• •

陈毓秋1( ), 潘婉莹2, 闫佳淇2, 周嘉萍2, 雷杨2(

), 潘婉莹2, 闫佳淇2, 周嘉萍2, 雷杨2( ), 张香平1,3(

), 张香平1,3( )

)

收稿日期:2025-09-02

修回日期:2025-10-06

出版日期:2025-12-01

通讯作者:

雷杨,张香平

作者简介:陈毓秋(1989—),男,博士,特聘教授,yuqch@cup.edu.cn

基金资助:

Yuqiu CHEN1( ), Wanying PAN2, Jiaqi YAN2, Jiaping ZHOU2, Xiangping ZHANG2(

), Wanying PAN2, Jiaqi YAN2, Jiaping ZHOU2, Xiangping ZHANG2( ), Yang LEI1,3(

), Yang LEI1,3( )

)

Received:2025-09-02

Revised:2025-10-06

Online:2025-12-01

Contact:

Xiangping ZHANG, Yang LEI

摘要:

在石油化工中,分离过程是关键过程环节,且能耗占比大,其技术复杂度与效率直接决定了产品质量、能耗水平及环保性能。诸多难分离体系如芳烃与非芳烃、烯烃与烷烃等,因组分性质相近、易形成共沸物、近沸物等特性,给传统分离技术带来严峻挑战。首先系统梳理和分析了石油化工难分离体系类型及特征,并详细介绍了精馏、萃取、结晶等传统分离技术方法的应用及其局限性,探讨了离子液体萃取精馏、膜分离及吸附等新型分离技术带来的分离流程创新和过程瓶颈。并提出了面向过程低碳化绿色化要求的分离技术未来发展方向,以实现石油化工难分离体系的高效、节能、环保分离,推动石油化工行业低碳绿色可持续发展。

中图分类号:

陈毓秋, 潘婉莹, 闫佳淇, 周嘉萍, 雷杨, 张香平. 面向石油化工难分离体系的分离技术研究进展[J]. 化工学报, DOI: 10.11949/0438-1157.20250981.

Yuqiu CHEN, Wanying PAN, Jiaqi YAN, Jiaping ZHOU, Xiangping ZHANG, Yang LEI. Advances in separation technologies for difficult-to-separate systems in petrochemical industry[J]. CIESC Journal, DOI: 10.11949/0438-1157.20250981.

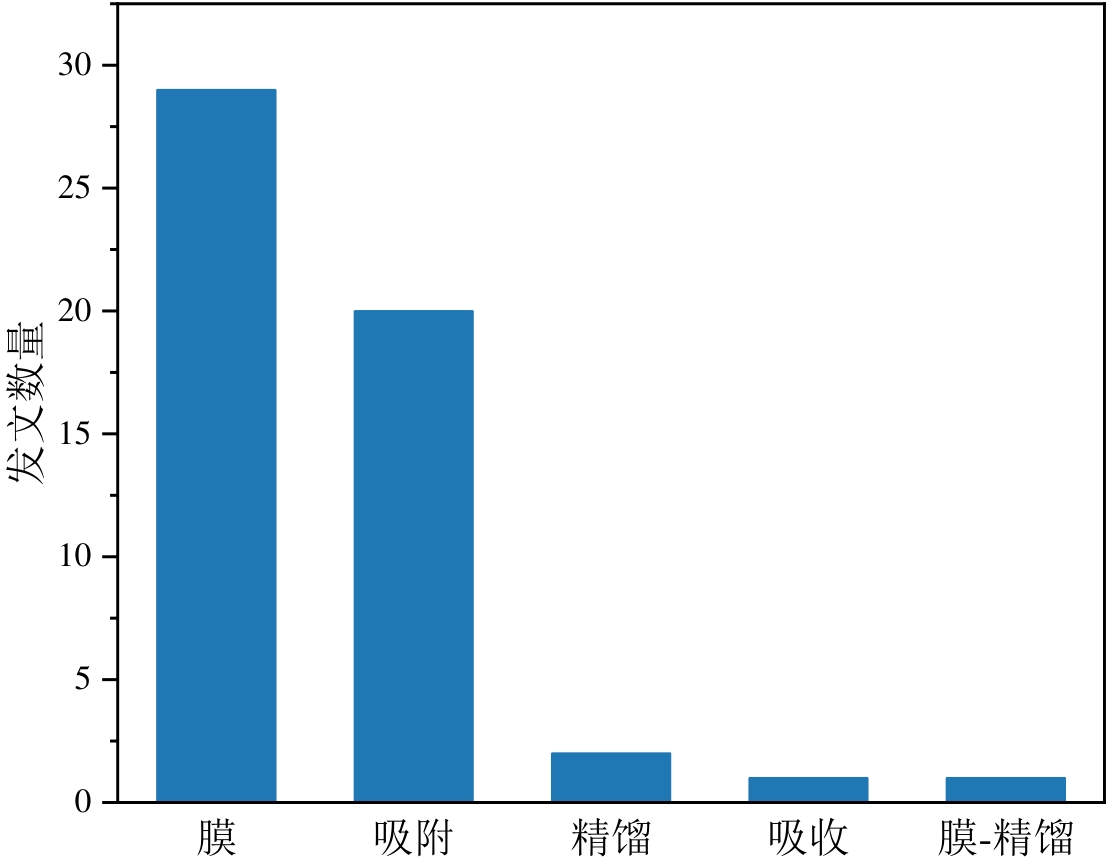

图2 基于Web of Science(WOS)数据库的丙烯/丙烷分离方法近五年发文数量统计注:(注:数据检索范围为"last five year",检索关键词为:"propylene/propane" and "separation technology",文献类型限定为 "Article")

Fig.2 Statistical data of the number of published papers on separation methods of propylene/propane in the Web of Science (WOS) database in the past five years(Note: The data retrieval range is "last five years", the search keywords are "propylene/propane" and "separation technology", and the document type is limited to "Article".)

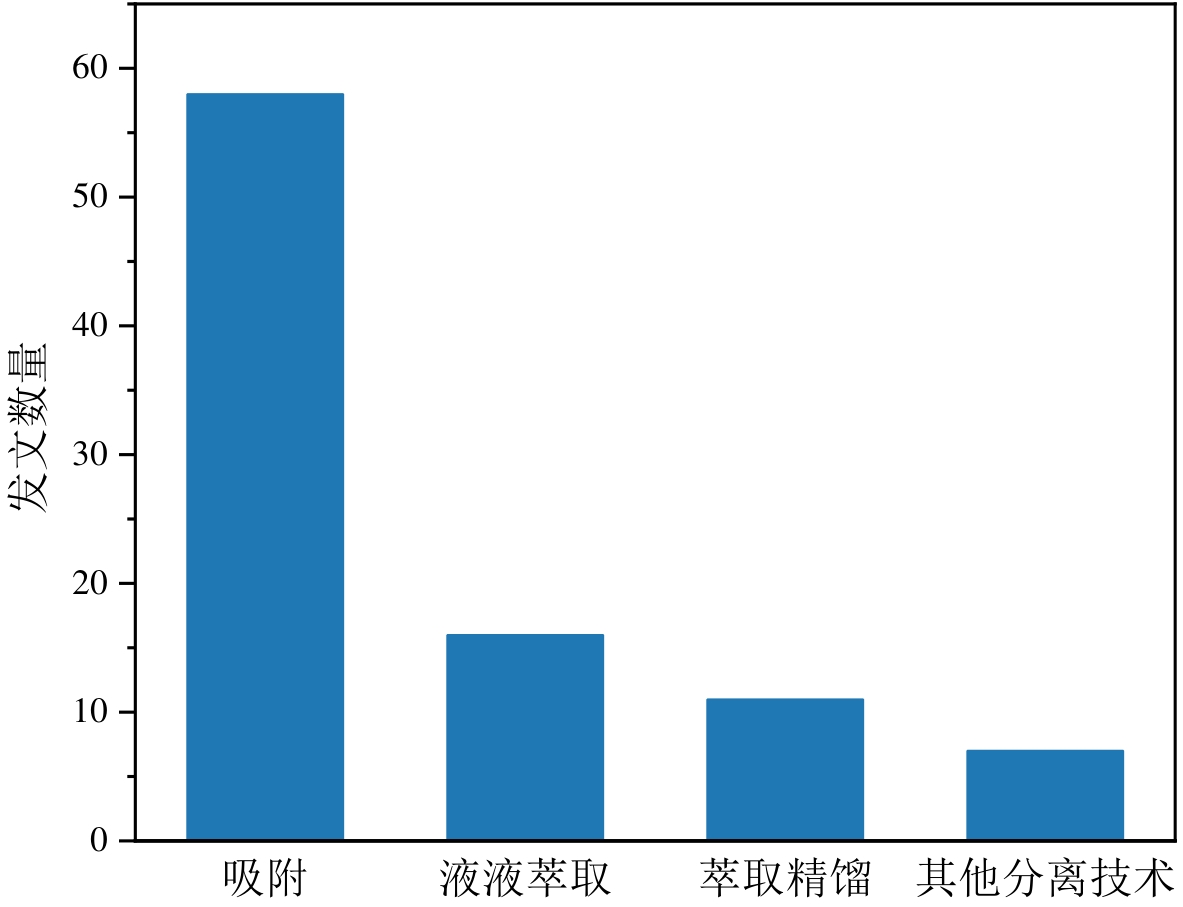

图3 基于Web of Science(WOS)数据库的苯/环己烷分离方法近五年发文数量统计注:(注:数据检索范围为"last five year",检索关键词为:"benzene cyclohexane separation",文献类型限定为 "Article")

Fig.3 Statistics of the number of published papers on benzene/cyclohexane separation methods in the past five years based on the Web of Science (WOS) database(Note: The data retrieval range is "last five years", the search keywords are "benzene cyclohexane separation", and the document type is limited to "Article")

图5 基于分子机理的混合萃取剂分离环己烷-异丙醇-水体系[44]

Fig.5 Separation of the cyclohexane-iso-propanol-water system using a mixed extractant based on molecular mechanism [44]

| 分离技术 | 能耗 | 环境影响 | 优点 | 缺点 |

|---|---|---|---|---|

| 传统精馏 | 高 | 大 | 技术成熟,操作简单 | 投资高,能耗高 |

| 萃取精馏 | 中 | 中 | 操作灵活,能耗较低 | 溶剂回收成本高 |

| 共沸精馏 | 中 | 中 | 投资较少,能耗较低 | 溶剂回收成本高 |

| 液液萃取 | 低 | 中 | 操作简便,选择性强 | 溶剂回收成本高 |

| 结晶分离 | 低 | 低 | 工艺简单,能耗低 | 连续工业化生产难 |

表1 不同传统分离技术的对比

Table 1 Comparison of Different Traditional Separation Techniques

| 分离技术 | 能耗 | 环境影响 | 优点 | 缺点 |

|---|---|---|---|---|

| 传统精馏 | 高 | 大 | 技术成熟,操作简单 | 投资高,能耗高 |

| 萃取精馏 | 中 | 中 | 操作灵活,能耗较低 | 溶剂回收成本高 |

| 共沸精馏 | 中 | 中 | 投资较少,能耗较低 | 溶剂回收成本高 |

| 液液萃取 | 低 | 中 | 操作简便,选择性强 | 溶剂回收成本高 |

| 结晶分离 | 低 | 低 | 工艺简单,能耗低 | 连续工业化生产难 |

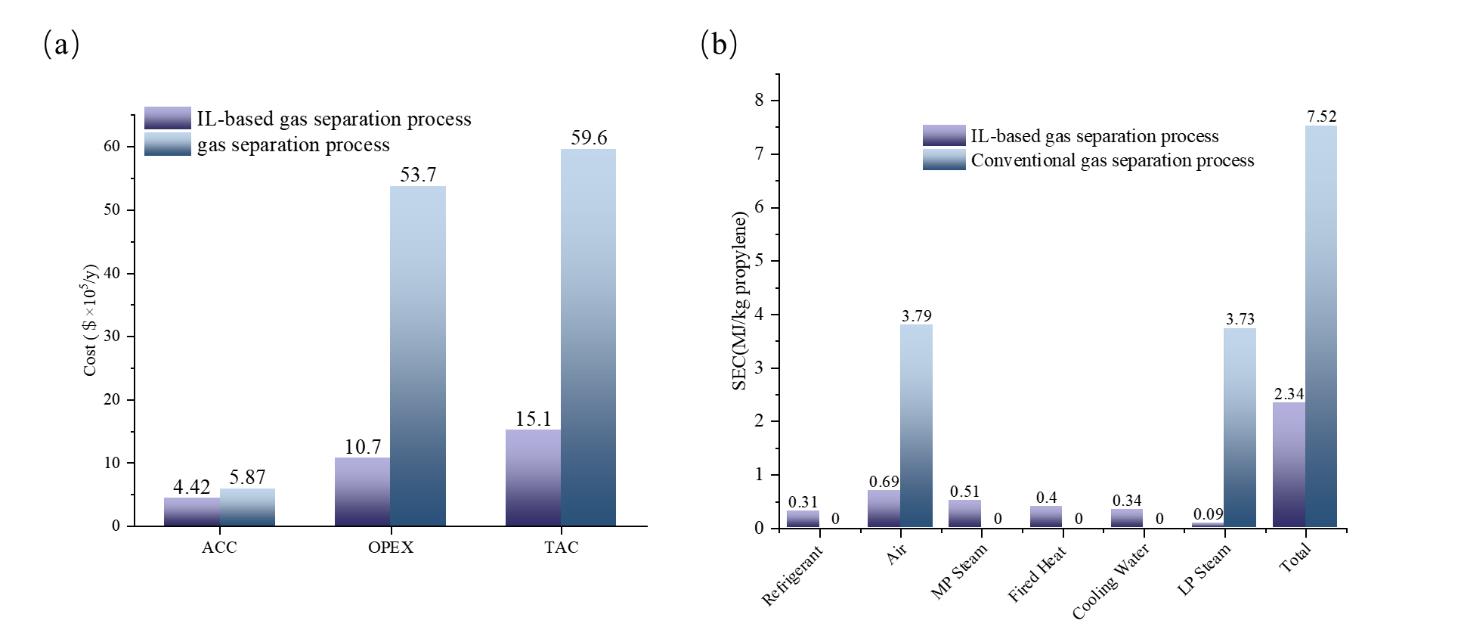

图8 离子液体萃取精馏分离和传统分离丙烯/丙烷工艺的能源和成本比较[73]

Fig.8 Comparison of energy and cost between ionic liquid extractive distillation separation and traditional propylene/propane separation processes[73]

图9 离子液体萃取精馏分离和传统分离乙苯/苯乙烯工艺的能源和碳排放比较[70]

Fig.9 Comparison of energy and carbon emissions between ionic liquid extractive distillation separation and traditional ethylbenzene/styrene separation processes [70]

| 分离技术 | 能耗 | 环境影响 | 优点 | 缺点 |

|---|---|---|---|---|

| 离子液体 | 中 | 中 | 分离效果好 | 成本高,工业化难 |

| 膜分离 | 低 | 小 | 分离效率高,能耗低 | 成本高,适用范围窄 |

| 吸附分离 | 低 | 小 | 选择性高、低能耗 | 吸附剂再生成本高 |

| 超临界萃取 | 高 | 小 | 绿色环保,分离效率高 | 成本高,操作严格 |

表2 不同新型分离技术的对比

Table 2 Comparison of Different New Separation Technologies

| 分离技术 | 能耗 | 环境影响 | 优点 | 缺点 |

|---|---|---|---|---|

| 离子液体 | 中 | 中 | 分离效果好 | 成本高,工业化难 |

| 膜分离 | 低 | 小 | 分离效率高,能耗低 | 成本高,适用范围窄 |

| 吸附分离 | 低 | 小 | 选择性高、低能耗 | 吸附剂再生成本高 |

| 超临界萃取 | 高 | 小 | 绿色环保,分离效率高 | 成本高,操作严格 |

| [1] | Corma A, Corresa E, Mathieu Y, et al. Crude oil to chemicals: light olefins from crude oil[J]. Catalysis Science & Technology, 2017, 7(1): 12-46. |

| [2] | Sadrameli S M. Thermal/catalytic cracking of liquid hydrocarbons for the production of olefins: a state-of-the-art review II: Catalytic cracking review[J]. Fuel, 2016, 173: 285-297. |

| [3] | Griffiths S, Sovacool B K, Kim J, et al. Decarbonizing the oil refining industry: a systematic review of sociotechnical systems, technological innovations, and policy options[J]. Energy Research & Social Science, 2022, 89: 102542. |

| [4] | 李明丰, 李延军, 吴昊. 中国石化企业低碳发展路径探索与实践[J]. 石油学报(石油加工), 2025, 41(5): 1161-1168. |

| Li M F, Li Y J, Wu H. Exploration and practice of low-carbon development pathway of China's petrochemical enterprises[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2025, 41(5): 1161-1168. | |

| [5] | 罗伊雯, 赵亮, 张宇豪, 等. 轻烃分离材料和机理的研究进展[J]. 化工进展, 2025, 44(5): 2938-2954. |

| Luo Y W, Zhao L, Zhang Y H, et al. Progress on separation materials and mechanisms of light hydrocarbons[J]. Chemical Industry and Engineering Progress, 2025, 44(5): 2938-2954. | |

| [6] | Chen Y W, Tu S, Fu P, et al. A cobalt-based metal–organic framework for efficient separation of propene from propane via electrostatic effect[J]. AIChE Journal, 2022, 68(8): e17730. |

| [7] | 蔡艾梓, 董海峰, 任梦雨, 等. 离子液体强化丙烯/丙烷分离的研究进展[J]. 科学通报, 2025, 70(26): 4488-4500. |

| Cai A Z, Dong H F, Ren M Y, et al. Reviews on propylene/propane separation by using ionic liquids materials[J]. Chinese Science Bulletin, 2025, 70(26): 4488-4500. | |

| [8] | Wang Y X, Peh S B, Zhao D. Alternatives to cryogenic distillation: advanced porous materials in adsorptive light olefin/paraffin separations[J]. Small, 2019, 15(25): 1900058. |

| [9] | Xie Y, Shi Y S, Cedeño Morales E M, et al. Optimal binding affinity for sieving separation of propylene from propane in an oxyfluoride anion-based metal–organic framework[J]. Journal of the American Chemical Society, 2023, 145(4): 2386-2394. |

| [10] | Yang L F, Qian S H, Wang X B, et al. Energy-efficient separation alternatives: metal–organic frameworks and membranes for hydrocarbon separation[J]. Chemical Society Reviews, 2020, 49(15): 5359-5406. |

| [11] | 朱炜, 李庆, 豆琳琳, 等. 正己烷+1-丁基-3-甲基咪唑硫氰酸盐的分子动力学[J]. 纺织高校基础科学学报, 2020, 33(2): 93-99. |

| Zhu W, Li Q, Dou L L, et al. Molecular dynamics of n-hexane+1-butyl-3-methylimidazolium thiocyanate binary system[J]. Basic Sciences Journal of Textile Universities, 2020, 33(2): 93-99. | |

| [12] | 莫凯, 问菲, 金花, 等. ZIF-8膜分离丙烯/丙烷的研究进展[J]. 膜科学与技术, 2020, 40(2): 136-145. |

| Mo K, Wen F, Jin H, et al. Recent advances in ZIF-8 membrane for efficient separation of propylene/propane[J]. Membrane Science and Technology, 2020, 40(2): 136-145. | |

| [13] | 张延鹏, 张胜中, 王红涛, 等. 丙烯/丙烷吸附分离材料研究进展[J]. 精细化工, 2020, 37(7): 1327-1333. |

| Zhang Y P, Zhang S Z, Wang H T, et al. Research process of adsorption-separation materials for propylene/propane separation[J]. Fine Chemicals, 2020, 37(7): 1327-1333. | |

| [14] | Cong S Z, Feng X Q, Guo L L, et al. Rational design of mixed matrix membranes modulated by trisilver complex for efficient propylene/propane separation[J]. Advanced Science, 2023, 10(10): 2206858. |

| [15] | Yang L F, Cui X L, Yang Q W, et al. A single-molecule propyne trap: highly efficient removal of propyne from propylene with anion-pillared ultramicroporous materials[J]. Advanced Materials, 2018, 30(10): 1705374. |

| [16] | Li L B, Wen H M, He C H, et al. A metal–organic framework with suitable pore size and specific functional sites for the removal of trace propyne from propylene[J]. Angewandte Chemie International Edition, 2018, 57(46): 15183-15188. |

| [17] | Bloch E D, Queen W L, Krishna R, et al. Hydrocarbon separations in a metal-organic framework with open iron(II) coordination sites[J]. Science, 2012, 335(6076): 1606-1610. |

| [18] | Li L B, Lin R B, Krishna R, et al. Flexible–robust metal–organic framework for efficient removal of propyne from propylene[J]. Journal of the American Chemical Society, 2017, 139(23): 7733-7736. |

| [19] | Wang J, Zhang Y, Zhang P X, et al. Optimizing pore space for flexible-robust metal–organic framework to boost trace acetylene removal[J]. Journal of the American Chemical Society, 2020, 142(21): 9744-9751. |

| [20] | Liu J X, Zhu S J, Zhang L, et al. Study on characterization and coke compositions of deactivated 5 A molecular sieve for adsorption separation of industrial naphtha[J]. ChemistrySelect, 2020, 5(42): 12844-12852. |

| [21] | Peralta D, Chaplais G, Simon-Masseron A, et al. Separation of C6 paraffins using zeolitic imidazolate frameworks: comparison with zeolite 5A[J]. Industrial & Engineering Chemistry Research, 2012, 51(12): 4692-4702. |

| [22] | 王宇轩, 花敬贤, 潘宜昌, 等. 两步干凝胶转化法制备UiO-66膜并用于己烷异构体的高效分离[J]. 石油炼制与化工, 2024, 55(1): 112-121. |

| Wang Y X, Hua J X, Pan Y C, et al. Fabrication of uio-66 membrane by two-step dry gel conversion for efficient separation of hexane isomer[J]. Petroleum Processing and Petrochemicals, 2024, 55(1): 112-121. | |

| [23] | 张亚明, 徐荣, 黄维秋, 等. UiO-66膜的制备及其对正/异丁烷体系的分离[J]. 精细化工, 2019, 36(1): 25-30. |

| Zhang Y M, Xu R, Huang W Q, et al. Fabrication of UiO-66 membrane for the separation of n-butane/i-butane[J]. Fine Chemicals, 2019, 36(1): 25-30. | |

| [24] | Sun Y W, Yan J H, Jiang J, et al. Hierarchical defect-rich UiO-66 membrane towards superior flue gas and butane isomer separations[J]. Science Bulletin, 2024, 69(14): 2174-2178. |

| [25] | Lotkhov V A, Kvashnin S Y, Kulov N N. Effect of separating agent in extractive distillation[J]. Theoretical Foundations of Chemical Engineering, 2020, 54(1): 172-177. |

| [26] | Perkar T, Choksi N, Modi C, et al. Simulation studies of n-heptane/toluene separation by extractive distillation using sulfolane, phenol, and NMP[J]. International Journal of Chemical Reactor Engineering, 2021, 19(8): 829-837. |

| [27] | 赵闯, 陈自浩, 张博宇, 等. 分子筛吸附剂对不同类型柴油吸附分离性能的研究[J]. 无机盐工业, 2024, 56(3): 80-85. |

| Zhao C, Chen Z H, Zhang B Y, et al. Study on adsorption and separation performance of molecular sieve adsorbents for different types of diesel[J]. Inorganic Chemicals Industry, 2024, 56(3): 80-85. | |

| [28] | Sapianik A A, Kovalenko K A, Samsonenko D G, et al. Exceptionally effective benzene/cyclohexane separation using a nitro-decorated metal–organic framework[J]. Chemical Communications, 2020, 56(59): 8241-8244. |

| [29] | 叶宏, 李继定, 林阳政, 等. 聚氨酯脲和聚氨酯酰亚胺膜的制备与渗透汽化芳烃/烷烃分离性能研究[J]. 膜科学与技术, 2009, 29(2): 40-46. |

| Ye H, Li J D, Lin Y Z, et al. Preparation of polyurethaneurea and polyurethaneimide membranes and their pervaporation performances to aromatic/aliphatic hydrocarbon mixtures[J]. Membrane Science and Technology, 2009, 29(2): 40-46. | |

| [30] | 俞健. 基于碳吸附剂的油品芳烃/非芳烃吸附分离研究[D]. 广州: 华南理工大学, 2024. |

| Yu J. Absorptive separation of aromatic and non-aromatic hydrocarbons in fossil fuels using carbon materials[D]. Guangzhou: South China University of Technology, 2024. | |

| [31] | Wu X C, Wei W, Jiang J W, et al. High-flux high-selectivity metal–organic framework MIL-160 membrane for xylene isomer separation by pervaporation[J]. Angewandte Chemie International Edition, 2018, 57(47): 15354-15358. |

| [32] | 张瑞琪, 姜斌, 任海伦, 等. 环丁砜萃取精馏提纯连三甲苯的实验和模拟[J]. 化工进展, 2016, 35(11): 3465-3469. |

| Zhang R Q, Jiang B, Ren H L, et al. Experiment and simulation on the purification of 1, 2, 3-trimethylbenzene by extractive distillation with sulfolane[J]. Chemical Industry and Engineering Progress, 2016, 35(11): 3465-3469. | |

| [33] | 何燎, 李俊, 高梦舒, 等. 石油烃中芳烃分离技术研究进展[J]. 化工学报, 2025, 76(5): 1909-1926. |

| He L, Li J, Gao M S, et al. Research progress on aromatic hydrocarbons separation from petroleum hydrocarbons[J]. CIESC Journal, 2025, 76(5): 1909-1926. | |

| [34] | 赵东东, 余波, 黎春霖, 等. 活性炭吸附预处理对真油加氢脱硫脱氮的影响[J]. 有色金属设计, 2019, 46(1): 78-81. |

| Zhao D D, Yu B, Li C L, et al. Effect of adsorption pretreatment by activated carbon on hydro-desulfurization and hydro-denitrogenation of real oil[J]. Nonferrous Metals Design, 2019, 46(1): 78-81. | |

| [35] | 李丽娜. 燃料油加氢精制催化剂载体的研究进展[J]. 精细石油化工进展, 2022, 23(4): 27-32, 58. |

| Li L N. Research progress on catalyst supports for fuel oil hydrotreating[J]. Advances in Fine Petrochemicals, 2022, 23(4): 27-32, 58. | |

| [36] | 林赛燕, 刘丹, 王红, 等. 酸性离子液体萃取脱除焦化柴油中碱性氮化物[J]. 石油化工高等学校学报, 2012, 25(1): 8-12. |

| Lin S Y, Liu D, Wang H, et al. Removing basic nitrogen compounds from coker diesel by extraction with acidic ionic liquid[J]. Journal of Petrochemical Universities, 2012, 25(1): 8-12. | |

| [37] | 舒展. 超临界流体萃取油品的工艺研究进展[J]. 广东化工, 2019, 46(5): 144-145, 138. |

| Shu Z. Research progress on supercritical fluid extraction technology of petroleum products[J]. Guangdong Chemical Industry, 2019, 46(5): 144-145, 138. | |

| [38] | 韦存福, 王伦, 杨燕. 超临界流体萃取分馏法分离石油重质油的应用研究[J]. 化工设计通讯, 2020, 46(6): 46, 68. |

| Wei C F, Wang L, Yang Y. Study on the application of supercritical fluid extraction and fractionation in the separation of heavy oil[J]. Chemical Engineering Design Communications, 2020, 46(6): 46, 68. | |

| [39] | 杨光, 陈松, 刘旭丹, 等. 超临界流体萃取技术在重油加工领域的应用进展[J]. 化学工程师, 2017, 31(6): 54-57. |

| Yang G, Chen S, Liu X D, et al. Application of supercritical fluid extraction technology in the field of heavy oil processing[J]. Chemical Engineer, 2017, 31(6): 54-57. | |

| [40] | Leo M, Dutta A, Farooq S. Process synthesis and optimization of heat pump assisted distillation for ethylene-ethane separation[J]. Industrial & Engineering Chemistry Research, 2018, 57(34): 11747-11756. |

| [41] | 王远航. 催化裂解分离流程模拟与优化[D]. 大连: 大连理工大学, 2021. |

| Wang Y H. Simulation and optimization of catalytic cracking separation process[D]. Dalian: Dalian University of Technology, 2021. | |

| [42] | Li X G, Cui C T, Li H, et al. Process synthesis and simulation-based optimization of ethylbenzene/styrene separation using double-effect heat integration and self-heat recuperation technology: a techno-economic analysis[J]. Separation and Purification Technology, 2019, 228: 115760. |

| [43] | Qiu X M, Shen Y Y, Hou Z K, et al. Mechanism analysis of solvent selectivity and energy-saving optimization in vapor recompression-assisted extractive distillation for separation of binary azeotrope[J]. Chinese Journal of Chemical Engineering, 2022, 46: 271-279. |

| [44] | Zhang H R, Zhao F, Ma Z Y, et al. Design and optimization for the separation of cyclohexane-isopropanol-water using mixed extractants with thermal integration based on molecular mechanism[J]. Separation and Purification Technology, 2021, 266: 118541. |

| [45] | Lyu H, Hu Y X, Zhou T. Dimethyl carbonate/methanol separation by azeotropic distillation with water: an alternative process driven by low-pressure steam[J]. Separation and Purification Technology, 2025, 355: 129677. |

| [46] | Zhang F K, Sun D F, Li Y N, et al. Heat integration and dynamic control for separating the ternary azeotrope of butanone/isopropanol/n-heptane via pressure-swing distillation[J]. Chemical Engineering and Processing - Process Intensification, 2022, 170: 108657. |

| [47] | Liu X J, Xu Q L, Ma C C, et al. Design and multi-objective optimization of reactive pressure-swing distillation process for separating tetrahydrofuran-methanol-water[J]. Separation and Purification Technology, 2024, 329: 125160. |

| [48] | Salman M, Javed N, Liu X Y, et al. Azeotrope separation of ethyl propionate and ethanol by extractive distillation and pressure swing distillation method[J]. Separation and Purification Technology, 2023, 311: 123361. |

| [49] | 李欣宇. 含氮杂环类功能化溶剂萃取分离柴油中芳烃/烷烃的研究[D]. 北京: 北京化工大学, 2023. |

| Li X Y. Extraction separation of aromatics/alkanes from diesel fuel by nitrogen-containing heterocyclic functionalized solvents[D]. Beijing: Beijing University of Chemical Technology, 2023. | |

| [50] | Liu Q H, Li G X, Gui C M, et al. Solvents evaluation for extraction of polycyclic aromatics from FCC diesel: Experimental and computational thermodynamics[J]. Chemical Engineering Science, 2022, 264: 118205. |

| [51] | Li H, Guo J J, Zhang Y H, et al. Research on separation of aromatics from FCC diesel using organic solvent: a combination of experiments and quantum chemical calculations[J]. Fuel, 2022, 308: 121982. |

| [52] | Li H, Guo J J, Zhang Y H, et al. Influence of solvent structure on the extraction of aromatics from FCC diesel and computational thermodynamics study[J]. Fuel Processing Technology, 2021, 224: 107021. |

| [53] | Zhou N X, Wang F T, Huang Z B, et al. Molecular-level insights into extractant selection for aromatic–saturate separation in FCC slurry oil[J]. Journal of Molecular Liquids, 2025, 435: 128093. |

| [54] | Yan J L, Li X N, Meng M M, et al. Mechanistic investigation of isobutanol/isobutyl acetate separation by extraction using low-transition temperature mixtures[J]. Industrial & Engineering Chemistry Research, 2023, 62(33): 13223-13234. |

| [55] | Dong S L, Sun X Y, Wang L L, et al. Prediction, application, and mechanism exploration of liquid–liquid equilibrium data in the extraction of aromatics using sulfolane[J]. Processes, 2023, 11(4): 1228. |

| [56] | 张琳娜, 李冬, 朱永红, 等. 煤基石脑油萃取脱芳制备溶剂油工艺研究[J]. 精细化工, 2016, 33(6): 703-708. |

| Zhang L N, Li D, Zhu Y H, et al. Study on the liquid-liquid extraction aromatic process for the coal-derived naphtha to produce solvent oil[J]. Fine Chemicals, 2016, 33(6): 703-708. | |

| [57] | 薛凤凤, 李冬, 张琳娜, 等. 煤基石脑油萃取脱芳复合萃取剂[J]. 化工进展, 2017, 36(8): 2897-2902. |

| Xue F F, Li D, Zhang L N, et al. Composite extractant of liquid-liquid extraction aromatics for the coal-derived naphtha[J]. Chemical Industry and Engineering Progress, 2017, 36(8): 2897-2902. | |

| [58] | 冯弦, 李冬, 张琳娜, 等. 煤基石脑油芳烃抽提的实验与模拟[J]. 化学工程, 2017, 45(11): 23-28. |

| Feng X, Li D, Zhang L N, et al. Experiment and simulation of coal-based naphtha aromatics extraction[J]. Chemical Engineering (China), 2017, 45(11): 23-28. | |

| [59] | 杨勇, 张钊, 王东亮, 等. 二甲苯异构体不同分离策略的技术经济评价[J]. 化工进展, 2025, 44(8): 4732-4740. |

| Yang Y, Zhang Z, Wang D L, et al. Technical-economic evaluation for different separation strategies of xylene isomers[J]. Chemical Industry and Engineering Progress, 2025, 44(8): 4732-4740. | |

| [60] | Anderson K, Atkins M P, Estager J, et al. Carbon dioxide uptake from natural gas by binary ionic liquid–water mixtures[J]. Green Chemistry, 2015, 17(8): 4340-4354. |

| [61] | Lei Z G, Dai C N, Zhu J Q, et al. Extractive distillation with ionic liquids: a review[J]. AIChE Journal, 2014, 60(9): 3312-3329. |

| [62] | Lei Z G, Dai C N, Chen B H. Gas solubility in ionic liquids[J]. Chemical Reviews, 2014, 114(2): 1289-1326. |

| [63] | Li G X, Chen K, Lei Z G, et al. Condensable gases capture with ionic liquids[J]. Chemical Reviews, 2023, 123(16): 10258-10301. |

| [64] | Siami H, Razmkhah M, Moosavi F. Does side chain group of anion affect absorption of SO2 in amino acid ionic liquid?[J]. Journal of Molecular Liquids, 2023, 376: 121479. |

| [65] | 黄少轩, 李安, 赵佳豪, 等. 离子液体吸收法碳捕集系统的热力学分析[J]. 热科学与技术, 2025, 24(3): 249-260. |

| Huang S X, Li A, Zhao J H, et al. Thermodynamic analysis of carbon capture system based on ionic liquid absorption[J]. Journal of Thermal Science and Technology, 2025, 24(3): 249-260. | |

| [66] | Zhang X C, Jiang K, Liu Z P, et al. Insight into the performance of acid gas in ionic liquids by molecular simulation[J]. Industrial & Engineering Chemistry Research, 2019, 58(3): 1443-1453. |

| [67] | 刘茹飞, 刘涛, 姚远, 等. 离子液体用于燃烧后二氧化碳捕集的热力学及过程模拟研究[J]. 环境工程, 2023, 41(S2): 451-459. |

| Liu R F, Liu T, Yao Y, et al. Thermodynamic and process simulation of ionic liquids for carbon dioxide capture after combustion[J]. Environmental Engineering, 2023, 41(S2): 451-459. | |

| [68] | Lei Y, Zhou Y H, Wei Z Q, et al. Optimal design of an ionic liquid (IL)-based aromatic extractive distillation process involving energy and economic evaluation[J]. Industrial & Engineering Chemistry Research, 2021, 60(9): 3605-3616. |

| [69] | Yu G Q, Dai C N, Gao H, et al. Capturing condensable gases with ionic liquids[J]. Industrial & Engineering Chemistry Research, 2018, 57(36): 12202-12214. |

| [70] | Lei Y, Yan J Q, Chen Y M, et al. Energy-efficient styrene production by incorporating ionic liquid-based separation technology[J]. Chemical Engineering & Technology, 2025, 48(4): e70008. |

| [71] | Lei Y, Yu Z Y, Wei Z Q, et al. Structure optimization of task-specific ionic liquids targeting low-carbon-emission ethylbenzene production[J]. Separation and Purification Technology, 2023, 308: 122827. |

| [72] | Yang K, Ban Y J, Yang W S. Layered MOF membranes modified with ionic liquid/AgBF4 composite for olefin/paraffin separation[J]. Journal of Membrane Science, 2021, 639: 119771. |

| [73] | Lei Y, Yu Z Y, Wei Z Q, et al. Energy-efficient separation of propylene/propane by introducing a tailor-made ionic liquid solvent[J]. Fuel, 2022, 326: 124930. |

| [74] | Ayuso M, Palma A M, Larriba M, et al. Experimental and CPA EoS description of the key components in the BTX separation from gasolines by extractive distillation with tricyanomethanide-based ionic liquids[J]. Industrial & Engineering Chemistry Research, 2020, 59(33): 15058-15068. |

| [75] | Ayuso M, Navarro P, Moya C, et al. Extractive distillation with ionic liquids to separate benzene, toluene, and xylene from pyrolysis gasoline: process design and techno-economic comparison with the morphylane process[J]. Industrial & Engineering Chemistry Research, 2022, 61(6): 2511-2523. |

| [76] | Guo C, Luo K, Hou W, et al. A novel [MMIM]-based ionic liquid extractive distillation process for achieving liquid-phase propylene at 1.8 MPa with enhanced energy-economic-environmental benefits[J]. Journal of Cleaner Production, 2025, 525: 146579. |

| [77] | Shang Z J, Liu Y P, Shang W Z, et al. Green separation pathway for hydrocarbon compounds: Ionic liquid extraction technology[J]. Separation and Purification Technology, 2025, 362: 131858. |

| [78] | Li G X, Gao Q H, Liu Q H, et al. Extraction of polycyclic aromatic hydrocarbons from fluid catalytic cracking diesel with ionic liquids[J]. AIChE Journal, 2023, 69(2): e17914. |

| [79] | Zhao X, Xing H B, Yang Q W, et al. Differential solubility of ethylene and acetylene in room-temperature ionic liquids: a theoretical study[J]. The Journal of Physical Chemistry B, 2012, 116(13): 3944-3953. |

| [80] | Arenas-Fernández P, Suárez I, Coto B. Liquid-liquid extraction of polyaromatic compounds with ionic liquid. A theoretical and experimental approach[J]. Separation and Purification Technology, 2022, 303: 122160. |

| [81] | 惠燕华, 王辉, 刘福胜, 等. 三乙烯二胺类离子液体的合成及其用于脱除非碱性氮[J]. 石油化工, 2021, 50(2): 123-129. |

| Hui Y H, Wang H, Liu F S, et al. Synthesis of triethylenediamine ionic liquids and their use in removing non-basic nitrogen[J]. Petrochemical Technology, 2021, 50(2): 123-129. | |

| [82] | 蒋斯麒, 胡玉峰, 程永强, 等. 离子液体萃取分离FCC柴油中双环芳香性硫氮组分: 实验和分子机理[J]. 化工学报, 2024, 75(10): 3651-3659. |

| Jiang S Q, Hu Y F, Cheng Y Q, et al. Extraction of bicyclic S/N-compounds from FCC diesel with ionic liquid: experimental and molecular insight[J]. CIESC Journal, 2024, 75(10): 3651-3659. | |

| [83] | 李斯文, 雷敏, 刘玉霜, 等. 离子液体多酸在燃油氧化脱硫中的研究进展[J]. 化工进展, 2024, 43(6): 3322-3335. |

| Li S W, Lei M, Liu Y S, et al. Research progress of ionic liquid polyacid in fuel oxidation desulfurization[J]. Chemical Industry and Engineering Progress, 2024, 43(6): 3322-3335. | |

| [84] | Lei Y, Pan W Y, Hu S B, et al. Ionic liquid-assisted extractive distillation for ethylene/ethane separation: molecular design and process assessment[J]. Industrial & Engineering Chemistry Research, 2024, 63(44): 19187-19199. |

| [85] | Lei Y, Guo Z Q, Du L, et al. Replacing DMF with ionic liquid in isoprene/n-pentane separation in C5 plants: Solvent design, process optimization, and industrial-scale assessment[J]. Fuel, 2024, 357: 130006. |

| [86] | 杨乘宇. 基于新型聚酰亚胺的超滤膜与纳滤膜制备及性能研究[D]. 西安: 西北工业大学, 2021. |

| Yang C Y. Research on preparation and performance of ultrafiltration membrane and nanofiltration membrane based on novel polyimide[D]. Xi'an: Northwestern Polytechnical University, 2021. | |

| [87] | Pendergast M M, Hoek E M V. A review of water treatment membrane nanotechnologies[J]. Energy & Environmental Science, 2011, 4(6): 1946-1971. |

| [88] | Li B F, Qi B, Guo Z Y, et al. Recent developments in the application of membrane separation technology and its challenges in oil-water separation: a review[J]. Chemosphere, 2023, 327: 138528. |

| [89] | 马云, 查辉, 田伟, 等. 膜分离技术在油气田采出水处理中的应用现状与发展趋势[J]. 水处理技术, 2025, 51(8): 8-14, 22. |

| Ma Y, Zha H, Tian W, et al. Application and development of membrane separation technology in treating produced water from oil and gas field[J]. Technology of Water Treatment, 2025, 51(8): 8-14, 22. | |

| [90] | Sholl D S, Lively R P. Seven chemical separations to change the world[J]. Nature, 2016, 532(7600): 435-437. |

| [91] | 潘宜昌, 周荣飞, 邢卫红. 高效分离同碳数烃的先进微孔膜: 现状与挑战[J]. 化工进展, 2023, 42(8): 3926-3942. |

| Pan Y C, Zhou R F, Xing W H. Advanced microporous membranes for efficient separation of same-carbon-number hydrocarbon mixtures: State-of-the-art and challenges[J]. Chemical Industry and Engineering Progress, 2023, 42(8): 3926-3942. | |

| [92] | Knebel A, Caro J. Metal–organic frameworks and covalent organic frameworks as disruptive membrane materials for energy-efficient gas separation[J]. Nature Nanotechnology, 2022, 17(9): 911-923. |

| [93] | Chen G N, Chen C L, Guo Y N, et al. Solid-solvent processing of ultrathin, highly loaded mixed-matrix membrane for gas separation[J]. Science, 2023, 381(6664): 1350-1356. |

| [94] | 花敬贤, 罗宇荣, 顾亚伟, 等. 超薄取向ZIF-8膜的制备及乙烯/乙烷高效分离[J]. 化工学报, 2025, 76(5): 2209-2218. |

| Hua J X, Luo Y R, Gu Y W, et al. Preparation of ultra-thin oriented ZIF-8 membrane for efficient ethylene/ethane separation[J]. CIESC Journal, 2025, 76(5): 2209-2218. | |

| [95] | Pan Y C, Li T, Lestari G, et al. Effective separation of propylene/propane binary mixtures by ZIF-8 membranes[J]. Journal of Membrane Science, 2012, 390/391: 93-98. |

| [96] | Zhou S, Shekhah O, Jia J T, et al. Electrochemical synthesis of continuous metal–organic framework membranes for separation of hydrocarbons[J]. Nature Energy, 2021, 6(9): 882-891. |

| [97] | Zhang Z N, Zhu H, Jin H, et al. Restricting linker rotation in nanocages of ZIF-8 membranes using crown ether "molecular locks" for enhanced propylene/propane separation[J]. Angewandte Chemie International Edition, 2025, 64(3): e202415023. |

| [98] | Sun Y W, Yan J H, Jiang J, et al. Hierarchical defect-rich UiO-66 membrane towards superior flue gas and butane isomer separations[J]. Science Bulletin, 2024, 69(14): 2174-2178. |

| [99] | Yang W H, Yang X, Wang Y X, et al. Pervaporation separation of C6 alkane isomers by Al-bttotb membrane[J]. Journal of Membrane Science, 2022, 661: 120916. |

| [100] | Wang Y C, Ban Y J, Hu Z Y, et al. Energy-efficient extraction of linear alkanes from various isomers using structured metal-organic framework membrane[J]. Nature Communications, 2023, 14: 6617. |

| [101] | Kosinov N, Gascon J, Kapteijn F, et al. Recent developments in zeolite membranes for gas separation[J]. Journal of Membrane Science, 2016, 499: 65-79. |

| [102] | Liu M L, Ge Y Y, Du J H, et al. Hierarchical MFI zeolite membranes for superior xylene separation[J]. Advanced Functional Materials, 2024, 34(34): 2400772. |

| [103] | Sakai M, Sasaki Y, Tomono T, et al. Olefin selective Ag-exchanged X-type zeolite membrane for propylene/propane and ethylene/ethane separation[J]. ACS Applied Materials & Interfaces, 2019, 11(4): 4145-4151. |

| [104] | 李明, 吴红丹, 周志辉. 渗透气化膜分离混合有机溶剂研究进展[J]. 现代化工, 2021, 41(4): 43-47. |

| Li M, Wu H D, Zhou Z H. Research progress on separation of organic solvent mixtures by pervaporation membrane[J]. Modern Chemical Industry, 2021, 41(4): 43-47. | |

| [105] | Han G L, Chen Z, Cai L F, et al. Post-synthetic MIL-53(Al)-SO3H incorporated sulfonated polyarylethersulfone with cardo (SPES-C) membranes for separating methanol and methyl tert-butyl ether mixture[J]. Separation and Purification Technology, 2019, 220: 268-275. |

| [106] | Castro-Muñoz R, Galiano F, de la Iglesia Ó, et al. Graphene oxide–Filled polyimide membranes in pervaporative separation of azeotropic methanol–MTBE mixtures[J]. Separation and Purification Technology, 2019, 224: 265-272. |

| [107] | Wu T, Wang N X, Li J, et al. Tubular thermal crosslinked-PEBA/ceramic membrane for aromatic/aliphatic pervaporation[J]. Journal of Membrane Science, 2015, 486: 1-9. |

| [108] | Zhang Y, Wang N X, Ji S L, et al. Metal–organic framework/poly(vinyl alcohol) nanohybrid membrane for the pervaporation of toluene/n-heptane mixtures[J]. Journal of Membrane Science, 2015, 489: 144-152. |

| [109] | Zheng H Y, Yoshikawa M. Molecularly imprinted cellulose membranes for pervaporation separation of xylene isomers[J]. Journal of Membrane Science, 2015, 478: 148-154. |

| [110] | Jiang Y H, Zhang Y Q, Wang Z H, et al. Controllable construction of multifunctional superhydrophobic coating with ultra-stable efficiency for oily water treatment[J]. Journal of Colloid and Interface Science, 2022, 628: 356-365. |

| [111] | Lin J Y, Lin F, Liu R R, et al. Scalable fabrication of robust superhydrophobic membranes by one-step spray-coating for gravitational water-in-oil emulsion separation[J]. Separation and Purification Technology, 2020, 231: 115898. |

| [112] | Gu H H, Li G Q, Li P P, et al. Superhydrophobic and breathable SiO2/polyurethane porous membrane for durable water repellent application and oil-water separation[J]. Applied Surface Science, 2020, 512: 144837. |

| [113] | Xiong W, Li L, Qiao F, et al. Air superhydrophilic-superoleophobic SiO2-based coatings for recoverable oil/water separation mesh with high flux and mechanical stability[J]. Journal of Colloid and Interface Science, 2021, 600: 118-126. |

| [114] | Xu Z Z, Li L, Liu J W, et al. Mussel-inspired superhydrophilic membrane constructed on a hydrophilic polymer network for highly efficient oil/water separation[J]. Journal of Colloid and Interface Science, 2022, 608: 702-710. |

| [115] | 王莹, 田梦圆, 张振展, 等. 钯及其合金膜制备研究进展[J]. 膜科学与技术, 2025, 45(2): 192-204. |

| Wang Y, Tian M Y, Zhang Z Z, et al. Research progress in preparation of palladium and its alloy films[J]. Membrane Science and Technology, 2025, 45(2): 192-204. | |

| [116] | 段翠佳, 齐迹, 郭宇, 等. 功能化聚酰亚胺膜的制备和气体分离性能研究[J]. 辽宁化工, 2025, 54(2): 252-255. |

| Duan C J, Qi J, Guo Y, et al. Preparation of functionalized polyimide membrane and its gas separation performance[J]. Liaoning Chemical Industry, 2025, 54(2): 252-255. | |

| [117] | Cowan M G, Gin D L, Noble R D. Poly(ionic liquid)/ionic liquid ion-gels with high "free" ionic liquid content: platform membrane materials for CO2/light gas separations[J]. Accounts of Chemical Research, 2016, 49(4): 724-732. |

| [118] | Zhou Z Y, Lu D W, Li X, et al. Fabrication of highly permeable polyamide membranes with large "leaf-like" surface nanostructures on inorganic supports for organic solvent nanofiltration[J]. Journal of Membrane Science, 2020, 601: 117932. |

| [119] | Liang B, He X, Hou J J, et al. Membrane separation in organic liquid: technologies, achievements, and opportunities[J]. Advanced Materials, 2019, 31(45): 1806090. |

| [120] | 易砖, 朱国栋, 刘洋, 等. 膜分离在石油化工领域中的应用: 现状、挑战及机遇[J]. 水处理技术, 2022, 48(8): 7-13. |

| Yi Z, Zhu G D, Liu Y, et al. Applications of membrane separation on petrochemical industry: progress, challenges and opportunities[J]. Technology of Water Treatment, 2022, 48(8): 7-13. | |

| [121] | Mukhtar A, Saqib S, Mellon N B, et al. CO2 capturing, thermo-kinetic principles, synthesis and amine functionalization of covalent organic polymers for CO2 separation from natural gas: a review[J]. Journal of Natural Gas Science and Engineering, 2020, 77: 103203. |

| [122] | Li B, Cui X L, O'Nolan D, et al. An ideal molecular sieve for acetylene removal from ethylene with record selectivity and productivity[J]. Advanced Materials, 2017, 29(47): 1704210. |

| [123] | Schmittmann S, Pasel C, Luckas M, et al. Adsorption of light alkanes and alkenes on activated carbon and zeolite 13X at low temperatures[J]. Journal of Chemical & Engineering Data, 2020, 65(2): 706-716. |

| [124] | 张连中, 丁元生, 李正, 等. 石油裂解碳五分离工艺中吸附法异戊二烯脱硫技术研究[J]. 应用化工, 2019, 48(S1): 55-59. |

| Zhang L Z, Ding Y S, Li Z, et al. Study on adsorption isoprene desulfurization technology in C5 separation process of petroleum cracking[J]. Applied Chemical Industry, 2019, 48(S1): 55-59. | |

| [125] | Jin Y N, Wu J F, Wang J Q, et al. Highly efficient capture of benzothiophene with a novel water-resistant-bimetallic Cu-ZIF-8 material[J]. Inorganica Chimica Acta, 2020, 503: 119412. |

| [126] | 徐子栋, 张功尚, 刘春晖, 等. 超疏水活性炭污水池废气VOCS长效吸附特性研究[J]. 石油化工安全环保技术, 2025, 41(2): 63-68, 8. |

| Xu Z D, Zhang G S, Liu C H, et al. Study on the long-term adsorption characteristics of superhydrophobic activated carbon for vocs in wastewater tank exhaust gas [J]. Petrochemical Safety and Environmental Protection Technology, 2025, 41(2): 63-68, 8. | |

| [127] | Yang G, Luo H C, Ohba T, et al. CO2 capture by carbon aerogel–potassium carbonate nanocomposites[J]. International Journal of Chemical Engineering, 2016, 2016(1): 4012967. |

| [128] | Cui W G, Hu T L, Bu X H. Metal–organic framework materials for the separation and purification of light hydrocarbons[J]. Advanced Materials, 2020, 32(3): 1806445. |

| [129] | da Silva R P F F, Rocha-Santos T A P, Duarte A C. Supercritical fluid extraction of bioactive compounds[J]. TrAC Trends in Analytical Chemistry, 2016, 76: 40-51. |

| [130] | 陈淦铭. 超临界流体萃取技术的研究与应用[J]. 辽宁化工, 2021, 50(1): 55-57. |

| Chen G M. Research and application of supercritical fluid extraction technology[J]. Liaoning Chemical Industry, 2021, 50(1): 55-57. | |

| [131] | 刘同举, 杜志国, 郭莹, 等. 超临界流体技术在石油化工中的应用[J]. 2011(8): 1676-1680. |

| Liu T J, Du Z G, Guo Y, et al. Application of supercritical fluid technology in petrochemical industry[J]. Chemical Industry and Engineering Progress, 2011(8): 1676-1680. | |

| [132] | 杨科. 超临界流体萃取技术在化工生产中的应用[J]. 山西化工, 2023, 43(8): 109-111. |

| Yang K. Application of supercritical fluid extraction technology in chemical production[J]. Shanxi Chemical Industry, 2023, 43(8): 109-111. | |

| [133] | Makaryan I A, Kostin A Y, Sedov I V. Application of supercritical fluid technologies in chemical and petrochemical industries (review)[J]. Petroleum Chemistry, 2020, 60(3): 244-254. |

| [134] | Chaves J O, de Souza M C, da Silva L C, et al. Extraction of flavonoids from natural sources using modern techniques[J]. Frontiers in Chemistry, 2020, 8: 507887. |

| [135] | Uwineza P A, Waśkiewicz A. Recent advances in supercritical fluid extraction of natural bioactive compounds from natural plant materials[J]. Molecules, 2020, 25(17): 3847. |

| [136] | 陈林凤. 分子印迹膜的设计构建及其在有机污染物分析中的应用[D]. 武汉: 华中师范大学, 2021. |

| Chen L F. Design and construction of molecularly imprinted membrane and its application in the analysis of organic pollutants[D]. Wuhan: Central China Normal University, 2021. | |

| [137] | Ostovan A, Arabi M, Wang Y Q, et al. Greenificated molecularly imprinted materials for advanced applications[J]. Advanced Materials, 2022, 34(42): 2203154. |

| [138] | Liu Y F, Zhao L L, Liu Y J, et al. Surface molecularly imprinted polymer/covalent organic framework/silica composite material with specific recognition ability and excellent chromatographic performance[J]. Talanta, 2024, 276: 126238. |

| [139] | 宋兴良. 分子印迹固相萃取材料的制备及应用研究[D]. 青岛: 中国海洋大学, 2010. |

| Song X L. Molecularly imprinting solid-phase extraction materials: preparation and its application[D]. Qingdao: Ocean University of China, 2010. | |

| [140] | 熊满艳, 王巧环, 王俊杰. 分子印迹固相萃取技术及其在环境中多环芳烃测定中的应用进展[J]. 环境化学, 2022, 41(5): 1522-1529. |

| Xiong M Y, Wang Q H, Wang J J. Recent advances of molecularly imprinted solid-phase extraction technique and its application for the determination of polycyclic aromatic hydrocarbons in environment[J]. Environmental Chemistry, 2022, 41(5): 1522-1529. | |

| [141] | Chen L X, Wang X Y, Lu W H, et al. Molecular imprinting: perspectives and applications[J]. Chemical Society Reviews, 2016, 45(8): 2137-2211. |

| [142] | Liu Y X, Wang L L, Li H T, et al. Rigorous recognition mode analysis of molecularly imprinted polymers: Rational design, challenges, and opportunities[J]. Progress in Polymer Science, 2024, 150: 101790. |

| [143] | Arabi M, Ostovan A, Li J H, et al. Molecular imprinting: green perspectives and strategies[J]. Advanced Materials, 2021, 33(30): 2100543. |

| [144] | 印振昌, 田雨, 方华, 等. 新型分离技术在化工工艺中的应用研究[J]. 辽宁化工, 2025, 54(3): 501-504. |

| Yin Z C, Tian Y, Fang H, et al. Research on application of new separation technology in chemical process[J]. Liaoning Chemical Industry, 2025, 54(3): 501-504. | |

| [145] | Zhao J, Wang X H, Tian Z H, et al. Optimization design and evaluation of the industrial distillation-membrane separation process[J]. Chemical Engineering & Technology, 2024, 47(2): 335-348. |

| [146] | Xu Q G, Dai Y S, Zhao Q, et al. Economy, environmental assessment and energy conservation for separation of isopropanol/diisopropyl ether/water multi-azeotropes via extractive distillation coupled pervaporation process[J]. Chinese Journal of Chemical Engineering, 2023, 54: 353-363. |

| [147] | Jiao Y Y, Yan M, Wang X L, et al. Economic, environmental, energy and exergy analysis and multi-objective optimization for efficient purification of a friendly gasoline additive by extractive distillation coupled with pervaporation[J]. Fuel, 2023, 335: 127069. |

| [148] | León J A, Fontalvo J. Theoretical and experimental evaluation of a distillation–pervaporation in a single unit column for the separation of an azeotropic mixture[J]. Industrial & Engineering Chemistry Research, 2020, 59(43): 19426-19437. |

| [149] | 宫春美. 生物质固定床吸附—精馏耦合分离异丙醇—水共沸物研究[D]. 天津: 天津大学, 2010. |

| Gong C M. Study on separation of isopropanol-water azeotrope using the coupling process of biomass-based fixed-bed adsorption and distillation[D]. Tianjin: Tianjin University, 2010. | |

| [150] | Neyestani F, Eslamloueyan R. A novel reactive-extractive distillation process for separation of water/methanol/tetrahydrofuran mixtures[J]. Scientific Reports, 2024, 14: 1931. |

| [1] | 密晓光, 孙国刚, 程昊, 张晓慧. 印刷电路板式天然气冷却器性能仿真模型和验证[J]. 化工学报, 2025, 76(S1): 426-434. |

| [2] | 黄灏, 王文, 李沛昀. 三角转子膨胀机串联运行特性研究[J]. 化工学报, 2025, 76(S1): 435-443. |

| [3] | 任现超, 谷雅秀, 段少斌, 贾文竹, 李汉林. 翅片式椭圆套管蒸发式冷凝器传热传质性能实验研究[J]. 化工学报, 2025, 76(S1): 75-83. |

| [4] | 张文锋, 郭玮, 张新玉, 曹昊敏, 丁国良. 铝管铝翅片换热器模型开发及软件实现[J]. 化工学报, 2025, 76(S1): 84-92. |

| [5] | 刘豪, 王林, 丁昊, 耿嘉怡. R1150+R1234ze(E)二元体系223.15~253.15 K汽液相平衡研究[J]. 化工学报, 2025, 76(S1): 1-8. |

| [6] | 苏伟, 赵大海, 金旭, 刘忠彦, 李静, 张小松. 吸湿液滴与混合润湿性表面协同抑霜特性研究[J]. 化工学报, 2025, 76(S1): 140-151. |

| [7] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [8] | 臧子晴, 李修真, 谈莹莹, 刘晓庆. 分凝器对两级分离自复叠制冷循环特性影响研究[J]. 化工学报, 2025, 76(S1): 17-25. |

| [9] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [10] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [11] | 郭纪超, 徐肖肖, 孙云龙. 基于植物工厂中的CO2浓度气流模拟及优化研究[J]. 化工学报, 2025, 76(S1): 237-245. |

| [12] | 裴星亮, 叶翠平, 裴赢丽, 李文英. 碱改性MIL-53(Cr)选择性吸附分离二甲苯异构体[J]. 化工学报, 2025, 76(S1): 258-267. |

| [13] | 李银龙, 刘国强, 晏刚. 分馏与闪蒸分离耦合自复叠制冷循环性能分析[J]. 化工学报, 2025, 76(S1): 26-35. |

| [14] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [15] | 马爱华, 赵帅, 王林, 常明慧. 太阳能吸收制冷循环动态特性仿真方法研究[J]. 化工学报, 2025, 76(S1): 318-325. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号