CIESC Journal ›› 2021, Vol. 72 ›› Issue (4): 1847-1862.DOI: 10.11949/0438-1157.20200901

• Reviews and monographs • Previous Articles Next Articles

SUN Linquan1,2,3( ),WANG Lina1,2,YU Hongdong1,2,SU Hui1,2,3,CHEN Desheng1,2,QI Tao1,2(

),WANG Lina1,2,YU Hongdong1,2,SU Hui1,2,3,CHEN Desheng1,2,QI Tao1,2( )

)

Received:2020-07-06

Revised:2020-09-28

Online:2021-04-05

Published:2021-04-05

Contact:

QI Tao

孙林泉1,2,3( ),王丽娜1,2,于宏东1,2,苏慧1,2,3,陈德胜1,2,齐涛1,2(

),王丽娜1,2,于宏东1,2,苏慧1,2,3,陈德胜1,2,齐涛1,2( )

)

通讯作者:

齐涛

作者简介:孙林泉(1996—),男,博士研究生,基金资助:CLC Number:

SUN Linquan, WANG Lina, YU Hongdong, SU Hui, CHEN Desheng, QI Tao. Research progress on extraction technologies of niobium from low-grade niobium-bearing minerals[J]. CIESC Journal, 2021, 72(4): 1847-1862.

孙林泉, 王丽娜, 于宏东, 苏慧, 陈德胜, 齐涛. 低品位含铌矿物中铌的提取工艺研究进展[J]. 化工学报, 2021, 72(4): 1847-1862.

Add to citation manager EndNote|Ris|BibTeX

| 国家 | 铌矿 (矿山) | 主要矿物 | 原矿 品位/% | 精矿 品位/% | 文献 |

|---|---|---|---|---|---|

| 巴西 | Araxa | 烧绿石 | 1.5~3.5 | 55~60 | [ |

| 巴西 | Catalao | 烧绿石 | 0.8~1.5 | 63.7 | [ |

| 加拿大 | Niobec | 烧绿石 | 0.4 | 58 | [ |

| 加拿大 | Aley | 烧绿石、铌铁矿 | 0.5 | — | [ |

| 加拿大 | Nechalcho | 烧绿石、褐钇铌矿 | 0.4 | — | [ |

| 沙特 | Ghuray yah | 烧绿石、铌铁矿 | 0.28 | — | [ |

| 肯尼亚 | Mrima Hill | 烧绿石 | 0.7 | — | [ |

| 美国 | EIK Creek | 烧绿石 | 0.79 | — | [ |

| 澳大利亚 | Mt Weld | 烧绿石、铌铁金红石 | 1.4 | — | [ |

| 加纳 | Mabou nie | 烧绿石、铌铁矿 | 1.2 | — | [ |

| 中国 | 白云鄂博 | 铌铁金红石、钕易解石 | 0.10~0.15 | 1.0~5.0 | [ |

| 中国 | 宜春 | 铌钽铁矿、细晶石 | 0.008 | 25 | [ |

Table 1 Niobium (Nb2O5) grade of raw ores and concentrates of main niobium ores (mines) in the world

| 国家 | 铌矿 (矿山) | 主要矿物 | 原矿 品位/% | 精矿 品位/% | 文献 |

|---|---|---|---|---|---|

| 巴西 | Araxa | 烧绿石 | 1.5~3.5 | 55~60 | [ |

| 巴西 | Catalao | 烧绿石 | 0.8~1.5 | 63.7 | [ |

| 加拿大 | Niobec | 烧绿石 | 0.4 | 58 | [ |

| 加拿大 | Aley | 烧绿石、铌铁矿 | 0.5 | — | [ |

| 加拿大 | Nechalcho | 烧绿石、褐钇铌矿 | 0.4 | — | [ |

| 沙特 | Ghuray yah | 烧绿石、铌铁矿 | 0.28 | — | [ |

| 肯尼亚 | Mrima Hill | 烧绿石 | 0.7 | — | [ |

| 美国 | EIK Creek | 烧绿石 | 0.79 | — | [ |

| 澳大利亚 | Mt Weld | 烧绿石、铌铁金红石 | 1.4 | — | [ |

| 加纳 | Mabou nie | 烧绿石、铌铁矿 | 1.2 | — | [ |

| 中国 | 白云鄂博 | 铌铁金红石、钕易解石 | 0.10~0.15 | 1.0~5.0 | [ |

| 中国 | 宜春 | 铌钽铁矿、细晶石 | 0.008 | 25 | [ |

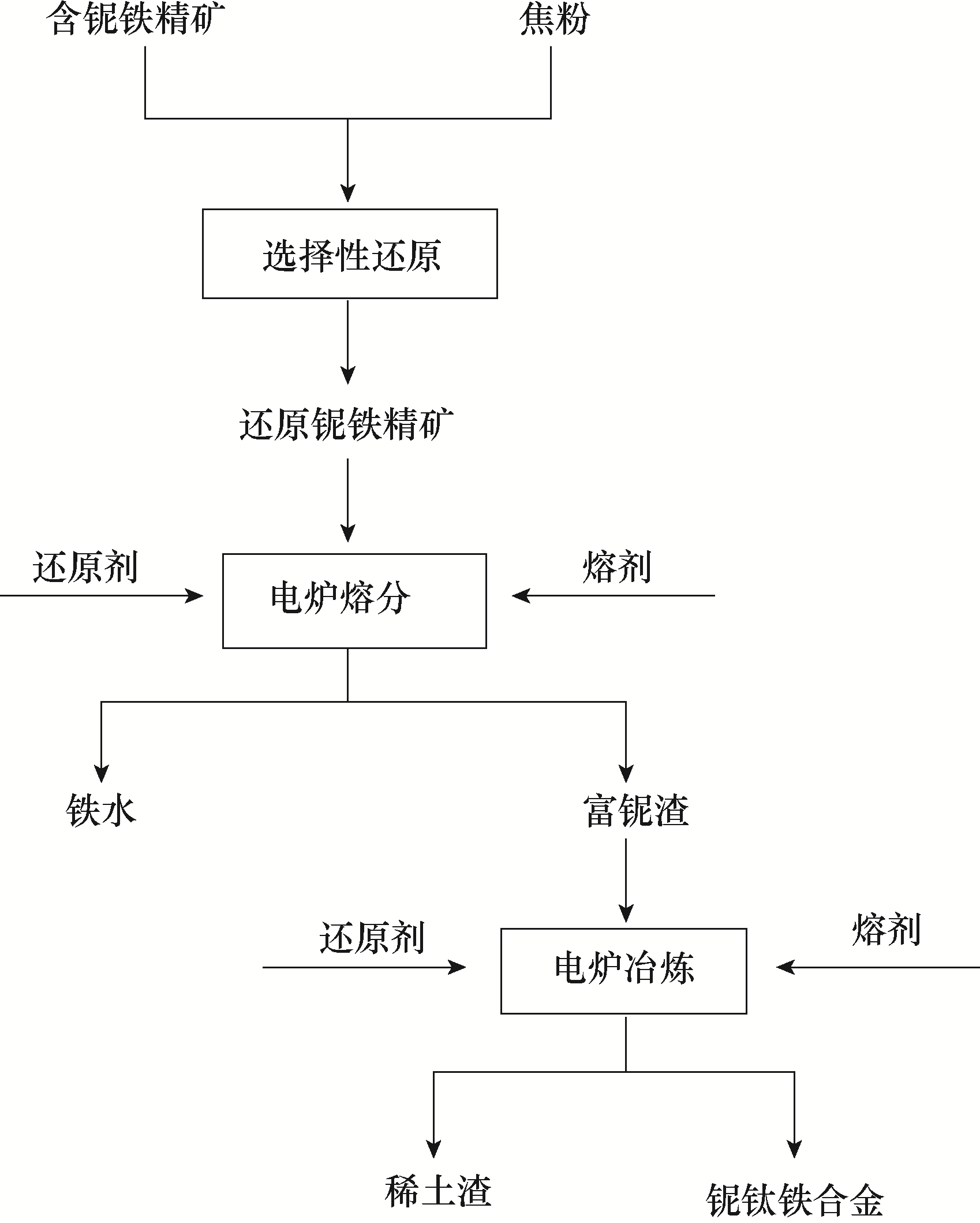

Fig.6 Flow diagram of selective reduction in tunnel kiln-smelting of intermediate frequency electric furnace-DC electric arc furnace carbothermal reduction process

| 原料 | 冶炼方法 | 产品 | 文献 |

|---|---|---|---|

| 铁水 | 铁水分段预处理、喷雾法连续提铌、氧气底(或顶)吹转炉提铌、空气侧吹转炉提铌 | 低级铌铁产品 | [ |

| 含铌铁水 | 中频感应电炉,脱硅-提铌-铌渣直接合金化 | 低硅含铌半钢 | [ |

| 含铌铁矿 | CO/CO2混合气体选择性热还原含铌铁矿、盐酸酸浸 | 含Nb2O5 29.6%,Nb/Fe=6,Nb/P≥12的酸浸渣 | [ |

| 含铌铁精矿 | 煤基直接还原 | Nb2O5 1.75%,回收率94% | [ |

Table 2 Low-grade niobium-containing minerals by pyrometallurgy

| 原料 | 冶炼方法 | 产品 | 文献 |

|---|---|---|---|

| 铁水 | 铁水分段预处理、喷雾法连续提铌、氧气底(或顶)吹转炉提铌、空气侧吹转炉提铌 | 低级铌铁产品 | [ |

| 含铌铁水 | 中频感应电炉,脱硅-提铌-铌渣直接合金化 | 低硅含铌半钢 | [ |

| 含铌铁矿 | CO/CO2混合气体选择性热还原含铌铁矿、盐酸酸浸 | 含Nb2O5 29.6%,Nb/Fe=6,Nb/P≥12的酸浸渣 | [ |

| 含铌铁精矿 | 煤基直接还原 | Nb2O5 1.75%,回收率94% | [ |

| 47 | Zhang B, Li C L, Jiang M F. Distribution ratio of niobium and phosphorus between slag and iron in the melting-separation process[J]. Journal of Northeastern University (Natural Science), 2014, 35(7): 983-986. |

| 48 | 赵二雄. 白云鄂博低品位铌精矿铌铁冶炼新工艺研究[D]. 包头: 内蒙古科技大学, 2019. |

| Zhao E X. The study on new process of smelting niobium iron alloy from Bayan Obo low grade niobium concentrate fines[D]. Baotou: Inner Mongolia University of Science & Technology, 2019. | |

| 49 | 张波, 刘承军, 姜茂发. 白云鄂博稀土铌铁复合矿提铌工艺的研究[C]//第七届(2009)中国钢铁年会. 北京: 冶金工业出版社, 2009: 14-19. |

| Zhang B, Li C L, Jiang M F. Study on the technologies of extracting niobium from Bayan Obo REE-Fe-Nb ore[C]//2009 CSM Annual Meeting Proceedings: Complement. Beijing: Metallurgical Industry Press, 2009: 9-14. | |

| 50 | 李楠. 低硅含铌铁水提铌的研究[D]. 包头: 内蒙古科技大学, 2013. |

| Li N. The study of extracting niobium from low silicon Nb-bearing hot metal[D]. Baotou: Inner Mongolia University of Science & Technology, 2013. | |

| 51 | 陈宏, 韩其勇, 魏寿昆, 等. 从含铌铁矿中提铌及制铌铁的新方法[J]. 钢铁, 1999, 34(3): 13-19 |

| Chen H, Han Q Y, Wei S K, et al. A new method on the extraction of Nb from Nb-bearing iron ore for making FeNb[J]. Iron and Steel, 1999, 34(3): 13-19 | |

| 52 | 蒋曼, 孙体昌, 寇珏, 等. 含铌铁精矿煤基直接还原过程中铌的行为研究[J]. 稀有金属, 2011, 35(5): 731-735. |

| Jiang M, Sun T C, Kou J, et al. Distribution behavior of niobium in process of coal-based direct reduction roasting of Nb-bearing iron concentrates[J]. Chinese Journal of Rare Metals, 2011, 35(5): 731-735. | |

| 53 | 冯运来, 陈义胜, 闫永旺, 等. 碳直接还原富铌渣制取铌铁合金温度的影响矿产综合利用[J/OL]. [2020-06-30]. . |

| Feng Y L, Chen Y S, Yan Y W, et al. Effect of direct reduction of carbon-rich slag on the temperature of strontium iron alloy[J/OL]. [2020-06-30]. . | |

| 54 | 侯晓志, 杨占峰, 王振江, 等. 白云鄂博铌精矿矿物组成特征及铌的分布规律研究[J]. 有色金属(选矿部分), 2018, (2): 4-7, 11. |

| 1 | 翟明国, 吴福元, 胡瑞忠, 等. 战略性关键金属矿产资源: 现状与问题[J]. 中国科学基金, 2019, 33(2): 106-111. |

| Zhai M G, Wu F Y, Hu R Z, et al. Critical metal mineral resources: current research status and scientific issues[J]. Bulletin of National Natural Science Foundation of China, 2019, 33(2): 106-111. | |

| 2 | 何海洋, 何敏, 李建武. 我国铌矿资源供需形势分析[J]. 中国矿业, 2018, 27(11): 1-5. |

| He H Y, He M, Li J W. Analysis of the niobium resources supply and demand pattern in China[J]. China Mining Magazine, 2018, 27(11): 1-5. | |

| 3 | 曹飞, 杨卉芃, 张亮, 等. 全球钽铌矿产资源开发利用现状及趋势[J]. 矿产保护与利用, 2019, 39(5): 56-67, 89. |

| Cao F, Yang H P, Zhang L, et al. Current situation and trend analysis of global tantalum and niobium mineral resources[J]. Conservation and Utilization of Mineral Resources, 2019, 39(5): 56-67, 89. | |

| 4 | Gulley A L,Nassar N T,Xun S. China,the United States,and competition for resources that enable emerging technologies[J]. Proceedings of the National Academy of Sciences of the United States of America,2018, 115: 4111-4115. |

| 5 | Cordeiro P F D O, Brod J A, Palmieri M, et al. The Catalão I niobium deposit, central Brazil: resources, geology and pyrochlore chemistry[J]. Ore Geology Reviews, 2011, 41(1): 112-121. |

| 6 | 艾永亮, 范光. 世界主要烧绿石资源及选矿技术特点[J]. 中国矿业, 2015, 24(4): 130-133, 143. |

| Ai Y L, Fan G. Resources status and mineral processing of pyrochlore[J]. China Mining Magazine, 2015, 24(4): 130-133, 143. | |

| 7 | 程征, 伍喜庆, 杨平伟. 我国钽铌矿物资源概况及选矿技术现状与发展[J]. 中国矿业, 2013, 22(4): 151-157. |

| Cheng Z, Wu X Q, Yang P W. Overview of tantalum and niobium mineral resources in China and present status and development of beneficiation technologies[J]. China Mining Magazine, 2013, 22(4): 151-157. | |

| 8 | 刘玉宝. 浅议白云鄂博矿铌资源开发及展望[J]. 稀土信息, 2015, (9): 30-31. |

| Liu Y B. Development and prospect of niobium resources in Bayan Obo [J]. Rare Earth Information, 2015, (9): 30-31. | |

| 9 | 刘健, 凌明星, 李印, 等. 白云鄂博超大型REE-Nb-Fe矿床的稀土成矿模式综述[J]. 大地构造与成矿学, 2009, 33(2): 270-282. |

| Liu J, Ling M X, Li Y, et al. REE ore-forming models of giant Bayan Obo REE-Nb-Fe ore deposit: a review[J]. Geotectonica et Metallogenia, 2009, 33(2): 270-282. | |

| 10 | 屈曙光, 毛拥军, 钟祥. 低品位铌精矿二步电炉熔炼Nb-Fe合金[J]. 矿冶工程, 1997, 17(2): 46-49. |

| Qu S G, Mao Y J, Zhong X. Smelting Nb Fe alloy from low and medium grade niobium concentrate by two-stage electric furnace process[J]. Mining and Metallurgical Engineering, 1997, 17(2): 46-49. | |

| 11 | 《稀有金属手册》编辑委员会. 稀有金属手册: 下册[M]. 北京: 冶金工业出版社, 1995. |

| Editorial Committee of “Handbook of Rare Metals”. Handbook of Rare Metals: Volume Ⅱ[M]. Beijing: Metallurgical Industry Press, 1995. | |

| 12 | 李小钢, 徐广尧. 开发内蒙古铌资源的战略意义[C]//2012年中国稀土资源综合利用与环境保护研讨会. 北京: 冶金工业出版社, 2012: 5-15. |

| Li X G, Xu G Y. Strategic significance of developing Inner Mongolia's niobium resources[C]//2012 China Rare Earth Resources Comprehensive Utilization and Environmental Protection Seminar Proceedings. Beijing: Metallurgical Industry Press, 2012: 5-15. | |

| 13 | 许延辉. 白云鄂博稀土矿清洁冶金现状及研究进展[J]. 稀土信息, 2015, (11): 10-13. |

| Xu Y H. The status and research progress of clean metallurgy of Bayan Obo rare earth ore [J]. Rare Earth Information, 2015, (11): 10-13. | |

| 14 | 郭财胜, 李梅, 柳召刚, 等. 白云鄂博稀土、铌资源综合利用现状及新思路[J]. 稀土, 2014, 35(1): 96-100. |

| Guo C S, Li M, Liu Z G, et al. Present status and new ideas on utilization of Bayan Obo rare earth and niobium resource[J]. Chinese Rare Earths, 2014, 35(1): 96-100. | |

| 15 | 董一诚, 孟涛. 包头矿选冶新流程的评价[J]. 包钢科技, 1988, 14(3): 36-39. |

| Dong Y C, Meng T. Evaluation of the novel process of beneficiation and smelting of Baotou ore [J]. Science & Technology of Baotou Steel (Group) Corporation, 1988, 14(3): 36-39. | |

| 16 | 何旭初, 范鹏, 杨天钧, 等. 提高高炉冶炼含铌铁矿铌回收率的研究[J]. 湖南冶金, 1990, 18(4): 1-3, 24. |

| He X C, Fan P, Yang T J, et al. Study on improving the recovery rate of niobium in Nb-bearing iron ore by blast furnace smelting [J]. Hunan Metallurgy, 1990, 18(4): 1-3, 24. | |

| 17 | 何旭初, 杨永宜, 董一诚. 富铌炉料还原冶炼时铌进入铁相过程的研究[J]. 湖南冶金, 1994, 22(5): 8-12. |

| He X C, Yang Y Y, Dong Y C. Study on the process of niobium entering iron phase during reduction smelting of niobium-rich furnace charge [J]. Hunan Metallurgy, 1994, 22(5): 8-12. | |

| 18 | 何旭初, 杨永宜, 董一诚. 富铌炉料中锰含量对还原冶炼时铌收率影响的研究[J]. 湖南冶金, 1991, 19(3): 16-20. |

| He X C, Yang Y Y, Dong Y C. Study on the effect of manganese content in niobium-rich furnace charge on niobium yield during reduction smelting [J]. Hunan Metallurgy, 1991, 19(3): 16-20. | |

| 19 | 何旭初, 杨永宜, 董一诚. 渣中铌向铁液传质行为的研究[J]. 稀有金属与硬质合金, 1992, 20(3): 1-6. |

| He X C, Yang Y Y, Dong Y C. Study on the mass transfer behavior of niobium in slag to molten iron [J]. Rare Metals and Cemented Carbides, 1992, 20(3): 1-6. | |

| 20 | 何旭初, 范鹏, 周渝生, 等. 高炉中铌还原产生的碳化铌滞留带[J]. 北京科技大学学报, 1990, 12(6): 504-509. |

| He X C, Fan P, Zhou Y S, et al. Formation of NbC detained layer in blast furnace process for Nb-bearing iron ore[J]. Journal of University of Science and Technology Beijing, 1990, 12(6): 504-509. | |

| 21 | 张波, 刘承军, 姜茂发. 白云鄂博尾矿中有价金属氧化物的选择性还原与富集[C]//中国稀土学会2017学术年会. 北京, 2017. |

| Zhang B, Liu C J, Jiang M F. Selective reduction and enrichment of valuable metal oxides in Bayan Obo tailings[C]//2017 Academic Annual Meeting of China Rare Earth Society. Beijing, 2017. | |

| 22 | 马伟, 钟祥, 贺泽全, 等. “两步”还原法制备中级铌铁新工艺中铌收率的研究[J]. 稀有金属, 1996, 20(4): 254-258. |

| Ma W, Zhong X, He Z Q, et al. Study on the niobium yield in the new process of preparation of intermediate ferro-niobium by “two-Step” reduction [J]. Chinese Journal of Rare Metals, 1996, 20(4): 254-258 | |

| 23 | 高强. 白云鄂博含铌铁精矿富氢熔融还原实验研究[D]. 包头: 内蒙古科技大学, 2015. |

| Gao Q. Study on the process of Bayan Obo iron ore with rich hydrogen smelting reduction[D]. Baotou: Inner Mongolia University of Science & Technology, 2015. | |

| 24 | 宿洪亮. 白云鄂博含铌铁矿粉气基还原提铌过程中脱磷的研究[D]. 包头: 内蒙古科技大学, 2015. |

| Su H L. Study of dephosphorization on hydrogen selective-reduction of Bayan Obo niobium-bearing iron ore powder[D]. Baotou: Inner Mongolia University of Science & Technology, 2015. | |

| 25 | 任树波. 气基还原白云鄂博含铌铁矿过程硫的去除实验研究[D]. 包头: 内蒙古科技大学, 2015. |

| Ren S B. Study on removal sulfur in Bayan Obo niobium-containing iron ore gas based reduction process[D]. Baotou: Inner Mongolia University of Science & Technology, 2015. | |

| 26 | 邹廷信, 钟祥, 黄元琼, 等. 电弧炉两步法冶炼包头低品位铌精矿能量平衡[J]. 矿冶工程, 2000, 20(3): 51-54. |

| Zou T X, Zhong X, Huang Y Q, et al. Smelting low-grade niobium concentrate of Baotou by two-step arc-furnace method: energy equilibrium[J]. Mining and Metallurgical Engineering, 2000, 20(3): 51-54. | |

| 27 | 曹永仙, 徐永香. 一种处理炼锡炉渣的新方法[J]. 稀有金属与硬质合金, 1997, 25(3): 42-45. |

| Cao Y X, Xu Y X. A new technology for treatment of Sn smelter slag[J]. Rare Metals and Cemented Carbides, 1997, 25(3): 42-45. | |

| 28 | 李尚诣. 铌资源开发应用技术[M]. 北京: 冶金工业出版社, 1992: 234-236. |

| Li S Y. Development and Application Technologies of Niobium Resources [M]. Beijing: Metallurgical Industry Press, 1992: 234-236. | |

| 29 | 曹永仙, 高连让. 三相交流工频等离子体冶炼铌铁工艺[C]//第五届等离子体科学技术会议. 大连,1989. |

| Cao Y X, Gao L R. Three-phase AC power frequency plasma smelting ferro-niobium process[C]//The 5th Plasma Science and Technology Conference Proceedings. Dalian, 1989. | |

| 30 | 张波, 姜茂发. 利用白云鄂博含铌尾矿制备铌铁工艺的研究[J]. 工业加热, 2011, 40(3): 56-59. |

| Zhang B, Jiang M F. Study on preparation process of ferrocolubium utilizing niobium-bearing tailings from Bayan Obo ore[J]. Industrial Heating, 2011, 40(3): 56-59. | |

| 31 | 杨世山, 沈甦, 李治全, 等. 包头2号矿体选冶经济高效流程的开发[J]. 北京科技大学学报, 1995, 17(3): 218-223. |

| Yang S S, Shen S, Li Z Q, et al. New combined process of niobium enrichment from No.2 ore body of Baotou niobium-bearing iron ore[J]. Journal of University of Science and Technology Beijing, 1995, 17(3): 218-223. | |

| 32 | Zhang B, Fan Y, Liu C J, et al. Reduction characteristics of carbon-containing REE–Nb–Fe ore pellets[J]. Metals, 2018, 8(4): 204. |

| 33 | Liu M D, You Z X, Peng Z W, et al. Enrichment of rare earth and niobium from a REE-Nb-Fe associated ore via reductive roasting followed by magnetic separation[J]. JOM, 2016, 68(2): 567-576. |

| 34 | 方觉, 王志荣, 张家元, 等. 包头铌铁矿冶炼实验室研究[J]. 东北大学学报(自然科学版), 1996, 17(1): 35-40. |

| Fang J, Wang Z R, Zhang J Y, et al. Experiment research on smelting of Baotou niobium ore with high iron content[J]. Journal of Northeastern University (Natural Science), 1996, 17(1): 35-40. | |

| 35 | 李墨漪, 贾中帅, 周鑫, 等. 碳热还原白云鄂博稀选尾矿试验研究[J]. 包钢科技, 2018, 44(3): 34-38. |

| Li M Y, Jia Z S, Zhou X, et al. Experimental study on tailings after beneficiation of rare earth in Bayan Obo with carbon thermal reduction[J]. Science & Technology of Baotou Steel, 2018, 44(3): 34-38. | |

| 36 | 贾中帅, 王继平, 周鑫, 等. 微波碳热还原白云鄂博稀选尾矿试验[J]. 中国有色冶金, 2019, 48(6): 80-85. |

| Jia Z S, Wang J P, Zhou X, et al. Experimental study on carbothermal reduction of Bayan Obo RE-flotation tailings in microwave field[J]. China Nonferrous Metallurgy, 2019, 48(6): 80-85. | |

| 37 | 张家元, 方觉. 包头铌铁矿冶炼实验研究[J]. 湖南冶金, 2004, 32(2): 7-10, 14. |

| Zhang J Y, Fang J. Experiment research on smelting of Baotou niobium ore[J]. Hunan Metallurgy, 2004, 32(2): 7-10, 14. | |

| 38 | Pang Z D, Lv X, Ling J W, et al. Blast furnace ironmaking process with super high TiO2 in the slag: high-temperature structure of the slag[J]. Metallurgical and Materials Transactions B, 2020, 51(5): 2348-2357. |

| 39 | Qiu J Y, Liu C J. Subsolidus phase relations in the CaO–SiO2–Nb2O5–La2O3 quarternary system at 1273 K[J]. ISIJ International, 2017, 57(12): 2107-2114. |

| 40 | Zhang R, Wang Y, Zhao X, et al. Structure and viscosity of molten CaO-SiO2-FexO slag during the early period of basic oxygen steelmaking[J]. Metallurgical and Materials Transactions B, 2020, 51(5): 2021-2029. |

| 41 | Ma J, Li W, Fu G Q, et al. Viscous flow behaviors of Cr-bearing high-titanium melting slag with different MgO contents[J]. Steel Research International, 2020, 91(7): 1-8. |

| 42 | 陈衍彪. 白云鄂博铁精矿预还原烧结过程中磷的迁移行为[D]. 包头: 内蒙古科技大学, 2019. |

| Chen Y B. Phosphorus migration behavior in pre-reduction sintering process of Bayan Obo iron concentrate[D]. Baotou: Inner Mongolia University of Science & Technology, 2019. | |

| 43 | You Z M, Jung I H. Critical evaluation and thermodynamic optimization of the Fe-P system[J]. Metallurgical and Materials Transactions B, 2020, 51(6): 3108-3129. |

| 44 | Yang J G, Park J H. Distribution behavior of aluminum and titanium between nickel-based alloys and molten slags in the electro slag remelting (ESR) process[J]. Metallurgical and Materials Transactions B, 2017, 48(4): 2147-2156. |

| 45 | 李春龙, 李小钢, 徐广尧. 白云鄂博共伴生矿资源综合利用技术开发与产业化[J]. 稀土, 2015, 36(5): 151-158. |

| Li C L, Li X G, Xu G Y. Technology development and industrialization of resources comprehensive utilization of intergrowth and associated ore in Baiyun Obo[J]. Chinese Rare Earths, 2015, 36(5): 151-158. | |

| 46 | 赵磊, 赵增武, 李岩. 白云鄂博铌精矿碳还原直接合金化热力学研究[J]. 内蒙古科技大学学报, 2014, 33(3): 230-233, 248. |

| Zhao L, Zhao Z W, Li Y. Thermodynamic analysis of Nb2O5 direct alloying by carbon reducing agent[J]. Journal of Inner Mongolia University of Science and Technology, 2014, 33(3): 230-233, 248. | |

| 47 | 张波, 李春龙, 姜茂发. 熔分过程中铌、磷在渣铁两相间的分配比[J]. 东北大学学报(自然科学版), 2014, 35(7): 983-986. |

| 54 | Hou X Z, Yang Z F, Wang Z J, et al. Study on minerals composition characteristics of niobium concentrate and distribution of niobium in Bayan Obo[J]. Nonferrous Metals (Mineral Processing Section), 2018, (2): 4-7, 11. |

| 55 | 张轰玉, 杨占峰, 焦登铭, 等. 白云鄂博主矿霓石型铌稀土铁矿石中铌在独立矿物中的富集状态和分布规律研究[J]. 有色金属(选矿部分), 2020, (1): 6-12. |

| Zhang H Y, Yang Z F, Jiao D M, et al. Distribution regularity and enrichment state of niobium in independent minerals in aegirine-type niobium rare earth iron ore in Bayan Obo main mine[J]. Nonferrous Metals (Mineral Processing Section), 2020, (1): 6-12. | |

| 56 | 《有色金属提取治金手册》编辑委员会. 有色金属提取冶金手册: 稀有高熔点金属下[M]. 北京: 冶金工业出版社, 1999: 32-35. |

| Editorial Committee of “Manual for Extraction of Nonferrous Metals”. Nonferrous Metals Extraction Metallurgy Manual: Rare High Melting Point Metals(Volume 2)[M]. Beijing: Metallurgical Industry Press, 1999: 32-35. | |

| 57 | Krismer B, Hoppe A. Process for recovering niobium and/or tantalum compounds from such residues further containing complexes of uranium, thorium, titanium and/or rare earth metals: US4446116[P]. 1984-05-01. |

| 58 | Rodriguez M H, Rosales G D, Pinna E G, et al. Extraction of niobium and tantalum from ferrocolumbite by hydrofluoric acid pressure leaching[J]. Hydrometallurgy, 2015, 156: 17-20. |

| 59 | Kasikova N I, Kasikov A G, Korotkova G V. Extraction of niobium from hydrochloric solutions with tertiary amines in aprotic diluents[J]. Russian Journal of Applied Chemistry, 2010, 83(3): 424-429. |

| 60 | El Hussaini O M, Rice N M. Liquid-liquid extraction of niobium and tantalum from aqueous sulphate/fluoride solutions by a tertiary amine[J]. Hydrometallurgy, 2004, 72(3/4): 259-267. |

| 61 | 韩建设, 周勇. 钽铌萃取分离工艺与设备进展[J]. 稀有金属与硬质合金, 2004, 32(2): 15-20. |

| Han J S, Zhou Y. Development of Ta & Nb extraction and stripping technology and equipment[J]. Rare Metals and Cemented Carbides, 2004, 32(2): 15-20. | |

| 62 | 匡国珍, 周火根, 张浩, 等. 仲辛醇-HF-H2SO4体系制取超高纯氧化钽和超高纯氧化铌[J]. 稀有金属与硬质合金, 2005, 33(2): 1-3, 8. |

| Kuang G Z, Zhou H G, Zhang H, et al. Production of ultra-pure tantalum oxide/ultra-pure niobium oxide from CH3(CH2)5 CHOHCH3-HF-H2SO4 system[J]. Rare Metals and Cemented Carbides, 2005, 33(2): 1-3, 8. | |

| 63 | Swain N, Mishra S. A review on the recovery and separation of rare earths and transition metals from secondary resources[J]. Journal of Cleaner Production, 2019, 220: 884-898. |

| 64 | El-Hazek M N, Amer T E, Abu El-Azm M G, et al. Liquid-liquid extraction of tantalum and niobium by octanol from sulfate leach liquor[J]. Arabian Journal of Chemistry, 2012, 5(1): 31-39. |

| 65 | Gupta C K, Suri A K. Extractive Metallurgy of Niobium[M]. London: CRC Press, 1994: 98-127. |

| 66 | El-Hussaini O M, El-Hakam Mahdy M A. Extraction of niobium and tantalum from nitrate and sulfate media by using MIBK[J]. Mineral Processing and Extractive Metallurgy Review, 2002, 22(4/5/6): 633-650. |

| 67 | Nete M, Purcell W, Nel J T. Non-fluoride dissolution of tantalum and niobium oxides and their separation using ion exchange[J]. Hydrometallurgy, 2017, 173: 192-198. |

| 68 | Rodriguez M, Rivarola J, del C Ruiz M. The effects of carboxylic acid addition on hydrofluoric acid autoclave leaching of a ferrocolumbite[J]. Hydrometallurgy, 2004, 74(1/2): 39-46. |

| 69 | Majima H, Awakura Y, Mashima M, et al. Dissolution of columbite and tantalite in acidic fluoride media[J]. Metallurgical Transactions B, 1988, 19(3): 355-363. |

| 70 | Yang X L, Huang W F, Fang Q, et al. Pressure leaching of manganotantalite by sulfuric acid using ammonium fluoride as an assistant reagent[J]. Hydrometallurgy, 2018, 175: 348-353. |

| 71 | El-Hussaini O M, Mahdy M A. Sulfuric acid leaching of Kab Amiri niobium-tantalum bearing minerals, Central Eastern Desert, Egypt[J]. Hydrometallurgy, 2002, 64(3): 219-229. |

| 72 | Balinski A, Atanasova P, Wiche O, et al. Recovery of REEs, Zr(+Hf), Mn and Nb by H2SO4 leaching of eudialyte concentrate[J]. Hydrometallurgy, 2019, 186: 176-186. |

| 73 | Yang X L, Zhang J W, Fang X H, et al. Kinetics of pressure leaching of niobium ore by sulfuric acid[J]. International Journal of Refractory Metals and Hard Materials, 2014, 45: 218-222. |

| 74 | 杨小红. 含铌稀有金属矿中铌的分选与综合利用工艺研究[D]. 湘潭: 湘潭大学, 2014. |

| Yang X H. Separation of niobium and comprehensive utilization of some rare metal ore[D]. Xiangtan: Xiangtan University, 2014. | |

| 75 | 刘勇, 刘牡丹, 刘珍珍. 复杂稀有金属伴生矿富集渣提取稀土和铌的工艺研究[J]. 稀有金属与硬质合金, 2015, 43(1): 21-25. |

| Liu Y, Liu M D, Liu Z Z. Technological study on rare earth and niobium extraction from tailings of beneficiated complex rare metal associated ore[J]. Rare Metals and Cemented Carbides, 2015, 43(1): 21-25. | |

| 76 | Toromanoff I, Habashi F. Hydrometallurgical production of technical niobium oxide from pyrochlore concentrates[J]. Journal of the Less Common Metals, 1983, 91(1): 71-82. |

| 77 | 秦希黎. KOH碱性水热法提铌基础研究[D]. 沈阳: 东北大学, 2015. |

| Qin X L. Fundamental research on niobium extraction by KOH alkaline hydrothermal process[D]. Shenyang: Northeastern University, 2015. | |

| 78 | Zhou H M, Zheng S L, Zhang Y. Leaching of a low-grade niobium-tantalum ore by highly concentrated caustic potash solution[J]. Hydrometallurgy, 2005, 80(1/2): 83-89. |

| 79 | 王中磊, 段赟, 沈少波, 等. 氯化法从包头铁矿尾矿中提取铌和稀土的研究[J]. 中国稀土学报, 2008, 26: 501-505. |

| Wang Z L, Duan Y, Shen S B, et al. Study on the extraction of niobium and rare earths from tailings of Baotou iron ores by carbochlorination[J]. Journal of the Chinese Rare Earth Society, 2008, 26: 501-505. | |

| 80 | 于秀兰. 碳热氯化法提取包钢选矿厂尾矿中有价元素可行性分析[J]. 化工进展, 2009, 28(S1): 544-547. |

| Yu X L. Feasibility analysis of extracting valuable elements from BaoSteel concentrator tailing by carbothermic chlorination [J]. Chemical Industry and Engineering Progress, 2009, 28(S1): 544-547. | |

| 81 | 于秀兰, 王之昌, 韩跃新, 等. AlCl3脱氟-碳热氯化法提取包钢选矿厂尾矿中稀土[J]. 稀土, 2006, 27(4): 30-34. |

| Yu X L, Wang Z C, Han Y X, et al. Extraction of rare earths from Baogang tailings by carbochlorination reaction taking AlCl3 as defluorinating agent[J]. Chinese Rare Earths, 2006, 27(4): 30-34. | |

| 82 | Zhang L Q, Wang Z C, Tong S X, et al. Rare earth extraction from bastnaesite concentrate by stepwise carbochlorination-chemical vapor transport-oxidation[J]. Metallurgical and Materials Transactions B, 2004, 35(2): 217-221. |

| 83 | 于秀兰, 王之昌, 韩跃新, 等. 碳热氯化法分解包钢选矿厂尾矿工艺的研究[J]. 金属矿山, 2007, (9): 113-115, 130. |

| Yu X L, Wang Z C, Han Y X, et al. Study on process of decomposition of BaoSteel concentrator tailing by carbothermic chlorination[J]. Metal Mine, 2007, (9): 113-115, 130. | |

| 84 | Wang Z C, Lei P X, Chi M Y, et al. Rare earth extraction and separation from mixed bastnaesite-monazite concentrate by stepwise carbochlorination-chemical vapor transport[J]. Metallurgical and Materials Transactions B, 2002, 33(5): 661-668. |

| 85 | 于秀兰, 郎晓川, 王之昌. MgO焙烧-碳热氯化法提取包钢选矿厂尾矿中的稀土[J]. 中国稀土学报, 2009, 27(2): 309-312. |

| Yu X L, Lang X C, Wang Z C. Extraction of rare earths from Baotou concentrating mill's tailing by MgO roasting and carbochlorination reaction[J]. Journal of the Chinese Rare Earth Society, 2009, 27(2): 309-312. | |

| 86 | Wang X H, Zheng S L, Xu H B, et al. Leaching of niobium and tantalum from a low-grade ore using a KOH roast-water leach system[J]. Hydrometallurgy, 2009, 98(3/4): 219-223. |

| 87 | 杨秀丽. 难分解钽铌矿低碱分解新工艺及应用基础研究[D]. 昆明: 昆明理工大学, 2013. |

| Yang X L. Fundamental research on novel technology and application of low alkali decomposition of refractory tantalum and niobium ore[D]. Kunming: Kunming University of Science and Technology, 2013. | |

| 88 | 胡根火. 钽铌湿法冶金分离方法评述[J]. 稀有金属与硬质合金, 2015, 43(1): 29-32. |

| Hu G H. Review of tantalum-niobium hydrometallurgical separation processes[J]. Rare Metals and Cemented Carbides, 2015, 43(1): 29-32. | |

| 89 | 李光伟, 许延辉, 赵文怡, 等. 富铌渣硫酸浸出液中铌的分离工艺研究[J]. 稀土, 2013, 34(4): 57-62. |

| Li G W, Xu Y H, Zhao W Y, et al. Study on separation process of Nb in sulfuric acid leaching solution of Nb-rich slag[J]. Chinese Rare Earths, 2013, 34(4): 57-62. | |

| 90 | 杨秀丽, 张军伟, 方夕辉. 低品位铌矿硫酸焙烧: 草酸浸出回收铌[J]. 有色金属工程, 2014, 4(3): 48-50. |

| Yang X L, Zhang J W, Fang X H. Recovery of niobium from low-grade niobium ore by sulfuric acid roasting-oxalic acid leaching [J]. Nonferrous Metals Engineering, 2014, 4(3): 48-50. | |

| 91 | 张德文, 赵文怡, 许延辉, 等. 活化焙烧硫酸分解提取富铌渣中铌、钛、钪和稀土[J]. 稀土, 2013, 34(6): 56-60. |

| Zhang D W, Zhao W Y, Xu Y H, et al. Extracting Ni, Ti, Sc and RE from niobium-enriched slag by CaCl2 roasing and H2SO4 decomposition method[J]. Chinese Rare Earths, 2013, 34(6): 56-60. | |

| 92 | Gao W C, Wen J K, Wu B, et al. Extraction of niobium, yttrium, and cerium from a low-grade niobium-bearing ore by roasting (NH4)2SO4-Na2SO4-H2SO4 system[J]. Rare Metals, 2014, 33(6): 754-760. |

| 93 | Zhang B, Liu C J, Li C L, et al. Separation and recovery of valuable metals from low-grade REE-Nb-Fe ore[J]. International Journal of Mineral Processing, 2016, 150: 16-23. |

| [1] | Runmiao GAO, Mengjie SONG, Enyuan GAO, Long ZHANG, Xuan ZHANG, Keke SHAO, Zekang ZHEN, Zhengyong JIANG. Review on greenhouse gas reduction related to refrigerants in cold chain [J]. CIESC Journal, 2023, 74(S1): 1-7. |

| [2] | Congqi HUANG, Yimei WU, Jianye CHEN, Shuangquan SHAO. Simulation study of thermal management system of alkaline water electrolysis device for hydrogen production [J]. CIESC Journal, 2023, 74(S1): 320-328. |

| [3] | Xiaoxiong FAN, Lifang HAO, Chuigang FAN, Songgeng LI. Study on the catalytic denitrification performance of low-temperature NH3-SCR over LaMnO3/biochar catalyst [J]. CIESC Journal, 2023, 74(9): 3821-3830. |

| [4] | Baiyu YANG, Yue KOU, Juntao JIANG, Yali ZHAN, Qinghong WANG, Chunmao CHEN. Chemical conversion of dissolved organic matter in petrochemical spent caustic along a wet air oxidation pretreatment process [J]. CIESC Journal, 2023, 74(9): 3912-3920. |

| [5] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [6] | Longyi LYU, Wenbo JI, Muda HAN, Weiguang LI, Wenfang GAO, Xiaoyang LIU, Li SUN, Pengfei WANG, Zhijun REN, Guangming ZHANG. Enhanced anaerobic removal of halogenated organic pollutants by iron-based conductive materials: research progress and future perspectives [J]. CIESC Journal, 2023, 74(8): 3193-3202. |

| [7] | Jiayi ZHANG, Jiali HE, Jiangpeng XIE, Jian WANG, Yu ZHAO, Dongqiang ZHANG. Research progress of pervaporation technology for N-methylpyrrolidone recovery in lithium battery production [J]. CIESC Journal, 2023, 74(8): 3203-3215. |

| [8] | Ruihang ZHANG, Pan CAO, Feng YANG, Kun LI, Peng XIAO, Chun DENG, Bei LIU, Changyu SUN, Guangjin CHEN. Analysis of key parameters affecting product purity of natural gas ethane recovery process via ZIF-8 nanofluid [J]. CIESC Journal, 2023, 74(8): 3386-3393. |

| [9] | Kexin HUANG, Tong LI, Anqi LI, Mei LIN. Mode decomposition of flow field in T-junction with rotating impeller [J]. CIESC Journal, 2023, 74(7): 2848-2857. |

| [10] | Yuying GUO, Jiaqiang JING, Wanni HUANG, Ping ZHANG, Jie SUN, Yu ZHU, Junxuan FENG, Hongjiang LU. Water-lubricated drag reduction and pressure drop model modification for heavy oil pipeline [J]. CIESC Journal, 2023, 74(7): 2898-2907. |

| [11] | Qiyu ZHANG, Lijun GAO, Yuhang SU, Xiaobo MA, Yicheng WANG, Yating ZHANG, Chao HU. Recent advances in carbon-based catalysts for electrochemical reduction of carbon dioxide [J]. CIESC Journal, 2023, 74(7): 2753-2772. |

| [12] | Yanmei ZHANG, Tao YUAN, Jiang LI, Yajie LIU, Zhanxue SUN. Study on the construction of high-efficient SRB mixed microflora and its performance under acid stress [J]. CIESC Journal, 2023, 74(6): 2599-2610. |

| [13] | Nan HU, Demin TAO, Zhaolan YANG, Xuebing WANG, Xiangxu ZHANG, Yulong LIU, Dexin DING. Remediation of percolate water from uranium tailings reservoir by coupling iron-carbon micro-electrolysis and sulfate reducing bacteria [J]. CIESC Journal, 2023, 74(6): 2655-2667. |

| [14] | Tan ZHANG, Guang LIU, Jinping LI, Yuhan SUN. Performance regulation strategies of Ru-based nitrogen reduction electrocatalysts [J]. CIESC Journal, 2023, 74(6): 2264-2280. |

| [15] | Ruiheng WANG, Pinjing HE, Fan LYU, Hua ZHANG. Parameter comparison and optimization of three solid-liquid separation methods for washed air pollution control residues from municipal solid waste incinerators [J]. CIESC Journal, 2023, 74(4): 1712-1723. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||