化工学报 ›› 2025, Vol. 76 ›› Issue (9): 4913-4921.DOI: 10.11949/0438-1157.20250103

收稿日期:2025-02-04

修回日期:2025-05-15

出版日期:2025-09-25

发布日期:2025-10-23

通讯作者:

张守玉

作者简介:黄小河(1994—),女,博士研究生,hxh_usst@163.com

Xiaohe HUANG( ), Shouyu ZHANG(

), Shouyu ZHANG( )

)

Received:2025-02-04

Revised:2025-05-15

Online:2025-09-25

Published:2025-10-23

Contact:

Shouyu ZHANG

摘要:

以准东五彩湾高碱煤(WCW)为实验对象及模型进行合成灰配比,选用SiO2、Al2O3、Fe2O3、Na2CO3和CaCO3/CaSO4为原料进行合成灰制备。对样品进行燃烧实验,对所得灰样进行筛分、XRD和FTIR检测,以探究不同钙对高碱煤灰烧结特性的影响。结果表明,使用CaCO3制备的合成灰(RR-1-Cal)初始烧结温度低于使用CaSO4制备的合成灰(RR-1-An),RR-1-An烧结倾向强于RR-1-Cal。灰中CaCO3对液相烧结的影响路径是因为Na-Si-Al之间反应生成钠长石,CaO与Si/Al反应生成含钙硅铝酸盐后,钠长石与含钙硅铝酸盐发生低温共熔。除此之外,硫酸根的加入会使得硅铝结构在高温下更不稳定,更易出现熔融烧结现象。在固相烧结过程中,CaCO3对煤灰硅结构先破坏后聚合,CaSO4则促进煤灰在更低温度下发生聚合。

中图分类号:

黄小河, 张守玉. Ca种类对准东煤灰烧结特性影响[J]. 化工学报, 2025, 76(9): 4913-4921.

Xiaohe HUANG, Shouyu ZHANG. Effect of Ca species on sintering characteristics of Zhundong coal ash[J]. CIESC Journal, 2025, 76(9): 4913-4921.

| 煤种 | 灰分分析/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | SO3 | K2O | Na2O | P2O5 | |

| WCW | 11.07 | 11.55 | 2.72 | 47.85 | 2.01 | 1.30 | 18.20 | 0.66 | 4.26 | 0.06 |

表1 五彩湾煤灰分分析

Table 1 Ash analysis of Wucaiwan coal

| 煤种 | 灰分分析/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | SO3 | K2O | Na2O | P2O5 | |

| WCW | 11.07 | 11.55 | 2.72 | 47.85 | 2.01 | 1.30 | 18.20 | 0.66 | 4.26 | 0.06 |

| 样品编号 | 钙种类 | 合成灰各组分比例/% | ||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | Na2CO3 | Ca* | ||

| RR-1-Cal | CaCO3 | 9.98 | 9.98 | 2.38 | 6.48 | 71.18 |

| RR-1-An | CaSO4 | 7.93 | 7.93 | 1.98 | 5.15 | 77.01 |

表2 不同钙种类合成灰样品编号及其配比

Table 2 Code and proportion of the synthetic ashes prepared by different calcium species

| 样品编号 | 钙种类 | 合成灰各组分比例/% | ||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | Na2CO3 | Ca* | ||

| RR-1-Cal | CaCO3 | 9.98 | 9.98 | 2.38 | 6.48 | 71.18 |

| RR-1-An | CaSO4 | 7.93 | 7.93 | 1.98 | 5.15 | 77.01 |

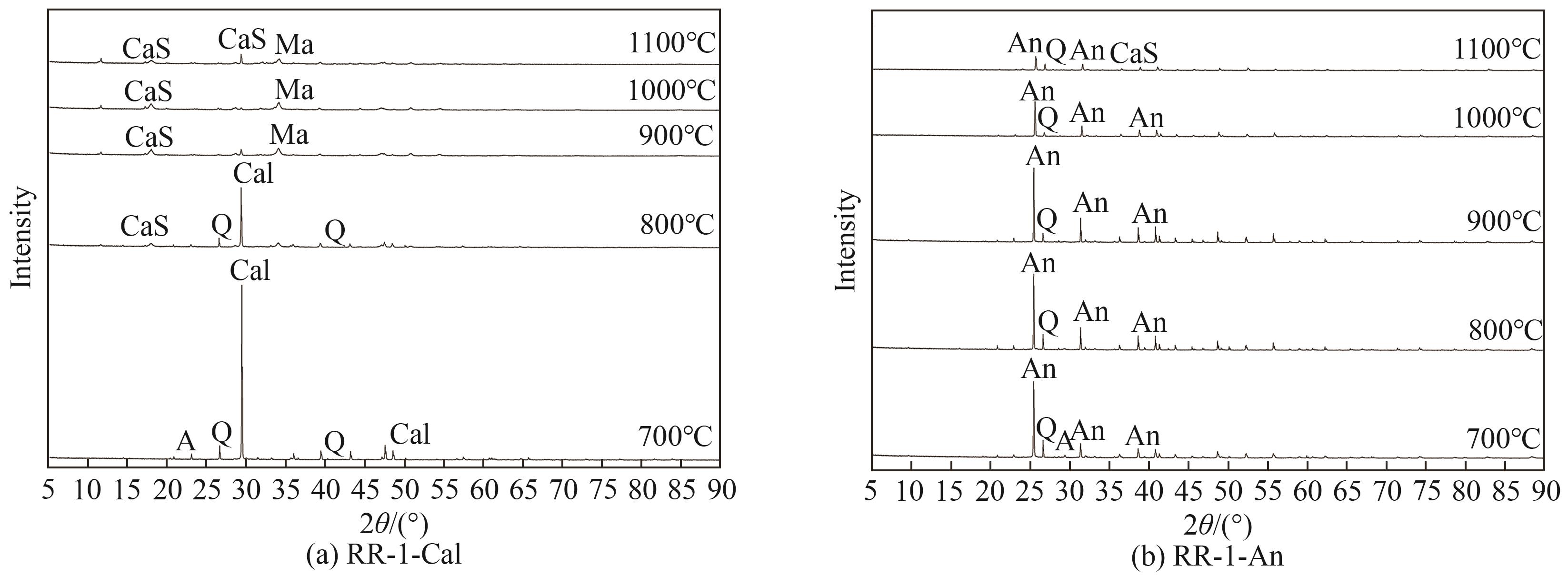

图2 不同钙种类合成灰经不同温度燃烧所得灰样XRD谱图A—钠长石 (NaAlSi3O8);An—硫酸钙 (CaSO4);Cal—碳酸钙 (CaCO3);CaS—硅酸钙 (Ca3SiO5);Ma—钙铝石 (Ca12Al14O33);Q—石英 (SiO2)

Fig.2 XRD patterns of synthetic ashes prepared by different calcium species after combustion at different temperature

| 波段/cm-1 | 吸收峰 | 文献 |

|---|---|---|

| 1440~1480 | 碳酸盐 | [ |

| 1432, 1425, 875, 867, 711, 717, 707 | 碳酸钙 | [ |

| 1405 | Al—O反对称伸长振动 | [ |

| 1147, 674, 663, 613, 593 | 硫酸钙 | [ |

| 1025 | Si—O对称伸长振动 | [ |

| 887 | 铝氧四面体AlO4 | [ |

| 850 | Si—O振动 | [ |

| 833 | 云母 | [ |

| 817 | Si—O—Si和Al—O对称伸缩振动 | [ |

| 698 | Si—O弯曲振动 | [ |

| 651 | 碱性长石O—Si(Al)—O弯曲振动 | [ |

| 636 | 碱性长石 | [ |

| 570 | Si—O延伸振动 | [ |

| 536 | Al—O—Si弯曲振动 | [ |

| 501 | Si—O(SiO4)弯曲振动 | [ |

| 485 | 变高岭石 | [ |

| 422 | 钠长石 | [ |

| 411, 404 | 云母 Si—O—Si变形振动 | [ |

表3 灰样中无机物的红外光谱吸收峰

Table 3 FTIR absorption peak of inorganic components in ash samples

| 波段/cm-1 | 吸收峰 | 文献 |

|---|---|---|

| 1440~1480 | 碳酸盐 | [ |

| 1432, 1425, 875, 867, 711, 717, 707 | 碳酸钙 | [ |

| 1405 | Al—O反对称伸长振动 | [ |

| 1147, 674, 663, 613, 593 | 硫酸钙 | [ |

| 1025 | Si—O对称伸长振动 | [ |

| 887 | 铝氧四面体AlO4 | [ |

| 850 | Si—O振动 | [ |

| 833 | 云母 | [ |

| 817 | Si—O—Si和Al—O对称伸缩振动 | [ |

| 698 | Si—O弯曲振动 | [ |

| 651 | 碱性长石O—Si(Al)—O弯曲振动 | [ |

| 636 | 碱性长石 | [ |

| 570 | Si—O延伸振动 | [ |

| 536 | Al—O—Si弯曲振动 | [ |

| 501 | Si—O(SiO4)弯曲振动 | [ |

| 485 | 变高岭石 | [ |

| 422 | 钠长石 | [ |

| 411, 404 | 云母 Si—O—Si变形振动 | [ |

图4 合成灰经不同温度燃烧所得灰样的二阶导数谱图

Fig.4 Second derivative spectra of synthetic ashes prepared by different calcium species after combustion at different temperature

| [2] | Song Y W, Chen Y F, Su S, et al. Effects of inorganic sodium on the combustion characteristics of Zhundong coal with fast-heating rate[J]. Fuel, 2022, 319: 123801. |

| [3] | Xiao R H, Wang Y, Zhang Y L, et al. Effect of kaolinite additive on water-soluble sodium release and particle matter formation during Zhundong coal combustion[J]. Fuel, 2023, 333: 126422. |

| [4] | Zhang L, Yan J C, Yang Q T, et al. Co-firing Zhundong coal with its gangue: combustion performance, sodium retention and ash fusion behaviors[J]. Sustainability, 2022, 14(24): 16451. |

| [5] | Zi J B, Ma D Y, Wang X B, et al. Slagging behavior and mechanism of high-sodium-chlorine coal combustion in a full-scale circulating fluidized bed boiler[J]. Journal of the Energy Institute, 2020, 93(6): 2264-2270. |

| [6] | Wang C A, Li G Y, Du Y B, et al. Ash deposition and sodium migration behaviors during combustion of Zhundong coals in a drop tube furnace[J]. Journal of the Energy Institute, 2018, 91(2): 251-261. |

| [7] | Wu X J, Zhang X, Dai B Q, et al. Ash deposition behaviours upon the combustion of low-rank coal blends in a 3 MWth pilot-scale pulverised coal-fired furnace[J]. Fuel Processing Technology, 2016, 152: 176-182. |

| [8] | Song G L, Qi X B, Song W J, et al. Slagging behaviors of high alkali Zhundong coal during circulating fluidized bed gasification[J]. Fuel, 2016, 186: 140-149. |

| [9] | 俞海淼, 曹欣玉, 张鹤声, 等. 若干典型煤灰样烧结熔融特性研究[J]. 同济大学学报(自然科学版), 2008, 36(5): 664-669. |

| Yu H M, Cao X Y, Zhang H S, et al. Research on sintering and fusion characteristics of several representative coal ashes[J]. Journal of Tongji University (Natural Science), 2008, 36(5): 664-669. | |

| [10] | Tang C W, Pan W G, Zhang J K, et al. A comprehensive review on efficient utilization methods of high-alkali coals combustion in boilers[J]. Fuel, 2022, 316: 123269. |

| [11] | 李君杰. 富氧燃烧下高钙/高碱煤成灰及沉积特性研究[D]. 武汉: 华中科技大学, 2018. |

| Li J J. Study on ash formation and deposition characteristics of high calcium/high alkali coal under oxygen-enriched combustion[D]. Wuhan: Huazhong University of Science and Technology, 2018. | |

| [12] | 卢啸风, 李建波, 刘卓, 等. 燃准东煤电站锅炉沾污结渣特性及防治措施研究进展[J]. 中国电机工程学报, 2024, 44(18): 7247-7264. |

| Lu X F, Li J B, Liu Z, et al. Research progress on the characteristics and countermeasures of ash slagging and fouling in boilers burning Zhundong coal[J]. Proceedings of the CSEE, 2024, 44(18): 7247-7264. | |

| [13] | Yuan Z S, Wang J, Kong L X, et al. Comparison study of fusibility between coal ash and synthetic ash[J]. Fuel Processing Technology, 2021, 211: 106593. |

| [14] | Zhang M R, Guo J W, Yao S Y, et al. The influence mechanism of ionic liquids on the ash melting and combustion characteristics of Zhundong high-alkali coal[J]. International Journal of Coal Preparation and Utilization, 2025, 45(1): 112-127. |

| [15] | Zhang X X, Huang L, Kong L X, et al. Effect of phosphorus-based additives on sodium release during Zhundong coal gasification in flat flame-assisted entrained flow reactor[J]. Combustion and Flame, 2023, 249: 112608. |

| [16] | Jung B, Schobert H H. Viscous sintering of coal ashes (1): Relationships of sinter point and sinter strength to particle size and composition[J]. Energy & Fuels, 1991, 5(4): 555-561. |

| [17] | Zbogar A, Frandsen F, Jensen P A, et al. Shedding of ash deposits[J]. Progress in Energy and Combustion Science, 2009, 35(1): 31-56. |

| [18] | 张守玉, 徐梓航, 黄东东, 等. 氯化钠蒸气对高钠煤煤灰钠捕获性能及其烧结温度的影响[J]. 煤炭学报, 2023, 48(1): 452-459. |

| Zhang S Y, Xu Z H, Huang D D, et al. Effect of NaCl vapor concentration on sodium-capturing performance and sintering temperature of coal ash[J]. Journal of China Coal Society, 2023, 48(1): 452-459. | |

| [19] | Lei T, Zhao J R, Zhang Z H. In-situ ash sintering process analysis during the co-combustion of the coal gasification fine slag and corn straw[J]. Energy, 2024, 310: 133311. |

| [20] | Liu K P, Wei B, Wang J J, et al. Effect of atmosphere and chemical composition on ash fusion process of Zhundong high iron coal[J]. Fuel, 2025, 386: 134223. |

| [21] | Zhao C Y, Wang C, Men X Y, et al. In-situ study of the effect of potassium release on ash sintering behavior during the co-gasification of coal and biomass[J]. Journal of Industrial and Engineering Chemistry, 2024, 140: 364-375. |

| [22] | Yang H R, Jin J, Liu D Y, et al. The effect on ash deposition by blending high-calcium Zhundong coal with vermiculite: focusing on minerals transformations[J]. Asia-Pacific Journal of Chemical Engineering, 2021, 16(1): e2571. |

| [23] | Yang S B, Song G L, Na Y J, et al. Alkali metal transformation and ash deposition performance of high alkali content Zhundong coal and its gasification fly ash under circulating fluidized bed combustion[J]. Applied Thermal Engineering, 2018, 141: 29-41. |

| [24] | Yang S B, Song G L, Na Y J, et al. Transformation characteristics of Na and K in high alkali residual carbon during circulating fluidized bed combustion[J]. Journal of the Energy Institute, 2019, 92(1): 62-73. |

| [25] | Yang Y P, Lin X C, Chen X J, et al. The formation of deposits and their evolutionary characteristics during pressurized gasification of Zhundong coal char[J]. Fuel, 2018, 224: 469-480. |

| [26] | 尹艳山, 尹杰, 张巍, 等. 红外和拉曼光谱的煤灰矿物组成研究[J]. 光谱学与光谱分析, 2018, 38(3): 789-793. |

| Yin Y S, Yin J, Zhang W, et al. Characterization of mineral matter in coal ashes with infrared and Raman spectroscopy[J]. Spectroscopy and Spectral Analysis, 2018, 38(3): 789-793. | |

| [27] | 黄小河, 张守玉, 杨靖宁, 等. 准东煤高温燃烧过程中含钙矿物质的转化规律[J]. 化工学报, 2017, 68(10): 3906-3911. |

| Huang X H, Zhang S Y, Yang J N, et al. Calcium transformation during Zhundong coal combustion process[J]. CIESC Journal, 2017, 68(10): 3906-3911. | |

| [28] | Zhou H, Ma W C. An experimental study on the effects of adding biomass ashes on ash sintering behavior of Zhundong coal[J]. Applied Thermal Engineering, 2017, 126: 689-701. |

| [29] | Ionescu B A, Barbu A M, Lăzărescu A V, et al. The influence of substitution of fly ash with marble dust or blast furnace slag on the properties of the alkali-activated geopolymer paste[J]. Coatings, 2023, 13(2): 403. |

| [30] | Yin Y S, Yin J, Zhang W, et al. FT-IR and micro-Raman spectroscopic characterization of minerals in high-calcium coal ashes[J]. Journal of the Energy Institute, 2018, 91(3): 389-396. |

| [31] | Yang J J, Sun H J, Peng T J, et al. Study on the overall reaction pathways and structural transformations during decomposition of coal fly ash in the process of alkali-calcination[J]. Materials, 2021, 14(5): 1163. |

| [32] | Dakhane A. Multiscale engineering response of alkali activated aluminosilicate binders[D]. Phoenix Arizona State University, 2016. |

| [33] | Criado M, Fernández-Jiménez A, Palomo A. Alkali activation of fly ash: effect of the SiO2/Na2O ratio[J]. Microporous and Mesoporous Materials, 2007, 106(1/2/3): 180-191. |

| [34] | 季杰强. 高碱煤燃烧碱金属钠迁移特性研究[D]. 杭州: 浙江大学, 2019. |

| Ji J Q. Study on migration characteristics of alkali metal sodium in high alkali coal combustion[D]. Hangzhou: Zhejiang University, 2019. | |

| [35] | Ge H J, Shen L H, Bai H C, et al. Characteristics of Zhundong coal ash in hematite-based chemical looping combustion[J]. Energy & Fuels, 2020, 34(7): 8150-8166. |

| [36] | Huang Z, Li N, Zhou Q L, et al. A comparative study of the pyrolysis and combustion characteristics of sodium-rich Zhundong coal in slow and rapid processes[J]. Energy Science & Engineering, 2019, 7(1): 98-107. |

| [37] | Fan H L, Li F H, Guo Q Q, et al. Effect of biomass ash on initial sintering and fusion characteristics of high melting coal ash[J]. Journal of the Energy Institute, 2021, 94: 129-138. |

| [38] | Bonafous L, Bessada C, Massiot D, et al. 29Si MAS NMR study of dicalcium silicate: the structural influence of sulfate and alumina stabilizers[J]. Journal of the American Ceramic Society, 1995, 78(10): 2603-2608. |

| [39] | Zhang X X, Dou H Y, Bai J, et al. Effect of phosphorus on viscosity-temperature behavior of high-sodium coal ash slag[J]. Fuel, 2023, 343: 127930. |

| [40] | Liu Y X, Zeng F G, Sun B L, et al. Structural characterizations of aluminosilicates in two types of fly ash samples from Shanxi Province, North China[J]. Minerals, 2019, 9(6): 358. |

| [41] | Ma F R, Wei B, Wang J J, et al. Influence mechanism of Na2O on the network structure depolymerization of ZD coal ash silicate under high temperature[J]. Journal of Non-Crystalline Solids, 2022, 584: 121507. |

| [1] | 马达夫, 张守玉, 何翔, 等. 改善准东煤锅炉受热面沾污的燃烧优化试验研究[J]. 煤炭科学技术, 2023, 51(8): 304-312. |

| Ma D F, Zhang S Y, He X, et al. Experimental study on combustion optimization to alleviate fouling on heating surface of a Zhundong coal boiler[J]. Coal Science and Technology, 2023, 51(8): 304-312. |

| [1] | 张圣美, 李明, 张莹, 易茜, 杨依婷, 刘雅莉. 乳化剂和温度对相变微胶囊性能的影响分析[J]. 化工学报, 2025, 76(S1): 444-452. |

| [2] | 毛建拥, 葛纪军, 徐盼, 毕荣山. HDI制备过程中副产物水解氯生成机理实验研究[J]. 化工学报, 2025, 76(S1): 384-392. |

| [3] | 段炼, 周星睿, 袁文君, 陈飞. 连续相速度脉动对微通道内聚合物液滴生成和形貌的影响规律[J]. 化工学报, 2025, 76(9): 4578-4585. |

| [4] | 李泽权, 蔡天宇, 刘家骏, 陈奇志, 肖沛文, 徐小飞, 赵双良. 木质素基絮凝剂的合成与应用[J]. 化工学报, 2025, 76(9): 4709-4722. |

| [5] | 徐佳琪, 张文君, 余燕萍, 苏宝根, 任其龙, 杨启炜. 热等离子体重整炼厂气制合成气过程数值模拟与实验研究[J]. 化工学报, 2025, 76(9): 4462-4473. |

| [6] | 钱慧慧, 王文婕, 陈文尧, 周兴贵, 张晶, 段学志. 聚丙烯定向转化制芳烃:金属-分子筛协同催化机制[J]. 化工学报, 2025, 76(9): 4838-4849. |

| [7] | 巢欣旖, 陈文尧, 张晶, 钱刚, 周兴贵, 段学志. 甲醇和乙酸甲酯一步法制丙酸甲酯催化剂的可控制备与性能调控[J]. 化工学报, 2025, 76(8): 4030-4041. |

| [8] | 周媚, 曾浩桀, 蒋火炎, 蒲婷, 曾星星, 刘宝玉. 二次晶化法改性合成MTW分子筛及其在苯和环己烯烷基化反应中的催化性能[J]. 化工学报, 2025, 76(8): 4071-4080. |

| [9] | 叶鑫煌, 薛嘉豪, 赵玉来. 可聚型Gemini表面活性剂的制备、表征及其稳定高内相乳液的研究[J]. 化工学报, 2025, 76(8): 4331-4340. |

| [10] | 张建伟, 刘玉成, 董鑫, 冯颖. 气泡扰动强化撞击流共沉淀法合成碳酸钙粉体[J]. 化工学报, 2025, 76(8): 4052-4060. |

| [11] | 戴元燊, 邵之江, 陈伟锋, 陈宁. 基于粒数衡算方程的三元前体结晶过程粒度分布动态预测方法[J]. 化工学报, 2025, 76(8): 4119-4128. |

| [12] | 张晓晨, 鲁中山, 郭腾, 桂恒, 宋红兵, 肖盟. 一株端羟基聚丁二烯降解菌的筛选及降解机理研究[J]. 化工学报, 2025, 76(8): 4205-4216. |

| [13] | 赵美, 甘雨欣, 赵绍磊, 杨令, 王亭杰. 硅橡胶用纳米二氧化硅表面有机修饰及补强机理研究进展[J]. 化工学报, 2025, 76(7): 3125-3136. |

| [14] | 乔亮, 李尚, 刘新亮, 王明, 张沛, 侯影飞. 三元共聚物稠油降黏剂的合成及分子模拟研究[J]. 化工学报, 2025, 76(7): 3686-3695. |

| [15] | 王子恒, 李文怀, 周嵬. 图形电极在固体氧化物燃料电池中的应用[J]. 化工学报, 2025, 76(7): 3153-3171. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号