CIESC Journal ›› 2025, Vol. 76 ›› Issue (7): 3605-3614.DOI: 10.11949/0438-1157.20241437

• Energy and environmental engineering • Previous Articles Next Articles

Tianwei XIA1( ), Anci WANG1, Zihan JU1, Xiaoxia SUN2, Dinghua HU1(

), Anci WANG1, Zihan JU1, Xiaoxia SUN2, Dinghua HU1( )

)

Received:2024-12-12

Revised:2025-03-19

Online:2025-08-13

Published:2025-07-25

Contact:

Dinghua HU

夏天炜1( ), 王谙词1, 句子涵1, 孙晓霞2, 胡定华1(

), 王谙词1, 句子涵1, 孙晓霞2, 胡定华1( )

)

通讯作者:

胡定华

作者简介:夏天炜(1998—),男,硕士研究生,xiatianwei1998@163.com

CLC Number:

Tianwei XIA, Anci WANG, Zihan JU, Xiaoxia SUN, Dinghua HU. Study on thermal storage and release characteristics of TPMS-based high density thermal storage device[J]. CIESC Journal, 2025, 76(7): 3605-3614.

夏天炜, 王谙词, 句子涵, 孙晓霞, 胡定华. 基于三周期极小曲面结构的高密度储热器蓄放热特性研究[J]. 化工学报, 2025, 76(7): 3605-3614.

Add to citation manager EndNote|Ris|BibTeX

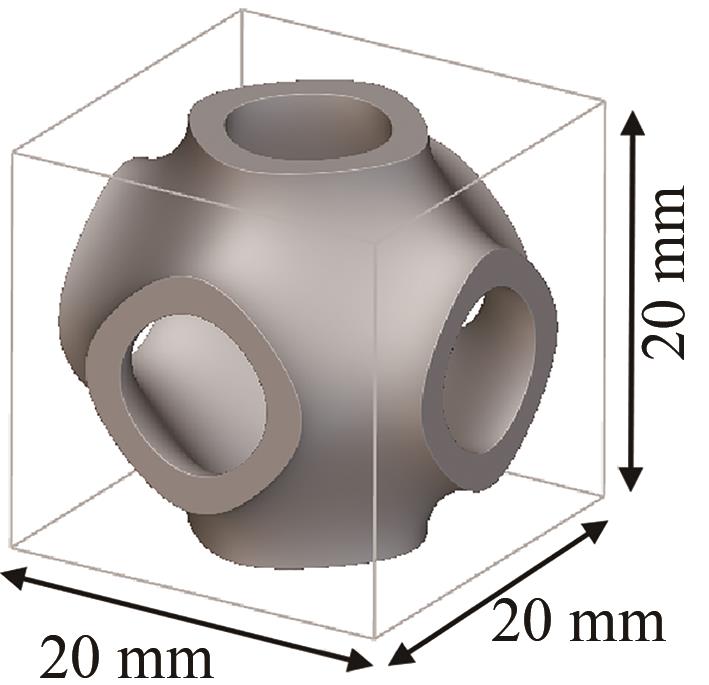

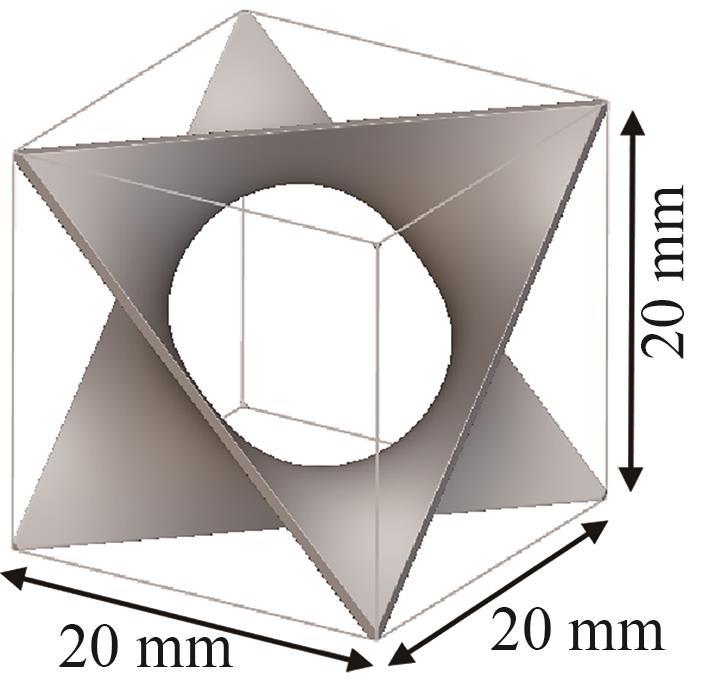

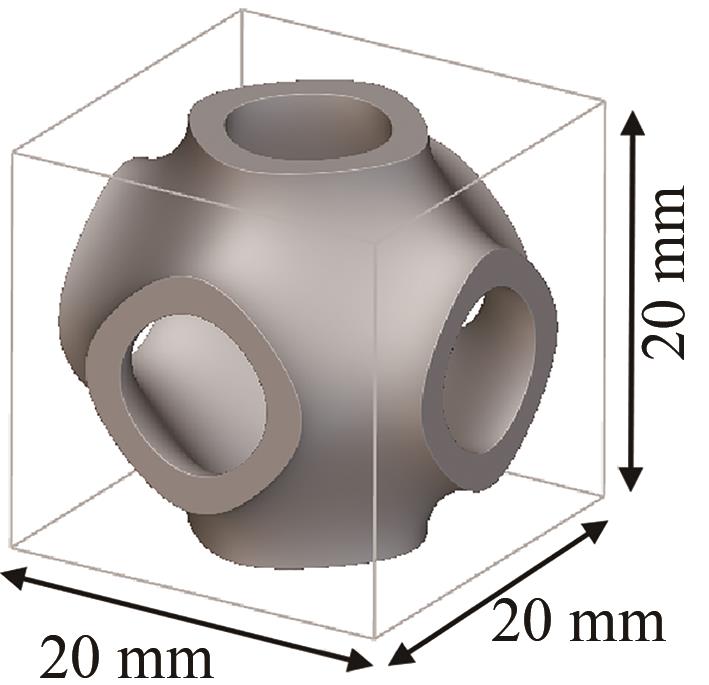

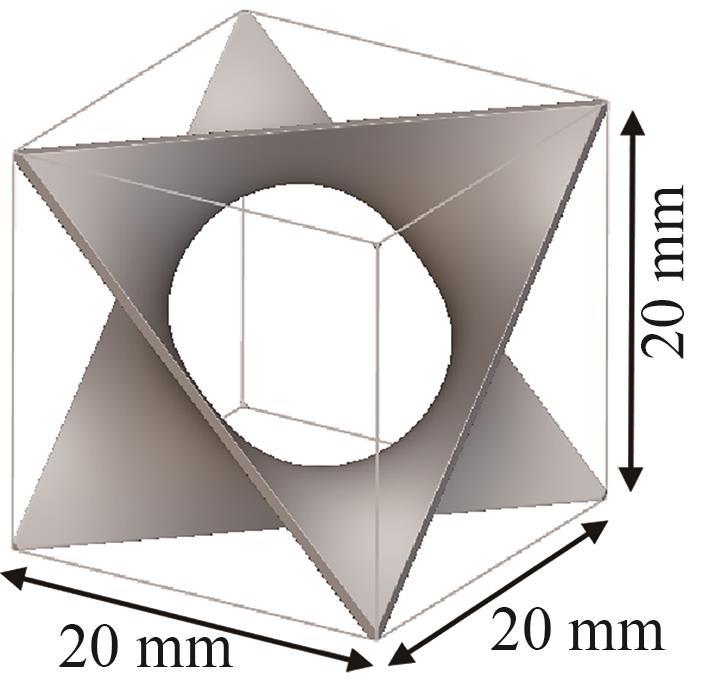

| 构型名称 | 晶胞单元图 | 结构表达式 |

|---|---|---|

| Schwarz型 |  | |

| Diamond型 |  |

Table 1 TPMS unit cell configuration classification

| 构型名称 | 晶胞单元图 | 结构表达式 |

|---|---|---|

| Schwarz型 |  | |

| Diamond型 |  |

| 晶胞构型 | 孔隙度/% | 骨架厚度/ mm | 热流域体积/ mm3 | 冷流域体积/ mm3 | PCM体积/ mm3 |

|---|---|---|---|---|---|

| Schwarz型 | 85 | 1.0 | 6544.3 | 6946.1 | 1108.4 |

| 75 | 1.5 | 5882.2 | 6028.7 | 1914.0 | |

| 65 | 2.1 | 5080.4 | 5226.8 | 2951.7 | |

| Diamond型 | 85 | 2.5 | 6453.7 | 7200.4 | 1141.4 |

| 75 | 4.3 | 5339.0 | 6639.4 | 2116.7 | |

| 65 | 6.0 | 4908.9 | 5485.1 | 3723.6 |

Table 2 TPMS model structural parameters

| 晶胞构型 | 孔隙度/% | 骨架厚度/ mm | 热流域体积/ mm3 | 冷流域体积/ mm3 | PCM体积/ mm3 |

|---|---|---|---|---|---|

| Schwarz型 | 85 | 1.0 | 6544.3 | 6946.1 | 1108.4 |

| 75 | 1.5 | 5882.2 | 6028.7 | 1914.0 | |

| 65 | 2.1 | 5080.4 | 5226.8 | 2951.7 | |

| Diamond型 | 85 | 2.5 | 6453.7 | 7200.4 | 1141.4 |

| 75 | 4.3 | 5339.0 | 6639.4 | 2116.7 | |

| 65 | 6.0 | 4908.9 | 5485.1 | 3723.6 |

| 物性参数 | 铝合金 | 水 | 八水合氢氧化钡 |

|---|---|---|---|

| 密度/(kg·m-3) | 2600 | 998 | 2125 |

| 比热容/(J·kg-1·K-1) | 880 | 4200 | 1810 |

| 热导率/(W·m-1·K-1) | 140 | 0.6 | 15 |

| 熔点/℃ | — | — | 78 |

| 相变潜热/(J·kg-1) | — | — | 243800 |

Table 3 Physical property parameters of simulation materials

| 物性参数 | 铝合金 | 水 | 八水合氢氧化钡 |

|---|---|---|---|

| 密度/(kg·m-3) | 2600 | 998 | 2125 |

| 比热容/(J·kg-1·K-1) | 880 | 4200 | 1810 |

| 热导率/(W·m-1·K-1) | 140 | 0.6 | 15 |

| 熔点/℃ | — | — | 78 |

| 相变潜热/(J·kg-1) | — | — | 243800 |

| 网格数/个 | Nu | 单位长度压降/(kPa·m-1) |

|---|---|---|

| 54万 | 201.04 | 29.818 |

| 122万 | 208.46 | 31.704 |

| 262万 | 209.05 | 32.443 |

| 386万 | 208.13 | 31.069 |

Table 4 Calculation results of grid independence assessment

| 网格数/个 | Nu | 单位长度压降/(kPa·m-1) |

|---|---|---|

| 54万 | 201.04 | 29.818 |

| 122万 | 208.46 | 31.704 |

| 262万 | 209.05 | 32.443 |

| 386万 | 208.13 | 31.069 |

| 晶胞构型 | 孔隙度/% | PCM填充量/mm3 | 总储热量/J | 储热密度/(MJ·m-3) | 功率密度/(MW·m-3) |

|---|---|---|---|---|---|

| Schwarz型 | 85 | 1108.4 | 658.2 | 41.1 | 185.6 |

| 75 | 1914.0 | 1142.9 | 71.4 | 108.6 | |

| 65 | 2951.7 | 1774.0 | 110.9 | 54.1 | |

| Diamond型 | 85 | 1141.4 | 701.8 | 43.9 | 146.4 |

| 75 | 2116.7 | 1300.4 | 81.3 | 109.7 | |

| 65 | 3723.6 | 2288.2 | 143.0 | 49.2 |

Table 5 Comparison of thermal storage performance between different structures

| 晶胞构型 | 孔隙度/% | PCM填充量/mm3 | 总储热量/J | 储热密度/(MJ·m-3) | 功率密度/(MW·m-3) |

|---|---|---|---|---|---|

| Schwarz型 | 85 | 1108.4 | 658.2 | 41.1 | 185.6 |

| 75 | 1914.0 | 1142.9 | 71.4 | 108.6 | |

| 65 | 2951.7 | 1774.0 | 110.9 | 54.1 | |

| Diamond型 | 85 | 1141.4 | 701.8 | 43.9 | 146.4 |

| 75 | 2116.7 | 1300.4 | 81.3 | 109.7 | |

| 65 | 3723.6 | 2288.2 | 143.0 | 49.2 |

| [1] | Schoen B A H. Infinite Periodic Minimal Surfaces without Self-intersections[M]. Washington D C: National Aeronautics and Space Administration, 1970. |

| [2] | Al-Ketan O, Ali M H, Khalil M, et al. Forced convection computational fluid dynamics analysis of architected and three-dimensional printable heat sinks based on triply periodic minimal surfaces[J]. Journal of Thermal Science and Engineering Applications, 2021, 13(2): 021010. |

| [3] | Cheng Z L, Xu R N, Jiang P X. Morphology, flow and heat transfer in triply periodic minimal surface based porous structures[J]. International Journal of Heat and Mass Transfer, 2021, 170: 120902. |

| [4] | Liang D, Shi C W, Li W H, et al. Design, flow characteristics and performance evaluation of bioinspired heat exchangers based on triply periodic minimal surfaces[J]. International Journal of Heat and Mass Transfer, 2023, 201: 123620. |

| [5] | Yan K X, Deng H W, Xiao Y W, et al. Thermo-hydraulic performance evaluation through experiment and simulation of additive manufactured Gyroid-structured heat exchanger[J]. Applied Thermal Engineering, 2024, 241: 122402. |

| [6] | Wang J H, Chen K, Zeng M, et al. Investigation on flow and heat transfer in various channels based on triply periodic minimal surfaces (TPMS)[J]. Energy Conversion and Management, 2023, 283: 116955. |

| [7] | Min R, Wang Z H, Yang H N, et al. Heat transfer characterization of waste heat recovery heat exchanger based on flexible hybrid triply periodic minimal surfaces (TPMS)[J]. International Communications in Heat and Mass Transfer, 2024, 157: 107760. |

| [8] | Deng X, Liu F, Zhang Z, et al. The effect of periodic porous Al on the heat transfer performance of paraffin[J]. IOP Conference Series: Earth and Environmental Science, 2021, 680(1): 012069. |

| [9] | Fan Z H, Gao R J, Liu S T. Thermal conductivity enhancement and thermal saturation elimination designs of battery thermal management system for phase change materials based on triply periodic minimal surface[J]. Energy, 2022, 259: 125091. |

| [10] | 杨喆, 刘飞, 张涛, 等. TPMS多孔铝-石蜡复合相变材料蓄热过程数值模拟及实验[J].化工进展, 2022, 41(9): 4918-4927. |

| Yang Z, Liu F, Zhang T, et al. Numerical simulation and experiment of heat storage process of TPMS porous aluminum-paraffin composite phase change material[J]. Chemical Industry and Engineering Progress, 2022, 41(9): 4918-4927. | |

| [11] | 周祥, 周静, 宗晓同, 等. 基于TPMS结构的高效换热技术研究综述[C]//第七届空天动力联合会议暨中国航天第三专业信息网第四十三届技术交流会论文集(第三册).北京: 北京动力机械研究所, 2023: 10. |

| Zhou X, Zhou J, Zong X T, et al. A review of efficient heat transfer technology based on TPMS structure[C]//Proceedings of the 7th Aerospace Propulsion Joint Conference and the 43rd Technical Exchange Conference of China Aerospace Third Professional Information Network (Vol 3). Beijing: Beijing Institute of Power Machinery, 2023:10. | |

| [12] | Vlahinos M, O'Hara R. Unlocking advanced heat exchanger design and simulation with nTop platform and ANSYS CFX[R]. nTopology Inc, 2020. |

| [13] | 杨晓军, 张雪丽, 李国良. 基于TPMS的空气-燃油换热器流动和传热特性研究[J]. 热能动力工程, 2024, 39(5): 123-133, 174. |

| Yang X J, Zhang X L, Li G L. Study on flow and heat transfer characteristics of air-fuel heat exchanger based on TPMS[J]. Journal of Engineering for Thermal Energy and Power, 2024, 39(5): 123-133, 174. | |

| [14] | Kim J, Yoo D J. 3D printed compact heat exchangers with mathematically defined core structures[J]. Journal of Computational Design and Engineering, 2020, 7(4): 527-550. |

| [15] | Li W H, Yu G P, Yu Z B. Bioinspired heat exchangers based on triply periodic minimal surfaces for supercritical CO2 cycles[J]. Applied Thermal Engineering, 2020, 179: 115686. |

| [16] | Femmer T, Kuehne A J C, Wessling M. Estimation of the structure dependent performance of 3-D rapid prototyped membranes[J]. Chemical Engineering Journal, 2015, 273: 438-445. |

| [17] | Maskery I, Aremu A O, Parry L, et al. Effective design and simulation of surface-based lattice structures featuring volume fraction and cell type grading[J]. Materials & Design, 2018, 155: 220-232. |

| [18] | Thomas N, Sreedhar N, Al-Ketan O, et al. 3D printed triply periodic minimal surfaces as spacers for enhanced heat and mass transfer in membrane distillation[J]. Desalination, 2018, 443: 256-271. |

| [19] | Sreedhar N, Thomas N, Al-Ketan O, et al. 3D printed feed spacers based on triply periodic minimal surfaces for flux enhancement and biofouling mitigation in RO and UF[J]. Desalination, 2018, 425: 12-21. |

| [20] | Iyer J, Moore T, Nguyen D, et al. Heat transfer and pressure drop characteristics of heat exchangers based on triply periodic minimal and periodic nodal surfaces[J]. Applied Thermal Engineering, 2022, 209: 118192. |

| [21] | Dixit T, Al-Hajri E, Paul M C, et al. High performance, microarchitected, compact heat exchanger enabled by 3D printing[J]. Applied Thermal Engineering, 2022, 210: 118339. |

| [22] | Alteneiji M, Ali M I H, Khan K A, et al. Heat transfer effectiveness characteristics maps for additively manufactured TPMS compact heat exchangers[J]. Energy Storage and Saving, 2022, 1(3): 153-161. |

| [23] | Qureshi Z, Al-Omari S, Elnajjar E, et al. Using triply periodic minimal surfaces (TPMS)-based metal foams structures as skeleton for metal-foam-PCM composites for thermal energy storage and energy management applications[J]. International Communications in Heat and Mass Transfer, 2021, 124: 105265. |

| [24] | Zhang T, Liu F, Deng X, et al. Experimental study on the thermal storage performance of phase change materials embedded with additively manufactured triply periodic minimal surface architected lattices[J]. International Journal of Heat and Mass Transfer, 2022, 199: 123452. |

| [25] | Wang J B, Pu W H, Zhao H S, et al. Experimental and numerical investigations on the intermittent heat transfer performance of phase change material (PCM)-based heat sink with triply periodic minimal surfaces (TPMS)[J]. Applied Thermal Engineering, 2024, 254: 123864. |

| [26] | Wang J, Pu W, Zhao H, et al. Investigations on the heat transfer performance of phase change material (PCM)-based heat sink with triply periodic minimal surfaces (TPMS)[J]. International Journal of Heat and Mass Transfer, 2024, 234: 126078. |

| [27] | Rao Z H, Wang Q C, Huang C L. Investigation of the thermal performance of phase change material/mini-channel coupled battery thermal management system[J]. Applied Energy, 2016, 164: 659-669. |

| [28] | Mehrabi-Kermani M, Houshfar E, Ashjaee M. A novel hybrid thermal management for Li-ion batteries using phase change materials embedded in copper foams combined with forced-air convection[J]. International Journal of Thermal Sciences, 2019, 141: 47-61. |

| [29] | Li C M, Sun X X, Gao H Y, et al. Pre-research on enhanced heat transfer method for special vehicles at high altitude based on machine learning[J]. Chinese Journal of Mechanical Engineering, 2023, 36(1): 48. |

| [30] | Zhao K, Sun X X, Xia Y Q, et al. Cold plate performance enhancement based on parametric modeling of multiple structures[J]. Frontiers in Energy Research, 2023, 10: 1087682. |

| [31] | Voller V R, Prakash C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems[J]. International Journal of Heat and Mass Transfer, 1987, 30(8): 1709-1719. |

| [32] | Tian R, Meng S, Zheng S Y, et al. Thermo-hydraulic performance evaluation of lattice structures with triply periodic minimal surfaces for latent heat storage devices[J]. Journal of Energy Storage, 2024, 102: 114234. |

| [33] | Samson S, Tran P, Marzocca P. Design and modelling of porous gyroid heatsinks: influences of cell size, porosity and material variation[J]. Applied Thermal Engineering, 2023, 235: 121296. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||