CIESC Journal ›› 2025, Vol. 76 ›› Issue (1): 81-92.DOI: 10.11949/0438-1157.20240417

• Thermodynamics • Previous Articles Next Articles

Yuanhui TANG1,2,3( ), Yuanji BAI2,3, Qiang GUO1, Xiaolei HE4, Lixin YU3, Yakai LIN3(

), Yuanji BAI2,3, Qiang GUO1, Xiaolei HE4, Lixin YU3, Yakai LIN3( ), Xiaolin WANG3

), Xiaolin WANG3

Received:2024-04-16

Revised:2024-08-18

Online:2025-02-08

Published:2025-01-25

Contact:

Yakai LIN

唐元晖1,2,3( ), 柏元吉2,3, 郭强1, 何晓磊4, 余立新3, 林亚凯3(

), 柏元吉2,3, 郭强1, 何晓磊4, 余立新3, 林亚凯3( ), 王晓琳3

), 王晓琳3

通讯作者:

林亚凯

作者简介:唐元晖(1986—),女,博士,副教授,tyh@cumtb.edu.cn

基金资助:CLC Number:

Yuanhui TANG, Yuanji BAI, Qiang GUO, Xiaolei HE, Lixin YU, Yakai LIN, Xiaolin WANG. Prediction and verification of calcium sulfate scaling trend in hydrothermal desalination process of high salinity mine[J]. CIESC Journal, 2025, 76(1): 81-92.

唐元晖, 柏元吉, 郭强, 何晓磊, 余立新, 林亚凯, 王晓琳. 高矿化度矿井水热法脱盐过程中硫酸钙的结垢趋势预测及验证[J]. 化工学报, 2025, 76(1): 81-92.

Add to citation manager EndNote|Ris|BibTeX

| 水质 | 矿井水1 | 矿井水2 | 油田水1 | 油田水2 | 油田水3 | 海水 |

|---|---|---|---|---|---|---|

| K+/(mg·L-1) | 12 | — | — | — | — | 399 |

| Ca2+/(mg·L-1) | 194 | 562 | 1587 | 652 | 212 | 412 |

| Na+/(mg·L-1) | 1803 | — | — | 385 | — | 10770 |

| Mg2+/(mg·L-1) | 289 | 342 | 784 | 385 | 40.5 | 1294 |

| Ba2+/(mg·L-1) | — | — | 528 | 423 | 80.2 | — |

| Sr2+/(mg·L-1) | — | — | 435 | 12. | 52.4 | 3.3 |

| COD/(mg·L-1) | 19.92 | — | 19.92 | 60 | — | 50 |

| 总碱度(以CaCO3计)/(mg·L-1) | 388 | — | 150 | 372 | 330 | 300 |

| Cl-/(mg·L-1) | 1789 | 1.45 | 23578 | 17482 | 7658 | 19354 |

| 1732 | 1940 | 75.81 | 15.2 | 16.8 | 2712 | |

| pH | 7.67 | 3.38 | 7.9 | 7.2 | 7.3 | 8.1 |

| 含盐量/(mg·L-1) | 5963 | 2773 | 30782 | 25745 | 14879 | 35000 |

Table 1 Main water quality indexes of high salinity mine water, sea water and oilfield water[27-29]

| 水质 | 矿井水1 | 矿井水2 | 油田水1 | 油田水2 | 油田水3 | 海水 |

|---|---|---|---|---|---|---|

| K+/(mg·L-1) | 12 | — | — | — | — | 399 |

| Ca2+/(mg·L-1) | 194 | 562 | 1587 | 652 | 212 | 412 |

| Na+/(mg·L-1) | 1803 | — | — | 385 | — | 10770 |

| Mg2+/(mg·L-1) | 289 | 342 | 784 | 385 | 40.5 | 1294 |

| Ba2+/(mg·L-1) | — | — | 528 | 423 | 80.2 | — |

| Sr2+/(mg·L-1) | — | — | 435 | 12. | 52.4 | 3.3 |

| COD/(mg·L-1) | 19.92 | — | 19.92 | 60 | — | 50 |

| 总碱度(以CaCO3计)/(mg·L-1) | 388 | — | 150 | 372 | 330 | 300 |

| Cl-/(mg·L-1) | 1789 | 1.45 | 23578 | 17482 | 7658 | 19354 |

| 1732 | 1940 | 75.81 | 15.2 | 16.8 | 2712 | |

| pH | 7.67 | 3.38 | 7.9 | 7.2 | 7.3 | 8.1 |

| 含盐量/(mg·L-1) | 5963 | 2773 | 30782 | 25745 | 14879 | 35000 |

| 水质 | 数值 | 水质 | 数值 |

|---|---|---|---|

| 含盐量/(mg·L-1) | 7191 | Mg2+/(mg·L-1) | 75.6 |

| K+/(mg·L-1) | 38.4 | Cl-/(mg·L-1) | 1302 |

| Ca2+/( mg·L-1) | 267.3 | 2925 | |

| Na+/( mg·L-1) | 1881 | pH | 7.7 |

Table 2 Main water quality indices of high salinity mine water

| 水质 | 数值 | 水质 | 数值 |

|---|---|---|---|

| 含盐量/(mg·L-1) | 7191 | Mg2+/(mg·L-1) | 75.6 |

| K+/(mg·L-1) | 38.4 | Cl-/(mg·L-1) | 1302 |

| Ca2+/( mg·L-1) | 267.3 | 2925 | |

| Na+/( mg·L-1) | 1881 | pH | 7.7 |

| 编号 | MgCl2/(mg·L-1) | Na2SO4/(mg·L-1) | CaCl2/(mg·L-1) |

|---|---|---|---|

| A-1 | 395.8 | 8135 | 1803 |

| A-2 | 1781 | 8135 | 1803 |

| A-3 | 3166 | 8135 | 1803 |

| A-4 | 4552 | 8135 | 1803 |

| A-5 | 5937 | 8135 | 1803 |

| A-6 | 3166 | 1479 | 1803 |

| A-7 | 3166 | 4807 | 1803 |

| A-8 | 3166 | 11463 | 1803 |

| A-9 | 3166 | 14791 | 1803 |

Table 3 Compositions of the simulated feed solutions

| 编号 | MgCl2/(mg·L-1) | Na2SO4/(mg·L-1) | CaCl2/(mg·L-1) |

|---|---|---|---|

| A-1 | 395.8 | 8135 | 1803 |

| A-2 | 1781 | 8135 | 1803 |

| A-3 | 3166 | 8135 | 1803 |

| A-4 | 4552 | 8135 | 1803 |

| A-5 | 5937 | 8135 | 1803 |

| A-6 | 3166 | 1479 | 1803 |

| A-7 | 3166 | 4807 | 1803 |

| A-8 | 3166 | 11463 | 1803 |

| A-9 | 3166 | 14791 | 1803 |

| 序号 | Cl-/(mg·L-1) | Ca2+/(mg·L-1) | Mg2+/(mg·L-1) | Na+/(mg·L-1) | 温度/℃ | 离子强度/(mol·L-1) | SI | |

|---|---|---|---|---|---|---|---|---|

| 1 | 3409 | 1477 | 672.0 | 316.0 | 1126 | 45 | 0.17 | 0.002 |

| 2 | 4961 | 2946 | 735.0 | 664.0 | 2245 | 45 | 0.29 | 0.006 |

| 3 | 4961 | 2946 | 735.0 | 664.0 | 2946 | 45 | 0.31 | -0.010 |

| 4 | 6424 | 3432 | 647.0 | 450.0 | 3432 | 45 | 0.32 | 0.009 |

| 5 | 6424 | 3432 | 647.0 | 450.0 | 3713 | 45 | 0.33 | 0.001 |

| 6 | 2953 | 2759 | 1078.0 | 292.0 | 1855 | 55 | 0.22 | 0.010 |

| 7 | 2953 | 2759 | 1078.0 | 292.0 | 2759 | 55 | 0.24 | 0.030 |

| 8 | 6191 | 3335 | 553.0 | 450.0 | 3335 | 55 | 0.31 | -0.010 |

| 9 | 6191 | 3335 | 553.0 | 450.0 | 3713 | 55 | 0.32 | -0.020 |

| 10 | 8124 | 2950 | 587.4 | 467.0 | 4331 | 55 | 0.37 | 0.050 |

| 11 | 3488 | 2069 | 571.0 | 467.0 | 1466 | 65 | 0.20 | -0.003 |

| 12 | 3488 | 2069 | 571.0 | 467.0 | 2069 | 65 | 0.21 | -0.030 |

| 13 | 6093 | 3392 | 510.0 | 450.0 | 3713 | 65 | 0.32 | -0.020 |

| 14 | 6866 | 3123 | 599.9 | 456.3 | 3859 | 65 | 0.34 | -0.020 |

| 15 | 7480 | 3463 | 537.0 | 800.0 | 3713 | 65 | 0.38 | 0.007 |

Table 4 Compositions of feed solution used for the verification of the saturation index equation

| 序号 | Cl-/(mg·L-1) | Ca2+/(mg·L-1) | Mg2+/(mg·L-1) | Na+/(mg·L-1) | 温度/℃ | 离子强度/(mol·L-1) | SI | |

|---|---|---|---|---|---|---|---|---|

| 1 | 3409 | 1477 | 672.0 | 316.0 | 1126 | 45 | 0.17 | 0.002 |

| 2 | 4961 | 2946 | 735.0 | 664.0 | 2245 | 45 | 0.29 | 0.006 |

| 3 | 4961 | 2946 | 735.0 | 664.0 | 2946 | 45 | 0.31 | -0.010 |

| 4 | 6424 | 3432 | 647.0 | 450.0 | 3432 | 45 | 0.32 | 0.009 |

| 5 | 6424 | 3432 | 647.0 | 450.0 | 3713 | 45 | 0.33 | 0.001 |

| 6 | 2953 | 2759 | 1078.0 | 292.0 | 1855 | 55 | 0.22 | 0.010 |

| 7 | 2953 | 2759 | 1078.0 | 292.0 | 2759 | 55 | 0.24 | 0.030 |

| 8 | 6191 | 3335 | 553.0 | 450.0 | 3335 | 55 | 0.31 | -0.010 |

| 9 | 6191 | 3335 | 553.0 | 450.0 | 3713 | 55 | 0.32 | -0.020 |

| 10 | 8124 | 2950 | 587.4 | 467.0 | 4331 | 55 | 0.37 | 0.050 |

| 11 | 3488 | 2069 | 571.0 | 467.0 | 1466 | 65 | 0.20 | -0.003 |

| 12 | 3488 | 2069 | 571.0 | 467.0 | 2069 | 65 | 0.21 | -0.030 |

| 13 | 6093 | 3392 | 510.0 | 450.0 | 3713 | 65 | 0.32 | -0.020 |

| 14 | 6866 | 3123 | 599.9 | 456.3 | 3859 | 65 | 0.34 | -0.020 |

| 15 | 7480 | 3463 | 537.0 | 800.0 | 3713 | 65 | 0.38 | 0.007 |

| 编号 | Ca2+/(mg·L-1) | Mg2+/(mg·L-1) | Na+/(mg·L-1) | Cl-/(mg·L-1) | 温度/℃ | SI | 有无沉淀 | |

|---|---|---|---|---|---|---|---|---|

| S-1 | 600 | 800 | 4313 | 3431.7 | 9000 | 65 | 0.08 | 无 |

| S-2 | 650 | 800 | 4313 | 3520 | 9000 | 65 | 0.11 | 无 |

| S-3 | 700 | 800 | 4313 | 3609 | 9000 | 65 | 0.14 | 无 |

| S-4 | 750 | 800 | 4313 | 3698 | 9000 | 65 | 0.16 | 无 |

| S-5 | 800 | 800 | 4313 | 3786 | 9000 | 65 | 0.20 | 有 |

| S-6 | 850 | 800 | 4313 | 3874 | 9000 | 65 | 0.21 | 有 |

| S-7 | 900 | 800 | 4313 | 3964.2 | 9000 | 65 | 0.23 | 有 |

| S-8 | 950 | 800 | 4313 | 4053 | 9000 | 65 | 0.25 | 有 |

Table 5 The fouling on the surface of stainless steel pipe with different saturation indices

| 编号 | Ca2+/(mg·L-1) | Mg2+/(mg·L-1) | Na+/(mg·L-1) | Cl-/(mg·L-1) | 温度/℃ | SI | 有无沉淀 | |

|---|---|---|---|---|---|---|---|---|

| S-1 | 600 | 800 | 4313 | 3431.7 | 9000 | 65 | 0.08 | 无 |

| S-2 | 650 | 800 | 4313 | 3520 | 9000 | 65 | 0.11 | 无 |

| S-3 | 700 | 800 | 4313 | 3609 | 9000 | 65 | 0.14 | 无 |

| S-4 | 750 | 800 | 4313 | 3698 | 9000 | 65 | 0.16 | 无 |

| S-5 | 800 | 800 | 4313 | 3786 | 9000 | 65 | 0.20 | 有 |

| S-6 | 850 | 800 | 4313 | 3874 | 9000 | 65 | 0.21 | 有 |

| S-7 | 900 | 800 | 4313 | 3964.2 | 9000 | 65 | 0.23 | 有 |

| S-8 | 950 | 800 | 4313 | 4053 | 9000 | 65 | 0.25 | 有 |

| 元素 | 质量分数/% | |||

|---|---|---|---|---|

| S-5 | S-6 | S-7 | S-8 | |

| O | 73.34 | 71.54 | 67.30 | 76.68 |

| Na | — | 0.06 | 0.12 | 0.03 |

| Mg | 0.01 | 0.03 | — | 0.04 |

| S | 25.13 | 14.36 | 15.85 | 11.66 |

| Ca | 19.91 | 14.00 | 16.73 | 11.58 |

Table 6 The composition and content of precipitated elements at different saturation index

| 元素 | 质量分数/% | |||

|---|---|---|---|---|

| S-5 | S-6 | S-7 | S-8 | |

| O | 73.34 | 71.54 | 67.30 | 76.68 |

| Na | — | 0.06 | 0.12 | 0.03 |

| Mg | 0.01 | 0.03 | — | 0.04 |

| S | 25.13 | 14.36 | 15.85 | 11.66 |

| Ca | 19.91 | 14.00 | 16.73 | 11.58 |

| 水质 | 真实矿井水A | 模拟矿井水SA | 真实矿井水B | 模拟矿井水SB |

|---|---|---|---|---|

| K+/(mg·L-1) | 6.86 | 6.50 | 12.8 | 12.8 |

| Ca2+/(mg·L-1) | 283 | 293 | 89.1 | 89.0 |

| Na+/(mg·L-1) | 1150 | 1329 | 627 | 627 |

| Mg2+/(mg·L-1) | 48.8 | 49 | 25.2 | 25.2 |

| 氨氮/(mg·L-1) | 0.166 | — | 2.11 | — |

| Mn2+/(mg·L-1) | 0.139 | — | 0.06 | — |

| Ba2+/(mg·L-1) | <0.01 | — | 0.04 | — |

| Fe2+/(mg·L-1) | <0.03 | — | 0.08 | — |

| Al3+/(mg·L-1) | <0.07 | — | 0.014 | — |

| 镧/(mg·L-1) | <0.04 | — | — | — |

| 锌/(mg·L-1) | <0.009 | — | 0.127 | — |

| 3580 | 3500 | 975 | 975 | |

| Cl-/(mg·L-1) | 91 | 91 | 434 | 612 |

| 66 | 66 | — | — | |

| 5 | 5 | — | — | |

| F-/(mg·L-1) | 0.208 | — | 0.384 | — |

| 磷酸根/(mg·L-1) | <0.051 | — | — | — |

| <0.016 | — | — | — | |

| COD/(mg·L-1) | 0.6 | — | — | — |

| 总碱度/(mg·L-1) | 69 | — | 401 | — |

| 悬浮物/(mg·L-1) | <5 | — | — | — |

| 总有机碳/(mg·L-1) | <0.1 | — | — | — |

| pH | 8.42 | 7.7 | ||

| 含盐量/(mg·L-1) | 4010 | 5457 | 2397 |

Table 7 Composition of real mine water and simulated mine water

| 水质 | 真实矿井水A | 模拟矿井水SA | 真实矿井水B | 模拟矿井水SB |

|---|---|---|---|---|

| K+/(mg·L-1) | 6.86 | 6.50 | 12.8 | 12.8 |

| Ca2+/(mg·L-1) | 283 | 293 | 89.1 | 89.0 |

| Na+/(mg·L-1) | 1150 | 1329 | 627 | 627 |

| Mg2+/(mg·L-1) | 48.8 | 49 | 25.2 | 25.2 |

| 氨氮/(mg·L-1) | 0.166 | — | 2.11 | — |

| Mn2+/(mg·L-1) | 0.139 | — | 0.06 | — |

| Ba2+/(mg·L-1) | <0.01 | — | 0.04 | — |

| Fe2+/(mg·L-1) | <0.03 | — | 0.08 | — |

| Al3+/(mg·L-1) | <0.07 | — | 0.014 | — |

| 镧/(mg·L-1) | <0.04 | — | — | — |

| 锌/(mg·L-1) | <0.009 | — | 0.127 | — |

| 3580 | 3500 | 975 | 975 | |

| Cl-/(mg·L-1) | 91 | 91 | 434 | 612 |

| 66 | 66 | — | — | |

| 5 | 5 | — | — | |

| F-/(mg·L-1) | 0.208 | — | 0.384 | — |

| 磷酸根/(mg·L-1) | <0.051 | — | — | — |

| <0.016 | — | — | — | |

| COD/(mg·L-1) | 0.6 | — | — | — |

| 总碱度/(mg·L-1) | 69 | — | 401 | — |

| 悬浮物/(mg·L-1) | <5 | — | — | — |

| 总有机碳/(mg·L-1) | <0.1 | — | — | — |

| pH | 8.42 | 7.7 | ||

| 含盐量/(mg·L-1) | 4010 | 5457 | 2397 |

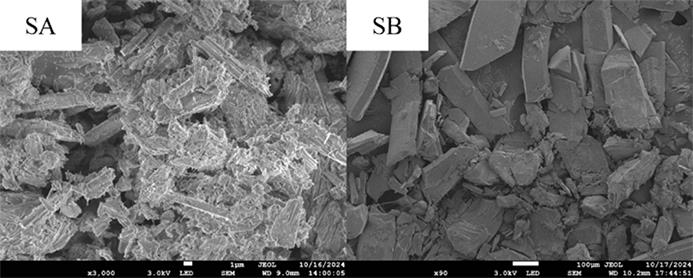

Fig.9 The microscopic morphology of the precipitate obtained from simulated wastewater SA after 1-fold concentration and SB after 9-fold concentration

| 元素 | 质量分数/% | |

|---|---|---|

| SA | SB | |

| O | 43.95 | 41.87 |

| S | 23.69 | 24.73 |

| Ca | 32.36 | 33.39 |

Table 8 The elemental composition and content of the precipitate obtained from simulated wastewater SA after 1-fold concentration and SB after 9-fold concentration

| 元素 | 质量分数/% | |

|---|---|---|

| SA | SB | |

| O | 43.95 | 41.87 |

| S | 23.69 | 24.73 |

| Ca | 32.36 | 33.39 |

| 24 | Wang L, Tang H W, Gao Y. Study of gathering system scaling prediction[J]. Pipeline Technique and Equipment, 2012(3): 12-13. |

| 25 | 倪兵, 沈胜强, 陈石, 等. 高盐海水中硫酸钙结垢趋势预测及验证[J]. 大连理工大学学报, 2019, 59(5): 471-479. |

| Ni B, Shen S Q, Chen S, et al. Prediction and verification of calcium sulfate scaling tendency in high salinity seawater[J]. Journal of Dalian University of Technology, 2019, 59(5): 471-479. | |

| 26 | 陈浩. 含盐废水CaSO4结垢倾向及其软化工艺研究[D]. 杭州: 浙江理工大学, 2018. |

| Chen H. Study on scaling tendency and softening process of CaSO4 in saline wastewater[D]. Hangzhou: Zhejiang Sci-Tech University, 2018. | |

| 27 | 郭强, 李井峰, 刘兆峰, 等. 高矿化度矿井水的膜蒸馏处理[J]. 煤炭学报, 2023, 48(9): 3494-3502. |

| Guo Q, Li J F, Liu Z F, et al. Membrane distillation treatment of high-salinity mine water[J]. Journal of China Coal Society, 2023, 48(9): 3494-3502. | |

| 28 | 林光鑫, 许昶, 沈飞, 等. 酸性矿井水的治理思路及工程实例分析[J]. 四川环境, 2023, 42(6): 219-225. |

| Lin G X, Xu C, Shen F, et al. Thoughts on treatment of acid mine water and analysis of engineering examples[J]. Sichuan Environment, 2023, 42(6): 219-225. | |

| 29 | 路遥军, 石美, 刁永强, 等. 油田采出水结垢趋势及工艺优化技术研究[J]. 石油工程建设, 2020, 46(5): 14-20. |

| Lu Y J, Shi M, Diao Y Q, et al. Trend of scaling in oilfield produced water and process optimization[J]. Petroleum Engineering Construction, 2020, 46(5): 14-20. | |

| 30 | Li Z B, Demopoulos G P. Effect of NaCl, MgCl2, FeCl2, FeCl3, and AlCl3 on solubility of CaSO4 phases in aqueous HCl or HCl + CaCl2 solutions at 298 to 353 K[J]. Journal of Chemical & Engineering Data, 2006, 51(2): 569-576. |

| 31 | Ling Y B, Demopoulos G P. Solubility of calcium sulfate hydrates in (0 to 3.5) mol·kg-1 sulfuric acid solutions at 100℃[J]. Journal of Chemical & Engineering Data, 2004, 49(5): 1263-1268. |

| 1 | 张春晖, 赵桂峰, 苏佩东, 等. 基于 "深地-井下-地面" 联动的煤矿矿井水处理利用模式初探[J]. 矿业科学学报, 2024, 9(1): 1-12. |

| Zhang C H, Zhao G F, Su P D, et al. Treatment and utilization of coal mine water based on "deep ground-underground-surface ground" linkage system[J]. Journal of Mining Science and Technology, 2024, 9(1): 1-12. | |

| 2 | 龙玉桥, 崔婷婷, 李伟, 等. 地下水污染物溯源的数学模拟方法研究进展[J]. 地下水, 2017, 39(1): 1-7. |

| Long Y Q, Cui T T, Li W, et al. A Review of mathematical simulation methods for groundwater pollution source identification[J]. Ground Water, 2017, 39(1): 1-7. | |

| 3 | 发展改革委水利部关于印发《国家节水行动方案》的通知[J]. 中华人民共和国国务院公报, 2019 (22): 39-45. |

| Notice of the Ministry of Water Resources of the National Development and Reform Commission on issuing the 《National Water-Saving Action Plan》[J]. Bulletin of The State Council of the People's Republic of China, 2019 (22): 39-45. | |

| 4 | 马莲净, 王颂, 杜松, 等. 宁东煤田枯竭油层回注存储高矿化度矿井水技术思路[J]. 煤炭科学技术, 2023, 51(12): 149-158. |

| Ma L J, Wang S, Du S, et al. Depleted petroleum reservoirs reinjection and storage technical thinking of highly-mineralized mine water in Ningdong Coalfield[J]. Coal Science and Technology, 2023, 51(12): 149-158. | |

| 5 | 刘遵义, 李小亮. 高矿化度矿井水处理技术应用现状[J]. 洁净煤技术, 2023, 29(S2): 436-441. |

| Liu Z Y, Li X L. Application status of high salinity mine water treatment technology[J]. Clean Coal Technology, 2023, 29(S2): 436-441. | |

| 6 | 卞伟, 李井峰, 刘淑琴, 等. 宁东基地高矿化度矿井水处理工程实践与发展方向[J]. 水处理技术, 2021, 47(8): 120-123, 127. |

| Bian W, Li J F, Liu S Q, et al. Study on the technical route of highly mineralized mine water treatment in ningdong energy base[J]. Technology of Water Treatment, 2021, 47(8): 120-123, 127. | |

| 7 | 李岸然, 杨庆卫. 高盐矿井水蒸馏处理工艺中水质结垢趋势分析[J]. 煤炭加工与综合利用, 2019(1): 75-78. |

| Li A R, Yang Q W. Analysis of water scaling tendency in high-salt mine water distillation treatment process[J]. Coal Processing & Comprehensive Utilization, 2019(1): 75-78. | |

| 8 | 方惠明, 戚凯, 李向东, 等. 高矿化度矿井水结垢趋势及影响因素研究[J]. 中国煤炭地质, 2021, 33(2): 60-63. |

| Fang H M, Qi K, Li X D, et al. A research for highly mineralized mine water scaling trend and impacting factors[J]. Coal Geology of China, 2021, 33(2): 60-63. | |

| 9 | Olajire A A. A review of oilfield scale management technology for oil and gas production[J]. Journal of Petroleum Science and Engineering, 2015, 135: 723-737. |

| 10 | 王天媛, 陈春波, 孙琳, 等. 基于全周期缓慢结垢的多效蒸发海水淡化慢时变系统优化设计[J]. 化工学报, 2022, 73(2): 759-769. |

| Wang T Y, Chen C B, Sun L, et al. Optimal design of slow-time-varying system for multi-effect distillation desalination based on full-cycle slow fouling[J]. CIESC Journal, 2022, 73(2): 759-769. | |

| 11 | 赖富国, 高国华, 肖燕飞, 等. 氯-硫酸盐体系下硫酸钙溶解度相图的研究进展[J]. 无机盐工业, 2018, 50(8): 16-21. |

| Lai F G, Gao G H, Xiao Y F, et al. Research progress on solubility phase diagrams of calcium sulfate in chloride-sulfate solutions[J]. Inorganic Chemicals Industry, 2018, 50(8): 16-21. | |

| 12 | Wu X Q, He W, Guan B H, et al. Solubility of calcium sulfate dihydrate in Ca-Mg-K chloride salt solution in the range of (348.15 to 371.15) K[J]. Journal of Chemical & Engineering Data, 2010, 55(6): 2100-2107. |

| 13 | Bock E. On the solubility of anhydrous calcium sulphate and of gypsum in concentrated solutions of sodium chloride at 25℃, 30℃, 40℃, and 50℃[J]. Canadian Journal of Chemistry, 1961, 39(9): 1746-1751. |

| 14 | Glew D N, Hames D A. Gypsum, disodium pentacalcium sulfate, and anhydrite solubilities in concentrated sodium chloride solutions[J]. Canadian Journal of Chemistry, 1970, 48(23): 3733-3738. |

| 15 | 王可苗. Ca-Mg-K-Cl-H2O盐溶液体系中硫酸钙的结晶过程[D]. 武汉: 武汉科技大学, 2013. |

| Wang K M. Crystallization process of calcium sulfate in Ca-Mg-K-Cl-H2O salt solution system[D]. Wuhan: Wuhan University of Science and Technology, 2013. | |

| 16 | 尹忠, 赵晓东. 硫酸钙在盐酸和氯化钠水溶液中的溶解度[J]. 油田化学, 1994, 11(4): 345-347. |

| Yin Z, Zhao X D. Solubilities of calcium sulfate in hydrochloric acid and aqueous sodiium chloride solution[J]. Oilfield Chemistry, 1994, 11(4): 345-347. | |

| 17 | Barba D, Brandani V, di Giacomo G. A thermodynamic model of CaSO4 solubility in multicomponent aqueous solutions[J]. The Chemical Engineering Journal, 1982, 24(2): 191-200. |

| 18 | Meijer J A M, van Rosmalen G M. Solubilities and supersaturations of calcium sulfate and its hydrates in seawater[J]. Desalination, 1984, 51(3): 255-305. |

| 19 | 田萍, 宁朋歌, 曹宏斌, 等. 二水硫酸钙在铵盐溶液中溶解度测定及热力学计算[J]. 过程工程学报, 2012, 12(4): 625-630. |

| Tian P, Ning P G, Cao H B, et al. Solubility measurement of calcium sulfate dihydrate in NH4Cl-(NH4)2SO4 solutions and thermodynamic calculation[J]. The Chinese Journal of Process Engineering, 2012, 12(4): 625-630. | |

| 20 | Li Z B, Demopoulos G P. Speciation-based chemical equilibrium model of CaSO4 solubility in the H + Na + Ca+ Mg + Al + Fe(Ⅱ) + Cl + SO4 + H2O system[J]. Industrial & Engineering Chemistry Research, 2007, 46(20): 6385-6392. |

| 21 | Azimi G, Papangelakis V G, Dutrizac J E. Development of an MSE-based chemical model for the solubility of calcium sulphate in mixed chloride-sulphate solutions[J]. Fluid Phase Equilibria, 2008, 266(1/2): 172-186. |

| 22 | Oddo J E, Tomson M B. Why scale forms in the oil field and methods to predict it[J]. SPE Production & Facilities, 1994, 9(1): 47-54. |

| 23 | 袁存光, 唐仕明, 于剑峰, 等. 江苏油田卤水输送管道中硫酸钙结垢趋势预测[J]. 中国石油大学学报, 2011, 35(4): 154-156. |

| Yuan C G, Tang S M, Yu J F, et al. Scaling trend prediction of calcium sulfate in brine pipeline in Jiangsu Oilfield[J]. Journal of China University of Petroleum, 2011, 35(4): 154-156. | |

| 24 | 王磊, 唐红伟, 高雨. 油气田地面集输系统结垢预测模型研究[J]. 管道技术与设备, 2012(3): 12-13. |

| 32 | Li Z B, Demopoulos G P. Solubility of CaSO4, phases in aqueous HCl + CaCl2 solutions from 283 K to 353 K[J]. ChemInform, 2006, 37(7): 1971-1982. |

| 33 | 石征宇, 石大安, 吕孟. 物质溶解度影响因素的调研[J]. 大众科技, 2007, 9(11): 102-103. |

| Shi Z Y, Shi D A, Lyu M. Investigation on the factors affecting the solubility of substances[J]. Popular Science & Technology, 2007, 9(11): 102-103. | |

| 34 | Barba D, Brandani V, Di Giacomo G. Solubility of calcium sulfate dihydrate in the system sodium sulfate-magnesium chloride-water[J]. Journal of Chemical & Engineering Data, 1984, 29(1): 42-45. |

| 35 | 葛敬, 朱家骅, 夏素兰, 等. 二水硫酸钙在硫酸铵溶液中的溶解度测定[J]. 化工学报, 2018, 69(7): 2829-2837. |

| Ge J, Zhu J H, Xia S L, et al. Solubility determination of calcium sulfate dihydrate in ammonium sulfate solution[J]. CIESC Journal, 2018, 69(7): 2829-2837. |

| [1] | Nan TU, Xiaoqun LIU, Chiyu WANG, Jiabin FANG. Study on adaptability of scaling law to residence time distribution in bubbling fluidized beds with continuous operation [J]. CIESC Journal, 2024, 75(2): 543-552. |

| [2] | Hao ZHANG, Yu ZHAO, Zhiming XU, Jinhui LI. Study on scale inhibition characteristics of carboxymethyl dextran by fast controlled precipitation method [J]. CIESC Journal, 2022, 73(4): 1515-1522. |

| [3] | Wenjie HAN, Jiazhong ZHOU, Di WU, Yongjie GUAN, Qinghua SUN. Study on influence of suspended carrier scaling on CANON-MBBR system and restoration control [J]. CIESC Journal, 2019, 70(6): 2298-2307. |

| [4] | Yuling ZHANG, Liping ZHANG, Qian WANG, Xudong LI, Xiaodong LIU, Jinghong ZHANG. Optimization of extraction process of inorganic phosphorus in scale of circulating cooling system [J]. CIESC Journal, 2019, 70(3): 1083-1088. |

| [5] | GE Jing, ZHU Jiahua, XIA Sulan, LIU Shizhong. Solubility determination of calcium sulfate dihydrate in ammonium sulfate solution [J]. CIESC Journal, 2018, 69(7): 2829-2837. |

| [6] | LUO Zhiqiang, YANG Qingfeng. Effect of rotating magnetic field coupled with water volume on CaCO3 crystallization [J]. CIESC Journal, 2018, 69(7): 3029-3037. |

| [7] | LIU Tonghai, DOU Yan, FANG Yang, CUI Peng, SHEN Hao, ZHENG Zhiyin, LIU Rong. Influence of Al3+, Na+ and Mg2+ on crystallization of calcium sulfate dihydrate [J]. CIESC Journal, 2016, 67(S1): 296-301. |

| [8] | HAN Qiaoyun, YANG Xiaojie, ZOU Shenghua. Micro-mechanism of scaling in a cooling system under deep mine [J]. CIESC Journal, 2016, 67(9): 3936-3945. |

| [9] | DOU Yan, LIU Tonghai, SHEN Hao, ZHENG Zhiyin, LIU Rong, CUI Peng. Characteristic and structure of calcium sulfate dihydrate crystallites in crystallization process during reaction [J]. CIESC Journal, 2016, 67(6): 2449-2455. |

| [10] | WANG Zining, ZHOU Jiabei, ZHU Jiahua, WU Hui, CHEN Changguo, LIU Shizhong. Dissolution kinetics of calcium sulfate dihydrate [J]. CIESC Journal, 2015, 66(3): 1001-1006. |

| [11] | WANG Jianguo, LI Yutong, DENG Lijuan. Influence of electromagnetic frequency on scale inhibition for spiral winding variable frequency electromagnetic water processor [J]. CIESC Journal, 2015, 66(3): 972-978. |

| [12] | FENG Juan1,TANG Yongbo2,3,PENG Tao3. Prediction model of penicillin fed-batch fermentation based on KTA-LSSVM [J]. Chemical Industry and Engineering Progree, 2014, 33(09): 2438-2443. |

| [13] | MA Baoguo, RU Xiaohong, ZOU Kaibo, LU Siwen, FU Haobing. Preparation of α-calcium sulfate hemihydrate from phosphogypsum in Ca-Na-Cl solutions under atmospheric pressure [J]. CIESC Journal, 2013, 64(7): 2701-2707. |

| [14] | Lü Pengfei,FEI Dejun,DANG Yagu. Preparation of calcium sulfate whisker from phosphogypsum and its application [J]. Chemical Industry and Engineering Progree, 2013, 32(04): 842-847. |

| [15] | XIONG Lan, MIAO Xuefei, WU Yimei, CHEN Jiapeng, XIE Zijie. Anti-scaling effect comparison of high-frequency electromagnetic pulses stimulation in processing chambers with different electrodes [J]. CIESC Journal, 2012, 63(10): 3220-3224. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||