Qiyuan ZHENG( ), Fei SHI(

), Fei SHI( ), Xiaowang REN, Weifan WANG, Yi YANG, Ye YUAN(

), Xiaowang REN, Weifan WANG, Yi YANG, Ye YUAN( ), Zhi WANG(

), Zhi WANG( )

)

Received:2025-09-08

Revised:2025-10-22

Published:2025-10-23

Contact:

Ye YUAN, Zhi WANG

郑淇元( ), 时飞(

), 时飞( ), 任肖旺, 王卫凡, 杨毅, 原野(

), 任肖旺, 王卫凡, 杨毅, 原野( ), 王志(

), 王志( )

)

通讯作者:

原野,王志

作者简介:郑淇元(2002—),男,硕士研究生,2024207070@tju.edu.cn基金资助:CLC Number:

Qiyuan ZHENG, Fei SHI, Xiaowang REN, Weifan WANG, Yi YANG, Ye YUAN, Zhi WANG. Preparation process development of UiO-66-NH2@PVAm mixed matrix membranes for CO2 capture[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251009.

郑淇元, 时飞, 任肖旺, 王卫凡, 杨毅, 原野, 王志. 用于CO2捕集的UiO-66-NH2@PVAm混合基质膜制备工艺开发[J]. 化工学报, DOI: 10.11949/0438-1157.20251009.

Add to citation manager EndNote|Ris|BibTeX

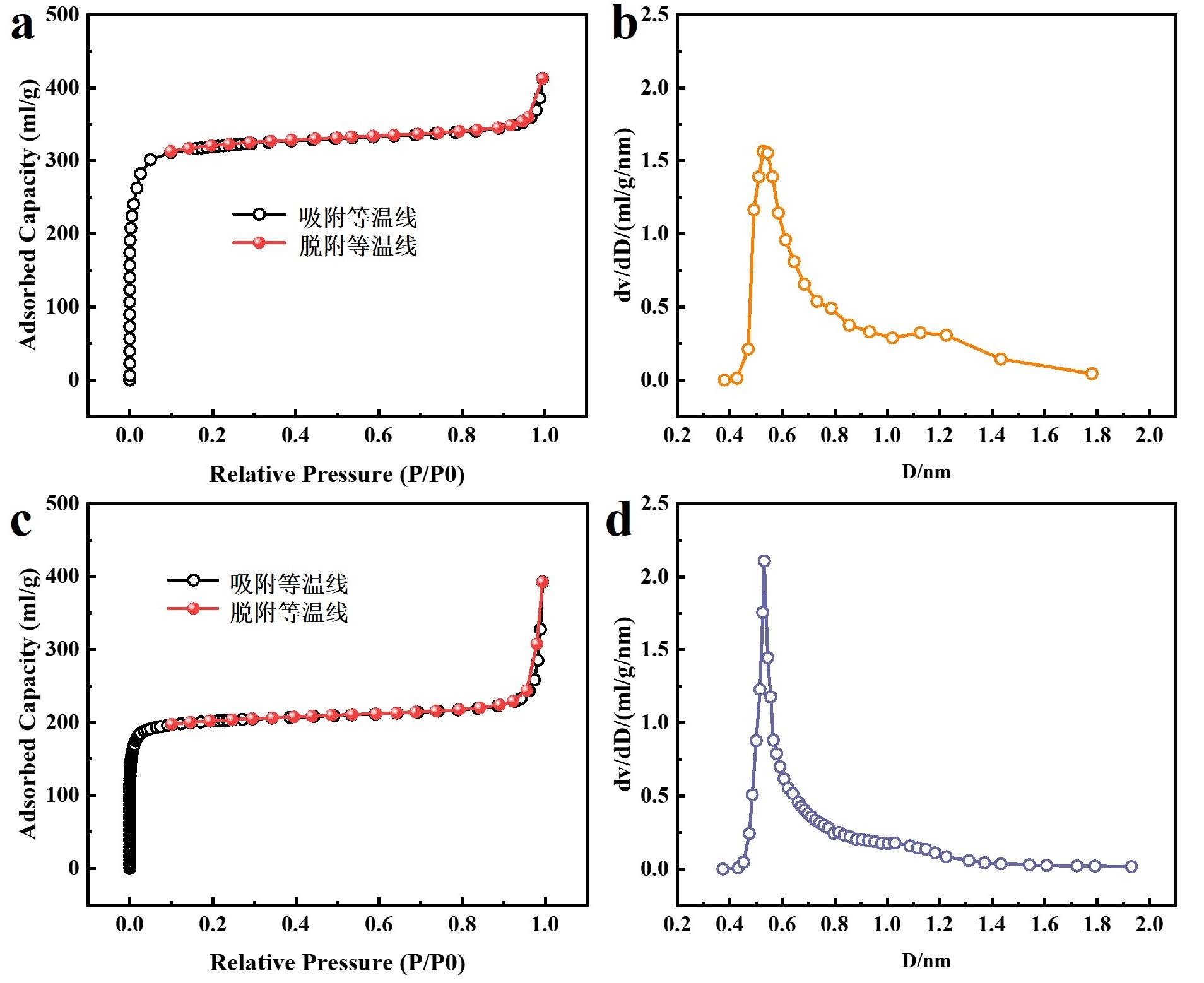

Fig.5 Adsorption-desorption isotherms of nano-fillers at 77K: (a) UiO-66-NH2; (c) UiO-66-NH2@PVAm and pore size distribution map: (b) UiO-66-NH2; (d) UiO-66-NH2@PVAm

| 样品 | BET比表面积/ (m2·g-1) | 总孔体积/ (cm3·g-1) | 平均微孔孔径/ (nm) |

|---|---|---|---|

| UiO-66-NH2 | 973.35 | 0.61 | 0.68 |

| UiO-66-NH2@PVAm | 631.71 | 0.55 | 0.62 |

Table 1 The pore parameters of UiO-66-NH2 and UiO-66-NH2@PVAm

| 样品 | BET比表面积/ (m2·g-1) | 总孔体积/ (cm3·g-1) | 平均微孔孔径/ (nm) |

|---|---|---|---|

| UiO-66-NH2 | 973.35 | 0.61 | 0.68 |

| UiO-66-NH2@PVAm | 631.71 | 0.55 | 0.62 |

| 填料类型 | 流体力学粒径/(nm) | Zeta电位/(mV) | 粘度/(mPa·s) | 接触角/(°) |

|---|---|---|---|---|

| UiO-66-NH2 | 441.20 | 20.70 | 73.06 | 64.06 |

| UiO-66-NH2@PVAm | 376.60 | 42.50 | 83.41 | 59.69 |

Table 2 The physical parameters of the dispersion and coating solution prepared by UiO-66-NH2 and UiO-66-NH2@PVAm

| 填料类型 | 流体力学粒径/(nm) | Zeta电位/(mV) | 粘度/(mPa·s) | 接触角/(°) |

|---|---|---|---|---|

| UiO-66-NH2 | 441.20 | 20.70 | 73.06 | 64.06 |

| UiO-66-NH2@PVAm | 376.60 | 42.50 | 83.41 | 59.69 |

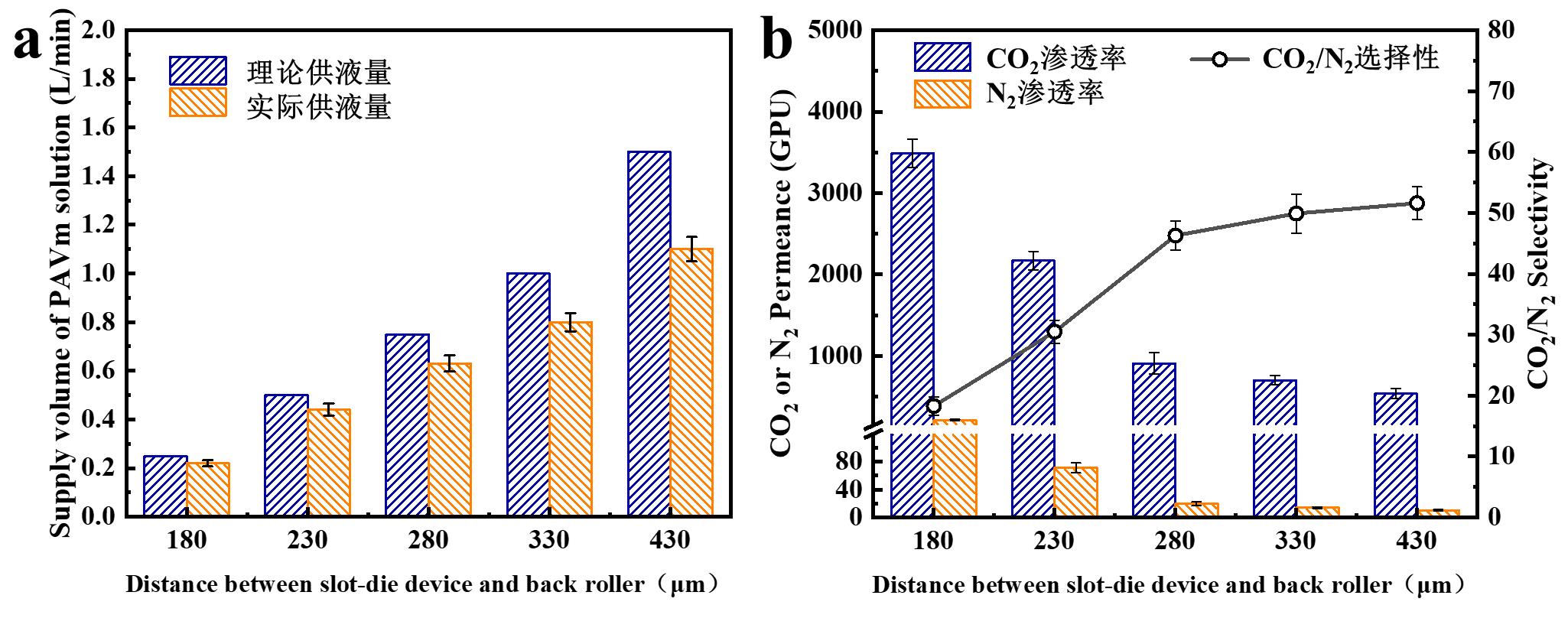

Fig.7 (a) The effects of slit gap distance on the supply volume of the slot-die coating device and (b) the CO2/N2 separation performance of PVAm TFC membranes (feed gas: CO2:N2=15:85, humidified, 0.5 MPa, 25°C)

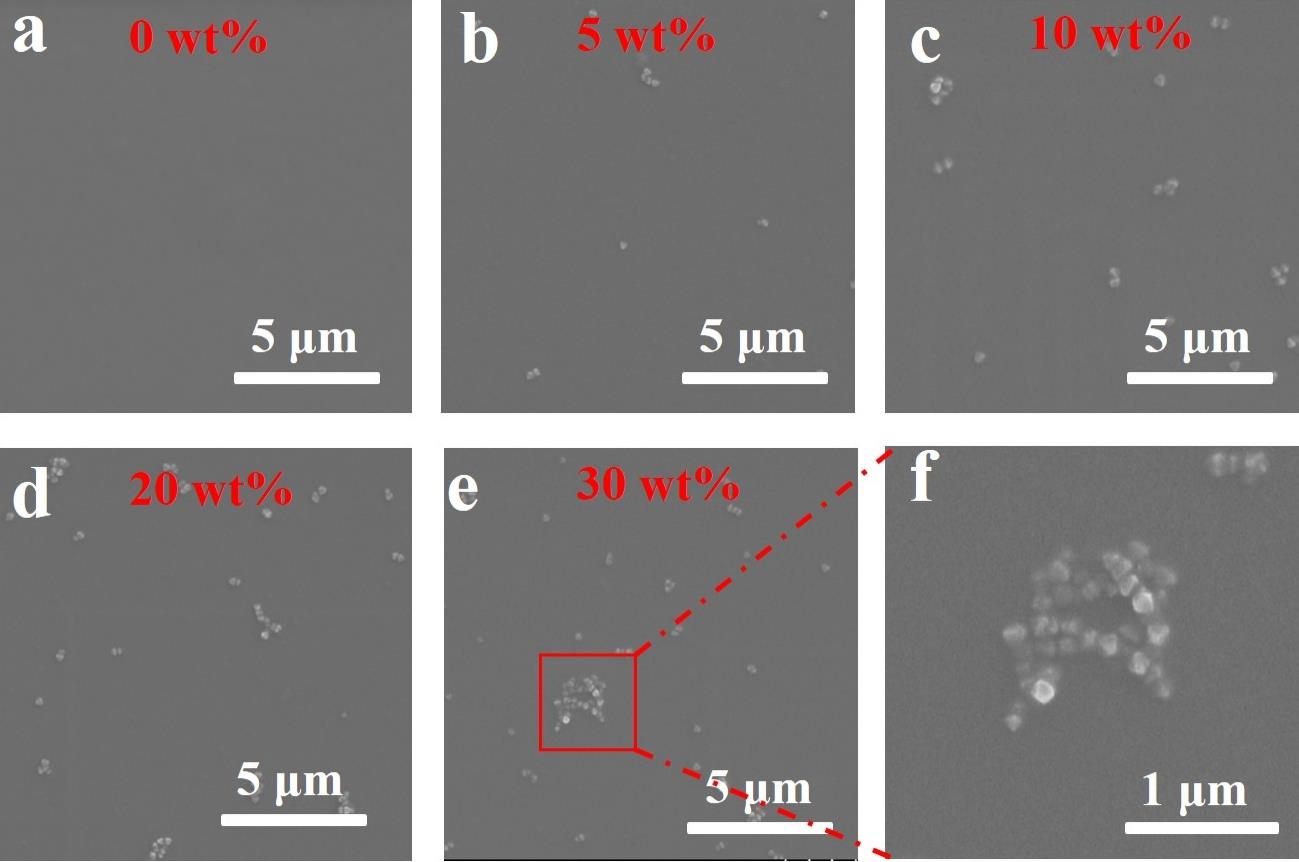

Fig.9 The surface SEM images of MMMs prepared with different UiO-66-NH2@PVAm loading: (a) 0 wt%, (b) 5 wt%, (c) 10 wt%, (d) 20 wt% and (e) 30 wt%; (f) the high-resolution SEM image of MMMs with 30 wt% UiO-66-NH2@PVAm loading

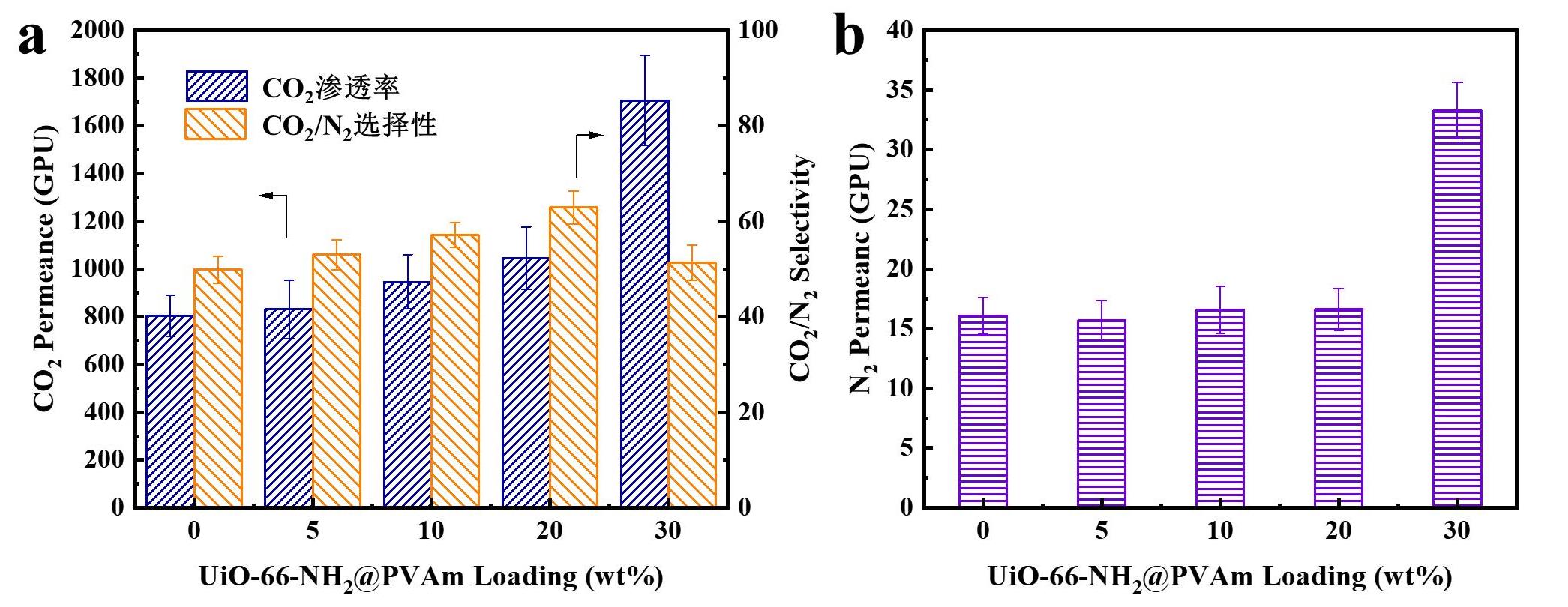

Fig.10 (a) The CO2/N2 separation performance and (b) the N2 permeance of MMMs prepared by slot-die coating process (feed gas: CO2:N2=15:85, humidified, 0.5 MPa, 25℃)

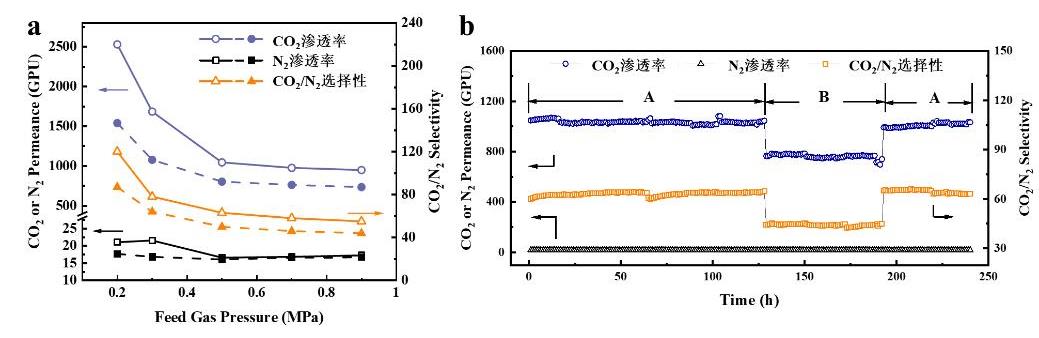

Fig.11 (a) The effects of feed gas pressure on the CO2/N2 separation performance of PVAm/UiO-66-NH2@PVAm(20) membrane (hollow symbol) and PVAm membrane (solid symbol) (feed gas: CO2:N2=15:85, humidified, 25°C); (b) Long-term performance stability of PVAm/UiO-66-NH2@PVAm(20) membrane (feed gas A: CO2:N2=15:85, feed gas B: 10 ppm SO2+30 ppm NO2+15 ppm CO+15% CO2+N2 balance, humidified, 0.5 MPa, 25℃)

| 膜 | 原料气条件 | 规模 | Ref. | ||

|---|---|---|---|---|---|

| Pebax-C60(OH)24/PAN | 0.5 MPa,35 ℃ 混合气,RH=0 | 实验室规模 | 388 | 41 | [ |

| Pebax-MXene | 0.5 MPa,25 ℃ 混合气,RH=0 | 实验室规模 | 1360 | 31.4 | [ |

| PEG-SiO2 | 0.45 MPa,35 ℃ 纯气,RH=0 | 实验室规模 | 1300 | 27 | [ |

| MKP-PVAm/mPSf | 0.5 MPa,25 ℃ 混合气,RH=100% | 实验室规模 | 823 | 242 | [ |

| PVAm/HNTs | 0.2 MPa,25 ℃ 混合气,RH=100% | 实验室规模 | 179 | 127.9 | [ |

| Pebax/UiO-66-NH2 | 0.4 MPa,35 ℃ 混合气,RH=0 | 实验室规模 | 277 | 44.6 | [ |

| GO MMMs | 0.2 MPa,25 ℃ 混合气,RH=0 | 中试规模 | 1200 | 54 | [ |

| PVAm/UiO-66-NH2@PVAm(20) | 0.2 MPa,25 ℃ 混合气,RH=100% | 工业规模 | 2528 | 120 | 本工作 |

| PVAm/UiO-66-NH2@PVAm(20) | 0.5 MPa,25 ℃ 混合气,RH=100% | 工业规模 | 1046 | 63 | 本工作 |

Table 3 Comparison of the CO2/N2 separation performance of the MMMs produced in this chapter with the membranes reported in the literatures

| 膜 | 原料气条件 | 规模 | Ref. | ||

|---|---|---|---|---|---|

| Pebax-C60(OH)24/PAN | 0.5 MPa,35 ℃ 混合气,RH=0 | 实验室规模 | 388 | 41 | [ |

| Pebax-MXene | 0.5 MPa,25 ℃ 混合气,RH=0 | 实验室规模 | 1360 | 31.4 | [ |

| PEG-SiO2 | 0.45 MPa,35 ℃ 纯气,RH=0 | 实验室规模 | 1300 | 27 | [ |

| MKP-PVAm/mPSf | 0.5 MPa,25 ℃ 混合气,RH=100% | 实验室规模 | 823 | 242 | [ |

| PVAm/HNTs | 0.2 MPa,25 ℃ 混合气,RH=100% | 实验室规模 | 179 | 127.9 | [ |

| Pebax/UiO-66-NH2 | 0.4 MPa,35 ℃ 混合气,RH=0 | 实验室规模 | 277 | 44.6 | [ |

| GO MMMs | 0.2 MPa,25 ℃ 混合气,RH=0 | 中试规模 | 1200 | 54 | [ |

| PVAm/UiO-66-NH2@PVAm(20) | 0.2 MPa,25 ℃ 混合气,RH=100% | 工业规模 | 2528 | 120 | 本工作 |

| PVAm/UiO-66-NH2@PVAm(20) | 0.5 MPa,25 ℃ 混合气,RH=100% | 工业规模 | 1046 | 63 | 本工作 |

| [1] | CO2 emissions in 2023[R]. International Energy Agency, 2023. |

| [2] | 张贤, 杨晓亮, 鲁玺, 等. 中国CO2利用与封存(CCUS)年度报告(2023)[R]. 中国21世纪议程管理中心、全球碳捕集与封存研究院、清华大学, 2023. |

| Zhang X, Yang X L, Lu X, et al. Annual Report on China's CO2 Utilization and Storage (CCUS) (2023) [R]. China 21st Century Agenda Management Center, Global Carbon Capture and Storage Research Institute, Tsinghua University, 2023. | |

| [3] | 蔡博峰, 李琦, 张贤, 等. 中国二氧化碳捕集利用与封存(CCUS) 年度报告(2021)――中国CCUS路径研究[R]. 生态环境部环境规划院、中国科学院武汉岩土所、中国21世纪议程管理中心, 2021. |

| Cai B F, Li Q, Zhang X, et al. Annual Report on Carbon Dioxide Capture, Utilization and Storage (CCUS) in China (2021) - Research on the CCUS Pathway in China [R] Chinese Academy of Environmental Planning, Ministry of Ecology and Environment, Institute of Rock and Soil Mechanics, Chinese Academy of Sciences, Wuhan, China 21st Century Agenda Management Center, 2021. | |

| [4] | 王志, 王宇新, 李保安, 等. 膜科学与技术[M]. 北京: 科学出版社, 2022. |

| Wang Z, Wang Y X, Li B A, et al. Membrane science and technology[M]. Beijing: Science Press, 2022. | |

| [5] | 荷)M . 米尔德著, 李琳 译. 膜技术基本原理[M]. 2版. 北京: 清华大学出版社, 1999: 221. |

| Mulder M, Li L, trans. Basic principles of membrane technology[M]. 2nd ed. Beijing: Tsinghua University Press, 1999: 221. | |

| [6] | Dechnik J, Gascon J, Doonan C J, et al. Mixed-matrix membranes[J]. Angewandte Chemie International Edition, 2017, 56(32): 9292-9310. |

| [7] | Vu D Q, Koros W J, Miller S J. Mixed matrix membranes using carbon molecular sieves I. Preparation and experimental results[J]. Journal of Membrane Science, 2003, 211(2): 311-334. |

| [8] | Wang B, Qiao Z H, Xu J Y, et al. Unobstructed ultrathin gas transport channels in composite membranes by interfacial self-assembly[J]. Advanced Materials, 2020, 32(22): 1907701. |

| [9] | Yoo M J, Lee J H, Yoo S Y, et al. Defect control for large-scale thin-film composite membrane and its bench-scale demonstration[J]. Journal of Membrane Science, 2018, 566: 374-382. |

| [10] | Xu R, Wang Z, Wang M, et al. High nanoparticles loadings mixed matrix membranes via chemical bridging-crosslinking for CO2 separation[J]. Journal of Membrane Science, 2019, 573: 455-464. |

| [11] | Yuan Y, Yang Y, Shi F, et al. Polymer-modified nanofillers for enhancing CO2 separation performance of MMMs: a comparative study on the role of bridging ligands[J]. Journal of Membrane Science, 2024, 711: 123220. |

| [12] | Han Y, Salim W, Chen K K, et al. Field trial of spiral-wound facilitated transport membrane module for CO2 capture from flue gas[J]. Journal of Membrane Science, 2019, 575: 242-251. |

| [13] | 伍泓宇. 碳捕集膜组件及装置构建研究[D]. 天津: 天津大学, 2023. |

| Wu H Y. Construction of membrane modules and plants for CO2 capture [D]. Tianjin: Tianjin University, 2023. | |

| [14] | 马翠花. 分离CO2薄层复合膜的结构设计调控[D]. 天津: 天津大学, 2022. |

| Ma C H. Structure design and control of thin-film composite membranes for CO2 separation[D]. Tianjin: Tianjin University, 2022. | |

| [15] | Yuan Y, Pan Y R, Sheng M L, et al. Synthesis and optimization of high-performance amine-based polymer for CO2 separation[J]. Chinese Journal of Chemical Engineering, 2022, 50: 168-176. |

| [16] | 陈羿戬, 生梦龙, 李庆华, 等. UiO-66-NH2合成及其在混合基质碳捕集膜中的应用[J]. 洁净煤技术, 2024, 30(10): 58-68. |

| Chen Y J, Sheng M L, Li Q H, et al. Synthesis of UiO-66-NH2 nanoparticles and its application in preparation of mixed-matrix membranes for carbon capture[J]. Clean Coal Technology, 2024, 30(10): 58-68. | |

| [17] | 生梦龙. CO2分离多层复合膜结构优化及性能强化[D]. 天津: 天津大学, 2022. |

| Sheng M L. Structure optimization and performance enhancement of the multilayer composite membrane for CO2 separation[D]. Tianjin: Tianjin University, 2022. | |

| [18] | Sheng M L, Dong S L, Qiao Z H, et al. Large-scale preparation of multilayer composite membranes for post-combustion CO2 capture[J]. Journal of Membrane Science, 2021, 636: 119595. |

| [19] | 董松林. 高性能CO2分离多层复合膜的研制及放大[D]. 天津: 天津大学, 2020. |

| Dong S L. Development and scaling up of the high-performance multilayer composite membrane for CO2 separation[D]. Tianjin: Tianjin University, 2020. | |

| [20] | Kandiah M, Nilsen M H, Usseglio S, et al. Synthesis and stability of tagged UiO-66 Zr-MOFs[J]. Chemistry of Materials, 2010, 22(24): 6632-6640. |

| [21] | Li B Y, Liu J X, He X T, et al. Covalent "Bridge-crosslinking" strategy constructs facilitated transport mixed matrix membranes for highly-efficient CO2 separation[J]. Journal of Membrane Science, 2023, 680: 121755. |

| [22] | Zhu J J, Wu L B, Bu Z Y, et al. Polyethyleneimine-modified UiO-66-NH2(Zr) metal–organic frameworks: preparation and enhanced CO2 selective adsorption[J]. ACS Omega, 2019, 4(2): 3188-3197. |

| [23] | Cavka J H, Jakobsen S, Olsbye U, et al. A new zirconium inorganic building brick forming metal organic frameworks with exceptional stability[J]. Journal of the American Chemical Society, 2008, 130(42): 13850-13851. |

| [24] | Wang W F, Yuan Y, Shi F, et al. Enhancing dispersibility of nanofiller via polymer-modification for preparation of mixed matrix membrane with high CO2 separation performance[J]. Journal of Membrane Science, 2023, 683: 121791. |

| [25] | Ren X L, Ren J Z, Li H, et al. Poly (amide-6-b-ethylene oxide) multilayer composite membrane for carbon dioxide separation[J]. International Journal of Greenhouse Gas Control, 2012, 8: 111-120. |

| [26] | 何文娟. 强化CO2分离膜选择透过机制的研究[D]. 天津: 天津大学, 2014. |

| He W J. Studies on improvement of permselectivity of: membranes for CO2 separation[D]. Tianjin: Tianjin University, 2014. | |

| [27] | Diaf A, Garcia J L, Beckman E J. Thermally reversible polymeric sorbents for acid gases: CO2, SO2, and NO x [J]. Journal of Applied Polymer Science, 1994, 53(7): 857-875. |

| [28] | Wu Y D, Zhao D, Ren J Z, et al. A novel Pebax-C60(OH)24/PAN thin film composite membrane for carbon dioxide capture[J]. Separation and Purification Technology, 2019, 215: 480-489. |

| [29] | Shamsabadi A A, Isfahani A P, Salestan S K, et al. Pushing rubbery polymer membranes to be economic for CO2 separation: embedment with Ti3C2T x MXene nanosheets[J]. ACS Applied Materials & Interfaces, 2020, 12(3): 3984-3992. |

| [30] | Kim J, Fu Q, Xie K, et al. CO2 separation using surface-functionalized SiO2 nanoparticles incorporated ultra-thin film composite mixed matrix membranes for post-combustion carbon capture[J]. Journal of Membrane Science, 2016, 515: 54-62. |

| [31] | Wang Y H, Bai X, Zhang X R, et al. Improving CO2 separation performance of PVAm membrane by the addition of polyethylenimine-functionalized halloysite nanotubes[J]. Journal of Membrane Science, 2023, 677: 121609. |

| [32] | Martínez-Izquierdo L, García-Comas C, Dai S, et al. Ultrasmall functionalized UiO-66 nanoparticle/polymer pebax 1657 thin-film nanocomposite membranes for optimal CO2 separation[J]. ACS Applied Materials & Interfaces, 2024, 16(3): 4024-4034. |

| [1] | Ziqing ZANG, Xiuzhen LI, Yingying TAN, Xiaoqing LIU. Investigation on effect of fractionation on performance of two-stage separation-based auto-cascade refrigeration cycle [J]. CIESC Journal, 2025, 76(S1): 17-25. |

| [2] | Hao HUANG, Wen WANG, Longkun HE. Simulation and analysis on precooling process of membrane LNG carriers [J]. CIESC Journal, 2025, 76(S1): 187-194. |

| [3] | Bo HUANG, Hao HUANG, Wen WANG, Longkun HE. Analysis of temperature field of membrane liquid cargo in a LNG carrier [J]. CIESC Journal, 2025, 76(S1): 195-204. |

| [4] | Xingliang PEI, Cuiping YE, Yingli PEI, Wenying LI. Selective adsorption and separation of xylene isomers by alkali-modified MIL-53(Cr) [J]. CIESC Journal, 2025, 76(S1): 258-267. |

| [5] | Yinlong LI, Guoqiang LIU, Gang YAN. Perfromance assessment of auto-cascade cycle integrating fractionation and flash separation [J]. CIESC Journal, 2025, 76(S1): 26-35. |

| [6] | Wenlong LI, Cheng CHANG, Xiaolin WU, Zhongli JI. Research on liquid distribution characteristics and pressure drop evolution in oil-water coalescing filters [J]. CIESC Journal, 2025, 76(9): 4850-4861. |

| [7] | Jianmin ZHANG, Meigui HE, Wanxin JIA, Jing ZHAO, Wanqin JIN. Poly(ethylene oxide)/crown ether blend membrane and performance for CO2 separation [J]. CIESC Journal, 2025, 76(9): 4862-4871. |

| [8] | Xu GUO, Jining JIA, Kejian YAO. Modeling of batch distillation process based on optimized CNN-BiLSTM neural network [J]. CIESC Journal, 2025, 76(9): 4613-4629. |

| [9] | Jie WANG, Qucheng LIN, Xianming ZHANG. Global optimization of mixed gas multistage membrane separation system based on decomposition algorithm [J]. CIESC Journal, 2025, 76(9): 4670-4682. |

| [10] | Yu WANG, Yingnan FENG, Tao WANG, Zhiping ZHAO. Constructing nano-composite nanofiltration membranes by in-situ growth: membrane preparation and application [J]. CIESC Journal, 2025, 76(9): 4723-4736. |

| [11] | Shichang LIU, Yibai LI, Jing WANG, Yongzhong LIU. Modular design and optimization of hydrogen-driven electrochemical CO2 capture systems [J]. CIESC Journal, 2025, 76(8): 4108-4118. |

| [12] | Huiqin ZHANG, Hongjun ZHAO, Zhengjun FU, Li ZHUANG, Kai DONG, Tianzhi JIA, Xueli CAO, Shipeng SUN. Application of nanofiltration membrane in concentration of ionic rare earth leach solution [J]. CIESC Journal, 2025, 76(8): 4095-4107. |

| [13] | Zhihong CHEN, Jiawei WU, Xiaoling LOU, Junxian YUN. Recent advances in machine learning for biomanufacturing of chemicals [J]. CIESC Journal, 2025, 76(8): 3789-3804. |

| [14] | Minghu JIANG, Fan WANG, Lei XING, Lixin ZHAO, Xinya LI, Dingwei CHEN. Influence of gas-containing on flow field characteristics and separation performance in oil-water separation string [J]. CIESC Journal, 2025, 76(7): 3361-3372. |

| [15] | Zirui LI, Kai QI, Jun WANG, Guodong XIA. Molecular dynamics study of ion rejection process based on Janus nanochannel [J]. CIESC Journal, 2025, 76(7): 3531-3538. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||