 52(3): 24-29, 40. |

| Jiang H, Cheng X, Chen Y C, et al. Ethane deep decarbonization process with PZ activated MDEA[J]. Chemical Engineering of Oil & Gas, 2023, 52(3): 24-29, 40. | |

| 14 | 陈杰, 张媛媛, 花亦怀, 等. 天然气半贫液脱碳工艺三元胺液配方优选[J]. 化工进展, 2020, 39(3): 975-983. |

| Chen J, Zhang Y Y, Hua Y H, et al. Screening of ternary amine solution for natural gas semi-lean liquid decarburization process[J]. Chemical Industry and Engineering Progress, 2020, 39(3): 975-983. | |

| 15 | 李亚清, 宋沆, 张玉涛, 等. 醇胺法吸收烟道气中二氧化碳的研究进展[J]. 低碳化学与化工, 2024, 49(10): 81-91. |

| Li Y Q, Song H, Zhang Y T . et al. Progress of carbon dioxide absorption in flue gas by alcohol-amine method[J]. Low Carbon Chemistry and Chemical Industry, 2024, 49(10): 81-91. | |

| 16 | 孟令琦, 聂乐愉. 混合有机胺溶液吸收CO2的研究进展[J]. 浙江化工, 2022, 53(10): 40-44. |

| Meng L Q, Nie L Y. Research progress on CO2 absorption by mixed organic amine solutions[J]. Zhejiang Chemical Industry, 2022, 53(10): 40-44.. | |

| 17 | 李媛, 张辰, 张腾, 等. 新型CO2捕集溶剂及工艺的研究进展[J]. 热力发电, 2023, 52(7): 14-25. |

| Li Y, Zhang C, Zhang T, et al. Research progress of novel carbon dioxide capture solvents and processes[J]. Thermal Power Generation, 2023, 52(7): 14-25. | |

| 18 | 程亮, 张昌建, 张超, 等. 基于Aspen Plus的燃煤电厂CO2捕集系统模拟分析[J]. 河北工程大学学报(自然科学版), 2019, 36(1): 51-53, 63. |

| Cheng L, Zhang C J, Zhang C, et al. Simulation analysis of CO2 capture system in coal fired power plant based on aspen plus[J]. Journal of Hebei University of Engineering (Natural Science Edition), 2019, 36(1): 51-53, 63. | |

| 19 | 马文亮. MDEA脱碳装置优化改造流程[J]. 云南化工, 2022, 49(10): 105-108. |

| Ma W L. Research on optimization, capacity expansion and energy saving of MDEA decarbonization unit[J]. Yunnan Chemical Technology, 2022, 49(10): 105-108. | |

| 20 | Moreno D, Ferro V R, de Riva J, et al. Absorption refrigeration cycles based on ionic liquids: refrigerant/absorbent selection by thermodynamic and process analysis[J]. Applied Energy, 2018, 213: 179-194. |

| 21 | Dong Y X, Yan H Z, Wang R Z. Significant thermal upgrade via cascade high temperature heat pump with low GWP working fluids[J]. Renewable and Sustainable Energy Reviews, 2024, 190: 114072. |

| 22 | Yan H Z, Ahrens M U, Hertwich E, et al. Heat pumps as a sustainable bridge for global heating and cooling at multi-scale[J]. Energy & Environmental Science, 2024, 17(6): 2081-2087. |

| 23 | Arpagaus C, Bless F, Uhlmann M, et al. High temperature heat pumps: market overview, state of the art, research status, refrigerants, and application potentials[J]. Energy, 2018, 152: 985-1010. |

| 24 | 杨凤, 刘清江, 宁璐璐, 等. R245fa高温热泵系统性能实验研究[J]. 低温与超导, 2020, 48(12): 85-90. |

| Yang F, Liu Q J, Ning L L, et al. Experimental study on performance of R245fa high temperature heat pump system[J]. Cryogenics & Superconductivity, 2020, 48(12): 85-90. | |

| 25 | 孙健, 秦宇, 王寅武, 等. 基于新型工质热泵的烟气余热回收优化温度研究[J]. 综合智慧能源, 2023, 45(4): 19-25. |

| Sun J, Qin Y, Wang Y W, et al. Study on the optimal temperature for flue gas waste heat recovery of the heat pump with new working fluid[J]. Integrated Intelligent Energy, 2023, 45(4): 19-25. | |

| 26 | 孙健, 马世财, 霍成, 等. 烟气余热回收高温电动热泵混合工质性能研究[J]. 华北电力大学学报(自然科学版), 2021, 48(2): 120-126. |

| Sun J, Ma S C, Huo C, et al. Study on performance of high temperature electric heat pump mixture for flue gas waste heat recovery[J]. Journal of North China Electric Power University (Natural Science Edition), 2021, 48(2): 120-126. | |

| 27 | Guo H, Gong M, Qin X. Performance analysis of a modified subcritical zeotropic mixture recuperative high-temperature heat pump[J]. Applied Energy, 2019, 237: 338-352. |

| 28 | 庄绪成, 郭健翔, 孙晋飞, 等. R134a/R245fa对比R245fa高温热泵循环性能实验研究[J]. 青岛理工大学学报, 2020, 41(4): 81-86. |

| Zhuang X C, Guo J X, Sun J F, et al. Experimental research on cyclic performance of high temperature heat pump with R134a/R245fa in comparison with R245fa[J]. Journal of Qingdao University of Technology, 2020, 41(4): 81-86. | |

| 29 | Yang M B, Li T, Feng X, et al. A simulation-based targeting method for heat pump placements in heat exchanger networks[J]. Energy, 2020, 203: 117907. |

| 30 | Mikielewicz D, Wajs J. Performance of the very high-temperature heat pump with low GWP working fluids[J]. Energy, 2019, 182: 460-470. |

| 31 | 杨金文. 以R245fa为工质的高温水源热泵样机研制及实验研究[D]. 青岛: 青岛理工大学, 2018. |

| Yang J W. Development and experimental study of high temperature water source heat pump prototype with R245fa as working fluid[D]. Qingdao: Qingdao University of Technology, 2018. | |

| 32 | Bamigbetan O, Eikevik T M, Nekså P, et al. Theoretical analysis of suitable fluids for high temperature heat pumps up to 125℃ heat delivery[J]. International Journal of Refrigeration, 2018, 92: 185-195. |

| 33 | Bai T, Yan G, Yu J L. Thermodynamic assessment of a condenser outlet split ejector-based high temperature heat pump cycle using various low GWP refrigerants[J]. Energy, 2019, 179: 850-862. |

| 34 | 王怀信, 郭涛, 王继霄. 几种中高温热泵工质的理论循环性能[J]. 太阳能学报, 2010, 31(5): 592-597. |

| Wang H X, Guo T, Wang J X. The theoretical cycle performance of some working fluids for moderate/high temperature heat pump[J]. Acta Energiae Solaris Sinica, 2010, 31(5): 592-597. | |

| 35 | 周洁. 靖边气田天然气净化系统模拟与关键参数研究[D]. 西安: 西安石油大学, 2022. |

| Zhou J. Simulation of natural gas purification system in Jingbian gas field and study on key parameters[D]. Xi'an: Xi'an Shiyou University, 2022. | |

| 36 | 陈南翔. 活化MDEA脱碳的应用研究[D]. 成都: 西南石油大学, 2016. |

| Chen N X. Applied research on decarbonization of activated MDEA[D]. Chengdu: Southwest Petroleum University, 2016. | |

| 37 | 张福亭, 张明, 陈浩, 等.煤制天然气装置生产废水处理及回收利用总结[J]. 中氮肥, 2024(1): 66-70. |

| Zhang F T, Zhang M, Chen H . et al. Summary of production wastewater treatment and recycling of coal-to-gas plant[J]. China Nitrogen Fertilizer, 2024(1): 66-70. | |

| 38 | 王曼, 王林平, 覃川, 等.天然气净化处理系统节能技术在靖边气田的应用[J]. 节能技术, 2014, 32(6): 4. |

| Wang M, Wang L P, Qin C . et al. Application of energy-saving technology of natural gas purification and treatment system in Jingbian gas field[J]. Energy Saving Technology, 2014, 32(6): 4. | |

| 39 | 王约翰. 高效环保的高热泵系统节流特性及补气策略研究[D]. 西安: 西安建筑科技大学, 2023. |

| Wang Y H. Study on throttling characteristics and air supply strategy of high efficiency and environmental protection high heat pump system[D]. Xi'an: Xi'an University of Architecture and Technology, 2023. | |

| 40 | 徐畅. 新型混合工质高温热泵变工况热力性能研究[D]. 天津: 河北工业大学, 2021. |

| Xu C. Study on thermal performance of new mixed refrigerant high temperature heat pump under off-design conditions[D]. Tianjin: Hebei University of Technology, 2021. | |

| 41 | 张悦. 复叠式中高温空气源热泵的能耗与经济性分析[D]. 邯郸: 河北工程大学, 2021. |

| Zhang Y. Energy consumption and economic analysis of cascade medium and high temperature air source heat pump[D]. Handan: Hebei University of Engineering, 2021. | |

| 42 | 李巍. 工业级复叠式高温热泵的性能研究[D]. 天津: 天津大学, 2018. |

| Li W. Study on performance of industrial cascade high temperature heat pump[D]. Tianjin: Tianjin University, 2018. |

| [1] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [2] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [3] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [4] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [5] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [6] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [7] | 郭明钢, 杨晓航, 代岩, 米盼盼, 马世鑫, 贺高红, 肖武, 崔福军. 贫氦管输天然气提氦多元化产品耦合工艺优化设计[J]. 化工学报, 2025, 76(5): 2251-2261. |

| [8] | 郭彭涛, 王婷, 薛波, 应允攀, 刘大欢. 用于CH4/N2分离的多吸附位点超微孔MOF[J]. 化工学报, 2025, 76(5): 2304-2312. |

| [9] | 刘璐, 万开, 王文玥, 王太, 汤建成, 王少恒. 基于氦膨胀制冷的正仲氢转化耦合流动换热研究[J]. 化工学报, 2025, 76(4): 1513-1522. |

| [10] | 许成城, 邵索拉, 魏文建, 郑旭. 多工况下直凝式蓄热型铝制辐射板换热器供暖性能研究[J]. 化工学报, 2025, 76(4): 1545-1558. |

| [11] | 贾文龙, 肖欢, 冷翔宇, 黄巧竞, 刘程玮, 吴瑕. 原油储罐重质沉积物超声波空化微射流清洗实验及数值模拟[J]. 化工学报, 2025, 76(3): 1288-1296. |

| [12] | 周印洁, 吉思蓓, 何松阳, 吉旭, 贺革. 机器学习辅助高通量筛选金属有机骨架用于富碳天然气中分离CO2[J]. 化工学报, 2025, 76(3): 1093-1101. |

| [13] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 重质颗粒流态化研究现状与展望[J]. 化工学报, 2025, 76(2): 466-483. |

| [14] | 黄云龙, 许剑, 刘通, 元昕彤, 徐强. 气藏水平井温度分布特征及流量测试实验研究[J]. 化工学报, 2025, 76(2): 612-622. |

| [15] | 张珂, 任维杰, 王梦娜, 范凯锋, 常丽萍, 李佳斌, 马涛, 田晋平. Bunsen反应产物在微通道中的液-液两相混合特性[J]. 化工学报, 2025, 76(2): 623-636. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号