CIESC Journal ›› 2023, Vol. 74 ›› Issue (10): 4182-4190.DOI: 10.11949/0438-1157.20230820

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Chenya LI1( ), Jie LIU1, Jianzhi WANG1, Yanping LIU2, Xiao LIN1, Faquan YU1(

), Jie LIU1, Jianzhi WANG1, Yanping LIU2, Xiao LIN1, Faquan YU1( )

)

Received:2023-08-09

Revised:2023-09-27

Online:2023-12-22

Published:2023-10-25

Contact:

Faquan YU

李晨亚1( ), 刘捷1, 王建芝1, 刘艳萍2, 林笑1, 喻发全1(

), 刘捷1, 王建芝1, 刘艳萍2, 林笑1, 喻发全1( )

)

通讯作者:

喻发全

作者简介:李晨亚(1991—),男,硕士研究生,2262659737@qq.com

基金资助:CLC Number:

Chenya LI, Jie LIU, Jianzhi WANG, Yanping LIU, Xiao LIN, Faquan YU. Preparation of caprolactam by Beckmann rearrangement in spiral microchannel reactor[J]. CIESC Journal, 2023, 74(10): 4182-4190.

李晨亚, 刘捷, 王建芝, 刘艳萍, 林笑, 喻发全. 螺旋微通道反应器贝克曼重排制备己内酰胺[J]. 化工学报, 2023, 74(10): 4182-4190.

Add to citation manager EndNote|Ris|BibTeX

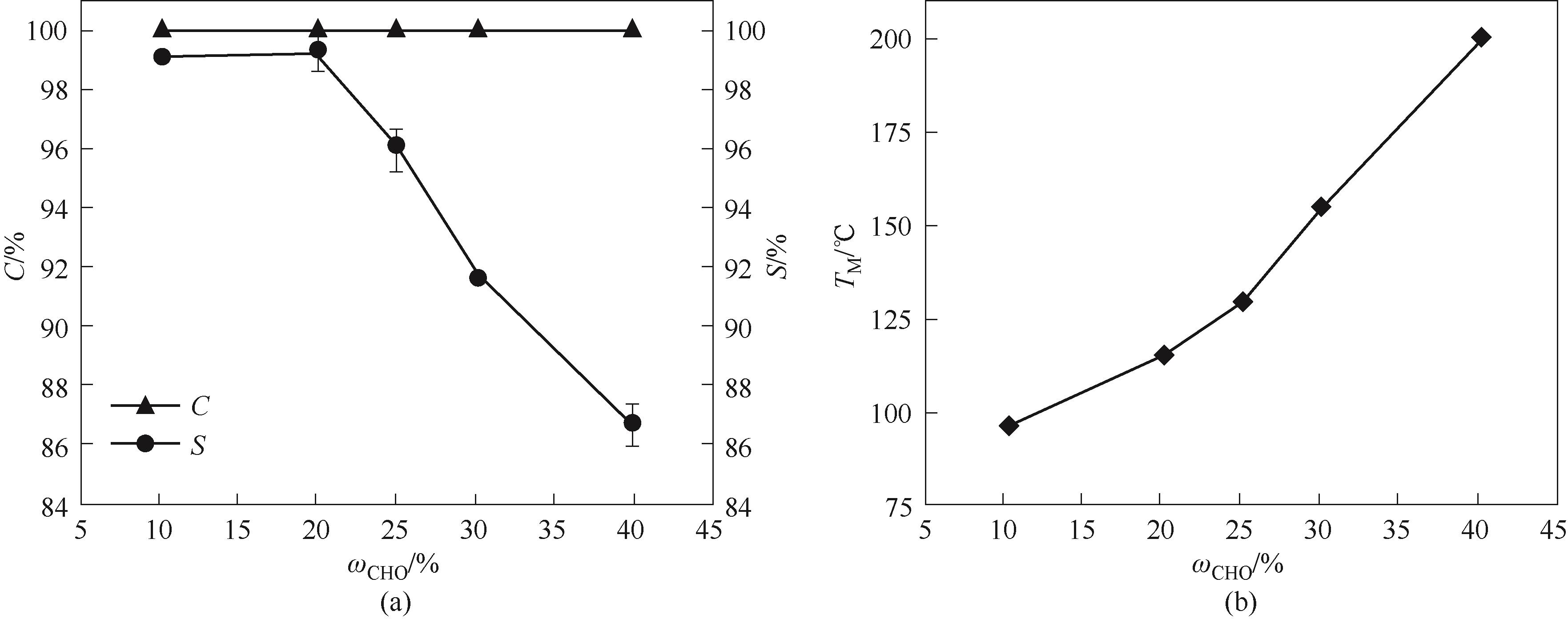

Fig.10 Effect of mass fraction of cyclohexanone oxime solution(ωCHO) on cyclohexanone oxime conversion, caprolactam selectivity and material temperature

| 23 | Ronchin L, Vavasori A. On the mechanism of the organocatalyzed Beckmann rearrangement of cyclohexanone oxime by trifluoroacetic acid in aprotic solvent[J]. Journal of Molecular Catalysis A: Chemical, 2009, 313(1/2): 22-30. |

| 24 | Su Y H, Chen G W, Zhao Y C, et al. Intensification of liquid-liquid two-phase mass transfer by gas agitation in a microchannel[J]. AIChE Journal, 2009, 55(8): 1948-1958. |

| 25 | Qamareen A, Ansari M A, Alam S S, et al. Modulation of secondary flows in curved serpentine micromixers[J]. Chemical Engineering Communications, 2022, 209(5): 648-667. |

| 26 | Di Carlo D. Inertial microfluidics[J]. Lab on a Chip, 2009, 9(21): 3038. |

| 27 | Zhao Q B, Yuan D, Zhang J, et al. A review of secondary flow in inertial microfluidics[J]. Micromachines, 2020, 11(5): 461. |

| 28 | Du C C, Zhang J S, Li L T, et al. Impurity formation in the Beckmann rearrangement of cyclohexanone oxime to yield ε-caprolactam[J]. Industrial & Engineering Chemistry Research, 2017, 56(48): 14207-14213. |

| 29 | Wang X D, Wang Y M, Li F, et al. Scale-up of microreactor: effects of hydrodynamic diameter on liquid-liquid flow and mass transfer[J]. Chemical Engineering Science, 2020, 226: 115838. |

| 30 | Du C C, Zhang J S, Li L T, et al. A modified mixed-acid catalytic system for Beckmann rearrangement of cyclohexanone oxime[J]. AIChE Journal, 2019, 65(6): e16603. |

| 1 | Kumar R, Shah S, Paramita Das P, et al. An overview of caprolactam synthesis[J]. Catalysis Reviews, 2019, 61(4): 516-594. |

| 2 | Dahlhoff G, Niederer J P M, Hoelderich W F. ε-Caprolactam: new by-product free synthesis routes[J]. Catalysis Reviews, 2001, 43(4): 381-441. |

| 3 | 杨军, 冯美平. 己内酰胺生产技术进展及项目投资分析[J]. 合成纤维工业, 2013, 36(1): 50-53. |

| Yang J, Feng M P. Caprolactam production technological prowess and project investment analysis[J]. China Synthetic Fiber Industry, 2013, 36(1): 50-53. | |

| 4 | 周云, 卢建国, 朱明乔. 环己酮肟贝克曼重排制己内酰胺绿色催化研究进展[J]. 合成纤维工业, 2015, 38(2): 51-56. |

| Zhou Y, Lu J G, Zhu M Q. Research progress in green catalytic Beckmann rearrangement of cyclohexanone oxime into caprolactam[J]. China Synthetic Fiber Industry, 2015, 38(2): 51-56. | |

| 5 | Tinge J, Groothaert M, op het Veld H, et al. Caprolactam[M]//Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA, 2018. |

| 6 | Zuidhof K T, de Croon M H J M, Schouten J C. Beckmann rearrangement of cyclohexanone oxime to ε-caprolactam in microreactors[J]. AIChE Journal, 2009, 56(5): 1297-1304. |

| 7 | Horn P, Grosskinsky OA, Thoma R, et al. Continuous preparation of ε-caprolactam by Beckmann rearrangement: US4257950[P]. 1981-03-24. |

| 8 | 任文杰, 李识寒, 贾会敏. 发烟硫酸条件下环己酮肟贝克曼重排工艺进展[J]. 化学工业与工程技术, 2014(5): 32-35. |

| Ren W J, Li S H, Jia H M. Technology progress of Beckmann rearrangement reaction of cyclohexanone oxime in the presence of oleum[J]. Journal of Chemical Industry & Engineering, 2014(5): 32-35. | |

| 9 | 张经纬, 周弋惟, 陈卓, 等. 微反应器内的有机合成前沿进展[J]. 化工学报, 2022, 73(8): 3472-3482. |

| Zhang J W, Zhou Y W, Chen Z, et al. Advances in frontiers of organic synthesis in microreactor[J]. CIESC Journal, 2022, 73(8): 3472-3482. | |

| 10 | Wu Y X, Chen Z, Wang F J, et al. Efficient organocatalytic synthesis of styrene oxide from styrene and its kinetic study in a continuous-flow microreaction system[J]. Chemical Engineering Science, 2022, 247: 117045. |

| 11 | 王瀚琳, 王德强, 王凯, 等. 微反应器内苯甲醚连续合成[J]. 化工学报, 2019, 70(3): 922-928. |

| Wang H L, Wang D Q, Wang K, et al. Continuous synthesis of anisole in microreactor system[J]. CIESC Journal, 2019, 70(3): 922-928. | |

| 12 | Chen Y Z, Zhao Y C, Han M, et al. Safe, efficient and selective synthesis of dinitro herbicides via a multifunctional continuous-flow microreactor: one-step dinitration with nitric acid as agent[J]. Green Chemistry, 2013, 15(1): 91-94. |

| 13 | 孙美玉, 庞秀江, 马秀明, 等. T形微反应器共沉淀法制备Mg-Al层状双金属氢氧化物及其粒径可控性[J]. 高等学校化学学报, 2013, 34(7): 1691-1696. |

| Sun M Y, Pang X J, Ma X M, et al. Preparation and particle size controllability of Mg-Al layered double hydroxides via coprecipitation method using T-type microchannel reactor[J]. Chemical Journal of Chinese Universities, 2013, 34(7): 1691-1696. | |

| 14 | Mason Brian P, Price Kristin E, Steinbacher Jeremy L, et al. Greener approaches to organic synthesis using microreactor technology[J]. Chemical Reviews, 2007, 107(6): 2300-2318. |

| 15 | Kockmann N, Roberge D M. Harsh reaction conditions in continuous-flow microreactors for pharmaceutical production[J]. Chemical Engineering & Technology, 2009, 32(11): 1682-1694. |

| 16 | Zhang J, Zhang S Q, Peng C, et al. Continuous synthesis of 2, 5-hexanedione through direct C—C coupling of acetone in a Hilbert fractal photo microreactor[J]. Reaction Chemistry & Engineering, 2020, 5(12): 2250-2259. |

| 17 | Bojang A A, Wu H S. Design, fundamental principles of fabrication and applications of microreactors[J]. Processes, 2020, 8(8): 891. |

| 18 | Suryawanshi P L, Gumfekar S P, Bhanvase B A, et al. A review on microreactors: reactor fabrication, design, and cutting-edge applications[J]. Chemical Engineering Science, 2018, 189: 431-448. |

| 19 | Poe S L, Cummings M A, Haaf M P, et al. Solving the clogging problem: precipitate-forming reactions in flow[J]. Angewandte Chemie International Edition, 2006, 45(10): 1544-1548. |

| 20 | Zuidhof N T, de Croon M H J M, Schouten J C, et al. Beckmann rearrangement of cyclohexanone oxime to ε-caprolactam in a microreactor[J]. Chemical Engineering & Technology, 2012, 35(7): 1257-1261. |

| 21 | Zhang J S, Wang K, Lu Y C, et al. Beckmann rearrangement in a microstructured chemical system for the preparation of ε-caprolactam[J]. AIChE Journal, 2012, 58(3): 925-931. |

| 22 | Zhang J S, Wang K, Lin X Y, et al. Intensification of fast exothermic reaction by gas agitation in a microchemical system[J]. AIChE Journal, 2014, 60(7): 2724-2730. |

| [1] | Xiaoqing ZHOU, Chunyu LI, Guang YANG, Aifeng CAI, Jingyi WU. Icing kinetics and mechanism of droplet impinging on supercooled corrugated plates with different curvature [J]. CIESC Journal, 2023, 74(S1): 141-153. |

| [2] | Lisen BI, Bin LIU, Hengxiang HU, Tao ZENG, Zhuorui LI, Jianfei SONG, Hanming WU. Molecular dynamics study on evaporation modes of nanodroplets at rough interfaces [J]. CIESC Journal, 2023, 74(S1): 172-178. |

| [3] | Junfeng LU, Huaiyu SUN, Yanlei WANG, Hongyan HE. Molecular understanding of interfacial polarization and its effect on ionic liquid hydrogen bonds [J]. CIESC Journal, 2023, 74(9): 3665-3680. |

| [4] | Dian LIN, Guomei JIANG, Xiubin XU, Bo ZHAO, Dongmei LIU, Xu WU. Preparation and drag reduction effect of silicon-based liquid-like anti-crude-oil-adhesion coatings [J]. CIESC Journal, 2023, 74(8): 3438-3445. |

| [5] | Yu FU, Xingchong LIU, Hanyu WANG, Haimin LI, Yafei NI, Wenjing ZOU, Yue LEI, Yongshan PENG. Research on F3EACl modification layer for improving performance of perovskite solar cells [J]. CIESC Journal, 2023, 74(8): 3554-3563. |

| [6] | Ben ZHANG, Songbai WANG, Ziya WEI, Tingting HAO, Xuehu MA, Rongfu WEN. Capillary liquid film condensation and heat transfer enhancement driven by superhydrophilic porous metal structure [J]. CIESC Journal, 2023, 74(7): 2824-2835. |

| [7] | Feng ZHU, Kailin CHEN, Xiaofeng HUANG, Yinzhu BAO, Wenbin LI, Jiaxin LIU, Weiqiang WU, Wangwei GAO. Performance study of KOH modified carbide slag for removal of carbonyl sulfide [J]. CIESC Journal, 2023, 74(6): 2668-2679. |

| [8] | Chi YIN, Zhengguo ZHANG, Ziye LING, Xiaoming FANG. Combining paraffin@silica nanocapsules with carbon fiber to develop a phase change thermal interface material for efficient heat dissipation [J]. CIESC Journal, 2023, 74(4): 1795-1804. |

| [9] | Xingyu YANG, You MA, Chunying ZHU, Taotao FU, Youguang MA. Study on liquid-liquid distribution in comb parallel microchannels [J]. CIESC Journal, 2023, 74(2): 698-706. |

| [10] | Chenghao ZHANG, Jing LUO, Jisong ZHANG. Advances in continuous aerobic oxidation based on nitroxyl radical catalyst in microreactors [J]. CIESC Journal, 2023, 74(2): 511-524. |

| [11] | Weijiang CHENG, Heqi WANG, Xiang GAO, Na LI, Sainan MA. Research progress on film-forming electrolyte additives for Si-based lithium-ion batteries [J]. CIESC Journal, 2023, 74(2): 571-584. |

| [12] | Yu XIE, Min ZHANG, Weiguo HU, Yujun WANG, Guangsheng LUO. Study on efficient dissolution of D-7-ACA using membrane dispersion microreactor [J]. CIESC Journal, 2023, 74(2): 748-755. |

| [13] | Jiawei FU, Shuaishuai CHEN, Kailun FANG, Xin JIANG. Advantage of microreactor on the synthesis of high-activity Cu-Mn catalyst by co-precipitation [J]. CIESC Journal, 2023, 74(2): 776-783. |

| [14] | Shengwei XU, Longbo SONG, Can KANG. Effects of liquid medium on geometric and kinetic characteristics of a rising bubble [J]. CIESC Journal, 2023, 74(10): 4140-4152. |

| [15] | Yu CHEN, Xiaoyan ZHENG, Hui ZHAO, Erqiang WANG, Jie LI, Chunshan LI. Heterogeneous aldol condensation catalyzed with Pickering emulsion [J]. CIESC Journal, 2023, 74(1): 449-458. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||