化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2251-2261.DOI: 10.11949/0438-1157.20240772

郭明钢1,2( ), 杨晓航2, 代岩2, 米盼盼2, 马世鑫3, 贺高红1,2(

), 杨晓航2, 代岩2, 米盼盼2, 马世鑫3, 贺高红1,2( ), 肖武1, 崔福军2

), 肖武1, 崔福军2

收稿日期:2024-07-10

修回日期:2024-10-31

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

贺高红

作者简介:郭明钢(1988—),男,博士研究生,高级工程师,guomg@dlut.edu.cn

基金资助:

Minggang GUO1,2( ), Xiaohang YANG2, Yan DAI2, Panpan MI2, Shixin MA3, Gaohong HE1,2(

), Xiaohang YANG2, Yan DAI2, Panpan MI2, Shixin MA3, Gaohong HE1,2( ), Wu XIAO1, Fujun CUI2

), Wu XIAO1, Fujun CUI2

Received:2024-07-10

Revised:2024-10-31

Online:2025-05-25

Published:2025-06-13

Contact:

Gaohong HE

摘要:

目前氦气提取过程,存在过度依赖于液化天然气生产过程的富氦尾气、催化氧化破坏式脱氢引入新杂质和高能耗的问题。因此,提出基于资源广泛的贫氦管输天然气的多级膜-电化学氢泵-吸附耦合提氦工艺,利用管输天然气压力和多技术梯度产品化除杂提氦策略,生产氦气、燃料电池氢和二氧化碳多元化产品,实现贫氦管输天然气经济性提氦。运用Aspen HYSYS软件对1.00×105 m3/h贫氦管输天然气耦合提氦工艺模拟优化,考察了回收率、膜性能和氦气浓度对工艺经济性的影响,模拟结果表明:在典型管输压力4.0 MPa和0.04%(体积分数)He时,采用中渗透性中选择性气体分离膜,且氦气回收率为50%~70%时,贫氦管输天然气提氦耦合工艺经济性较好,氦气盈亏平衡价格为115.5~123.2 CNY/m3,且随着氦气浓度增加盈亏平衡价格逐渐减小,为贫氦资源经济性利用提供极具工业前景技术路线。

中图分类号:

郭明钢, 杨晓航, 代岩, 米盼盼, 马世鑫, 贺高红, 肖武, 崔福军. 贫氦管输天然气提氦多元化产品耦合工艺优化设计[J]. 化工学报, 2025, 76(5): 2251-2261.

Minggang GUO, Xiaohang YANG, Yan DAI, Panpan MI, Shixin MA, Gaohong HE, Wu XIAO, Fujun CUI. Optimal design of integration process for helium extraction from helium-poor pipeline natural gas with diversified products[J]. CIESC Journal, 2025, 76(5): 2251-2261.

| 天然气基础条件 | 值 |

|---|---|

| 气相分率 | 1.00 |

| 温度/℃ | 40 |

| 压力/MPa | 4.0 |

| 标准状态体积流率/(m3/h) | 1.00 ×105 |

| 组分体积分数/% | |

| He | 0.0400 |

| H2 | 0.0020 |

| CO2 | 1.0200 |

| CH4 | 98.1190 |

| C2H6 | 0.2930 |

| C3H8 | 0.0080 |

| N2 | 0.5180 |

表1 某管输天然气基础条件

Table 1 Basic conditions of the pipeline natural gas

| 天然气基础条件 | 值 |

|---|---|

| 气相分率 | 1.00 |

| 温度/℃ | 40 |

| 压力/MPa | 4.0 |

| 标准状态体积流率/(m3/h) | 1.00 ×105 |

| 组分体积分数/% | |

| He | 0.0400 |

| H2 | 0.0020 |

| CO2 | 1.0200 |

| CH4 | 98.1190 |

| C2H6 | 0.2930 |

| C3H8 | 0.0080 |

| N2 | 0.5180 |

| 气体 | 渗透速率(Prism-Ⅱ, 80℃)/GPU |

|---|---|

| He | 200 |

| H2 | 210 |

| N2 | 2.2 |

| C1 | 1.5 |

| C2 | 1.4 |

| C3 | 1.3 |

| CO2 | 51 |

| H2O | 1000 |

表2 分离膜气体渗透速率

Table 2 Gas permeation rates in membrane for process simulation

| 气体 | 渗透速率(Prism-Ⅱ, 80℃)/GPU |

|---|---|

| He | 200 |

| H2 | 210 |

| N2 | 2.2 |

| C1 | 1.5 |

| C2 | 1.4 |

| C3 | 1.3 |

| CO2 | 51 |

| H2O | 1000 |

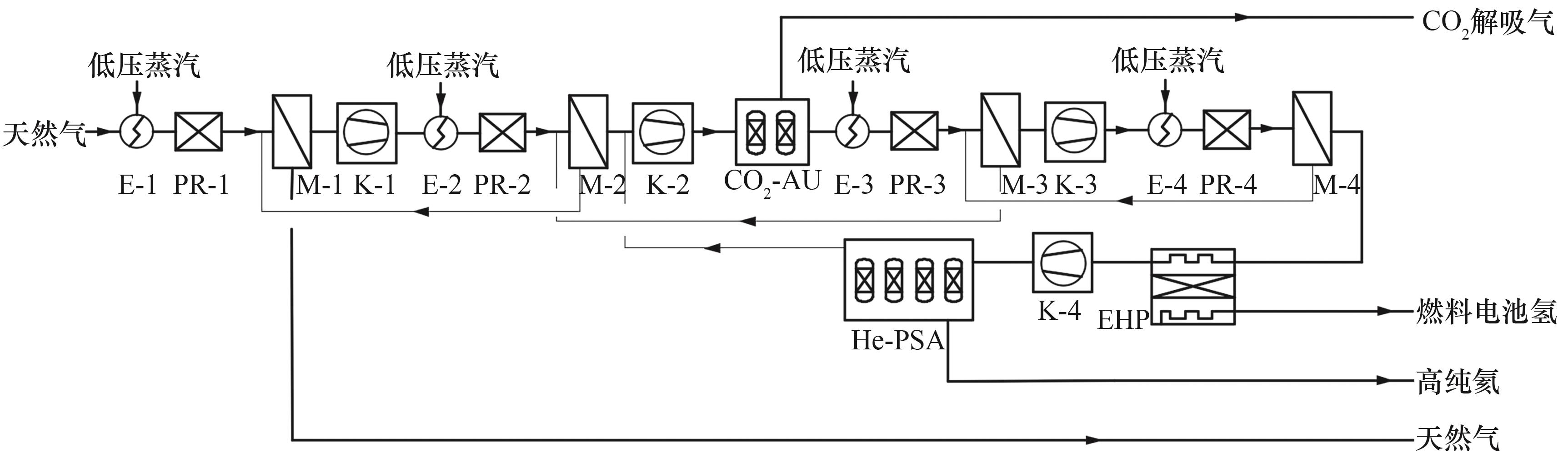

图1 多级膜-电化学氢泵-吸附耦合工艺示意流程图E-1~4—预热器;PR-1~4—预处理单元;M-1~4—膜单元;K-1~4—压缩机单元;CO2-AU—CO2吸收单元;EHP—电化学氢泵单元;He-PSA—He深度净化吸附单元

Fig.1 Chematic diagram of multi-stage membrane-electrochemical hydrogen pump-adsorption integration process

| 项目 | 膜 | 压缩机 | 吸收 | 吸附 | 电化学氢泵 | 其他 |

|---|---|---|---|---|---|---|

| 设备投资/104CNY | 2094.50 | 597.14 | 33.00 | 18.07 | 0.11 | 694.08 |

| 折旧占比/% | 82.00 | 7.79 | 0.43 | 0.71 | 0.01 | 9.06 |

表3 固定投资及年化设备成本占比情况

Table 3 Fixed investment and percentage contributions of equipment items annualized cost

| 项目 | 膜 | 压缩机 | 吸收 | 吸附 | 电化学氢泵 | 其他 |

|---|---|---|---|---|---|---|

| 设备投资/104CNY | 2094.50 | 597.14 | 33.00 | 18.07 | 0.11 | 694.08 |

| 折旧占比/% | 82.00 | 7.79 | 0.43 | 0.71 | 0.01 | 9.06 |

| 分离技术 | 原料 | He体积分数/% | He回收率/% | He盈亏平衡价格/ (CNY/m3) | 文献 | |

|---|---|---|---|---|---|---|

| 原料 | 产品 | |||||

| 二级膜工艺 | 贫氦天然气 | 0.05 | 90.000 | 95 | 505.5 | [ |

| 二级膜工艺 | 富氦天然气 | 4.00 | 97.000 | 90 | 1.7 | [ |

| 深冷+三级膜耦合工艺 | 富氦天然气 | 0.50 | 99.000 | 91 | 11.2 | [ |

| 深冷+吸附耦合工艺 | NRU尾气 | 3.00 | 99.999 | - | 3.7 | [ |

| 二级膜+吸附耦合工艺 | NRU尾气 | 3.47 | 99.999 | 91 | 2.5 | [ |

| 本文研究 | 贫氦天然气 | 0.04 | 99.999 | 60 | 115.5 | |

表4 氦气生产成本的经济比较

Table 4 Economic comparison of the cost of helium production

| 分离技术 | 原料 | He体积分数/% | He回收率/% | He盈亏平衡价格/ (CNY/m3) | 文献 | |

|---|---|---|---|---|---|---|

| 原料 | 产品 | |||||

| 二级膜工艺 | 贫氦天然气 | 0.05 | 90.000 | 95 | 505.5 | [ |

| 二级膜工艺 | 富氦天然气 | 4.00 | 97.000 | 90 | 1.7 | [ |

| 深冷+三级膜耦合工艺 | 富氦天然气 | 0.50 | 99.000 | 91 | 11.2 | [ |

| 深冷+吸附耦合工艺 | NRU尾气 | 3.00 | 99.999 | - | 3.7 | [ |

| 二级膜+吸附耦合工艺 | NRU尾气 | 3.47 | 99.999 | 91 | 2.5 | [ |

| 本文研究 | 贫氦天然气 | 0.04 | 99.999 | 60 | 115.5 | |

| 1 | 肖永厚, 肖红岩, 李本源, 等. 基于Aspen Adsorption的氦气/甲烷吸附分离过程模拟优化[J]. 化工学报, 2019, 70(7): 2556-2563. |

| Xiao Y H, Xiao H Y, Li B Y, et al. Optimization of helium/methane adsorption separation process based on Aspen Adsorption simulation[J]. CIESC Journal, 2019, 70(7): 2556-2563. | |

| 2 | Rufford T E, Chan K I, Huang S H, et al. A review of conventional and emerging process technologies for the recovery of helium from natural gas[J]. Adsorption Science & Technology, 2014, 32(1): 49-72. |

| 3 | 秦胜飞, 李济远, 王佳美, 等. 中国含油气盆地富氦天然气藏氦气富集模式[J]. 天然气工业, 2022, 42(7): 125-134. |

| Qin S F, Li J Y, Wang J M, et al. Helium enrichment model of helium-rich gas reservoirs in petroliferous basins in China[J]. Natural Gas Industry, 2022, 42(7): 125-134. | |

| 4 | 唐金荣, 张宇轩, 周俊林, 等. 全球氦气产业链分析与中国应对策略[J]. 地质通报, 2023, 42(1): 1-13. |

| Tang J R, Zhang Y X, Zhou J L, et al. Analysis of global helium industry chain and China’s strategy[J]. Geological Bulletin of China, 2023, 42(1): 1-13. | |

| 5 | 陈践发, 刘凯旋, 董勍伟, 等. 天然气中氦资源研究现状及我国氦资源前景[J]. 天然气地球科学, 2021, 32(10): 1436-1449. |

| Chen J F, Liu K X, Dong Q W, et al. Research status of helium resources in natural gas and prospects of helium resources in China[J]. Natural Gas Geoscience, 2021, 32(10): 1436-1449. | |

| 6 | 周军, 陈玉麟, 王璿清, 等. 氦气资源产量及市场发展现状分析[J]. 天然气化工—C1化学与化工, 2022, 47(5): 42-48. |

| Zhou J, Chen Y L, Wang X Q, et al. Analysis of helium resource production and market development status[J]. Natural Gas Chemical Industry, 2022, 47(5): 42-48. | |

| 7 | 国家能源局. 中国天然气发展报告[R]. 北京: 石油工业出版社, 2023. |

| National Energy Administration. Natural Gas Development Report[R]. Beijing: Petroleum Industry Press, 2023. | |

| 8 | Al-Sobhi S A, AlNouss A, Alsaba W, et al. Sustainable design and analysis for helium extraction from sale gas in liquefied natural gas production[J]. Journal of Natural Gas Science and Engineering, 2022, 102: 104599. |

| 9 | Sunarso J, Hashim S S, Lin Y S, et al. Membranes for helium recovery: an overview on the context, materials and future directions[J]. Separation and Purification Technology, 2017, 176: 335-383. |

| 10 | McElroy L, Xiao G K, Weh R, et al. A case study of helium recovery from Australian natural gas[J]. Case Studies in Chemical and Environmental Engineering, 2022, 5: 100200. |

| 11 | Soleimany A, Hosseini S S, Gallucci F. Recent progress in developments of membrane materials and modification techniques for high performance helium separation and recovery: a review[J]. Chemical Engineering and Processing: Process Intensification, 2017, 122: 296-318. |

| 12 | Jahromi P E, Fatemi S, Vatani A, et al. Purification of helium from a cryogenic natural gas nitrogen rejection unit by pressure swing adsorption[J]. Separation and Purification Technology, 2018, 193: 91-102. |

| 13 | Dai Z D, Deng J, He X Z, et al. Helium separation using membrane technology: recent advances and perspectives[J]. Separation and Purification Technology, 2021, 274: 119044. |

| 14 | Hamedi H, Karimi I A, Gundersen T. Optimization of helium extraction processes integrated with nitrogen removal units: a comparative study[J]. Computers & Chemical Engineering, 2019, 121: 354-366. |

| 15 | 张丽萍, 巨永林. 天然气及液化天然气蒸发气提氦技术研究进展[J]. 天然气化工—C1化学与化工, 2022, 47(5): 32-41. |

| Zhang L P, Ju Y L. Research progress of helium extraction of natural gas and liquefied natural gas boil-off gas[J]. Natural Gas Chemical Industry, 2022, 47(5): 32-41. | |

| 16 | Zheng P J, Xie W, Liu H Y, et al. Process design and techno-economic analysis of membrane-mediated helium recovery from low-grade natural gas[J]. Industrial & Engineering Chemistry Research, 2023, 62(50): 21770-21776. |

| 17 | Scholes C A, Gosh U K, Ho M T. The economics of helium separation and purification by gas separation membranes[J]. Industrial & Engineering Chemistry Research, 2017, 56(17): 5014-5020. |

| 18 | Palizdar A, Vatani A. Design and analysis of a novel self-refrigerated natural gas liquefaction system integrated with helium recovery and CO2 liquefaction processes[J]. Journal of Cleaner Production, 2023, 423: 138600. |

| 19 | He T B, Ju Y L. A novel process for small-scale pipeline natural gas liquefaction[J]. Applied Energy, 2014, 115: 17-24. |

| 20 | 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 纯氦、高纯氦和超纯氦: [S]. 北京: 中国标准出版社, 2012. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. Pure helium, high pure helium and ultra pure helium: [S]. Beijing: Standards Press of China, 2012. | |

| 21 | 国家市场监督管理总局, 中国国家标准化管理委员会. 质子交换膜燃料电池汽车用燃料 氢气: [S]. 北京: 中国标准出版社, 2018. |

| State Administration for Market Regulation, Standardization Administration of the People’s Republic of China. Fuel specification for proton exchange membrane fuel cell vehicles—Hydrogen: [S]. Beijing: Standards Press of China, 2018. | |

| 22 | 缪明富, 彭子成, 钟国利. 利用二氧化碳资源提高气田开发效益[J]. 石油与天然气化工, 2005, 34(6): 470-481. |

| Miao M F, Peng Z C, Zhong G L. Use CO2 resource to increase gas field development benefit[J]. Chemical Engineering of Oil & Gas, 2005, 34(6): 470-481. | |

| 23 | Quader M A, Smart S, Rufford T E. Techno-economic evaluation of multistage membrane combinations using three different materials to recover helium from natural gas[M]//Computer Aided Chemical Engineering. Amsterdam: Elsevier, 2018: 1201-1206. |

| 24 | Hägg M, Lindbråthen A, Haider S, et al. Techno-economic evaluation of helium recovery from natural gas; a comparison between inorganic and polymeric membrane technology[J]. Journal of Membrane Science and Research, 2019, 5: 126-136. |

| 25 | 阮雪华, 贺高红, 肖武, 等. 生物甲烷膜分离提纯系统的设计与优化[J]. 化工学报, 2014, 65(5): 1688-1695. |

| Ruan X H, He G H, Xiao W, et al. Design and optimization of membrane-based system for bio-methane purification[J]. CIESC Journal, 2014, 65(5): 1688-1695. | |

| 26 | Alders M, Winterhalder D, Wessling M. Helium recovery using membrane processes[J]. Separation and Purification Technology, 2017, 189: 433-440. |

| 27 | Ruan X H, Huo W B, Wang J M, et al. Multi-technique integration separation frameworks after steam reforming for coal-based hydrogen generation[J]. Chinese Journal of Chemical Engineering, 2021, 35: 163-172. |

| 28 | 程安迪, 刘世帅, 吴雪梅, 等. 膜分离耦合电化学氢泵提氦工艺设计与优化[J]. 清华大学学报(自然科学版), 2023, 63(5): 704-713. |

| Cheng A D, Liu S S, Wu X M, et al. Design and optimization of a helium separation process by membrane coupled with an electrochemical hydrogen pump[J]. Journal of Tsinghua University (Science and Technology), 2023, 63(5): 704-713. | |

| 29 | Schorer L, Schmitz S, Weber A. Membrane based purification of hydrogen system (MEMPHYS)[J]. International Journal of Hydrogen Energy, 2019, 44(25): 12708-12714. |

| 30 | Hemmati A, Rashidi H, Behradfar K, et al. A comparative study of different mass transfer and liquid hold-up correlations in modeling CO2 absorption with MEA[J]. Journal of Natural Gas Science and Engineering, 2019, 62: 92-100. |

| 31 | Tiwari S C, Agarwal M, Pant K K, et al. A comparative study of polyamine and piperazine as promoter for CO2 absorption performance in aqueous methyldiethanolamine blend system: 430 MW power plant data simulation and economic assessment[J]. Sustainable Chemistry for the Environment, 2023, 4: 100054. |

| 32 | Xiao W, Wang H, Cheng A D, et al. Design and optimization of a novel hybrid membrane-electrochemical hydrogen pump process for recovering helium from NRU off gas[J]. Membranes, 2023, 13(7): 689. |

| 33 | Weh R, Xiao G K, Pouya E S, et al. Direct helium recovery from natural gas by dual reflux pressure swing adsorption cascade[J]. Chemical Engineering Journal, 2022, 450: 137894. |

| 34 | Das N K, Chaudhuri H, Bhandari R K, et al. Purification of helium from natural gas by pressure swing adsorption[J]. Current Science, 2008, 95(12): 1684-1687. |

| 35 | Li Y P, Xiao H Y, Zheng W J, et al. Multi-membrane integrated processes for helium and methane synergistic recovery after flash-vaporization units in LNG plants[J]. Separation and Purification Technology, 2023, 326: 124825. |

| 36 | Quader M A, Rufford T E, Smart S. Integration of hybrid membrane-distillation processes to recover helium from pre-treated natural gas in liquefied natural gas plants[J]. Separation and Purification Technology, 2021, 263: 118355. |

| [1] | 高冰冰, 许诺, 白云翔, 张春芳, 杨永强, 董亮亮. 氦气分离聚合物膜[J]. 化工学报, 2025, 76(5): 2119-2135. |

| [2] | 郭彭涛, 王婷, 薛波, 应允攀, 刘大欢. 用于CH4/N2分离的多吸附位点超微孔MOF[J]. 化工学报, 2025, 76(5): 2304-2312. |

| [3] | 李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357. |

| [4] | 花敬贤, 罗宇荣, 顾亚伟, 吴婷婷, 潘宜昌, 邢卫红. 超薄取向ZIF-8膜的制备及乙烯/乙烷高效分离[J]. 化工学报, 2025, 76(5): 2209-2218. |

| [5] | 刘鑫, 郑皓仁, 陈强, 丁静怡, 黄康, 徐至. 全钒液流电池用纤维素纳米晶掺杂混合基质膜[J]. 化工学报, 2025, 76(5): 2294-2303. |

| [6] | 徐泽海, 刘超, 张国亮. 聚合物基疏水渗透汽化膜及其溶剂回收应用[J]. 化工学报, 2025, 76(5): 2055-2069. |

| [7] | 王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959. |

| [8] | 陆艳秋, 狄扬, 石文博, 殷聪聪, 汪勇. 基于新型有机多孔聚合物的智能响应膜研究进展[J]. 化工学报, 2025, 76(5): 2101-2118. |

| [9] | 赵浩帆, 任豪杰, 刘宗凯, 董冠英, 张亚涛. MOFs玻璃膜在气体分离领域的研究进展[J]. 化工学报, 2025, 76(5): 2042-2054. |

| [10] | 张越, 刘佳鑫, 马敬, 刘毅. 金属有机骨架膜应用于海水提铀研究进展[J]. 化工学报, 2025, 76(5): 2087-2100. |

| [11] | 顾栋, 皮行健, 张叠, 张瑛. 不同粒径CAU-1/PI混合基质膜的构建与H2/CO2分离性能研究[J]. 化工学报, 2025, 76(5): 2410-2418. |

| [12] | 程刘惠美, 闫军营, 刘慧情, 王治澎, 王报英, 徐铜文, 汪耀明. 双极膜电渗析在醇水体系的应用研究进展[J]. 化工学报, 2025, 76(5): 1960-1972. |

| [13] | 张耀辉, 班宇杰, 杨维慎. 以蒸气加工法制备和修饰金属-有机框架膜[J]. 化工学报, 2025, 76(5): 2070-2086. |

| [14] | 杨紫博, 王有发, 岳寒松, 远双杰, 耿付江, 李晴晴, 奥德, 李斌, 叶茂, 顾振杰, 乔志华. MOF玻璃基气体分离膜的研究进展[J]. 化工学报, 2025, 76(5): 2158-2168. |

| [15] | 朱迪, 高守建, 方望熹, 靳健. 水蒸气诱导相分离构筑海绵孔结构超亲水聚醚砜膜及其油/水乳液分离性能研究[J]. 化工学报, 2025, 76(5): 2397-2409. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号