化工学报 ›› 2025, Vol. 76 ›› Issue (S1): 435-443.DOI: 10.11949/0438-1157.20241387

• 能源和环境工程 • 上一篇

收稿日期:2024-12-02

修回日期:2024-12-17

出版日期:2025-06-25

发布日期:2025-06-26

通讯作者:

王文

作者简介:黄灏(1999—),男,硕士研究生,paff-official@sjtu.edu.cn

Hao HUANG( ), Wen WANG(

), Wen WANG( ), Peiyun LI

), Peiyun LI

Received:2024-12-02

Revised:2024-12-17

Online:2025-06-25

Published:2025-06-26

Contact:

Wen WANG

摘要:

容积式膨胀机在有机朗肯循环及压缩空气储能等系统中扮演着重要角色。尤其在面临高膨胀比的场合时,多级膨胀运行成为不可或缺的选择。本文依据三角转子膨胀机的三个工作腔的运行原理,构建了相应的模型,并针对两级串联三角转子膨胀机的运行特征及其影响因素展开了深入分析。研究结果显示,通过合理匹配膨胀机的容积与转速比例,可以实现66%的功率密度增长和47%的输出功率提升。与单级膨胀机相比,在设计的膨胀比条件下或实际膨胀比较高时,多级串联膨胀机的功率密度至少提高了15%,即多级串联膨胀机可适合大膨胀比或膨胀比波动较大的工况中。

中图分类号:

黄灏, 王文, 李沛昀. 三角转子膨胀机串联运行特性研究[J]. 化工学报, 2025, 76(S1): 435-443.

Hao HUANG, Wen WANG, Peiyun LI. Research on properties of wankel expanders under series connection[J]. CIESC Journal, 2025, 76(S1): 435-443.

| 参数 | 数值 |

|---|---|

| 转子半径R/mm | 60.25 |

| 形状因子K | 5 |

| 腔体高度B/mm | 84 |

| 偏心度e/mm | 12.05 |

| 进气行程角φin/(°) | 110 |

| 有效工作容积Vdisp/mm3 | 316*105 |

| 容积效率ηv | 0.4 |

| 排气压力Pout/bar | 0.75 |

| 工质类型 | 水蒸气 |

表1 文献中给出的三角转子膨胀机数据[14-17]

Table 1 The parameters of the Wankel expander given in Refs. [14-17]

| 参数 | 数值 |

|---|---|

| 转子半径R/mm | 60.25 |

| 形状因子K | 5 |

| 腔体高度B/mm | 84 |

| 偏心度e/mm | 12.05 |

| 进气行程角φin/(°) | 110 |

| 有效工作容积Vdisp/mm3 | 316*105 |

| 容积效率ηv | 0.4 |

| 排气压力Pout/bar | 0.75 |

| 工质类型 | 水蒸气 |

转速/ (r/min) | 进口压力/ bar | 输出功率(实验)[ | 输出功率(计算)[ | 输出功率(本文)/kW |

|---|---|---|---|---|

| 1000 | 5.7 | 2.7 | 3.0 | 2.85 |

| 1000 | 6.4 | 3.8 | 3.5 | 3.55 |

| 1000 | 7.4 | 4.8 | 4.1 | 4.55 |

| 2000 | 5.4 | 5.4 | 5.2 | 5.46 |

| 2000 | 5.8 | 6.7 | 5.7 | 6.30 |

| 2000 | 6.6 | 8.4 | 6.8 | 7.96 |

| 3000 | 5.2 | 7.2 | 6.7 | 7.54 |

| 3000 | 5.9 | 9.2 | 7.9 | 9.73 |

| 3000 | 6.6 | 10.0 | 9.1 | 11.90 |

表2 不同进出参数与转速下文献实验结果[14]与计算结果对比

Table 2 Comparison of experimental and computational data in Ref.[14] under different rotational speeds

转速/ (r/min) | 进口压力/ bar | 输出功率(实验)[ | 输出功率(计算)[ | 输出功率(本文)/kW |

|---|---|---|---|---|

| 1000 | 5.7 | 2.7 | 3.0 | 2.85 |

| 1000 | 6.4 | 3.8 | 3.5 | 3.55 |

| 1000 | 7.4 | 4.8 | 4.1 | 4.55 |

| 2000 | 5.4 | 5.4 | 5.2 | 5.46 |

| 2000 | 5.8 | 6.7 | 5.7 | 6.30 |

| 2000 | 6.6 | 8.4 | 6.8 | 7.96 |

| 3000 | 5.2 | 7.2 | 6.7 | 7.54 |

| 3000 | 5.9 | 9.2 | 7.9 | 9.73 |

| 3000 | 6.6 | 10.0 | 9.1 | 11.90 |

| 参数 | 膨胀机1 | 膨胀机2 |

|---|---|---|

| 转子半径R/mm | 50 | 80 |

| 形状因子K | 6 | 6 |

| 腔体高度B/mm | 25 | 25 |

| 转速ω/(r/min) | 1200 | 1200 |

| 进气截面积Ain/mm2 | 80 | 80 |

| 排气截面积Aout/mm2 | 80 | 160 |

| 泄漏间隙δ/mm | 0.25 | 0.25 |

| 进气入口压力Pin/MPa | 70 | — |

| 进气入口温度Tin/K | 300 | — |

| 排气背压Pb/kPa | — | 20000 |

| 缓冲容积V/cm3 | 20 | — |

| 进气行程角φin/(°) | 135 | 135 |

| 理论体积膨胀比ε | 2 | 2 |

| 对流强度系数h/(W/ (m2·K)) | 1200 | 1800 |

表3 两级串联膨胀机参数

Table 3 Parameters of two-stage series expanders

| 参数 | 膨胀机1 | 膨胀机2 |

|---|---|---|

| 转子半径R/mm | 50 | 80 |

| 形状因子K | 6 | 6 |

| 腔体高度B/mm | 25 | 25 |

| 转速ω/(r/min) | 1200 | 1200 |

| 进气截面积Ain/mm2 | 80 | 80 |

| 排气截面积Aout/mm2 | 80 | 160 |

| 泄漏间隙δ/mm | 0.25 | 0.25 |

| 进气入口压力Pin/MPa | 70 | — |

| 进气入口温度Tin/K | 300 | — |

| 排气背压Pb/kPa | — | 20000 |

| 缓冲容积V/cm3 | 20 | — |

| 进气行程角φin/(°) | 135 | 135 |

| 理论体积膨胀比ε | 2 | 2 |

| 对流强度系数h/(W/ (m2·K)) | 1200 | 1800 |

| 序号 | 下级膨胀机转子半径/ mm | 下级膨胀机腔体高度/mm | 下级膨胀机转子半径/mm | 下级膨胀机腔体高度/mm | 上级转速/ (r/min) | 下级转速/ (r/min) |

|---|---|---|---|---|---|---|

| 1 | 50 | 25 | 40 | 40 | 1200 | 1200 |

| 2 | 50 | 25 | 70 | 25 | 1200 | 1200 |

| 3 | 50 | 25 | 80 | 40 | 1200 | 600 |

| 4 | 50 | 25 | 80 | 25 | 1200 | 1200 |

| 5 | 50 | 25 | 80 | 30 | 1200 | 1200 |

| 6 | 50 | 25 | 80 | 40 | 1200 | 1200 |

| 7 | 50 | 25 | 80 | 60 | 1200 | 1200 |

表4 序号1~7对应的膨胀机参数

Table 4 Expanders parameters in discussion

| 序号 | 下级膨胀机转子半径/ mm | 下级膨胀机腔体高度/mm | 下级膨胀机转子半径/mm | 下级膨胀机腔体高度/mm | 上级转速/ (r/min) | 下级转速/ (r/min) |

|---|---|---|---|---|---|---|

| 1 | 50 | 25 | 40 | 40 | 1200 | 1200 |

| 2 | 50 | 25 | 70 | 25 | 1200 | 1200 |

| 3 | 50 | 25 | 80 | 40 | 1200 | 600 |

| 4 | 50 | 25 | 80 | 25 | 1200 | 1200 |

| 5 | 50 | 25 | 80 | 30 | 1200 | 1200 |

| 6 | 50 | 25 | 80 | 40 | 1200 | 1200 |

| 7 | 50 | 25 | 80 | 60 | 1200 | 1200 |

| 序号 | 上下级体积 流量比 | 上级实际 膨胀比 | 下级实际 膨胀比 | 等熵效率/ % | 总输出功率/ kW | 功率密度/ (kJ/kg) |

|---|---|---|---|---|---|---|

| 1 | 1∶1.02 | 1.59 | 1.37 | 12.41 | 77.20 | 158.03 |

| 2 | 1∶1.96 | 1.32 | 1.50 | 16.22 | 100.32 | 235.71 |

| 3 | 1∶2.04 | 1.28 | 1.42 | 15.15 | 78.79 | 191.93 |

| 4 | 1∶2.56 | 1.48 | 1.95 | 17.20 | 114.04 | 262.82 |

| 5 | 1∶3.07 | 1.51 | 1.42 | 16.64 | 123.41 | 259.76 |

| 6 | 1∶4.11 | 1.79 | 1.30 | 14.47 | 126.39 | 237.39 |

| 7 | 1∶6.11 | 2.19 | 1.14 | 8.37 | 108.12 | 171.13 |

表5 不同参数条件下两级膨胀机的运行性能

Table 5 Performance of two-stage expanders

| 序号 | 上下级体积 流量比 | 上级实际 膨胀比 | 下级实际 膨胀比 | 等熵效率/ % | 总输出功率/ kW | 功率密度/ (kJ/kg) |

|---|---|---|---|---|---|---|

| 1 | 1∶1.02 | 1.59 | 1.37 | 12.41 | 77.20 | 158.03 |

| 2 | 1∶1.96 | 1.32 | 1.50 | 16.22 | 100.32 | 235.71 |

| 3 | 1∶2.04 | 1.28 | 1.42 | 15.15 | 78.79 | 191.93 |

| 4 | 1∶2.56 | 1.48 | 1.95 | 17.20 | 114.04 | 262.82 |

| 5 | 1∶3.07 | 1.51 | 1.42 | 16.64 | 123.41 | 259.76 |

| 6 | 1∶4.11 | 1.79 | 1.30 | 14.47 | 126.39 | 237.39 |

| 7 | 1∶6.11 | 2.19 | 1.14 | 8.37 | 108.12 | 171.13 |

| 进口压力/kPa | 出口压力/kPa | 上级实际膨胀比 | 下级实际膨胀比 | 总输出功率/kW | 质量流量/(kg/s) | 功率密度/(kJ/kg) |

|---|---|---|---|---|---|---|

| 70000 | 40000 | 1.19 | 1.07 | 39.96 | 0.3871 | 103.23 |

| 70000 | 20000 | 1.35 | 1.49 | 114.04 | 0.4339 | 262.82 |

| 70000 | 15000 | 1.39 | 1.71 | 134.32 | 0.4438 | 302.66 |

| 70000 | 10000 | 1.43 | 2.02 | 155.98 | 0.4514 | 345.54 |

| 70000 | 5000 | 1.44 | 2.28 | 180.77 | 0.4526 | 399.40 |

表6 不同进出口压力下两级串联膨胀机的工作情况

Table 6 Results of a two-stage series expanders system under different inlet and outlet pressures

| 进口压力/kPa | 出口压力/kPa | 上级实际膨胀比 | 下级实际膨胀比 | 总输出功率/kW | 质量流量/(kg/s) | 功率密度/(kJ/kg) |

|---|---|---|---|---|---|---|

| 70000 | 40000 | 1.19 | 1.07 | 39.96 | 0.3871 | 103.23 |

| 70000 | 20000 | 1.35 | 1.49 | 114.04 | 0.4339 | 262.82 |

| 70000 | 15000 | 1.39 | 1.71 | 134.32 | 0.4438 | 302.66 |

| 70000 | 10000 | 1.43 | 2.02 | 155.98 | 0.4514 | 345.54 |

| 70000 | 5000 | 1.44 | 2.28 | 180.77 | 0.4526 | 399.40 |

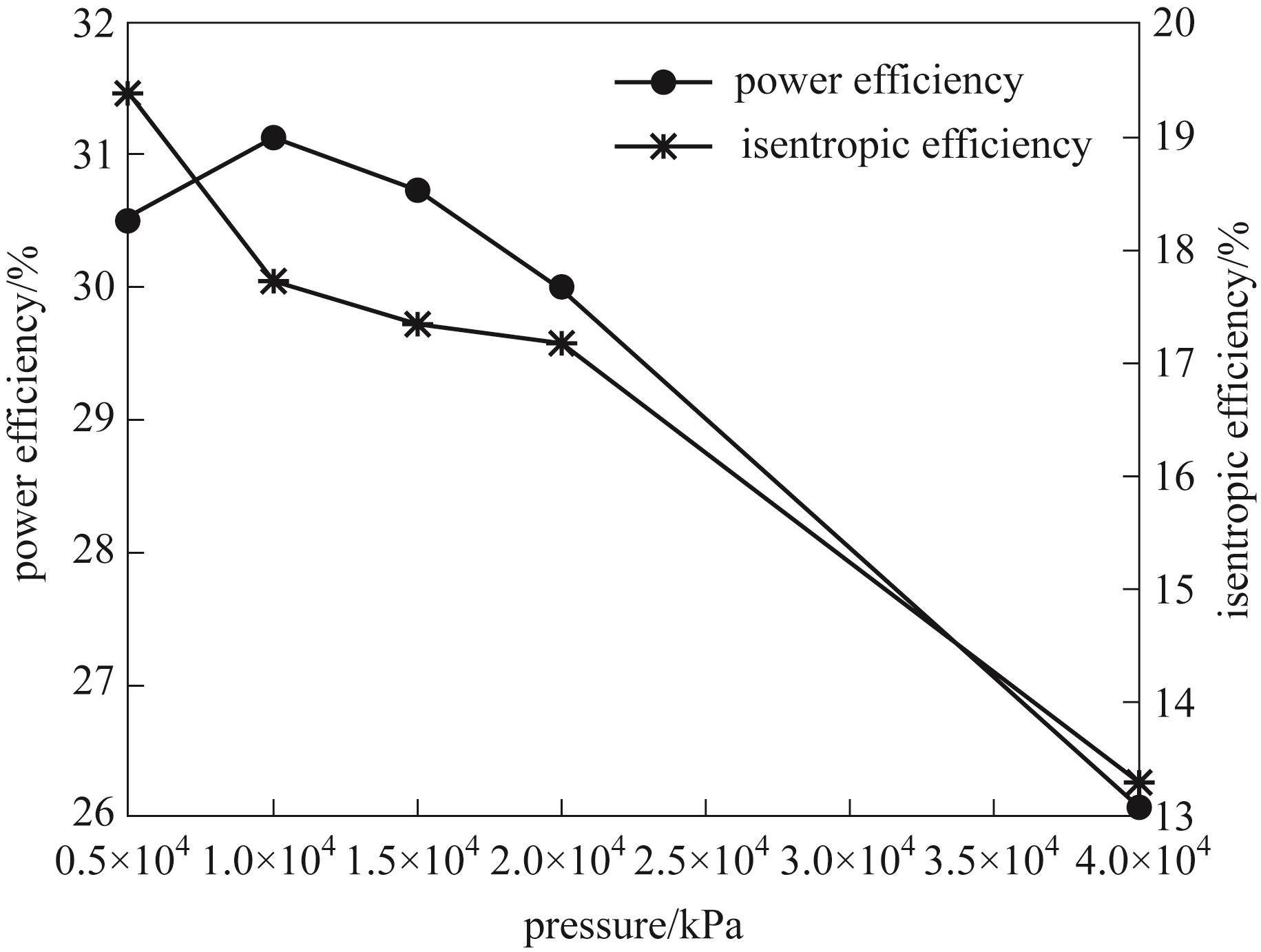

图11 两级串联膨胀机的能量转换效率与等熵效率随出口压力变化曲线

Fig.11 Energy conversion efficiency and isentropic efficiency of a two-stage series expanders system with different outlet pressure

| 参数 | 数值 |

|---|---|

| 转子半径R/ mm | 25 |

| 形状因子K | 6 |

| 腔体高度B/mm | 60 |

| 偏心度e / mm | 10 |

| 进气行程角φin/(°) | 90 |

| 转速ω/(r/min) | 1200 |

| 进气截面积Ain / mm2 | 80 |

| 排气截面积Aout / mm2 | 80 |

| 泄漏间隙δ/ mm | 0.25 |

| 理论体积膨胀比ε | 4 |

表7 单级膨胀机参数

Table 7 Parameters of a single-stage expander

| 参数 | 数值 |

|---|---|

| 转子半径R/ mm | 25 |

| 形状因子K | 6 |

| 腔体高度B/mm | 60 |

| 偏心度e / mm | 10 |

| 进气行程角φin/(°) | 90 |

| 转速ω/(r/min) | 1200 |

| 进气截面积Ain / mm2 | 80 |

| 排气截面积Aout / mm2 | 80 |

| 泄漏间隙δ/ mm | 0.25 |

| 理论体积膨胀比ε | 4 |

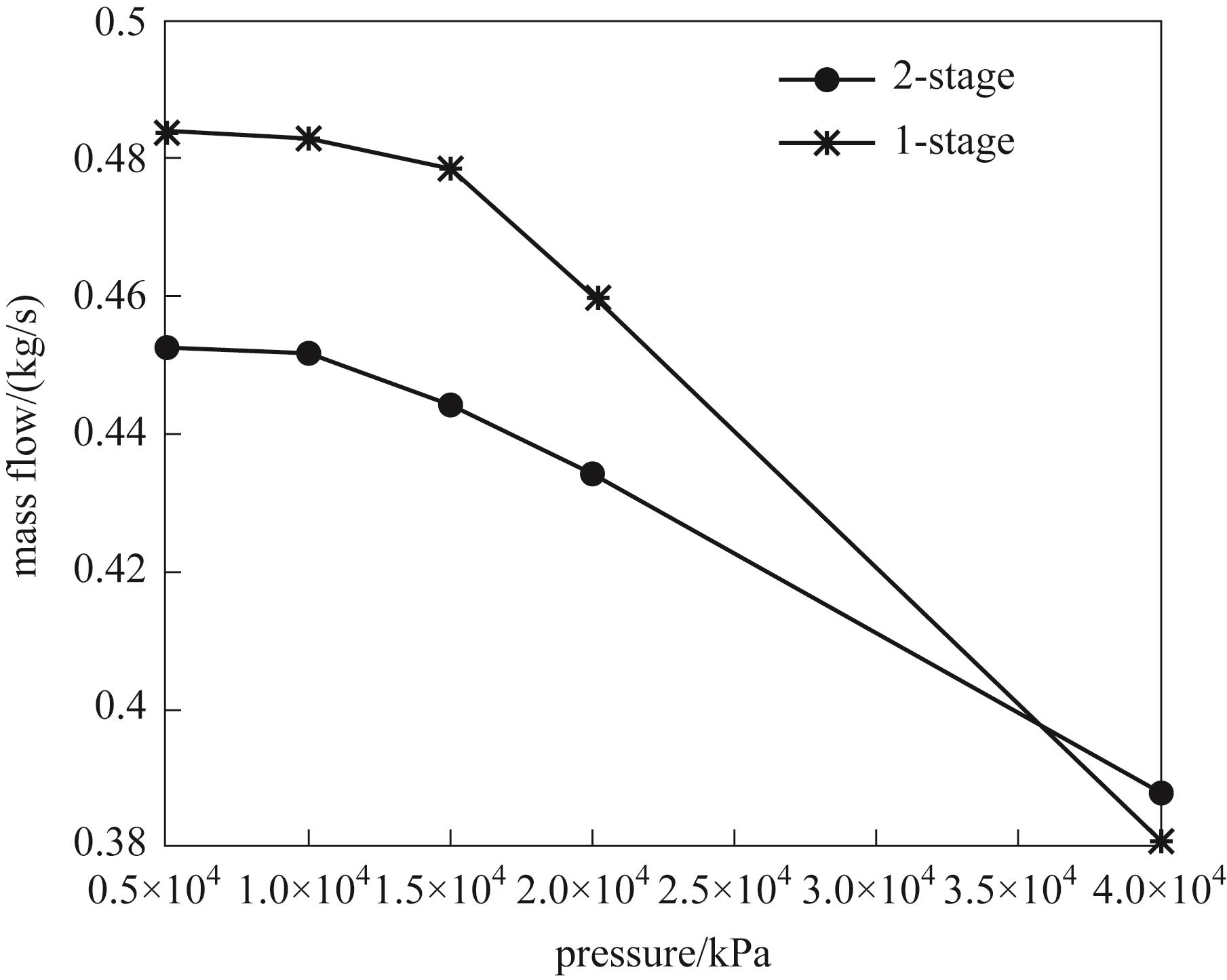

图12 在不同出口压力条件下两级串联和单级膨胀机质量流量的对比

Fig.12 Comparison of mass flow rate between two-stage series expanders and single-stage expander with different outlet pressure

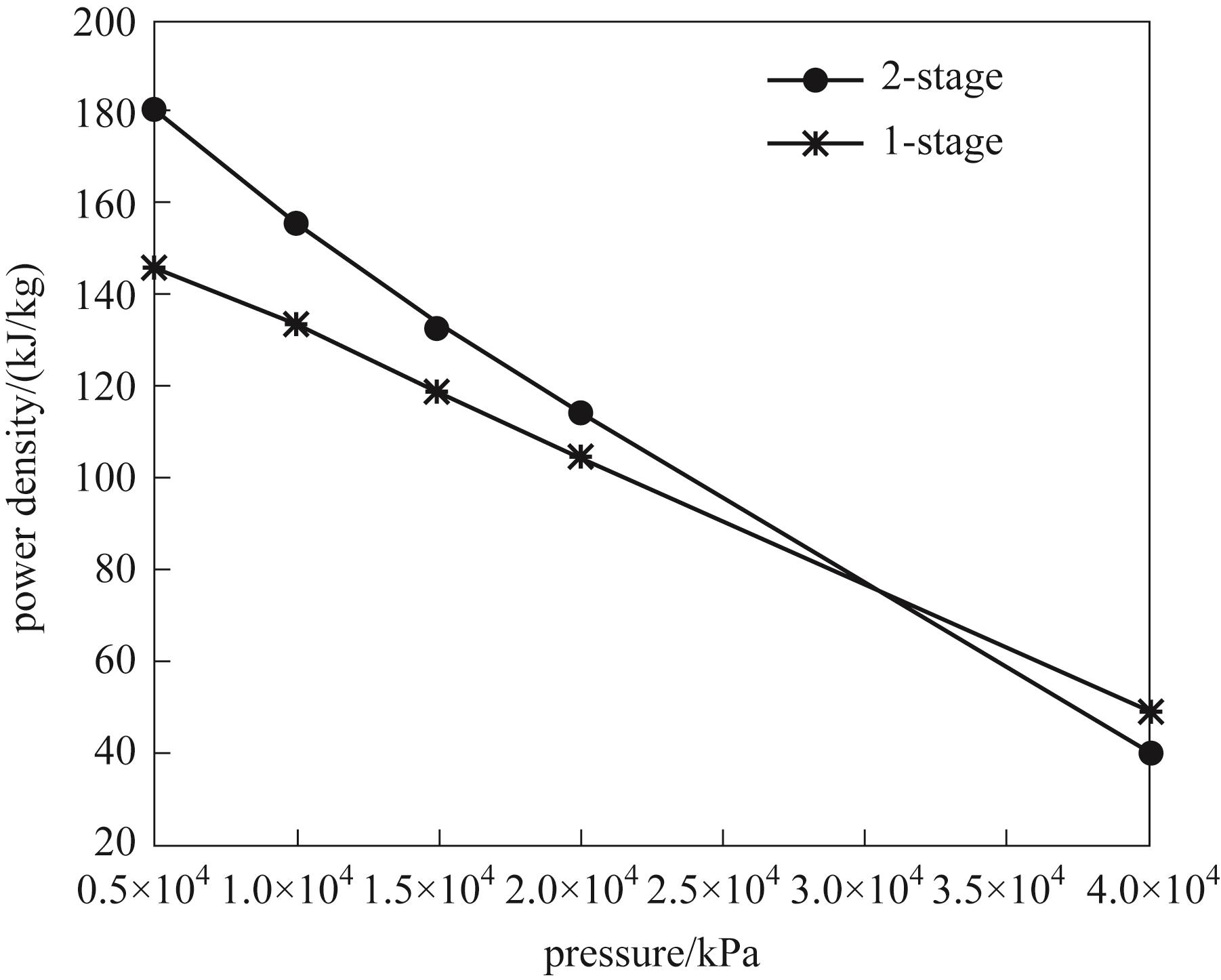

图13 在不同出口压力条件下,两级串联和单级膨胀机功率密度的对比

Fig.13 Comparison of power density between two-stage series expanders and single-stage expander with different outlet pressure

| 1 | Di Battista D, Mauriello M, Cipollone R. Waste heat recovery of an ORC-based power unit in a turbocharged diesel engine propelling a light duty vehicle[J]. Applied Energy, 2015, 152: 109-120. |

| 2 | Tian Y F, Xing Z W, He Z L, et al. Modeling and performance analysis of twin-screw steam expander under fluctuating operating conditions in steam pipeline pressure energy recovery applications[J]. Energy, 2017, 141: 692-701. |

| 3 | Li G, Zheng X F. Thermal energy storage system integration forms for a sustainable future[J]. Renewable and Sustainable Energy Reviews, 2016, 62: 736-757. |

| 4 | Qiu G Q, Liu H, Riffat S. Expanders for micro-CHP systems with organic Rankine cycle[J]. Applied Thermal Engineering, 2011, 31(16): 3301-3307. |

| 5 | Pantano F, Capata R. Expander selection for an on board ORC energy recovery system[J]. Energy, 2017, 141: 1084-1096. |

| 6 | Qyyum M A, Naquash A, Sial N R, et al. CO2 precooled dual phase expander refrigeration cycles for offshore and small-scale LNG production: Energy, exergy, and economic evaluation[J]. Energy, 2023, 262: 125378. |

| 7 | Sanaye S, Mohammadi Nasab A. Modeling and optimizing a CHP system for natural gas pressure reduction plant[J]. Energy, 2012, 40(1): 358-369. |

| 8 | Handa K, Oshima S, Rembutsu T. Precooling temperature relaxation technology in hydrogen refueling for fuel-cell vehicles[J]. International Journal of Hydrogen Energy, 2021, 46(67): 33511-33522. |

| 9 | Elgowainy A, Reddi K, Lee D Y, et al. Techno-economic and thermodynamic analysis of pre-cooling systems at gaseous hydrogen refueling stations[J]. International Journal of Hydrogen Energy, 2017, 42(49): 29067-29079. |

| 10 | Yoshida J, Matsuo E, Takata Y, et al. Thermodynamic analysis of high pressure hydrogen gas refueling system with turbo-expanders[J]. Mechanical Engineering Journal, 2019, 6(3): 18-388-18-00388. |

| 11 | 张兴. 井口高压天然气发电用三角转子气动机设计与仿真[D]. 成都: 西南石油大学, 2018. |

| Zhang X. Design and simulation of triangular rotor pneumatic motor for wellhead high-pressure natural gas power generation[D]. Chengdu: Southwest Petroleum University, 2018. | |

| 12 | Badr O, Naik S, O'Callaghan P W, et al. Rotary Wankel engines as expansion devices in steam Rankine-cycle engines[J]. Applied Energy, 1991, 39(1): 59-76. |

| 13 | Francesconi M, Caposciutti G, Antonelli M. An experimental and numerical analysis of the performances of a Wankel steam expander[J]. Energy, 2018, 164: 615-626. |

| 14 | Antonelli M, Baccioli A, Francesconi M, et al. Experimental and numerical analysis of the valve timing effects on the performances of a small volumetric rotary expansion device[J]. Energy Procedia, 2014, 45: 1077-1086. |

| 15 | Antonelli M, Baccioli A, Francesconi M, et al. Numerical and experimental analysis of the intake and exhaust valves of a rotary expansion device for micro generation[J]. Energy Procedia, 2015, 81: 461-471. |

| 16 | Antonelli M, Francesconi M, Baccioli A, et al. Experimental results of a wankel-type expander fuelled by compressed air and saturated steam[J]. Energy Procedia, 2017, 105: 2929-2934. |

| 17 | Francesconi M, Analysis and design of devices for medium temperature solar thermal energy conversion[D]. Pisa: University of Pisa. 2017: 168-230. |

| 18 | Sadiq G A, Tozer G, Al-Dadah R, et al. CFD simulations of compressed air two stage rotary Wankel expander–Parametric analysis[J]. Energy Conversion and Management, 2017, 142: 42-52. |

| 19 | 王云, 刘小勇, 周勇. 三角转子气动发动机设计及性能分析[J]. 机械科学与技术, 2009, 28(7): 950-954, 959. |

| Wang Y, Liu X Y, Zhou Y. Design and performance analysis of a triangle rotary piston air-powered engine[J]. Mechanical Science and Technology for Aerospace Engineering, 2009, 28(7): 950-954, 959. | |

| 20 | 潘剑锋, 肖曼, 范宝伟, 等. 配气相位对三角转子气动发动机性能的影响[J]. 江苏大学学报(自然科学版), 2016, 37(2): 141-146. |

| Pan J F, Xiao M, Fan B W, et al. Effect of valve timing on Wankel rotor air-powered engine[J]. Journal of Jiangsu University (Natural Science Edition), 2016, 37(2): 141-146. | |

| 21 | 李沛昀, 孟金龙, 王文, 等. 三角转子膨胀机在有机朗肯循环中应用分析[J]. 太阳能学报, 2023, 44(2): 1-8. |

| Li P Y, Meng J L, Wang W, et al. Application analysis of wankel expander for organic Rankine cycle[J]. Acta Energiae Solaris Sinica, 2023, 44(2): 1-8. | |

| 22 | 李沛昀, 李杨, 王文彬, 等. 三角转子膨胀机在跨临界CO2制冷循环中的应用分析[J]. 化工学报, 2021, 72(S1): 161-169. |

| Li P Y, Li Y, Wang W B, et al. Application analysis of triangular rotor expander in transcritical CO2 refrigeration cycle[J]. CIESC Journal, 2021, 72(S1): 161-169. |

| [1] | 李卫, 陈浩, 柯钢, 黄孝胜, 李成娇, 郭航, 叶芳. 高原环境适应性试验室模拟平台新风系统仿真[J]. 化工学报, 2025, 76(S1): 360-369. |

| [2] | 邵明成, 潘玉贵, 王增丽, 赵强. CO2/CH4混合物理论跨临界增压过程的热力性能研究[J]. 化工学报, 2024, 75(10): 3742-3751. |

| [3] | 董宜放, 于樱迎, 胡学功, 裴刚. 电场对竖直微槽润湿及毛细流动特性影响[J]. 化工学报, 2022, 73(7): 2952-2961. |

| [4] | 方远鑫, 肖武, 姜晓滨, 李祥村, 贺高红, 吴雪梅. 膜分离耦合CO2电催化加氢制甲酸工艺的设计及模拟[J]. 化工学报, 2021, 72(9): 4740-4749. |

| [5] | 于仙毅, 巫江虹, 高云辉. 基于主成分分析与支持向量机的热泵系统制冷剂泄漏识别研究[J]. 化工学报, 2020, 71(7): 3151-3164. |

| [6] | 郑传杰, 盛昌栋. 高温烟气中吸附剂捕集K的模型及其反应动力学研究[J]. 化工学报, 2019, 70(6): 2259-2268. |

| [7] | 张壮, 邓春, 孙海兰, 冯霄. 除盐水系统建模与物料衡算分析[J]. 化工学报, 2019, 70(2): 646-652. |

| [8] | 尤东江, 魏建云, 李雪菁, 娄景媛. 基于框架设计的液流电池流场优化模拟研究[J]. 化工学报, 2019, 70(11): 4437-4448. |

| [9] | 周新志, 邵伦, 李荣昆, 赵成萍, 董晨龙. 基于小波去噪和改进型PSO-SVM的微波加热温度预测模型研究[J]. 化工学报, 2018, 69(S2): 291-299. |

| [10] | 张培昆, 王立. 空分短期停车时间阈值对氧气生产调度的影响[J]. 化工学报, 2017, 68(6): 2423-2433. |

| [11] | 董泽, 陈利平, 陈网桦, 马莹莹. 密闭容器内失控反应超压的数学建模及其在压力泄放中的应用[J]. 化工学报, 2017, 68(11): 4453-4460. |

| [12] | 马彪, 李彦军, 郭家敏, 张国磊, 宋福元, 李健, 曾帅, 张晓宇. 不同充汽方式下供汽系统动态特性仿真[J]. 化工学报, 2016, 67(S1): 326-333. |

| [13] | 曾帅, 史智俊, 王鹏, 张国磊, 孙宝芝, 阙晨宇, 马彪, 李健. 舰用蒸汽动力系统主汽压力控制方法仿真[J]. 化工学报, 2016, 67(S1): 334-340. |

| [14] | 陈骏, 周伟国, 王海, 李苏. 基于等效电法的钢铁企业蒸汽系统多目标运行优化策略[J]. 化工学报, 2016, 67(9): 3804-3811. |

| [15] | 柴俪洪, 肖长发, 权全, 刘海亮, 陈明星, 赵斌. 同质增强型PMIA中空纤维膜污染及其MBR工艺处理城市生活污水[J]. 化工学报, 2016, 67(9): 3954-3964. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号