化工学报 ›› 2025, Vol. 76 ›› Issue (8): 4119-4128.DOI: 10.11949/0438-1157.20250094

收稿日期:2025-01-22

修回日期:2025-04-07

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

陈宁

作者简介:戴元燊(1983—),男,博士研究生,yuanshen.dai@basf.com

基金资助:

Yuanshen DAI1,2( ), Zhijiang SHAO1, Weifeng CHEN3, Ning CHEN4(

), Zhijiang SHAO1, Weifeng CHEN3, Ning CHEN4( )

)

Received:2025-01-22

Revised:2025-04-07

Online:2025-08-25

Published:2025-09-17

Contact:

Ning CHEN

摘要:

在高性能三元正极材料的制备过程中,三元前体作为核心原料,其品质尤其是粒度分布对正极烧结产物的理化性能具有决定性影响。三元前体的制备涉及多种工艺参数,氨水浓度、反应温度、反应过程pH、搅拌速率和反应时间均对粒径产生显著影响,其中反应时间对三元前体的粒径影响最为显著。提出了一种基于粒数衡算方程的三元前体结晶过程粒度分布动态预测模型。首先,针对三元前体共沉淀过程的生长特性,建立了基于粒数衡算方程的粒径预测模型,分别考虑了符合ASL方程的生长速率和具有普适性的生长速率表达式。其次,运用配点法对粒数衡算方程进行空间和时间维度的离散化求解,并通过构建优化问题对模型中的未知参数进行辨识。最终,仿真结果表明,所提出的预测方法能够准确模拟不同初始粒径的三元前体在结晶过程中的粒径变化,实现对粒度分布的精确预测,为优化三元正极材料的烧结工艺提供了重要的理论依据和参考。

中图分类号:

戴元燊, 邵之江, 陈伟锋, 陈宁. 基于粒数衡算方程的三元前体结晶过程粒度分布动态预测方法[J]. 化工学报, 2025, 76(8): 4119-4128.

Yuanshen DAI, Zhijiang SHAO, Weifeng CHEN, Ning CHEN. Dynamic prediction method of particle size distribution in ternary precursor crystallization process based on population balance equations[J]. CIESC Journal, 2025, 76(8): 4119-4128.

| 批次 | KG | γ | b |

|---|---|---|---|

| 1st (r0=2.4 μm) | 0.00797388 | 1006.63 | 0.499995 |

| 2nd (r0=2.48 μm) | 0.00792696 | 1019.0 | 0.49995 |

| 3rd (r0=2.56 μm) | 0.0080318 | 991.77 | 0.50002 |

表1 基于ASL方程的参数估计结果

Table 1 Parameter estimation results based on ASL equation

| 批次 | KG | γ | b |

|---|---|---|---|

| 1st (r0=2.4 μm) | 0.00797388 | 1006.63 | 0.499995 |

| 2nd (r0=2.48 μm) | 0.00792696 | 1019.0 | 0.49995 |

| 3rd (r0=2.56 μm) | 0.0080318 | 991.77 | 0.50002 |

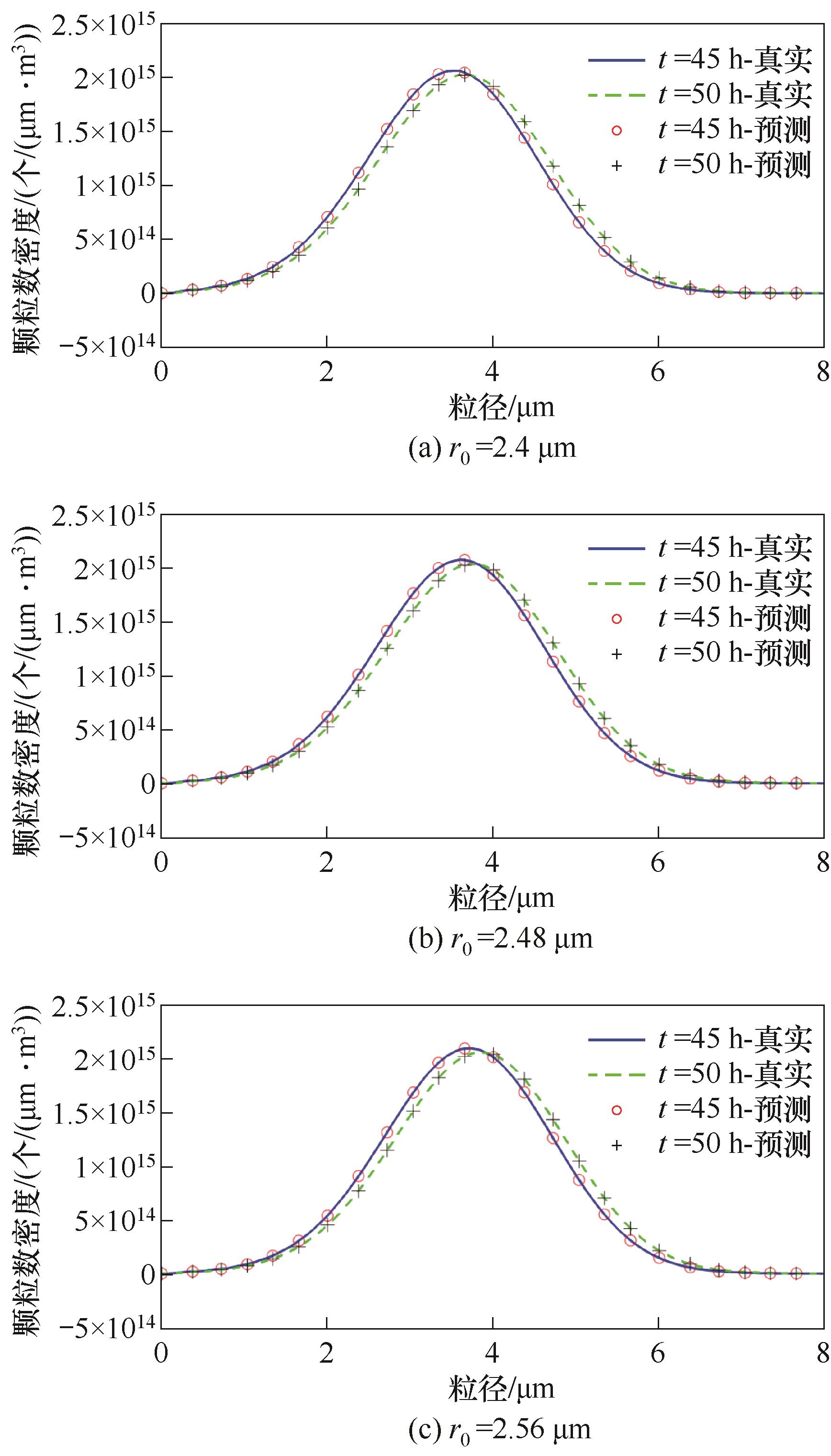

图2 生长速率满足ASL方程情况下,r0=2.4、2.48、2.56 μm时t=45 h和t=50 h对应的真实粒度分布曲线(蓝色实线—45 h、绿色虚线—50 h)和预测粒度分布曲线(红色圆圈—45 h、黑色加号—50 h)

Fig.2 Under the condition that the growth rate satisfies the ASL equation, the actual particle size distribution curves (blue solid lines—45 h, green dashed lines—50 h) and predicted particle size distribution curves (red circles—45 h, black plus sign—50 h) corresponding to t=45 h and t=50 h for r0=2.4,2.48,2.56 μm

| 批次 | 相对误差/% | ||

|---|---|---|---|

| KG | γ | b | |

| 1st (r0=2.4 μm) | 0.327 | 0.663 | 0.001 |

| 2nd (r0=2.48 μm) | 0.913 | 1.907 | 0.008 |

| 3rd (r0=2.56 μm) | 0.399 | 0.822 | 0.005 |

表2 参数估计相对误差

Table 2 Relative error of parameter estimation

| 批次 | 相对误差/% | ||

|---|---|---|---|

| KG | γ | b | |

| 1st (r0=2.4 μm) | 0.327 | 0.663 | 0.001 |

| 2nd (r0=2.48 μm) | 0.913 | 1.907 | 0.008 |

| 3rd (r0=2.56 μm) | 0.399 | 0.822 | 0.005 |

| 批次 | rd | |

|---|---|---|

| t=45 h | t=50 h | |

| 1st (r0=2.4 μm) | 5.10×10-6 | 5.62×10-6 |

| 2nd (r0=2.48 μm) | 8.89×10-6 | 9.43×10-6 |

| 3rd (r0=2.56 μm) | 4.07×10-6 | 4.45×10-6 |

表3 生长速率满足ASL方程时t=45和t=50 h对应的rd值

Table 3 The values of rd corresponding to t=45 h and t=50 h when the growth rate satisfies the ASL equation

| 批次 | rd | |

|---|---|---|

| t=45 h | t=50 h | |

| 1st (r0=2.4 μm) | 5.10×10-6 | 5.62×10-6 |

| 2nd (r0=2.48 μm) | 8.89×10-6 | 9.43×10-6 |

| 3rd (r0=2.56 μm) | 4.07×10-6 | 4.45×10-6 |

| 参数 | 1st (r0=2.4 μm) | 2nd (r0=2.48 μm) | 3rd (r0=2.56 μm) |

|---|---|---|---|

| g1 | 0.0251262 | 0.0251169 | 0.0251549 |

| g2 | 0.0557397 | 0.0556703 | 0.0556456 |

| g3 | 0.0861399 | 0.0861498 | 0.0861704 |

| g4 | 0.115193 | 0.115193 | 0.115192 |

| g5 | 0.142446 | 0.142449 | 0.142449 |

| g6 | 0.167488 | 0.167494 | 0.167497 |

| g7 | 0.189929 | 0.189931 | 0.189943 |

| g8 | 0.209357 | 0.209393 | 0.209465 |

| g9 | 0.228366 | 0.22766 | 0.227164 |

| g10 | 0.233492 | 0.233729 | 0.234133 |

| g11 | 0.237959 | 0.240243 | 0.242872 |

| g12 | 0.301832 | 0.297165 | 0.295236 |

表4 基于近似生长速率方程的参数估计结果

Table 4 Parameter estimation results based on approximate growth rate equation

| 参数 | 1st (r0=2.4 μm) | 2nd (r0=2.48 μm) | 3rd (r0=2.56 μm) |

|---|---|---|---|

| g1 | 0.0251262 | 0.0251169 | 0.0251549 |

| g2 | 0.0557397 | 0.0556703 | 0.0556456 |

| g3 | 0.0861399 | 0.0861498 | 0.0861704 |

| g4 | 0.115193 | 0.115193 | 0.115192 |

| g5 | 0.142446 | 0.142449 | 0.142449 |

| g6 | 0.167488 | 0.167494 | 0.167497 |

| g7 | 0.189929 | 0.189931 | 0.189943 |

| g8 | 0.209357 | 0.209393 | 0.209465 |

| g9 | 0.228366 | 0.22766 | 0.227164 |

| g10 | 0.233492 | 0.233729 | 0.234133 |

| g11 | 0.237959 | 0.240243 | 0.242872 |

| g12 | 0.301832 | 0.297165 | 0.295236 |

图3 生长速率具有普适情况下,r0=2.4、2.48、2.56 μm时t=45 h和t=50 h对应的真实粒度分布曲线(蓝色实线—45 h、绿色虚线—50 h)和预测粒度分布曲线(红色圆圈—45 h、黑色加号—50 h)

Fig.3 Under the condition that the growth rate is universal, the actual particle size distribution curves (blue solid lines—45 h, green dashed lines—50 h) and predicted particle size distribution curves (red circles—45 h, black plus sign—50 h) corresponding to t=45 h and t=50 h for r0=2.4,2.48,2.56

| 批次 | rd | |

|---|---|---|

| t=45 h | t=50 h | |

| 1st (r0=2.4 μm) | 3.20×10-4 | 3.69×10-4 |

| 2nd (r0=2.48 μm) | 2.66×10-4 | 3.15×10-4 |

| 3rd (r0=2.56 μm) | 2.14×10-4 | 2.62×10-4 |

表5 生长速率模型具有普适性的t=45 h和t=50 h对应的rd值

Table 5 The values of rd corresponding to t=45 h and t=50 h when the growth rate model has universality

| 批次 | rd | |

|---|---|---|

| t=45 h | t=50 h | |

| 1st (r0=2.4 μm) | 3.20×10-4 | 3.69×10-4 |

| 2nd (r0=2.48 μm) | 2.66×10-4 | 3.15×10-4 |

| 3rd (r0=2.56 μm) | 2.14×10-4 | 2.62×10-4 |

| [1] | Entwistle T, Sanchez-Perez E, Murray G J, et al. Co-precipitation synthesis of nickel-rich cathodes for Li-ion batteries[J]. Energy Reports, 2022, 8: 67-73. |

| [2] | Hua W B, Liu W Y, Chen M Z, et al. Unravelling the growth mechanism of hierarchically structured Ni1/3Co1/3Mn1/3(OH)2 and their application as precursors for high-power cathode materials[J]. Electrochimica Acta, 2017, 232: 123-131. |

| [3] | Shiea M, Querio A, Buffo A, et al. CFD-PBE modelling of continuous Ni-Mn-Co hydroxide co-precipitation for Li-ion batteries[J]. Chemical Engineering Research and Design, 2022, 177: 461-472. |

| [4] | Feng Z G, Barai P, Gim J, et al. In situ monitoring of the growth of nickel, manganese, and cobalt hydroxide precursors during co-precipitation synthesis of Li-ion cathode materials[J]. Journal of the Electrochemical Society, 2018, 165(13): A3077-A3083. |

| [5] | Lee S L, O'Connor T F, Yang X C, et al. Modernizing pharmaceutical manufacturing: from batch to continuous production[J]. Journal of Pharmaceutical Innovation, 2015, 10(3): 191-199. |

| [6] | Orehek J, Teslić D, Likozar B. Continuous crystallization processes in pharmaceutical manufacturing: a review[J]. Organic Process Research & Development, 2021, 25(1): 16-42. |

| [7] | Wang T, Lu H J, Wang J K, et al. Recent progress of continuous crystallization[J]. Journal of Industrial and Engineering Chemistry, 2017, 54: 14-29. |

| [8] | Schmuch R, Siozios V, Winter M, et al. High-Energy Lithium-Ion Batteries[Z/OL]. [2024-11-14].. |

| [9] | Myerson A S, Erdemir D, Lee A Y. Handbook of Industrial Crystallization[M]. Cambridge: Cambridge University Press, 2019. |

| [10] | Deschamps A, Hutchinson C R. Precipitation kinetics in metallic alloys: experiments and modeling[J]. Acta Materialia, 2021, 220: 117338. |

| [11] | Tavenner J P, Mendelev M I, Lawson J W. Molecular dynamics based kinetic Monte Carlo simulation for accelerated diffusion[J]. Computational Materials Science, 2023, 218: 111929. |

| [12] | Nellis C, Hin C. Kinetic Monte Carlo modeling of homogeneous precipitation of Y-O and Y-Ti-O oxides in bulk alpha iron[J]. Journal of Materials Science, 2022, 57(4): 2710-2730. |

| [13] | 贾丽霞, 王东杰, 王瑾, 等. Fe-Cr-W合金内富Cr团簇形核析出动力学的原子动力学蒙特卡罗模拟[J]. 原子能科学技术, 2023, 57(7): 1385-1396. |

| Jia L X, Wang D J, Wang J, et al. Atomic kinetic Monte Carlo simulation of nucleation kinetics of Cr-rich clusters in Fe-Cr-W alloy[J]. Atomic Energy Science and Technology, 2023, 57(7): 1385-1396. | |

| [14] | Wang Y, Yin J, Liu X B, et al. Precipitation kinetics in binary Fe-Cu and ternary Fe-Cu-Ni alloys via kMC method[J]. Progress in Natural Science: Materials International, 2017, 27(4): 460-466. |

| [15] | Shen Z Q, Gao J, Lv S S, et al. OKMC simulation of vacancy-enhanced Cu solute segregation affected by temperature/irradiation in the Fe-Cu system[J]. Nuclear Science and Techniques, 2022, 33(11): 149. |

| [16] | Miyoshi H, Kimizuka H, Ishii A, et al. Temperature-dependent nucleation kinetics of Guinier-Preston zones in Al-Cu alloys: an atomistic kinetic Monte Carlo and classical nucleation theory approach[J]. Acta Materialia, 2019, 179: 262-272. |

| [17] | Piotrowski K, Piotrowski J. Monte Carlo modelling of continuous adiabatic MSMPR crystallizer[J]. Chemical Engineering and Processing: Process Intensification, 2005, 44(5): 517-528. |

| [18] | Hutchinson C R, Nie J F, Gorsse S. Modeling the precipitation processes and strengthening mechanisms in a Mg-Al-(Zn) AZ91 alloy[J]. Metallurgical and Materials Transactions A, 2005, 36(8): 2093-2105. |

| [19] | Perez M, Dumont M, Acevedo-Reyes D. Implementation of classical nucleation and growth theories for precipitation[J]. Acta Materialia, 2008, 56(9): 2119-2132. |

| [20] | Balan A, Perez M, Chaise T, et al. Precipitation of γ" in Inconel 718 alloy from microstructure to mechanical properties[J]. Materialia, 2021, 20: 101187. |

| [21] | Assadiki A, Esin V A, Martinez R, et al. Modelling precipitation hardening in an A356+0.5 wt%Cu cast aluminum alloy[J]. Materials Science and Engineering: A, 2021, 819: 141450. |

| [22] | Xia X Y, Sanaty-Zadeh A, Zhang C, et al. Experimental investigation and simulation of precipitation evolution in Mg-3Nd-0.2Zn alloy[J]. Calphad, 2018, 60: 58-67. |

| [23] | Miao J S, Zhang C, Klarner A D, et al. Characterization and modeling of concurrent precipitation in Mg-Al-Sn alloys using an improved Kampmann-Wagner numerical (KWN) model[J]. Materialia, 2022, 21: 101348. |

| [24] | Bo G W, Wang Y L, Liu M C, et al. Experimental and modeling investigations of the non-isothermal and isothermal precipitations in an Al-Cu-Mg-Zr alloy with various pre-precipitation microstructures[J]. Materials & Design, 2022, 217: 110640. |

| [25] | Herrnring J, Sundman B, Staron P, et al. Modeling precipitation kinetics for multi-phase and multi-component systems using particle size distributions via a moving grid technique[J]. Acta Materialia, 2021, 215: 117053. |

| [26] | Li Y, Zheng X Y, Liu Y L, et al. Design of ultrahigh strength Al-Zn-Mg-Cu alloys through a hybrid approach of high-throughput precipitation simulation and decisive experiment[J]. Journal of Materials Science & Technology, 2024, 195: 234-247. |

| [27] | Sitapure N, Kwon J S. CrystalGPT: enhancing system-to-system transferability in crystallization prediction and control using time-series-transformers[J]. Computers & Chemical Engineering, 2023, 177: 108339. |

| [28] | Kokkila N. Data driven modelling of crystalliser particle size distribution[D]. Finland: University of Oulu, 2023. |

| [29] | Ramkrishna D. Population Balances: Theory and Applications to Particulate Systems in Engineering[M]. San Diego, CA: Academic Press, 2000. |

| [30] | Cao X M, Peng J P, Dong W X, et al. Theoretical study on the utilization of fluorine-containing wastewater in the aluminum industry: crystallization characteristics and particle size control of cryolite prepared by carbonization[J]. Journal of Environmental Chemical Engineering, 2024, 12(5): 113572. |

| [31] | Para M L, Alidoost M, Shiea M, et al. A modelling and experimental study on the co-precipitation of Ni0.8Mn0.1Co0.1(OH)2 as precursor for battery cathodes[J]. Chemical Engineering Science, 2022, 254: 117634. |

| [32] | Cheng J C, Yang C, Mao Z S. CFD-PBE simulation of premixed continuous precipitation incorporating nucleation, growth and aggregation in a stirred tank with multi-class method[J]. Chemical Engineering Science, 2012, 68(1): 469-480. |

| [33] | Bałdyga J, Makowski Ł, Orciuch W. Double-feed semibatch precipitation effects of mixing[J]. Chemical Engineering Research and Design, 2007, 85(5): 745-752. |

| [34] | 连斌, 龙妍, 徐啟蕾, 等. 间歇冷却结晶过程模型参数及操作敏感性分析[J]. 化工学报, 2024, 75(12): 4587-4595. |

| Lian B, Long Y, Xu Q L, et al. Sensitivity analysis of model parameters and process operation for batch cooling crystallization process[J]. CIESC Journal, 2024, 75(12): 4587-4595. | |

| [35] | Wu Z W, Zhou Y, Zeng J B, et al. Investigating the effect of pH on the growth of coprecipitated Ni0.8Co0.1Mn0.1(OH)2 agglomerates as precursors of cathode materials for Li-ion batteries[J]. Ceramics International, 2023, 49(10): 15851-15864. |

| [36] | Huang B, Cheng L, Li X Z, et al. Layered cathode materials: precursors, synthesis, microstructure, electrochemical properties, and battery performance[J]. Small, 2022, 18(20): 2107697. |

| [37] | 王伟东, 杨凯, 关豪元, 等. 三元材料前驱体: 产线设计及生产应用[M]. 北京: 化学工业出版社, 2021. |

| Wang W D, Yang K, Guan H Y. Precursors for Lithium-ion Battery Ternary Cathode Materials[M]. Beijing: Chemical Industry Press, 2021. | |

| [38] | Achermann R, Wiedmeyer V, Hosseinalipour M S, et al. Model-based design of pressure-driven product removal from stirred suspensions[J]. Chemical Engineering Research and Design, 2021, 174: 57-70. |

| [39] | Zhang W D, Przybycien T, Schmölder J, et al. Solving crystallization/precipitation population balance models in CADET(part Ⅰ): Nucleation growth and growth rate dispersion in batch and continuous modes on nonuniform grids[J]. Computers & Chemical Engineering, 2024, 183: 108612. |

| [40] | Abegg C F, Stevens J D, Larson M A. Crystal size distributions in continuous crystallizers when growth rate is size dependent[J]. AIChE Journal, 1968, 14(1): 118-122. |

| [41] | Garside J, Jančić S J. Prediction and measurement of crystal size distributions for size-dependent growth[J]. Chemical Engineering Science, 1978, 33(12): 1623-1630. |

| [42] | 刘勇, 王静康. 间歇结晶过程中几种可能的粒度分布[J]. 化工学报, 2005, 56(2): 276-280. |

| Liu Y, Wang J K. Several possible crystal size distributions for batch crystallization processes[J]. CIESC Journal, 2005, 56(2): 276-280. | |

| [43] | 李川, 洪振取, 单宝明, 等. 求解多维粒数衡算方程的高阶紧致差分方法[J]. 化工学报, 2024, 75(12): 4513-4522. |

| Li C, Hong Z Q, Shan B M, et al. High-order compact difference method for solving the multidimensional population balance equation[J]. CIESC Journal, 2024, 75(12): 4513-4522. | |

| [44] | Jie H, Zhu G Z, Hong W R. Direct approaches for PDE-constrained dynamic optimization based on space-time orthogonal collocation on finite elements[J]. Journal of Process Control, 2023, 124: 187-198. |

| [45] | Gautschi W. Orthogonal Polynomials: Computation and Approximation[M]. Oxford: Oxford University Press, 2004. |

| [1] | 张建伟, 刘玉成, 董鑫, 冯颖. 气泡扰动强化撞击流共沉淀法合成碳酸钙粉体[J]. 化工学报, 2025, 76(8): 4052-4060. |

| [2] | 梁碧麟, 余倩, 贾思琦, 李芳, 李其明. Ni-MOF-74金属有机框架膜的结构调变及气体分离性能研究[J]. 化工学报, 2025, 76(6): 2714-2721. |

| [3] | 胡家玮, 王聪, 刘美婧. 一种抑制隧道排水管道中结晶体形成的双层阻垢疏水涂层[J]. 化工学报, 2025, 76(6): 3053-3072. |

| [4] | 刘晗, 崔家馨, 殷梦凡, 郑涛, 张睿, 孟祥海, 刘植昌, 刘海燕, 徐春明. CuAlCl4-二甲苯络合物晶体结构及二元固液相平衡测定[J]. 化工学报, 2025, 76(5): 2241-2250. |

| [5] | 蔡本安, 张建新, 龙城君, 杜乔琛, 车勋建, 张义迎, 蔡伟华. 喷雾闪蒸制备微纳米颗粒[J]. 化工学报, 2025, 76(3): 1334-1345. |

| [6] | 党法璐, 孙志国, 高照, 王刚, 陈政宇, 张霖宙, 连竞存, 刘美佳, 张忠东, 刘超伟. 原油一步法催化裂解制低碳烯烃:实验和反应路径研究[J]. 化工学报, 2025, 76(2): 667-685. |

| [7] | 彭子林, 周蕾, 邓庆航, 叶光华, 周兴贵. 包含偏硅酸影响的3D NAND磷酸湿法刻蚀动力学[J]. 化工学报, 2025, 76(2): 645-653. |

| [8] | 董举, 余留洋, 贾晟哲, 史连军, 王诗瀚, 胡国涛, 汤伟伟, 王静康, 龚俊波. 电子级磷酸的结晶精制技术发展现状与研究进展[J]. 化工学报, 2025, 76(2): 438-453. |

| [9] | 黄娜, 蒋云龙, 王东涵, 吴明婷, 蒋雪莉, 钟豫. 通道振动频率对超临界正癸烷裂解流动换热影响的数值研究[J]. 化工学报, 2025, 76(1): 173-183. |

| [10] | 黄俊豪, 庞克亮, 孙方远, 刘福军, 谷致远, 韩龙, 段衍泉, 冯妍卉. 干熄炉料钟结构对焦炭布料粒径均匀度影响的模拟研究[J]. 化工学报, 2024, 75(S1): 158-169. |

| [11] | 齐琪, 郭利平, 石李明, 郑映, 潘鹏举. 山梨醇类成核剂改性聚丙烯及其共聚物的结晶行为与性能[J]. 化工学报, 2024, 75(7): 2688-2699. |

| [12] | 师毓辉, 邢继远, 姜雪晗, 叶爽, 黄伟光. 基于PBM的离心式叶轮内气泡破碎合并数值模拟[J]. 化工学报, 2024, 75(5): 1816-1829. |

| [13] | 李云璇, 刘新悦, 陈熙, 刘文, 周明月, 蓝兴英. 基于固液氧化还原靶向反应的能量存储技术:材料、器件及动力学[J]. 化工学报, 2024, 75(4): 1222-1240. |

| [14] | 李昂, 赵振宇, 李洪, 高鑫. 微波诱导高分散Pd/FeP催化剂构筑及其电催化性能研究[J]. 化工学报, 2024, 75(4): 1594-1606. |

| [15] | 刘静, 杨文博, 吕英迪, 陶胜洋. 喷雾-反溶剂结晶法制备掺杂铝粉的复合微球[J]. 化工学报, 2024, 75(4): 1724-1734. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号