CIESC Journal ›› 2021, Vol. 72 ›› Issue (11): 5883-5892.DOI: 10.11949/0438-1157.20211129

• Process safety • Previous Articles

Fan LI1( ),Aolin JIANG2,Haolin YANG1(

),Aolin JIANG2,Haolin YANG1( ),Xiaojun ZENG1,Liqiao JIANG1,Xiaohan WANG1

),Xiaojun ZENG1,Liqiao JIANG1,Xiaohan WANG1

Received:2021-08-06

Revised:2021-09-01

Online:2021-11-12

Published:2021-11-05

Contact:

Haolin YANG

李凡1( ),姜奥林2,杨浩林1(

),姜奥林2,杨浩林1( ),曾小军1,蒋利桥1,汪小憨1

),曾小军1,蒋利桥1,汪小憨1

通讯作者:

杨浩林

作者简介:李凡(1992—),男,博士,基金资助:CLC Number:

Fan LI, Aolin JIANG, Haolin YANG, Xiaojun ZENG, Liqiao JIANG, Xiaohan WANG. Study on enhancing flame stability using zirconia-based coating walls[J]. CIESC Journal, 2021, 72(11): 5883-5892.

李凡, 姜奥林, 杨浩林, 曾小军, 蒋利桥, 汪小憨. 氧化锆基涂层壁面改善火焰稳定性研究[J]. 化工学报, 2021, 72(11): 5883-5892.

Add to citation manager EndNote|Ris|BibTeX

| 涂层壁面材料 | 晶格常数a/b/c | OA/(OL+OA) | OL/(OL+OA) | 还原温度 /K | 耗氢量/(μmol/g) | |

|---|---|---|---|---|---|---|

| ZrO2 | 喷涂前 | 5.13/5.19/5.30 | 51.7% | 48.3% | 641.7 | 203.5 |

| 喷涂后 | 5.06/5.06/5.06 | 81.6% | 18.4% | 660.8 | 416.9 | |

| ZrO2+Al2O3 | 喷涂前 | 5.14/5.20/5.31 | 60.2% | 39.8% | 639.3 | 189.4 |

| 喷涂后 | 3.58/3.58/5.17 | 59.9% | 40.1% | 630.1 | 209.4 | |

Table 1 Analysis of lattice parameter, oxygen distribution, reduction temperature and hydrogen consumption of the coating materials before and after spraying

| 涂层壁面材料 | 晶格常数a/b/c | OA/(OL+OA) | OL/(OL+OA) | 还原温度 /K | 耗氢量/(μmol/g) | |

|---|---|---|---|---|---|---|

| ZrO2 | 喷涂前 | 5.13/5.19/5.30 | 51.7% | 48.3% | 641.7 | 203.5 |

| 喷涂后 | 5.06/5.06/5.06 | 81.6% | 18.4% | 660.8 | 416.9 | |

| ZrO2+Al2O3 | 喷涂前 | 5.14/5.20/5.31 | 60.2% | 39.8% | 639.3 | 189.4 |

| 喷涂后 | 3.58/3.58/5.17 | 59.9% | 40.1% | 630.1 | 209.4 | |

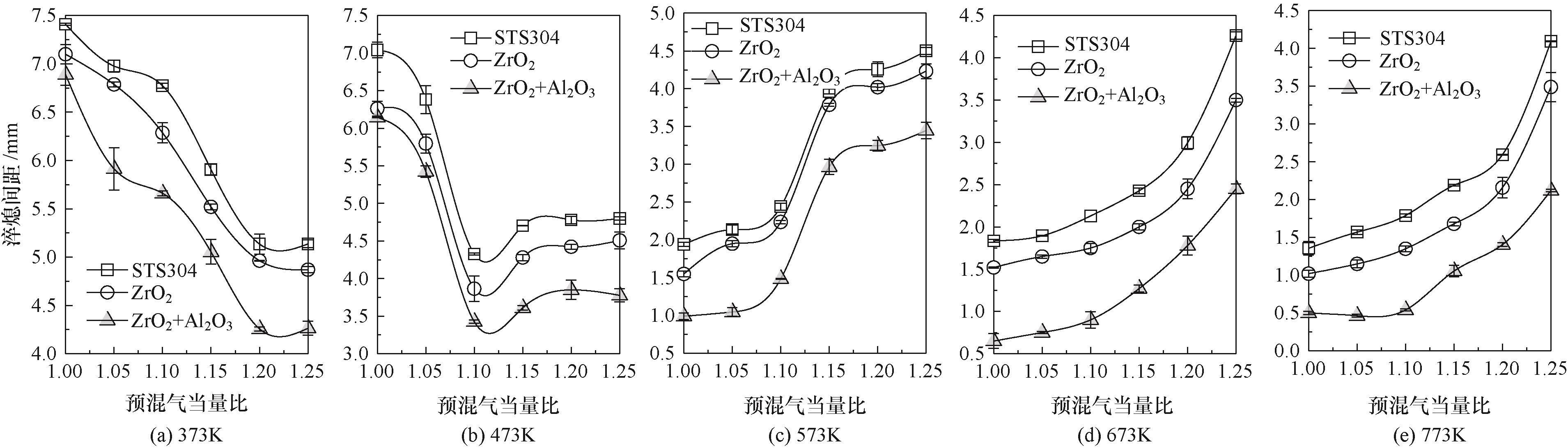

Fig.4 Variation of quenching distance with coating material at the equivalence ratio of 1.00—1.25 under the wall temperature conditions of 373K (a), 473K (b), 573K (c), 673K (d), and 773K (e)

涂层粉末 材料 | Tt/K | ρ/ (kg/m3) | cp/ (J/(g·K) ) | α/ (cm2/s) | λe/ (W/(m·K) ) |

|---|---|---|---|---|---|

| ZrO2 | 373 | 3.32 | 0.52 | 0.00288 | 0.497 |

| 1073 | 3.32 | 0.94 | 0.00183 | 0.377 | |

| ZrO2+Al2O3 | 373 | 3.10 | 0.94 | 0.00334 | 0.973 |

| 1073 | 3.10 | 1.24 | 0.00189 | 0.727 |

Table 2 Thermophysical parameters of the different coating materials measured by plate heat flow method

涂层粉末 材料 | Tt/K | ρ/ (kg/m3) | cp/ (J/(g·K) ) | α/ (cm2/s) | λe/ (W/(m·K) ) |

|---|---|---|---|---|---|

| ZrO2 | 373 | 3.32 | 0.52 | 0.00288 | 0.497 |

| 1073 | 3.32 | 0.94 | 0.00183 | 0.377 | |

| ZrO2+Al2O3 | 373 | 3.10 | 0.94 | 0.00334 | 0.973 |

| 1073 | 3.10 | 1.24 | 0.00189 | 0.727 |

| 板材材料类型 | λc/(W/(m·K)) | |

|---|---|---|

| 低温环境 | 高温环境 | |

| ZrO2 | 1.98 | 2.25 |

| Al2O3 | 29.73 | 7.25 |

| ZrO2+Al2O3 | 9.69 | 4.37 |

Table 3 Theoretical calculation of the thermal conductivities for different coating plate materials

| 板材材料类型 | λc/(W/(m·K)) | |

|---|---|---|

| 低温环境 | 高温环境 | |

| ZrO2 | 1.98 | 2.25 |

| Al2O3 | 29.73 | 7.25 |

| ZrO2+Al2O3 | 9.69 | 4.37 |

| 1 | Ju Y G, Maruta K. Microscale combustion: technology development and fundamental research[J]. Progress in Energy and Combustion Science, 2011, 37(6): 669-715. |

| 2 | 曹海亮, 年志远, 杨浩林, 等. 平板狭缝间C1~C4烷烃/空气预混射流火焰的燃烧特性[J]. 化工学报, 2016, 67(11): 4609-4614. |

| Cao H L, Nian Z Y, Yang H L, et al. Combustion characteristics of premixed C1—C4 alkane jet flames between two parallel walls[J]. CIESC Journal, 2016, 67(11): 4609-4614. | |

| 3 | Häber T, Suntz R. Effect of different wall materials and thermal-barrier coatings on the flame-wall interaction of laminar premixed methane and propane flames[J]. International Journal of Heat and Fluid Flow, 2018, 69: 95-105. |

| 4 | Li F, Yang H L, Zhang J Q, et al. OH-PLIF investigation of Y2O3-ZrO2 coating improving flame stability in a narrow channel[J]. Chemical Engineering Journal, 2021, 405: 126708. |

| 5 | Federici J A, Vlachos D G. A computational fluid dynamics study of propane/air microflame stability in a heat recirculation reactor[J]. Combustion and Flame, 2008, 153(1/2): 258-269. |

| 6 | 万建龙, 范爱武, 刘毅, 等. 固体材料对微型钝体燃烧器吹熄极限的影响[J]. 化工学报, 2014, 65(3): 1012-1017. |

| Wan J L, Fan A W, Liu Y, et al. Effects of solid material on blow-off limit in micro bluff body combustor[J]. CIESC Journal, 2014, 65(3): 1012-1017. | |

| 7 | Kang X, Veeraragavan A. Experimental investigation of flame stability limits of a mesoscale combustor with thermally orthotropic walls[J]. Applied Thermal Engineering, 2015, 85: 234-242. |

| 8 | Sui R. Catalytic microreactors for power generation and hetero-/homogeneous combustion of hydrogen/air over platinum[D]. Zurich: Sciences of Eth Zurich, 2017. |

| 9 | Saiki Y, Suzuki Y. Effect of wall surface reaction on a methane-air premixed flame in narrow channels with different wall materials[J]. Proceedings of the Combustion Institute, 2013, 34(2): 3395-3402. |

| 10 | Strassacker C, Bykov V, Maas U. REDIM reduced modeling of quenching at a cold wall including heterogeneous wall reactions[J]. International Journal of Heat and Fluid Flow, 2018, 69: 185-193. |

| 11 | Strassacker C, Bykov V, Maas U. Reduced modeling of flame-wall-interactions of premixed isooctane-air systems including detailed transport and surface reactions[J]. Proceedings of the Combustion Institute, 2021, 38(1): 1063-1070. |

| 12 | 欧阳静, 周正, 伦惠林, 等. 氧化锆(ZrO2)的热、化学性质与应用[J]. 中国材料进展, 2014, 33(6): 365-375. |

| Ouyang J, Zhou Z, Lun H L, et al. Thermal and chemical properties of zirconia (ZrO2) and their applications[J]. Materials China, 2014, 33(6): 365-375. | |

| 13 | Clarke D R. Materials selection guidelines for low thermal conductivity thermal barrier coatings[J]. Surface and Coatings Technology, 2003, 163/164: 67-74. |

| 14 | Li G R, Li W, Zhang M H, et al. Characterization and catalytic application of homogeneous nano-composite oxides ZrO2-Al2O3[J]. Catalysis Today, 2004, 93/94/95: 595-601. |

| 15 | Yang X C, Riehemann W, Dubiel M, et al. Nanoscaled ceramic powders produced by laser ablation[J]. Materials Science and Engineering: B, 2002, 95(3): 299-307. |

| 16 | Abbas S M, Elayaperumal A. Experimental investigation on the effect of ceramic coating on engine performance and emission characteristics for cleaner production[J]. Journal of Cleaner Production, 2019, 214: 506-513. |

| 17 | Aydın S, Sayın C. Impact of thermal barrier coating application on the combustion, performance and emissions of a diesel engine fueled with waste cooking oil biodiesel-diesel blends[J]. Fuel, 2014, 136(15): 334-340. |

| 18 | Liang B, Zhang G, Liao H L, et al. Friction and wear behavior of ZrO2-Al2O3 composite coatings deposited by air plasma spraying: correlation with physical and mechanical properties[J]. Surface and Coatings Technology, 2009, 203(20/21): 3235-3242. |

| 19 | Li F, Yang H L, Zeng X J, et al. Enhancing the flame stability in a slot burner using yttrium-doped zirconia coating[J]. Fuel, 2020, 262(1): 116502. |

| 20 | Zhu J, van Ommen J G, Knoester A, et al. Effect of surface composition of yttrium-stabilized zirconia on partial oxidation of methane to synthesis gas[J]. Journal of Catalysis, 2005, 230(2): 291-300. |

| 21 | Wu Y, Chen J J, Hu W, et al. Phase transformation and oxygen vacancies in Pd/ZrO2 for complete methane oxidation under lean conditions[J]. Journal of Catalysis, 2019, 377: 565-576. |

| 22 | 李淑莲, 陈光文, 孙继良, 等. CeO2-ZrO2复合氧化物对金属蜂窝整体催化剂性能的影响[J]. 催化学报, 2002, 23(4): 341-344. |

| Li S L, Chen G W, Sun J L, et al. Effect of CeO2-ZrO2 composite oxide on performance of catalyst with metal monolith substrate[J]. Chinese Journal of Catalysis, 2002, 23(4): 341-344. | |

| 23 | Kozlov A I, Kim D H, Yezerets A, et al. Effect of preparation method and redox treatment on the reducibility and structure of supported ceria-zirconia mixed oxide[J]. Journal of Catalysis, 2002, 209(2): 417-426. |

| 24 | Milcarek R J, Garrett M J, Wang K, et al. Micro-tubular flame-assisted fuel cells running methane[J]. International Journal of Hydrogen Energy, 2016, 41(45): 20670-20679. |

| 25 | 曾文, 解茂昭. 催化燃烧中表面反应-气相反应间相互作用及其对均质压燃发动机着火特性的影响[J]. 化工学报, 2006, 57(12): 2878-2884. |

| Zeng W, Xie M Z. Interactions between surface reactions and gas phase reactions in catalytic combustion and their influence on ignition of HCCI engine[J]. CIESC Journal, 2006, 57(12): 2878-2884. | |

| 26 | Kim K T, Lee D H, Kwon S. Effects of thermal and chemical surface-flame interaction on flame quenching[J]. Combustion and Flame, 2006, 146(1/2): 19-28. |

| 27 | 喻健良, 胡春明, 李江涛, 等. 平板阻火单元温度变化对火焰淬熄的影响[J]. 燃烧科学与技术, 2007, 13(1): 1-4. |

| Yu J L, Hu C M, Li J T, et al. Influence of parallel plate temperature on flame quenching[J]. Journal of Combustion Science and Technology, 2007, 13(1): 1-4. | |

| 28 | Wang J F, Carson J K, North M F, et al. A new approach to modelling the effective thermal conductivity of heterogeneous materials[J]. International Journal of Heat and Mass Transfer, 2006, 49(17/18): 3075-3083. |

| 29 | Ronney P D. Analysis of non-adiabatic heat-recirculating combustors[J]. Combustion and Flame, 2003, 135(4): 421-439. |

| 30 | Veeraragavan A, Cadou C P. Flame speed predictions in planar micro/mesoscale combustors with conjugate heat transfer[J]. Combustion and Flame, 2011, 158(11): 2178-2187. |

| 31 | 黄夏, 黄勇. 本生灯预混火焰淬熄距离实验分析[J]. 北京航空航天大学学报, 2015, 41(8): 1513-1519. |

| Huang X, Huang Y. Experimental analysis of wall quenching distance of a premixed Bunsen flame[J]. Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(8): 1513-1519. | |

| 32 | Yamamoto K, Ozeki M, Hayashi N, et al. Burning velocity and OH concentration in premixed combustion[J]. Proceedings of the Combustion Institute, 2009, 32(1): 1227-1235. |

| [1] | Xiaoshan DONG, Jian LI, Beibei YAN, Guanyi CHEN. Research progress of perovskite catalysts in thermochemical utilization of biomass [J]. CIESC Journal, 2022, 73(2): 504-520. |

| [2] | LIU Yifeng, SHEN Benxian, PI Zhipeng, CHEN Hua, ZHAO Jigang. Oxidation transferring mechanism of SO2 in FCC flue gas over CeO2 surface [J]. CIESC Journal, 2016, 67(12): 5015-5023. |

| [3] | SHEN Shikong, LI Ranjia, ZHOU Jiping, YU Changchun. Selective Oxidation of Light Hydrocarbons Using Lattice Oxygen Instead of Molecular Oxygen [J]. , 2003, 11(6): 649-655. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||