CIESC Journal ›› 2025, Vol. 76 ›› Issue (10): 5322-5335.DOI: 10.11949/0438-1157.20250230

• Energy and environmental engineering • Previous Articles Next Articles

Shixue WANG1,2( ), Zaihui YU1, Yu ZHU1,2, Jiting JIAN1

), Zaihui YU1, Yu ZHU1,2, Jiting JIAN1

Received:2025-03-10

Revised:2025-03-27

Online:2025-11-25

Published:2025-10-25

Contact:

Shixue WANG

通讯作者:

王世学

作者简介:王世学(1964—), 男, 博士, 教授, wangshixue_64@tju.edu.cn

基金资助:CLC Number:

Shixue WANG, Zaihui YU, Yu ZHU, Jiting JIAN. Temperature distribution characteristics and improvement of indirect internal reforming planar solid oxide fuel cells[J]. CIESC Journal, 2025, 76(10): 5322-5335.

王世学, 于在辉, 朱禹, 蹇季廷. 间接内重整板式固体氧化物燃料电池的温度分布特性及改进[J]. 化工学报, 2025, 76(10): 5322-5335.

Add to citation manager EndNote|Ris|BibTeX

| 参数 | 数值 |

|---|---|

| 阴/阳极流道宽度(w2)/mm | 2 |

| 阴/阳极流道高度(hcha,a/hcha,c) /mm | 1 |

| 流道长度(l) /mm | 100 |

| 重整流道宽度(w1) /mm | 4 |

| 重整流道高度(href) /mm | 4 |

| 阳极厚度(ha) /mm | 0.15 |

| 电解质厚度(hel) /mm | 0.1 |

| 阴极厚度(hc) /mm | 0.1 |

| 阳极/电解质/阴极宽度(w1) /mm | 4 |

| 连接体宽度(w1) /mm | 4 |

| 连接体高度(hcon,a/hcon,c)/mm | 2 |

Table 1 Geometric model parameters

| 参数 | 数值 |

|---|---|

| 阴/阳极流道宽度(w2)/mm | 2 |

| 阴/阳极流道高度(hcha,a/hcha,c) /mm | 1 |

| 流道长度(l) /mm | 100 |

| 重整流道宽度(w1) /mm | 4 |

| 重整流道高度(href) /mm | 4 |

| 阳极厚度(ha) /mm | 0.15 |

| 电解质厚度(hel) /mm | 0.1 |

| 阴极厚度(hc) /mm | 0.1 |

| 阳极/电解质/阴极宽度(w1) /mm | 4 |

| 连接体宽度(w1) /mm | 4 |

| 连接体高度(hcon,a/hcon,c)/mm | 2 |

| 边界条件 | 数值 |

|---|---|

| 重整流道入口气体组分(xfuel,in)(N2∶CH4∶H2O∶H2) | 0.225∶0.25∶0.5∶0.025 |

| 重整流道入口气体流速(ufuel,in) /(m/s) | ux =0.05,uy =uz =0 |

| 阴极入口气体组分(xair,in)(N2∶O2) | 79∶21 |

| 阴极入口流速(uair,in) /(m/s) | ux =1.5,uy =uz =0 |

| 阳/阴极出口压力(pout)/atm | 1 |

| 重整气体与阴极气体入口温度(T)/K | 1073 |

Table 2 Model boundary condition intent

| 边界条件 | 数值 |

|---|---|

| 重整流道入口气体组分(xfuel,in)(N2∶CH4∶H2O∶H2) | 0.225∶0.25∶0.5∶0.025 |

| 重整流道入口气体流速(ufuel,in) /(m/s) | ux =0.05,uy =uz =0 |

| 阴极入口气体组分(xair,in)(N2∶O2) | 79∶21 |

| 阴极入口流速(uair,in) /(m/s) | ux =1.5,uy =uz =0 |

| 阳/阴极出口压力(pout)/atm | 1 |

| 重整气体与阴极气体入口温度(T)/K | 1073 |

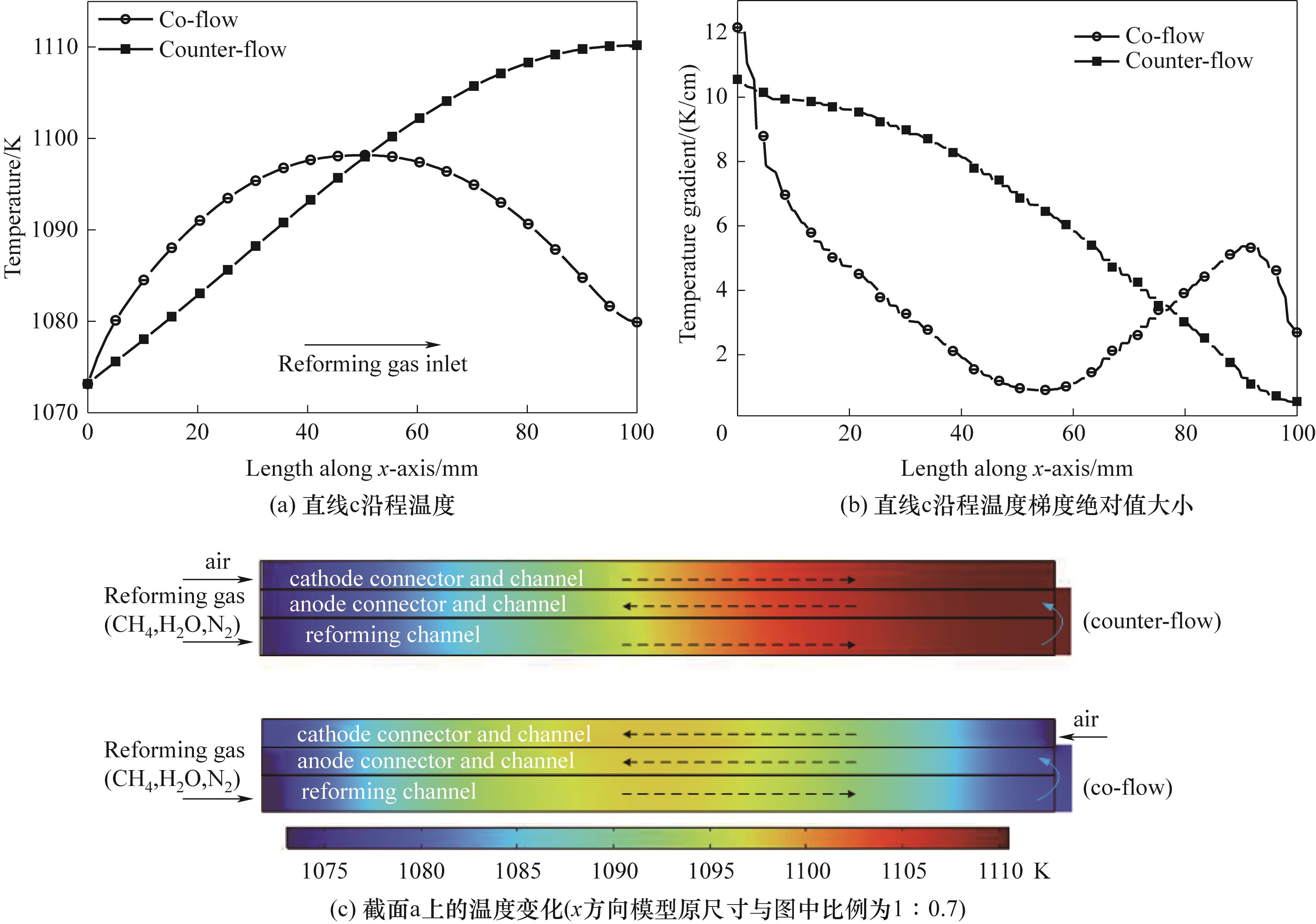

Fig.6 Variations in temperature and temperature gradient within battery under different flow configurations (T=1073 K,ufuel=0.05 m/s, uair=1.5 m/s,VCell=0.7 V,p=1 atm)

| 负载方式 | 最高温/K | 最低温/K | 最大温差/K | 最大温度梯度/(K/cm) |

|---|---|---|---|---|

| 均匀负载 | 1098.2 | 1073.15 | 25.0 | 12.16 |

| 两分区梯度负载 | 1091.1 | 1073.15 | 17.9 | 7.17 |

| 三分区梯度负载 | 1083.3 | 1073.15 | 10.1 | 5.12 |

Table 3 Statistics of maximum temperature, minimum temperature, maximum temperature difference, and temperature gradient within IIR-SOFC under different loading methods of reforming channel

| 负载方式 | 最高温/K | 最低温/K | 最大温差/K | 最大温度梯度/(K/cm) |

|---|---|---|---|---|

| 均匀负载 | 1098.2 | 1073.15 | 25.0 | 12.16 |

| 两分区梯度负载 | 1091.1 | 1073.15 | 17.9 | 7.17 |

| 三分区梯度负载 | 1083.3 | 1073.15 | 10.1 | 5.12 |

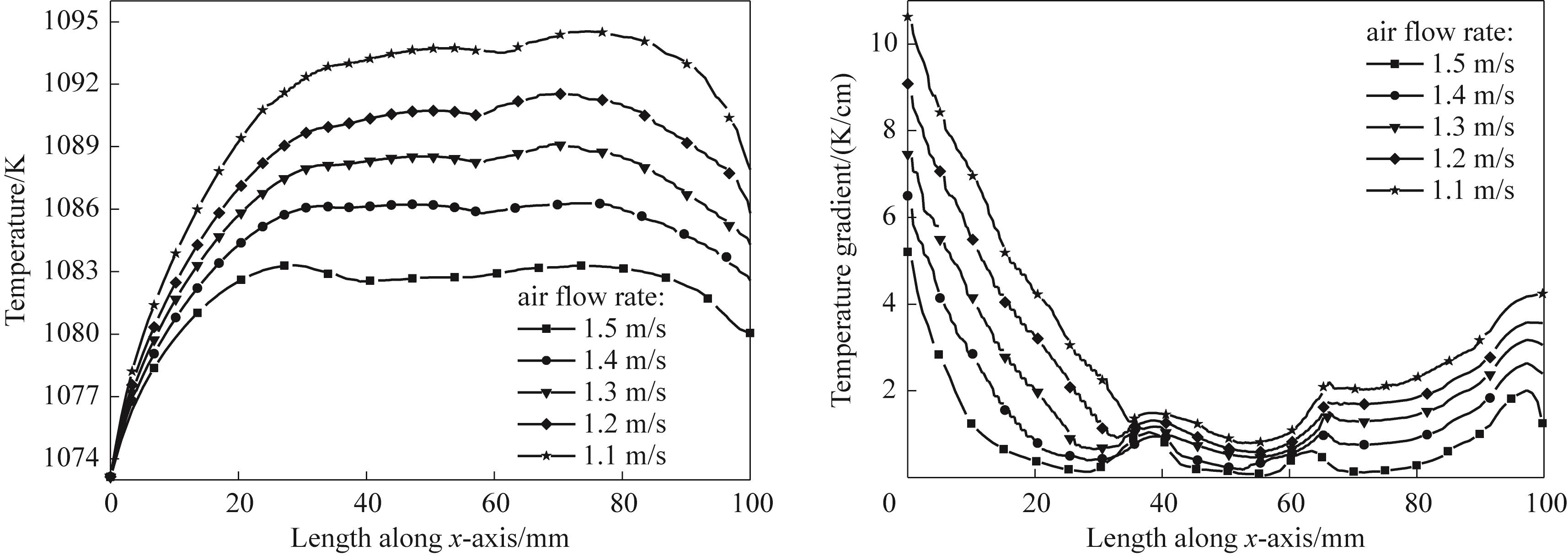

Fig.16 Temperature and temperature gradient distribution along Line c under different air flow velocities in three tiered loading configuration(T=1073 K,ufuel=0.05 m/s,VCell=0.7 V, p=1 atm)

| 空气流速/(m/s) | 最高温/K | 最低温/K | 最大温差/K | 最大温度梯度/(K/cm) |

|---|---|---|---|---|

| 1.1 | 1094.5 | 1073.15 | 21.35 | 10.63 |

| 1.2 | 1091.6 | 1073.15 | 18.45 | 9.08 |

| 1.3 | 1089.1 | 1073.15 | 15.9 | 7.48 |

| 1.4 | 1086.3 | 1073.15 | 13.15 | 6.50 |

| 1.5 | 1083.3 | 1073.15 | 10.1 | 5.12 |

Table 4 Statistics of maximum temperature, minimum temperature, maximum temperature difference and temperature gradient within battery under different air flow velocities in three tiered gradient loading configuration

| 空气流速/(m/s) | 最高温/K | 最低温/K | 最大温差/K | 最大温度梯度/(K/cm) |

|---|---|---|---|---|

| 1.1 | 1094.5 | 1073.15 | 21.35 | 10.63 |

| 1.2 | 1091.6 | 1073.15 | 18.45 | 9.08 |

| 1.3 | 1089.1 | 1073.15 | 15.9 | 7.48 |

| 1.4 | 1086.3 | 1073.15 | 13.15 | 6.50 |

| 1.5 | 1083.3 | 1073.15 | 10.1 | 5.12 |

| [1] | Bilal Hanif M, Motola M, Qayyum S, et al. Recent advancements, doping strategies and the future perspective of perovskite-based solid oxide fuel cells for energy conversion[J]. Chemical Engineering Journal, 2022, 428: 132603. |

| [2] | de Arespacochaga N, Valderrama C, Mesa C, et al. Biogas deep clean-up based on adsorption technologies for solid oxide fuel cell applications[J]. Chemical Engineering Journal, 2014, 255: 593-603. |

| [3] | Arteaga-Perez L E, Casas Y, Peralta L M, et al. An auto-sustainable solid oxide fuel cell system fueled by bio-ethanol. Process simulation and heat exchanger network synthesis[J]. Chemical Engineering Journal, 2009, 150(1): 242-251. |

| [4] | Xie Y Y, Ding H P, Xue X J. Direct methane fueled solid oxide fuel cell model with detailed reforming reactions[J]. Chemical Engineering Journal, 2013, 228: 917-924. |

| [5] | Zhang J G, Zhang D, Liu T, et al. An efficient and durable solid oxide fuel cell integrated with coal gasification system[J]. International Journal of Hydrogen Energy, 2023, 48(100): 40029-40036. |

| [6] | Wang J, Zhang D, Liu T, et al. Self-assembled FeRu bimetallic nanocatalysts for efficient and durable mutual CO-CO2 conversion in a reversible solid oxide electrochemical cell[J]. Science China Materials, 2024, 67(5): 1471-1480. |

| [7] | Janardhanan V M, Heuveline V, Deutschmann O. Performance analysis of a SOFC under direct internal reforming conditions[J]. Journal of Power Sources, 2007, 172(1): 296-307. |

| [8] | Sciazko A, Komatsu Y, Nakamura A, et al. 3D microstructures of solid oxide fuel cell Ni-YSZ anodes with carbon deposition[J]. Chemical Engineering Journal, 2023, 460: 141680. |

| [9] | Tran D L, Tran Q T, Sakamoto M, et al. Modelling of CH4 multiple-reforming within the Ni-YSZ anode of a solid oxide fuel cell[J]. Journal of Power Sources, 2017, 359: 507-519. |

| [10] | Fu Q R, Li Z Y, Liu Z J, et al. Performance study of solid oxide fuel cell with Ni-foam indirect internal reformer: intrinsic reforming kinetics and temperature uniformity[J]. Chemical Engineering Journal, 2023, 457: 141170. |

| [11] | Kim-Lohsoontorn P, Priyakorn F, Wetwatana U, et al. Modelling of a tubular solid oxide fuel cell with different designs of indirect internal reformer[J]. Journal of Energy Chemistry, 2014, 23(2): 251-263. |

| [12] | Dokmaingam P, Irvine J T S, Assabumrungrat S, et al. Modeling of IT-SOFC with indirect internal reforming operation fueled by methane: effect of oxygen adding as autothermal reforming[J]. International Journal of Hydrogen Energy, 2010, 35(24): 13271-13279. |

| [13] | Najafi Maharluie H, Rahmani M. Mathematical modeling of solid oxide fuel cell performance with indirect internal reforming and thermal interaction analysis[J]. Energy Conversion and Management, 2024, 316: 118842. |

| [14] | Nagata S, Momma A, Kato T, et al. Numerical analysis of output characteristics of tubular SOFC with internal reformer[J]. Journal of Power Sources, 2001, 101(1): 60-71. |

| [15] | Nishino T, Szmyd J S. Numerical analysis of a cell-based indirect internal reforming tubular SOFC operating with biogas[J]. Journal of Fuel Cell Science and Technology, 2010, 7(5): 051004. |

| [16] | Xu J G, Froment G F. Methane steam reforming, methanation and water-gas shift(Ⅰ): Intrinsic kinetics[J]. AIChE Journal, 1989, 35(1): 88-96. |

| [17] | Akkaya A V. Electrochemical model for performance analysis of a tubular SOFC[J]. International Journal of Energy Research, 2007, 31(1): 79-98. |

| [18] | Wang J S, Wang S X, Zhu Y, et al. Numerical investigation of parameter distributions in high-temperature PEMFCs under various cooling surface temperature gradients[J]. Fuel, 2024, 367: 131554. |

| [19] | Yuan J L, Huang Y, Sundén B, et al. Analysis of parameter effects on chemical reaction coupled transport phenomena in SOFC anodes[J]. Heat and Mass Transfer, 2009, 45(4): 471-484. |

| [20] | Le Bars M, Worster M G. Interfacial conditions between a pure fluid and a porous medium: implications for binary alloy solidification[J]. Journal of Fluid Mechanics, 2006, 550: 149. |

| [21] | Krishna R, Wesselingh J A. The Maxwell-Stefan approach to mass transfer[J]. Chemical Engineering Science, 1997, 52(6): 861-911. |

| [22] | Butcher H, Quenzel C J E, Breziner L, et al. Design of an annular microchannel reactor (AMR) for hydrogen and/or syngas production via methane steam reforming[J]. International Journal of Hydrogen Energy, 2014, 39(31): 18046-18057. |

| [23] | Wilhite B A, Breziner L, Mettes J, et al. Radial microchannel reactors (RMRs) for efficient and compact steam reforming of methane: experimental demonstration and design simulations[J]. Energy & Fuels, 2013, 27(8): 4403-4410. |

| [24] | Haberman B A, Young J B. Three-dimensional simulation of chemically reacting gas flows in the porous support structure of an integrated-planar solid oxide fuel cell[J]. International Journal of Heat and Mass Transfer, 2004, 47(17/18): 3617-3629. |

| [25] | Ferguson J R, Fiard J M, Herbin R. Three-dimensional numerical simulation for various geometries of solid oxide fuel cells[J]. Journal of Power Sources, 1996, 58(2): 109-122. |

| [26] | Ahmad Hajimolana S, Hussain M A, Daud W M A W, et al. Mathematical modeling of solid oxide fuel cells: a review[J]. Renewable and Sustainable Energy Reviews, 2011, 15(4): 1893-1917. |

| [27] | Khazaee I, Rava A. Numerical simulation of the performance of solid oxide fuel cell with different flow channel geometries[J]. Energy, 2017, 119: 235-244. |

| [28] | Newman J S, Balsara N P. Electrochemical Systems[M]. 4th ed. Hoboken, NJ: John Wiley & Sons, 2021. |

| [29] | Bove R, Ubertini S. Modeling Solid Oxide Fuel Cells: Methods, Procedures and Techniques[M]. Berlin: Springer, 2008. |

| [30] | Patcharavorachot Y, Arpornwichanop A, Chuachuensuk A. Electrochemical study of a planar solid oxide fuel cell: role of support structures[J]. Journal of Power Sources, 2008, 177(2): 254-261. |

| [31] | Milewski J. Advanced Methods of Solid Oxide Fuel Cell Modeling[M]. London: Springer, 2011. |

| [32] | Todd B, Young J B. Thermodynamic and transport properties of gases for use in solid oxide fuel cell modelling[J]. Journal of Power Sources, 2002, 110(1): 186-200. |

| [33] | Oliveira E L G, Grande C A, Rodrigues A E. Steam methane reforming in a Ni/Al2O3 catalyst: kinetics and diffusional limitations in extrudates[J]. The Canadian Journal of Chemical Engineering, 2009, 87(6): 945-956. |

| [34] | Singhal Subhash, Kendall Kevin. High Temperature Solid Oxide Fuel Cells: Fundamentals, Design, and Applicatons[M]. Oxford, UK: Elsevier, 2003. |

| [35] | Liese E A, Gemmen R S. Performance comparison of internal reforming against external reforming in a solid oxide fuel cell, gas turbine hybrid system[J]. Journal of Engineering for Gas Turbines and Power, 2005, 127(1): 86-90. |

| [1] | Wei SU, Dahai ZHAO, Xu JIN, Zhongyan LIU, Jing LI, Xiaosong ZHANG. Delaying condensation frosting using biphilic surfaces coupled with spatial control of liquid desiccant [J]. CIESC Journal, 2025, 76(S1): 140-151. |

| [2] | Haolei DUAN, Haoyuan CHEN, Kunfeng LIANG, Lin WANG, Bin CHEN, Yong CAO, Chenguang ZHANG, Shuopeng LI, Dengyu ZHU, Yaru HE, Dapeng YANG. Performance analysis and comprehensive evaluation of thermal management system schemes with low GWP refrigerants [J]. CIESC Journal, 2025, 76(S1): 54-61. |

| [3] | Songyuan GUO, Xiaoqing ZHOU, Wubing MIAO, Bin WANG, Rui ZHUAN, Qingtai CAO, Chengcheng CHEN, Guang YANG, Jingyi WU. Numerical study on characteristics of pressurized discharge in liquid oxygen tank equipped with porous plate in the ascent period of rocket [J]. CIESC Journal, 2025, 76(S1): 62-74. |

| [4] | Junpeng WANG, Jiaqi FENG, Enbo ZHANG, Bofeng BAI. Study on flow and cavitation characteristic in zigzag and array labyrinth valve core structures [J]. CIESC Journal, 2025, 76(S1): 93-105. |

| [5] | Zixiang ZHAO, Zhongdi DUAN, Haoran SUN, Hongxiang XUE. Numerical modelling of water hammer induced by two phase flow with large temperature difference [J]. CIESC Journal, 2025, 76(S1): 170-180. |

| [6] | Hao HUANG, Wen WANG, Longkun HE. Simulation and analysis on precooling process of membrane LNG carriers [J]. CIESC Journal, 2025, 76(S1): 187-194. |

| [7] | Siyuan WANG, Guoqiang LIU, Tong XIONG, Gang YAN. Characteristics of non-uniform wind velocity distribution in window air conditioner axial fans and their impact on optimizing condenser circuit optimization [J]. CIESC Journal, 2025, 76(S1): 205-216. |

| [8] | Qingtai CAO, Songyuan GUO, Jianqiang LI, Zan JIANG, Bin WANG, Rui ZHUAN, Jingyi WU, Guang YANG. Numerical study on influence of perforated plate on retention performance of liquid oxygen tank under negative gravity [J]. CIESC Journal, 2025, 76(S1): 217-229. |

| [9] | Jiuchun SUN, Yunlong SANG, Haitao WANG, Hao JIA, Yan ZHU. Study on influence of jet flow on slurry transport characteristics in slurry chamber of shield tunneling machines [J]. CIESC Journal, 2025, 76(S1): 246-257. |

| [10] | Ting HE, Shuyang HUANG, Kun HUANG, Liqiong CHEN. Research on the coupled process of natural gas chemical absorption decarbonization and high temperature heat pump based on waste heat utilization [J]. CIESC Journal, 2025, 76(S1): 297-308. |

| [11] | Tengfei ZHU, Ye LIU. Performance analysis of low GWP refrigerant used in new energy vehicle air conditioning [J]. CIESC Journal, 2025, 76(S1): 343-350. |

| [12] | Di WU, Bin HU, Jiatong JIANG. Experimental study and application analysis of R1233zd(E) high temperature heat pump [J]. CIESC Journal, 2025, 76(S1): 377-383. |

| [13] | Kaiyuan YANG, Xizhong CHEN. Comparison of discrete element method and finite-discrete element method for simulation of agglomerate breakage [J]. CIESC Journal, 2025, 76(9): 4398-4411. |

| [14] | Sheng CHEN, Zizheng LI, Chao MIAO, Xuegang BAI, Fei LI, Jiaxuan LIU, Tiantian LI, Shuang YANG, Rongrong LYU, Jiangyun WANG. Three-dimensional CFD simulation of non-uniform diffusion characteristic of high-risk chlorine gas in large-scale dense scene [J]. CIESC Journal, 2025, 76(9): 4630-4643. |

| [15] | Yiyang LIU, Zhixiang XING, Yecheng LIU, Ming PENG, Yuyang LI, Yunhao LI, Ningzhou SHEN. Numerical simulation study on the leakage diffusion characteristics and safety monitoring of liquid hydrogen in hydrogen refueling stations [J]. CIESC Journal, 2025, 76(9): 4694-4708. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||