化工学报 ›› 2025, Vol. 76 ›› Issue (2): 623-636.DOI: 10.11949/0438-1157.20240918

• 流体力学与传递现象 • 上一篇

张珂1( ), 任维杰1, 王梦娜1, 范凯锋2, 常丽萍2, 李佳斌3, 马涛1, 田晋平1

), 任维杰1, 王梦娜1, 范凯锋2, 常丽萍2, 李佳斌3, 马涛1, 田晋平1

收稿日期:2024-08-12

修回日期:2024-09-24

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

张珂

作者简介:张珂(1988—),男,博士,副教授,2019016@tyust.edu.cn

基金资助:

Ke ZHANG1( ), Weijie REN1, Mengna WANG1, Kaifeng FAN2, Liping CHANG2, Jiabin LI3, Tao MA1, Jinping TIAN1

), Weijie REN1, Mengna WANG1, Kaifeng FAN2, Liping CHANG2, Jiabin LI3, Tao MA1, Jinping TIAN1

Received:2024-08-12

Revised:2024-09-24

Online:2025-03-25

Published:2025-03-10

Contact:

Ke ZHANG

摘要:

为了解决热化学硫碘循环和硫化氢化学反应循环制氢的关键技术问题,提出使用ANSYS-FLUENT对Bunsen反应产物(HI/H2SO4/H2O/甲苯液-液两相混合物)在微通道内的流动混合特性进行数值模拟研究。系统分析了微通道内两相混合与入口方式、入口流速、两相流速比的关系,探讨了微通道内加入障碍物后对两相混合的强化作用。结果表明,当两相以上下分层方式进入通道时,混合效果更佳;提高流速可以显著增大两相流的混合程度,但是通道压力损失随之增加;两相流速比为1∶1、流速为0.035 m/s时,混合程度达到最大值88.72%,同时压力损失相对较小;在通道内部设置障碍物可以形成周期性的涡流,有效缩短两相混合时间,强化两相混合。与半圆形障碍物相比,矩形障碍物可以更有效地促进两相混合,但是压力损失更大。

中图分类号:

张珂, 任维杰, 王梦娜, 范凯锋, 常丽萍, 李佳斌, 马涛, 田晋平. Bunsen反应产物在微通道中的液-液两相混合特性[J]. 化工学报, 2025, 76(2): 623-636.

Ke ZHANG, Weijie REN, Mengna WANG, Kaifeng FAN, Liping CHANG, Jiabin LI, Tao MA, Jinping TIAN. Liquid-liquid mixing characteristics of Bunsen reaction products in microchannels[J]. CIESC Journal, 2025, 76(2): 623-636.

| 液相 | 密度/(kg/m3) | 动力黏度/(Pa·s) | 表面张力/(mN/m) |

|---|---|---|---|

| HI/H2SO4混酸 | 1080.3 | 9.067×10-4 | 28.9 |

| 甲苯 | 860.4 | 5.345×10-4 | 55.4 |

表1 两相物性参数

Table 1 Two-phase physical property parameters

| 液相 | 密度/(kg/m3) | 动力黏度/(Pa·s) | 表面张力/(mN/m) |

|---|---|---|---|

| HI/H2SO4混酸 | 1080.3 | 9.067×10-4 | 28.9 |

| 甲苯 | 860.4 | 5.345×10-4 | 55.4 |

| 边界条件 | 边界类型/名称 | 参数设置 |

|---|---|---|

| 入口 | 平均速度入口 | 0.014 m/s |

| 出口 | 自由出流出口 | 0 Pa |

| 壁面 | 无滑移壁面 | — |

| 对称轴 | AXIS | — |

表2 模拟条件

Table 2 Simulation conditions

| 边界条件 | 边界类型/名称 | 参数设置 |

|---|---|---|

| 入口 | 平均速度入口 | 0.014 m/s |

| 出口 | 自由出流出口 | 0 Pa |

| 壁面 | 无滑移壁面 | — |

| 对称轴 | AXIS | — |

| 网格划分方案 | 全局网格尺寸 | 网格单元数/个 |

|---|---|---|

| 方案1 | 0.35 | 1433700 |

| 方案2 | 0.4 | 948300 |

| 方案3 | 0.5 | 487872 |

| 方案4 | 0.6 | 278620 |

| 方案5 | 0.8 | 149523 |

表3 网格尺寸选择

Table 3 Mesh size

| 网格划分方案 | 全局网格尺寸 | 网格单元数/个 |

|---|---|---|

| 方案1 | 0.35 | 1433700 |

| 方案2 | 0.4 | 948300 |

| 方案3 | 0.5 | 487872 |

| 方案4 | 0.6 | 278620 |

| 方案5 | 0.8 | 149523 |

| 方案类型 | 压力损失/Pa |

|---|---|

| 方案1 | 174.28 |

| 方案2 | 166.52 |

表4 两种入口方式下通道的压力损失

Table 4 Pressure losses of the channel at different inlet modes

| 方案类型 | 压力损失/Pa |

|---|---|

| 方案1 | 174.28 |

| 方案2 | 166.52 |

| 流速/(m/s) | 压力损失/Pa |

|---|---|

| 0.014 | 172.85 |

| 0.035 | 296.53 |

| 0.070 | 498.26 |

| 0.140 | 1087.72 |

| 1.400 | 29786.82 |

表5 不同流速时通道的压力损失

Table 5 Pressure losses of the channelat different flow rates

| 流速/(m/s) | 压力损失/Pa |

|---|---|

| 0.014 | 172.85 |

| 0.035 | 296.53 |

| 0.070 | 498.26 |

| 0.140 | 1087.72 |

| 1.400 | 29786.82 |

| 两相流速比 | 两相流速/(m/s) | 压力损失/Pa | |

|---|---|---|---|

| 甲苯 | 混酸 | ||

| 1∶3 | 0.014 | 0.042 | 285.69 |

| 1∶2 | 0.014 | 0.028 | 215.36 |

| 1∶1 | 0.014 | 0.014 | 142.29 |

| 1∶0.5 | 0.014 | 0.007 | 53.94 |

表6 不同流速比时通道的压力损失

Table 6 Pressure losses of the channel at different flow ratios

| 两相流速比 | 两相流速/(m/s) | 压力损失/Pa | |

|---|---|---|---|

| 甲苯 | 混酸 | ||

| 1∶3 | 0.014 | 0.042 | 285.69 |

| 1∶2 | 0.014 | 0.028 | 215.36 |

| 1∶1 | 0.014 | 0.014 | 142.29 |

| 1∶0.5 | 0.014 | 0.007 | 53.94 |

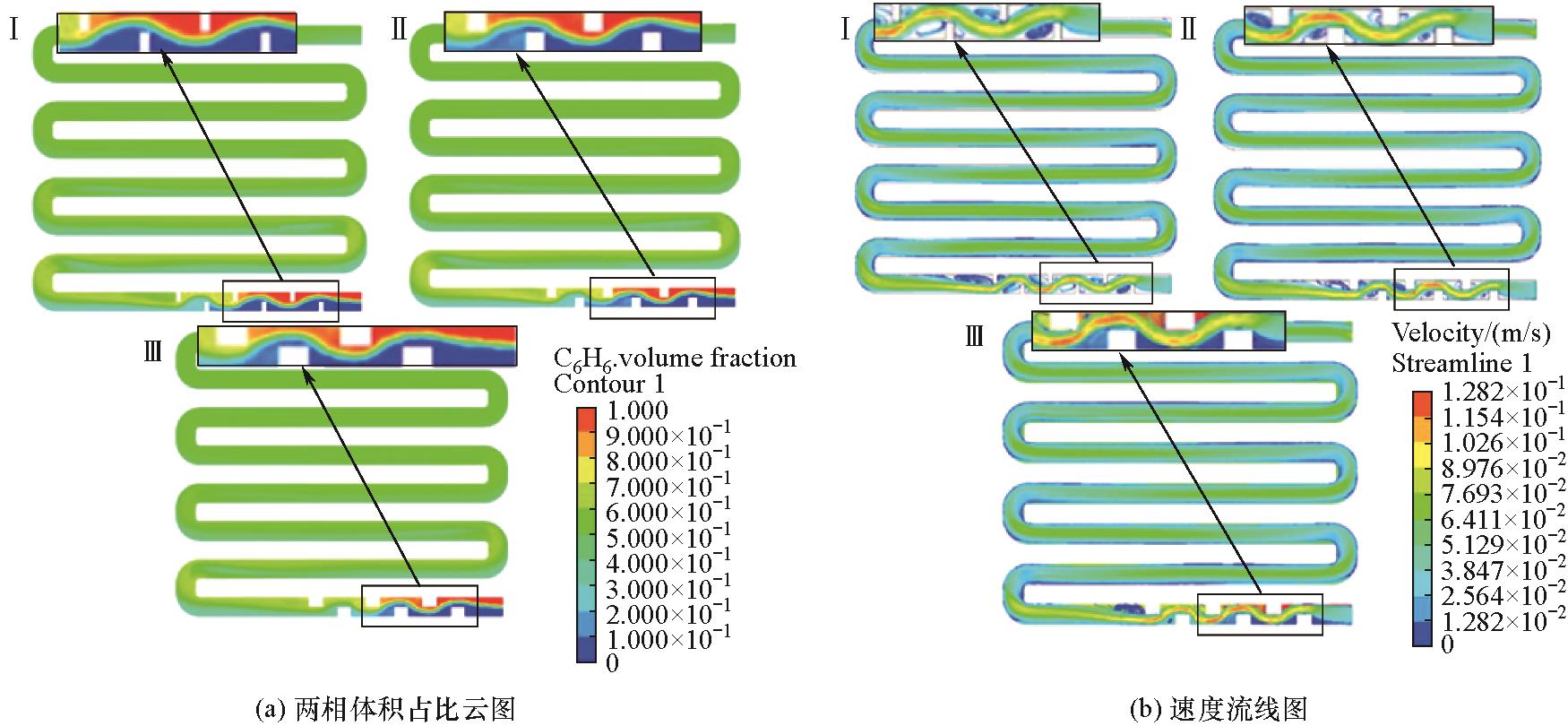

图14 不同障碍物高度下两相体积占比云图与速度流线图(Ⅰ: H=1 mm; Ⅱ: H=2 mm; Ⅲ: H=2.5 mm)

Fig.14 Cloud images of two-phase volume ratio and velocity flow diagrams at different obstacle heights (Ⅰ: H=1 mm; Ⅱ: H=2 mm; Ⅲ: H=2.5 mm)

| 障碍物高度/mm | 混合程度/% | 压力损失/Pa |

|---|---|---|

| 1 | 90.22 | 81.14 |

| 2 | 97.41 | 89.23 |

| 2.5 | 99.85 | 157.16 |

表7 不同障碍物高度下的混合程度和压力损失

Table 7 Mixing degrees and pressure losses at different obstacle heights

| 障碍物高度/mm | 混合程度/% | 压力损失/Pa |

|---|---|---|

| 1 | 90.22 | 81.14 |

| 2 | 97.41 | 89.23 |

| 2.5 | 99.85 | 157.16 |

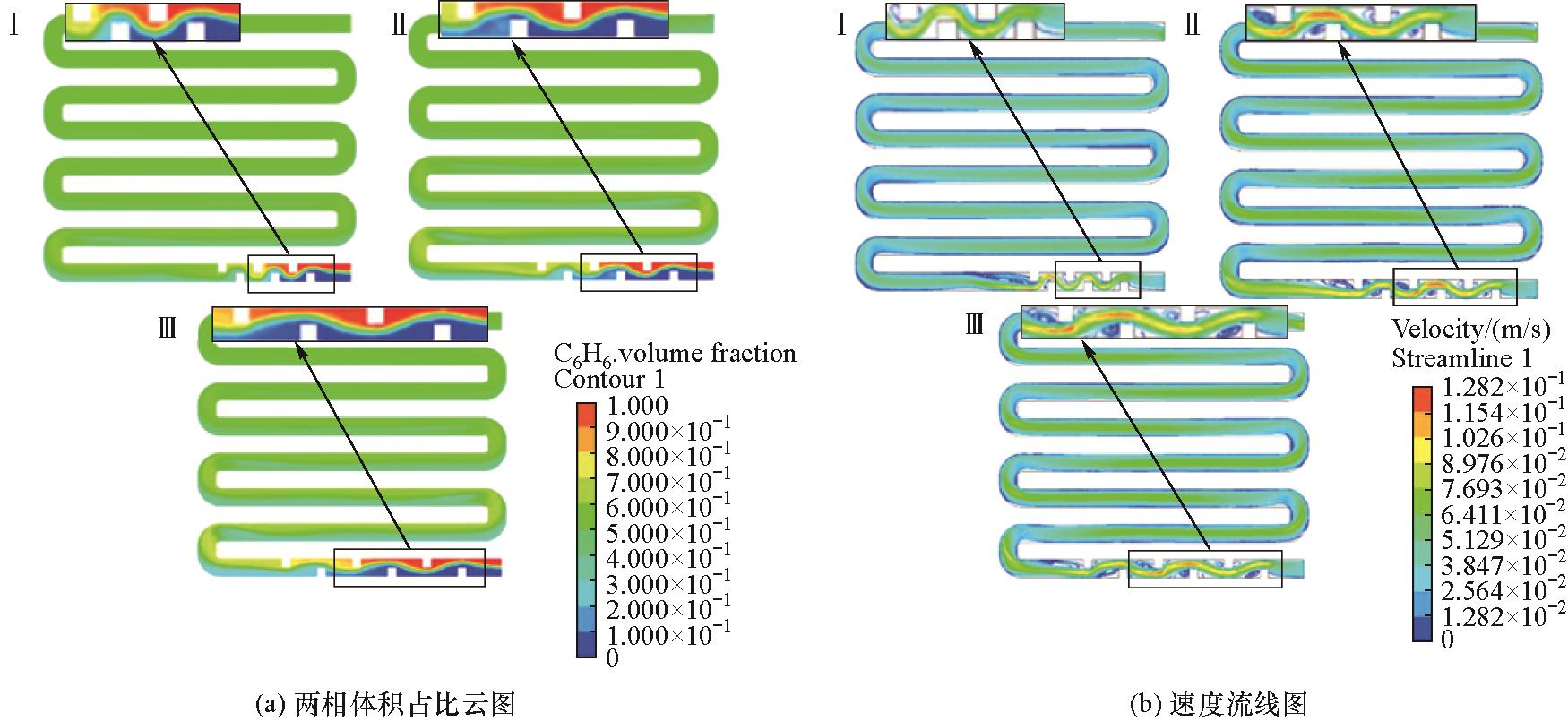

图15 不同障碍物宽度下两相体积占比云图与速度流线图(Ⅰ: W=1 mm; Ⅱ: W=2 mm; Ⅲ: W=3 mm)

Fig.15 Cloud images of two-phase volume ratio and velocity flow diagrams at different obstacle widths (Ⅰ: W=1 mm; Ⅱ: W=2 mm; Ⅲ: W=3 mm)

| 障碍物宽度/mm | 混合程度/% | 压力损失/Pa |

|---|---|---|

| 1 | 97.28 | 89.15 |

| 2 | 97.41 | 90.57 |

| 3 | 97.46 | 93.26 |

表8 不同障碍物宽度下的混合程度和压力损失

Table 8 Mixing degrees and pressure losses at different obstacle widths

| 障碍物宽度/mm | 混合程度/% | 压力损失/Pa |

|---|---|---|

| 1 | 97.28 | 89.15 |

| 2 | 97.41 | 90.57 |

| 3 | 97.46 | 93.26 |

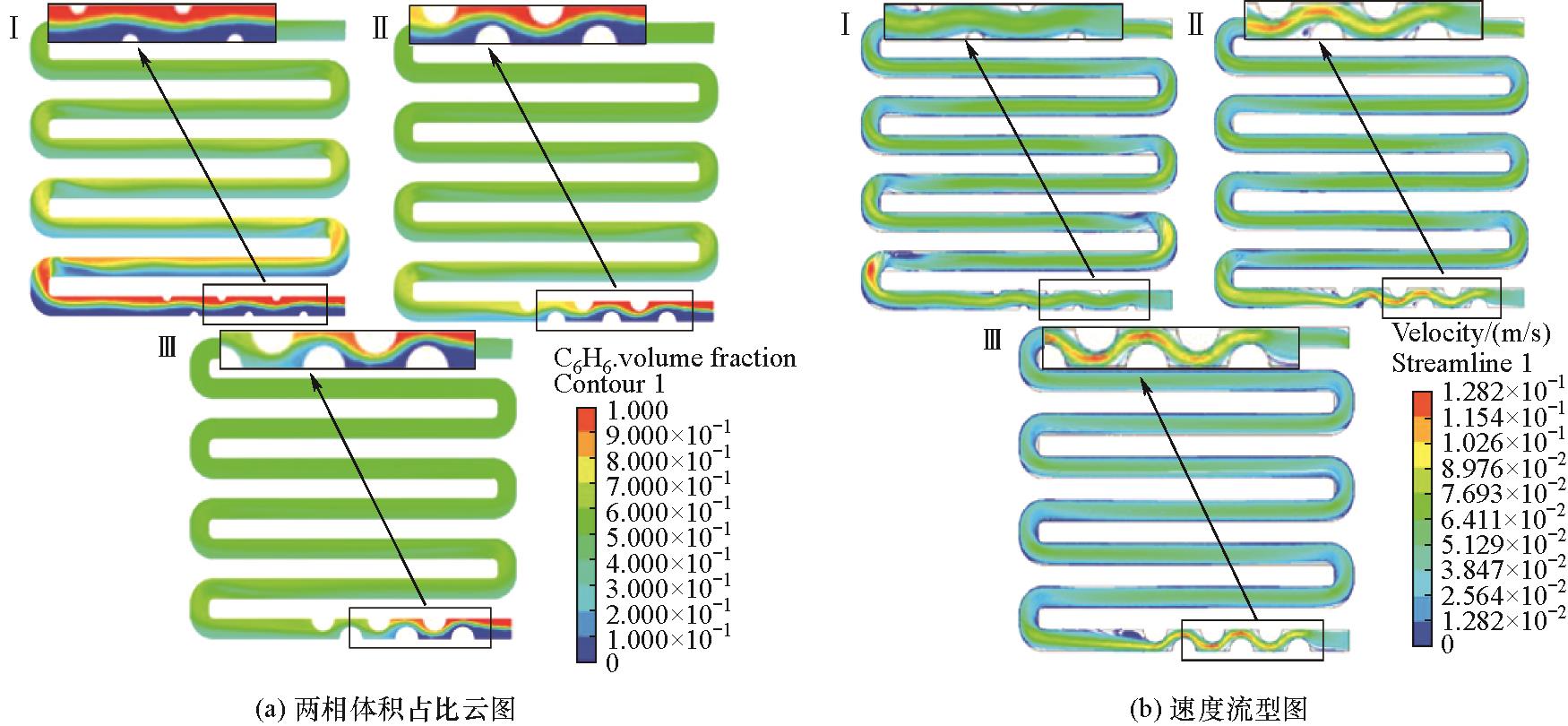

图16 不同障碍物间距下两相体积占比云图与速度流线图(Ⅰ: D=4 mm; Ⅱ: D=6 mm; Ⅲ: D=8 mm)

Fig.16 Cloud images of two-phase volume ratio and velocity flow diagrams at different obstacle separation distances (Ⅰ: D=4 mm; Ⅱ: D=6 mm; Ⅲ D=8 mm)

| 障碍物间距/mm | 混合程度/% | 压力损失/Pa |

|---|---|---|

| 4 | 98.62 | 99.40 |

| 6 | 97.41 | 89.52 |

| 8 | 96.29 | 87.11 |

表9 不同障碍物间距下的混合程度和压力损失

Table 9 Mixing degrees and pressure losses at different obstacle separation distances

| 障碍物间距/mm | 混合程度/% | 压力损失/Pa |

|---|---|---|

| 4 | 98.62 | 99.40 |

| 6 | 97.41 | 89.52 |

| 8 | 96.29 | 87.11 |

图18 不同半圆形障碍物半径下的两相体积占比云图与速度流线图(Ⅰ: R=1 mm; Ⅱ: R=2 mm; Ⅲ: R=2.5 mm)

Fig.18 Cloud images of two-phase volume ratio and velocity flow diagrams at different semicircular obstacle radius (Ⅰ: R=1 mm; Ⅱ: R=2 mm; Ⅲ: R=2.5 mm)

| 半圆形障碍物半径/mm | 混合程度/% | 压力损失/Pa |

|---|---|---|

| 1 | 89.40 | 81.12 |

| 2 | 95.84 | 83.32 |

| 2.5 | 97.68 | 94.22 |

表10 不同半圆形障碍物半径下的混合程度和压力损失

Table 10 Mixing degrees and pressure losses at different semicircular obstacle radius

| 半圆形障碍物半径/mm | 混合程度/% | 压力损失/Pa |

|---|---|---|

| 1 | 89.40 | 81.12 |

| 2 | 95.84 | 83.32 |

| 2.5 | 97.68 | 94.22 |

| 1 | 中国煤炭工业协会. 2023煤炭行业发展年度报告[R]. 北京: 中国煤炭工业协会, 2024. |

| China Coal Industry Association. 2023 Coal industry development annual report[R]. Beijing: China Coal Industry Association, 2024. | |

| 2 | Zhu H T, Cao S, Su Z M, et al. China's future energy vision: multi-scenario simulation based on energy consumption structure under dual carbon targets[J]. Energy, 2024, 301: 131751. |

| 3 | 张珂, 李晓玲, 常丽萍, 等. 硫化氢资源化技术研究进展[J]. 现代化工, 2022, 42(2): 72-77, 83. |

| Zhang K, Li X L, Chang L P, et al. Research progress on technology for reutilization of hydrogen sulfide[J]. Modern Chemical Industry, 2022, 42(2): 72-77, 83. | |

| 4 | De Crisci A G, Moniri A, Xu Y M. Hydrogen from hydrogen sulfide: towards a more sustainable hydrogen economy[J]. International Journal of Hydrogen Energy, 2019, 44(3): 1299-1327. |

| 5 | Xu W T, Hu X N, Xiang M, et al. Highly effective direct decomposition of H2S into H2 and S by microwave catalysis over CoS-MoS2/γ-Al2O3 microwave catalysts[J]. Chemical Engineering Journal, 2017, 326: 1020-1029. |

| 6 | Lum M M X, Ng K H, Lai S Y, et al. Sulfur dioxide catalytic reduction for environmental sustainability and circular economy: a review[J]. Process Safety and Environmental Protection, 2023, 176: 580-604. |

| 7 | Lei Y, Du L, Liu X Y, et al. Natural gas sweetening using tailored ionic liquid-methanol mixed solvent with selective removal of H2S and CO2 [J]. Chemical Engineering Journal, 2023, 476: 146424. |

| 8 | Safari F, Dincer I. A review and comparative evaluation of thermochemical water splitting cycles for hydrogen production[J]. Energy Conversion and Management, 2020, 205: 112182. |

| 9 | Wang H. Hydrogen production from a chemical cycle of H2S splitting[J]. International Journal of Hydrogen Energy, 2007, 32(16): 3907-3914. |

| 10 | Zhang S H, Huang B Y, He Y, et al. Demetallized Pt x Ni y /C catalyst for SO2 electrochemical oxidation in the SI/HyS hydrogen production cycles[J]. International Journal of Hydrogen Energy, 2021, 46(17): 10161-10171. |

| 11 | Wang H, Le Person A, Zhao X, et al. A low-temperature hydrogen production process based on H2S splitting cycle for sustainable oil sands bitumen upgrading[J]. Fuel Processing Technology, 2013, 108: 55-62. |

| 12 | Zhang K, Zhao X, Chen S H, et al. Direct electrolysis of Bunsen reaction product HI/H2SO4/H2O/toluene mixture for hydrogen production: Pt electrode characterization[J]. International Journal of Hydrogen Energy, 2018, 43(30): 13702-13710. |

| 13 | Zhang K, Bao W R, Chang L P, et al. A review of recent researches on Bunsen reaction for hydrogen production via S-I water and H2S splitting cycles[J]. Journal of Energy Chemistry, 2019, 33: 46-58. |

| 14 | 钱锦远, 李晓娟, 吴赞, 等. 微通道内液-液两相流流型及传质的研究进展[J]. 化工进展, 2019, 38(4): 1624-1633. |

| Qian J Y, Li X J, Wu Z, et al. Research progress on flow regimes and mass transfer of liquid-liquid two-phase flow in microchannels[J]. Chemical Industry and Engineering Progress, 2019, 38(4): 1624-1633. | |

| 15 | 刘冠颖, 方玉诚, 郭辉进, 等. 微反应器发展概况[J]. 当代化工, 2010, 39(3): 315-318. |

| Liu G Y, Fang Y C, Guo H J, et al. Development of microreactors[J]. Contemporary Chemical Industry, 2010, 39(3): 315-318. | |

| 16 | 刘熠, 郭兆寿, 韩永博, 等. 微通道反应器的研究进展[J]. 辽宁化工, 2018, 47(7): 681-684. |

| Liu Y, Guo Z S, Han Y B, et al. Research progress of microchannel reactors[J]. Liaoning Chemical Industry, 2018, 47(7): 681-684. | |

| 17 | Wang F, Zhu J M, Hu X J, et al. Rapid nitrate determination with a portable lab-on-chip device based on double microstructured assisted reactors[J]. Lab on a Chip, 2021, 21(6): 1109-1117. |

| 18 | Lorenzini D, Joshi Y. Numerical modeling and experimental validation of two-phase microfluidic cooling in silicon devices for vertical integration of microelectronics[J]. International Journal of Heat and Mass Transfer, 2019, 138: 194-207. |

| 19 | Shi H H, Nie K X, Dong B, et al. Recent progress of microfluidic reactors for biomedical applications[J]. Chemical Engineering Journal, 2019, 361: 635-650. |

| 20 | 叶飞飞, 张宝丹, 靳海波, 等. 微通道反应器合成纳米BaSO4颗粒及其在干片多功能层上的应用[J]. 化工学报, 2019, 70(3): 1179-1187. |

| Ye F F, Zhang B D, Jin H B, et al. Preparation of BaSO4 nanoparticles in microchannel reactor and its application in multifunctional layers of medical slices[J]. CIESC Journal, 2019, 70(3): 1179-1187. | |

| 21 | Nguyen N T, Wu Z G. Micromixers—a review[J]. Journal of Micromechanics and Microengineering, 2005, 15(2): R1-R16. |

| 22 | Chen K X, Lu H, Sun M, et al. Mixing enhancement of a novel C-SAR microfluidic mixer[J]. Chemical Engineering Research and Design, 2018, 132: 338-345. |

| 23 | 刘兆轩, 张程宾, 韩群, 等. 锯齿型微通道流动与传热特性数值模拟[J]. 化工进展, 2023, 42(11): 5622-5636. |

| Liu Z X, Zhang C B, Han Q, et al. Numerical simulation of fluid flow and heat transfer characteristics in a saw-like microchannel[J]. Chemical Industry and Engineering Progress, 2023, 42(11): 5622-5636. | |

| 24 | Yang A S, Chuang F C, Chen C K, et al. A high-performance micromixer using three-dimensional Tesla structures for bio-applications[J]. Chemical Engineering Journal, 2015, 263: 444-451. |

| 25 | 张伟业, 朱晓武, 罗永皓, 等. 复合型叶序微流道混合性能的数值模拟[J]. 化工进展, 2024, 43(S1): 154-165. |

| Zhang W Y, Zhu X W, Luo Y H, et al. Numerical simulation of mixing performance of composite phyllotaxy microfluidic channel[J]. Chemical Industry and Engineering Progress, 2024, 43(S1): 154-165. | |

| 26 | Lv H C, Wang J D, Shu Z M, et al. Residence time distribution and heat/mass transfer performance of a millimeter scale butterfly-shaped reactor[J]. Chinese Chemical Letters, 2023, 34(4): 107710. |

| 27 | Heibel A K, Lebens P J M, Middelhoff J W, et al. Liquid residence time distribution in the film flow monolith reactor[J]. AIChE Journal, 2005, 51(1): 122-133. |

| 28 | Chen S Z, Zhang P, Wang L J, et al. Viscosity-composition-temperature data of HI-I2-H2O solution at atmospheric pressure[J]. International Journal of Hydrogen Energy, 2018, 43(49): 22021-22031. |

| 29 | Qian J Y, Li X J, Gao Z X, et al. Mixing efficiency and pressure drop analysis of liquid-liquid two phases flow in serpentine microchannels[J]. Journal of Flow Chemistry, 2019, 9(3): 187-197. |

| 30 | Hou S Y, Sun M L, Cao L M, et al. Computational fluid dynamics simulation and experimental study on mixing performance of a three-dimensional circular cyclone-type microreactor[J]. Chinese Chemical Letters, 2024, 35(4): 108761. |

| 31 | Abiev R S, Makusheva I V, Mironova A I. Comparison of hydrodynamics and micromixing quality in a two-stage microreactor with intensely swirled flows and in a T-mixer[J]. Chemical Engineering and Processing-Process Intensification, 2024, 202: 109829. |

| 32 | 王林. 基于简化模型的T型微反应器设计[J]. 计算机与应用化学, 2012, 29(7): 859-862. |

| Wang L. Optimal design of T-shaped microreactors by using a simplified model[J]. Computers and Applied Chemistry, 2012, 29(7): 859-862. | |

| 33 | 杨雪芳, 林莹. 挡板结构对微混合器内流动与混合的影响[J]. 上海应用技术学院学报(自然科学版), 2016, 16(4): 338-343. |

| Yang X F, Lin Y. Effect of baffle structure on fluid flow and mixing in the micromixer[J]. Journal of Shanghai Institute of Technology (Natural Science), 2016, 16(4): 338-343. | |

| 34 | Zhao S F, Nie Y Y, Zhang W Y, et al. Microfluidic field strategy for enhancement and scale up of liquid-liquid homogeneous chemical processes by optimization of 3D spiral baffle structure[J]. Chinese Journal of Chemical Engineering, 2023, 56: 255-265. |

| 35 | Al-Azzawi M, Mjalli F S, Husain A, et al. A review on the hydrodynamics of the liquid-liquid two-phase flow in the microchannels[J]. Industrial & Engineering Chemistry Research, 2021, 60(14): 5049-5075. |

| 36 | Yoshimura M, Shimoyama K, Misaka T, et al. Optimization of passive grooved micromixers based on genetic algorithm and graph theory[J]. Microfluidics and Nanofluidics, 2019, 23(3): 30. |

| 37 | Bahei Islami S, Ahmadi S. The effect of flow parameters on mixing degree of a three dimensional rhombus micromixer with obstacles in the middle of the mixing channel using oscillatory inlet velocities[J]. Challenges in Nano and Micro Scale Science and Technology, 2019, 7(1): 62-71. |

| 38 | He X H, Xia T, Gao L F, et al. Simulation and experimental study of asymmetric split and recombine micromixer with D-shaped sub-channels[J]. Micro&Nano Letters, 2019, 14(3): 293-298. |

| 39 | Li T C, Chen X Y. Numerical investigation of 3D novel chaotic micromixers with obstacles[J]. International Journal of Heat and Mass Transfer, 2017, 115: 278-282. |

| 40 | Ganguli A, Bhatt V, Yagodnitsyna A, et al. A review of pressure drop and mixing characteristics in passive mixers involving miscible liquids[J]. Micromachines, 2024, 15(6): 691. |

| [1] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 重质颗粒流态化研究现状与展望[J]. 化工学报, 2025, 76(2): 466-483. |

| [2] | 戴晓宇, 徐强, 杨晨宇, 苏筱斌, 郭烈锦. 多级混流式混输泵气液两相增压特性[J]. 化工学报, 2025, 76(2): 554-563. |

| [3] | 张鑫源, 何呈祥, 李亚婷, 朱春英, 马友光, 付涛涛. 微通道内液液非均相传质的模拟和实验研究方法进展[J]. 化工学报, 2025, 76(2): 484-503. |

| [4] | 魏攀攀, 刘怿楠, 朱春英, 付涛涛, 高习群, 马友光. 改进的T型微通道内双水相液滴的制备[J]. 化工学报, 2025, 76(2): 576-583. |

| [5] | 黄云龙, 许剑, 刘通, 元昕彤, 徐强. 气藏水平井温度分布特征及流量测试实验研究[J]. 化工学报, 2025, 76(2): 612-622. |

| [6] | 李彦, 郭红利, 苏国庆, 张建文. 加氢装置空冷器气液两相流动与冲刷腐蚀问题[J]. 化工学报, 2025, 76(1): 141-150. |

| [7] | 王瀚彬, 胡帅, 毕丰雷, 李隽森, 贺来宾. 新型波纹翅片金属氢化物反应器的放氢性能有限元分析[J]. 化工学报, 2025, 76(1): 221-230. |

| [8] | 高羡明, 杨汶轩, 卢少辉, 任晓松, 卢方财. 双槽道结构对超疏水表面液滴合并弹跳的影响[J]. 化工学报, 2025, 76(1): 208-220. |

| [9] | 韩启沃, 刘永峰, 裴普成, 张璐, 姚圣卓. 工作温度对PEMFC水分布、质子传输及性能影响分析[J]. 化工学报, 2025, 76(1): 374-384. |

| [10] | 邓志诚, 杨欢, 王斯民, 王家瑞. 微混燃烧器中微管结构对氢燃料掺混效果与燃烧性能影响[J]. 化工学报, 2025, 76(1): 335-347. |

| [11] | 董沛洲, 喻慧文, 谈灵操, 徐百平, 杨芳. 基于移动粒子半隐式方法的非充满折流板双螺杆流道内混合[J]. 化工学报, 2025, 76(1): 198-207. |

| [12] | 陈晗, 蔡畅, 刘红, 尹洪超. 正戊醇添加剂强化喷雾冷却传热实验研究[J]. 化工学报, 2025, 76(1): 131-140. |

| [13] | 刘萍, 邱雨生, 李世婧, 孙瑞奇, 申晨. 微通道内纳米流体传热流动特性[J]. 化工学报, 2025, 76(1): 184-197. |

| [14] | 韩志敏, 周相宇, 张宏宇, 徐志明. 不同粗糙元结构下CaCO3污垢局部沉积特性[J]. 化工学报, 2025, 76(1): 151-160. |

| [15] | 董新宇, 边龙飞, 杨怡怡, 张宇轩, 刘璐, 王腾. 冷却条件下倾斜上升管S-CO2流动与传热特性研究[J]. 化工学报, 2024, 75(S1): 195-205. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号