CIESC Journal ›› 2021, Vol. 72 ›› Issue (12): 6122-6130.DOI: 10.11949/0438-1157.20211333

• Reviews and monographs • Previous Articles Next Articles

Received:2021-09-14

Revised:2021-11-09

Online:2021-12-22

Published:2021-12-05

Contact:

Fanxing LI

Supported by:通讯作者:

李凡星

作者简介:蔡润夏(1991—),男,博士后,CLC Number:

Runxia CAI, Fanxing LI. Tailoring the thermodynamic properties of complex oxides for thermochemical air separation and beyond[J]. CIESC Journal, 2021, 72(12): 6122-6130.

蔡润夏, 李凡星. 复杂氧化物载氧体的调变策略及在过程强化中的应用[J]. 化工学报, 2021, 72(12): 6122-6130.

Add to citation manager EndNote|Ris|BibTeX

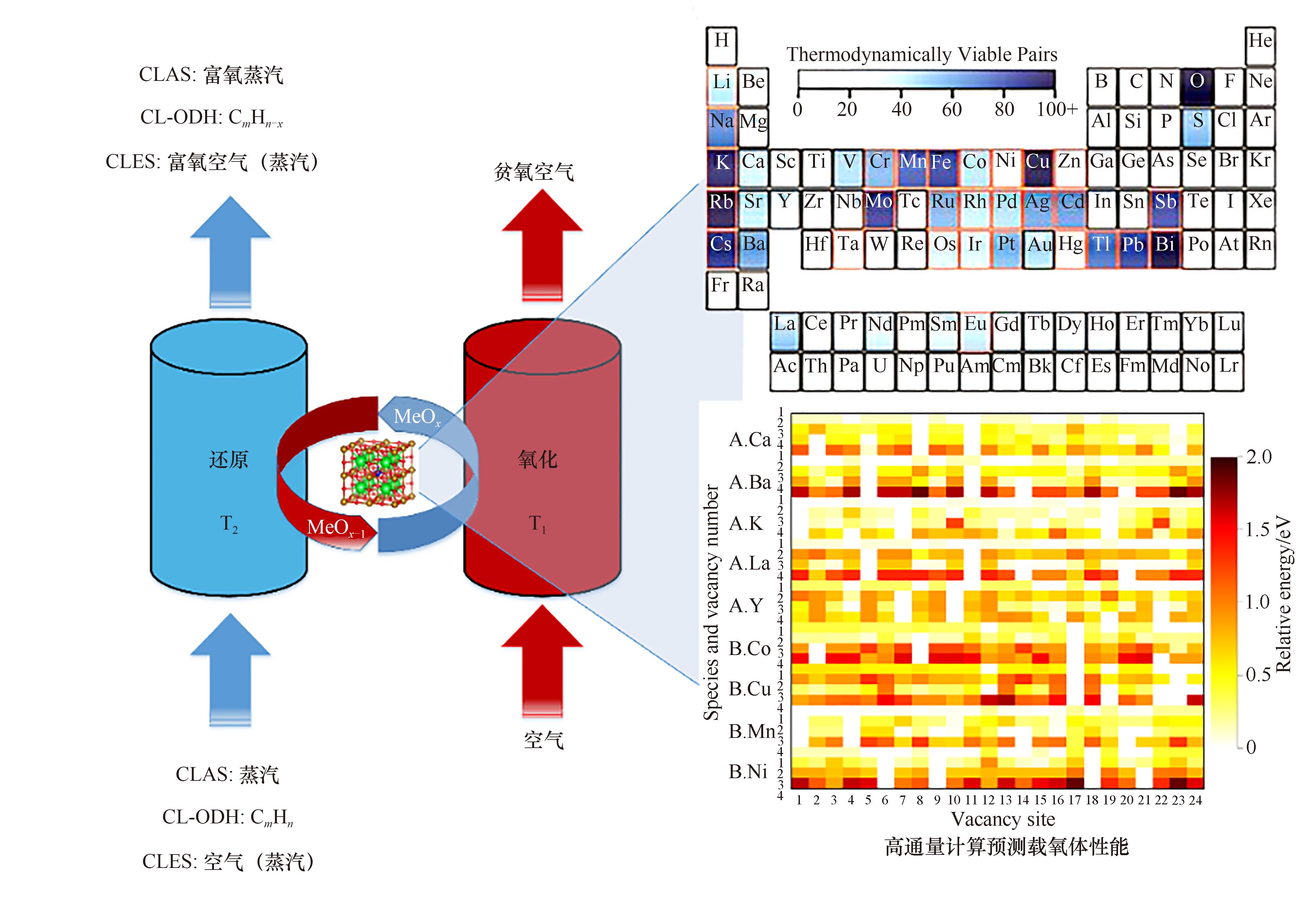

Fig.1 Schematics of a chemical looping reaction system and computationally predicted redox properties of complex oxides (the upper right figure was cited from Ref.[35])

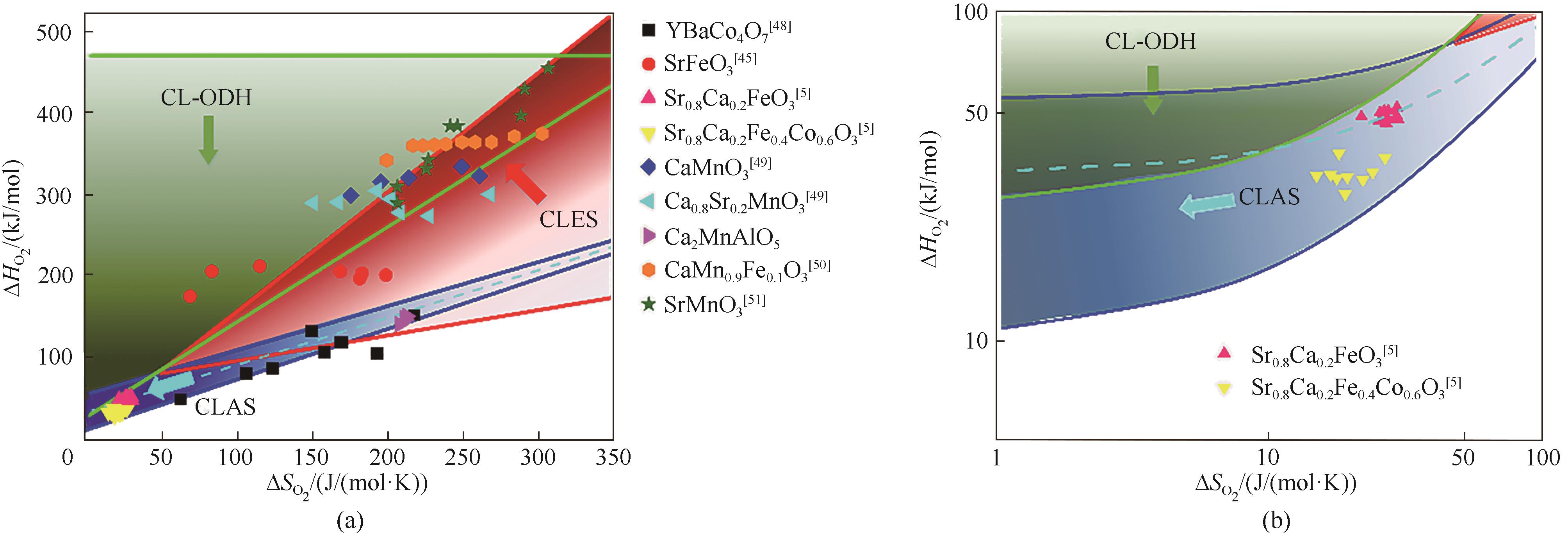

Fig.2 Desired thermodynamic properties of complex oxides for different chemical looping process: (a) Overview; (b) Callout view of the low entropy and enthalpy region (Some data points were cited from Refs.[5,45,48-51], data for Ca2MnAlO5 were collected from an on-going experimental study in the authors’ research group)

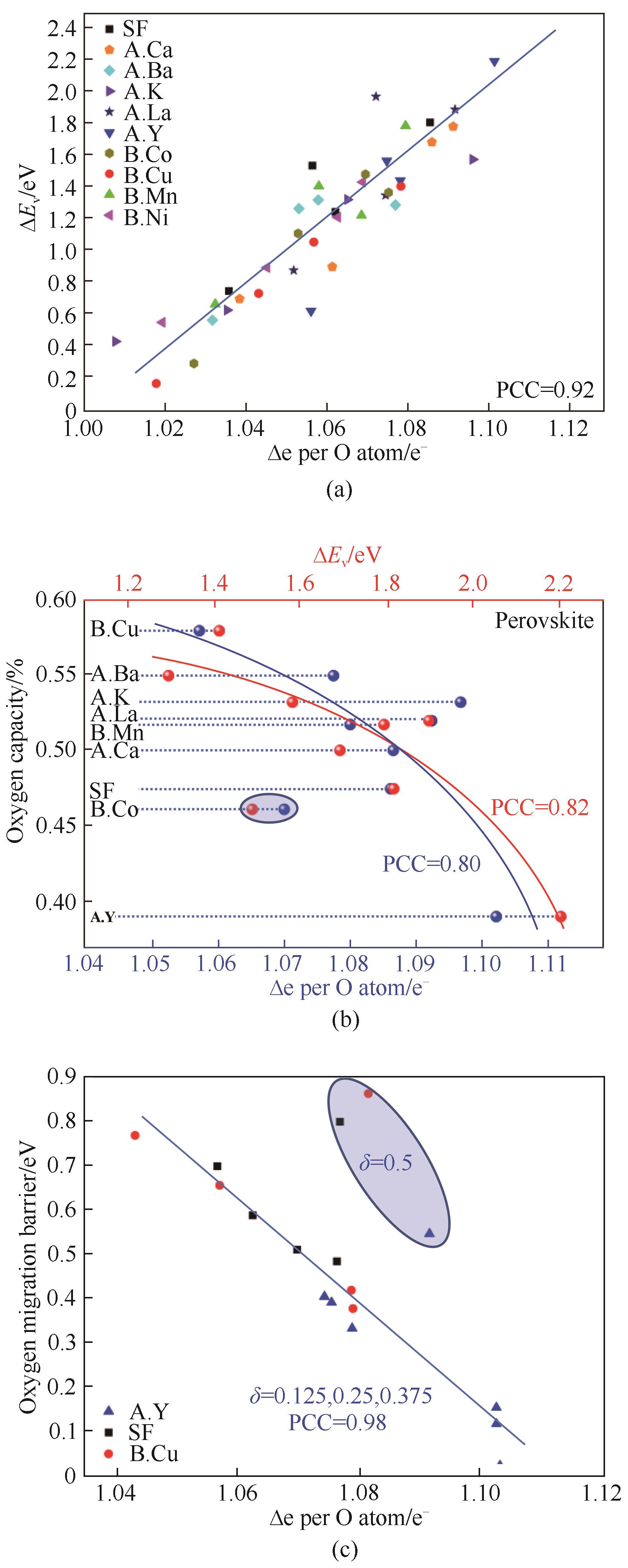

Fig.3 DFT was used for the design and optimization of SrxA1-xFeyB1-yO3-δoxygen sorbents in the CLAS process: (a) Linear relationship between ΔEv and Δe was observed; (b) Experimental oxygen capacity at 700 °C within 1%-20% PO2 swing as functions of ΔEv and Δe; (c) Oxygen migration barrier as a function of Δe per O atom[32]

| 1 | Fan L S, Zeng L, Wang W, et al. Chemical looping processes for CO2 capture and carbonaceous fuel conversion—prospect and opportunity[J]. Energy & Environmental Science, 2012, 5(6): 7254. |

| 2 | Kenarsari S D, Yang D L, Jiang G D, et al. Review of recent advances in carbon dioxide separation and capture[J]. RSC Advances, 2013, 3(45): 22739. |

| 3 | Ritchie H, Roser M. CO₂ and greenhouse gas emissions[EB/OL]. 2020. . |

| 4 | BoroumandJazi G, Rismanchi B, Saidur R. A review on exergy analysis of industrial sector[J]. Renewable and Sustainable Energy Reviews, 2013, 27: 198-203. |

| 5 | Dou J, Krzystowczyk E, Wang X J, et al. A- and B-site codoped SrFeO3 oxygen sorbents for enhanced chemical looping air separation[J]. ChemSusChem, 2020, 13(2): 385-393. |

| 6 | Al-Muslim H, Dincer I. Thermodynamic analysis of crude oil distillation systems[J]. International Journal of Energy Research, 2005, 29(7): 637-655. |

| 7 | El-Sayed Y M. Designing desalination systems for higher productivity[J]. Desalination, 2001, 134(1/2/3): 129-158. |

| 8 | Zhu X, Imtiaz Q, Donat F, et al. Chemical looping beyond combustion—a perspective[J]. Energy & Environmental Science, 2020, 13(3): 772-804. |

| 9 | Zhu X, Li K Z, Neal L, et al. Perovskites as geo-inspired oxygen storage materials for chemical looping and three-way catalysis: a perspective[J]. ACS Catalysis, 2018, 8(9): 8213-8236. |

| 10 | Zeng L, Cheng Z, Fan J A, et al. Metal oxide redox chemistry for chemical looping processes[J]. Nature Reviews Chemistry, 2018, 2(11): 349-364. |

| 11 | Adanez J, Abad A, Garcia-Labiano F, et al. Progress in chemical-looping combustion and reforming technologies[J]. Progress in Energy and Combustion Science, 2012, 38(2): 215-282. |

| 12 | Zhao X, Zhou H, Sikarwar V S, et al. Biomass-based chemical looping technologies: the good, the bad and the future[J]. Energy & Environmental Science, 2017, 10(9): 1885-1910. |

| 13 | Lyngfelt A, Leckner B, Mattisson T. A fluidized-bed combustion process with inherent CO2 separation: application of chemical-looping combustion[J]. Chemical Engineering Science, 2001, 56(10): 3101-3113. |

| 14 | Xu L, Wang J N, Li Z S, et al. Experimental study of cement-supported CuO oxygen carriers in chemical looping with oxygen uncoupling (CLOU)[J]. Energy & Fuels, 2013, 27(3): 1522-1530. |

| 15 | Ma J C, Zhao H B, Tian X, et al. Chemical looping combustion of coal in a 5 kWth interconnected fluidized bed reactor using hematite as oxygen carrier[J]. Applied Energy, 2015, 157: 304-313. |

| 16 | Fan J M, Hong H, Jin H G. Life cycle global warming impact of CO2 capture by in situ gasification chemical looping combustion using ilmenite oxygen carriers[J]. Journal of Cleaner Production, 2019, 234: 568-578. |

| 17 | Zheng Y E, Li K Z, Wang H, et al. Designed oxygen carriers from macroporous LaFeO3 supported CeO2 for chemical-looping reforming of methane[J]. Applied Catalysis B: Environmental, 2017, 202: 51-63. |

| 18 | Song T, Shen L H. Review of reactor for chemical looping combustion of solid fuels[J]. International Journal of Greenhouse Gas Control, 2018, 76: 92-110. |

| 19 | Bao J H, Li Z S, Cai N S. Promoting the reduction reactivity of ilmenite by introducing foreign ions in chemical looping combustion[J]. Industrial & Engineering Chemistry Research, 2013, 52(18): 6119-6128. |

| 20 | He F, Li H B, Zhao Z L. Advancements in development of chemical-looping combustion: a review[J]. International Journal of Chemical Engineering, 2009, 2009: 1-16. |

| 21 | Fan J M, Hong H, Zhu L, et al. Thermodynamic and environmental evaluation of biomass and coal co-fuelled gasification chemical looping combustion with CO2 capture for combined cooling, heating and power production[J]. Applied Energy, 2017, 195: 861-876. |

| 22 | Voitic G, Hacker V. Recent advancements in chemical looping water splitting for the production of hydrogen[J]. RSC Advances, 2016, 6(100): 98267-98296. |

| 23 | Gao Y F, Neal L M, Ding D, et al. Recent advances in intensified ethylene production—a review[J]. ACS Catalysis, 2019, 9(9): 8592-8621. |

| 24 | Li F X, Kim H R, Sridhar D, et al. Syngas chemical looping gasification process: oxygen carrier particle selection and performance[J]. Energy & Fuels, 2009, 23(8): 4182-4189. |

| 25 | Bao J H, Li Z S, Cai N S. Interaction between iron-based oxygen carrier and four coal ashes during chemical looping combustion[J]. Applied Energy, 2014, 115: 549-558. |

| 26 | Ge H J, Guo W J, Shen L H, et al. Biomass gasification using chemical looping in a 25 kWth reactor with natural hematite as oxygen carrier[J]. Chemical Engineering Journal, 2016, 286: 174-183. |

| 27 | Zhao K, He F, Huang Z, et al. Perovskite-type oxides LaFe1-xCoxO3 for chemical looping steam methane reforming to syngas and hydrogen co-production[J]. Applied Energy, 2016, 168: 193-203. |

| 28 | Zhu Y Y, Jin N N, Liu R L, et al. Bimetallic BaFe2MAl9O19 (M=Mn, Ni, and Co) hexaaluminates as oxygen carriers for chemical looping dry reforming of methane[J]. Applied Energy, 2020, 258: 114070. |

| 29 | Kang Y, Han Y J, Tian M, et al. Promoted methane conversion to syngas over Fe-based garnets via chemical looping[J]. Applied Catalysis B: Environmental, 2020, 278: 119305. |

| 30 | Lyngfelt A. Chemical-looping combustion of solid fuels—status of development[J]. Applied Energy, 2014, 113: 1869-1873. |

| 31 | Vieten J, Bulfin B, Huck P, et al. Materials design of perovskite solid solutions for thermochemical applications[J]. Energy & Environmental Science, 2019, 12(4): 1369-1384. |

| 32 | Wang X J, Krzystowczyk E, Dou J, et al. Net electronic charge as an effective electronic descriptor for oxygen release and transport properties of SrFeO3-based oxygen sorbents[J]. Chemistry of Materials, 2021, 33(7): 2446-2456. |

| 33 | Lau C Y, Dunstan M T, Hu W T, et al. Large scale in silico screening of materials for carbon capture through chemical looping[J]. Energy & Environmental Science, 2017, 10(3): 818-831. |

| 34 | Emery A A, Saal J E, Kirklin S, et al. High-throughput computational screening of perovskites for thermochemical water splitting applications[J]. Chemistry of Materials, 2016, 28(16):5621-5634. |

| 35 | Singstock N R, Bartel C J, Holder A M, et al. High-throughput analysis of materials for chemical looping processes[J]. Advanced Energy Materials, 2020, 10(27): 2000685. |

| 36 | Air separation plant market by process (cryogenic, non-cryogenic), (nitrogen gas, oxygen, argon, others), end-use industry (iron & steel, oil & gas, chemical, healthcare, others) and region-global forecast to 2026[EB/OL].2021.. |

| 37 | Fu Q, Kansha Y, Song C F, et al. A cryogenic air separation process based on self-heat recuperation for oxy-combustion plants[J]. Applied Energy, 2016, 162: 1114-1121. |

| 38 | Moghtaderi B. Application of chemical looping concept for air separation at high temperatures[J]. Energy & Fuels, 2010, 24(1): 190-198. |

| 39 | Tian X, Wei Y J, Zhao H B. Using a hierarchically-structured CuO@TiO2-Al2O3 oxygen carrier for chemical looping air separation in a paralleled fluidized bed reactor[J]. Chemical Engineering Journal, 2018, 334: 611-618. |

| 40 | Popczun E J, Jia T, Natesakhawat S, et al. Investigation of Sr0.7Ca0.3FeO3 oxygen carriers with variable cobalt B-site substitution[J]. ChemSusChem, 2021, 14(8): 1893-1901. |

| 41 | Xu M, Wu H C, Lin Y S, et al. Simulation and optimization of pressure swing adsorption process for high-temperature air separation by perovskite sorbents[J]. Chemical Engineering Journal, 2018, 354: 62-74. |

| 42 | Dou J, Krzystowczyk E, Wang X J, et al. Sr1-xCaxFe1-yCoyO3-δ as facile and tunable oxygen sorbents for chemical looping air separation[J]. Journal of Physics: Energy, 2020, 2(2): 025007. |

| 43 | Cai R X, Dou J, Krzystowczyk E, et al. Chemical looping air separation with Sr0.8Ca0.2Fe0.9Co0.1O3-δ perovskite sorbent: packed bed modeling, verification, and optimization[J]. Chemical Engineering Journal, 2022, 429: 132370. |

| 44 | Cormos C C. Energy and cost efficient manganese chemical looping air separation cycle for decarbonized power generation based on oxy-fuel combustion and gasification[J]. Energy, 2020, 191: 116579. |

| 45 | Bulfin B, Lapp J, Richter S, et al. Air separation and selective oxygen pumping via temperature and pressure swing oxygen adsorption using a redox cycle of SrFeO3 perovskite[J]. Chemical Engineering Science, 2019, 203: 68-75. |

| 46 | Saghafifar M, Scott S A. The use of high decomposition temperature materials for chemical looping electricity storage[J]. Chemical Engineering Journal, 2021, 423: 128789. |

| 47 | Krzystowczyk E, Wang X J, Dou J, et al. Substituted SrFeO3 as robust oxygen sorbents for thermochemical air separation: correlating redox performance with compositional and structural properties[J]. Physical Chemistry Chemical Physics, 2020, 22(16): 8924-8932. |

| 48 | Tsvetkov D S, Maram P S, Tsvetkova N S, et al. High-resolution thermochemical study of phase stability and rapid oxygen incorporation in YBaCo4–xZnxO7+δ 114-cobaltites[J]. The Journal of Physical Chemistry A, 2018, 122(50): 9597-9604. |

| 49 | Bulfin B, Vieten J, Starr D E, et al. Redox chemistry of CaMnO3 and Ca0.8Sr0.2MnO3 oxygen storage perovskites[J]. Journal of Materials Chemistry A, 2017, 5(17): 7912-7919. |

| 50 | Mastronardo E, Qian X, Coronado J M, et al. Impact of La doping on the thermochemical heat storage properties of CaMnO3-δ[J]. Journal of Energy Storage, 2021, 40: 102793. |

| 51 | Vieten J, Bulfin B, Senholdt M, et al. Redox thermodynamics and phase composition in the system SrFeO3- δ-SrMnO3- δ [J]. Solid State Ionics, 2017, 308: 149-155. |

| 52 | Krzystowczyk E, Haribal V, Dou J, et al. Chemical looping air separation using a perovskite-based oxygen sorbent: system design and process analysis[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(36): 12185-12195. |

| 53 | Cavani F, Ballarini N, Cericola A. Oxidative dehydrogenation of ethane and propane: How far from commercial implementation? [J]. Catalysis Today, 2007, 127(1/2/3/4): 113-131. |

| 54 | Dudek R B, Tian X, Blivin M, et al. Perovskite oxides for redox oxidative cracking of n-hexane under a cyclic redox scheme[J]. Applied Catalysis B: Environmental, 2019, 246: 30-40. |

| 55 | Dudek R B, Li F X. Selective hydrogen combustion as an effective approach for intensified chemical production via the chemical looping strategy[J]. Fuel Processing Technology, 2021, 218: 106827. |

| 56 | Zhu X, Gao Y F, Wang X J, et al. A tailored multi-functional catalyst for ultra-efficient styrene production under a cyclic redox scheme[J]. Nature Communications, 2021, 12(1): 1329. |

| 57 | Chen S, Chang X, Sun G D, et al. Propane dehydrogenation: catalyst development, new chemistry, and emerging technologies[J]. Chemical Society Reviews, 2021, 50(5): 3315-3354. |

| 58 | Chen S, Zeng L, Mu R T, et al. Modulating lattice oxygen in dual-functional Mo-V-O mixed oxides for chemical looping oxidative dehydrogenation[J]. Journal of the American Chemical Society, 2019, 141(47): 18653-18657. |

| 59 | Ding W X, Zhao K, Jiang S C, et al. Alkali-metal enhanced LaMnO3 perovskite oxides for chemical looping oxidative dehydrogenation of ethane[J]. Applied Catalysis A: General, 2021, 609: 117910. |

| 60 | Neal L M, Yusuf S, Sofranko J A, et al. Oxidative dehydrogenation of ethane: a chemical looping approach[J]. Energy Technology, 2016, 4(10): 1200-1208. |

| 61 | Yusuf S, Haribal V, Jackson D, et al. Mixed iron-manganese oxides as redox catalysts for chemical looping-oxidative dehydrogenation of ethane with tailorable heat of reactions[J]. Applied Catalysis B: Environmental, 2019, 257: 117885. |

| 62 | Gao Y F, Wang X J, Liu J C, et al. A molten carbonate shell modified perovskite redox catalyst for anaerobic oxidative dehydrogenation of ethane[J]. Science Advances, 2020, 6(17): eaaz9339. |

| 63 | Liu J C, Gao Y F, Wang X J, et al. Molten-salt-mediated carbon dioxide capture and superequilibrium utilization with ethane oxidative dehydrogenation[J]. Cell Reports Physical Science, 2021, 2(7): 100503. |

| 64 | Wang T, Gao Y F, Liu Y Z, et al. Core-shell Na2WO4/CuMn2O4 oxygen carrier with high oxygen capacity for chemical looping oxidative dehydrogenation of ethane[J]. Fuel, 2021, 303: 121286. |

| 65 | Tian X, Zheng C H, Li F X, et al. Co and Mo co-doped Fe2O3 for selective ethylene production via chemical looping oxidative dehydrogenation[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(23): 8002-8011. |

| 66 | Brody L, Neal L M, Haribal V, et al. Ethane to liquids via a chemical looping approach—redox catalyst demonstration and process analysis[J]. Chemical Engineering Journal, 2021, 417: 128886. |

| 67 | Yusuf S, Neal L M, Li F X. Effect of promoters on manganese-containing mixed metal oxides for oxidative dehydrogenation of ethane via a cyclic redox scheme[J]. ACS Catalysis, 2017, 7(8): 5163-5173. |

| 68 | Gao Y F, Neal L M, Li F X. Li-promoted LaxSr2–xFeO4–δ core–shell redox catalysts for oxidative dehydrogenation of ethane under a cyclic redox scheme[J]. ACS Catalysis, 2016, 6(11): 7293-7302. |

| 69 | Haribal V P, Neal L M, Li F X. Oxidative dehydrogenation of ethane under a cyclic redox scheme—process simulations and analysis[J]. Energy, 2017, 119: 1024-1035. |

| 70 | Yusuf S, Neal L, Haribal V, et al. Manganese silicate based redox catalysts for greener ethylene production via chemical looping - oxidative dehydrogenation of ethane[J]. Applied Catalysis B: Environmental, 2018, 232: 77-85. |

| 71 | Neal L M, Haribal V P, Li F X. Intensified ethylene production via chemical looping through an exergetically efficient redox scheme[J]. iScience, 2019, 19: 894-904. |

| 72 | Imponenti L, Albrecht K J, Wands J W, et al. Thermochemical energy storage in strontium-doped calcium manganites for concentrating solar power applications[J]. Solar Energy, 2017, 151: 1-13. |

| 73 | Saghafifar M, Schnellmann M A, Scott S A. Chemical looping electricity storage[J]. Applied Energy, 2020, 279: 115553. |

| 74 | Sunku Prasad J, Muthukumar P, Desai F, et al. A critical review of high-temperature reversible thermochemical energy storage systems[J]. Applied Energy, 2019, 254: 113733. |

| 75 | Sarbu I, Sebarchievici C. A comprehensive review of thermal energy storage[J]. Sustainability, 2018, 10(1): 191. |

| 76 | Bell S, Steinberg T, Will G. Corrosion mechanisms in molten salt thermal energy storage for concentrating solar power[J]. Renewable and Sustainable Energy Reviews, 2019, 114: 109328. |

| 77 | Yan Y L, Wang K, Clough P T, et al. Developments in calcium/chemical looping and metal oxide redox cycles for high-temperature thermochemical energy storage: a review[J]. Fuel Processing Technology, 2020, 199: 106280. |

| 78 | Jin F, Xu C, Yu H Y, et al. CaCo0.05Mn0.95O3–δ: a promising perovskite solid solution for solar thermochemical energy storage[J]. ACS Applied Materials & Interfaces, 2021, 13(3): 3856-3866. |

| 79 | Chen X Y, Kubota M, Yamashita S, et al. Investigation of Sr-based perovskites for redox-type thermochemical energy storage media at medium-high temperature[J]. Journal of Energy Storage, 2021, 38: 102501. |

| 80 | Wu S K, Zhou C, Doroodchi E, et al. A review on high-temperature thermochemical energy storage based on metal oxides redox cycle[J]. Energy Conversion and Management, 2018, 168: 421-453. |

| 81 | Mastronardo E, Qian X, Coronado J M, et al. The favourable thermodynamic properties of Fe-doped CaMnO3 for thermochemical heat storage[J]. Journal of Materials Chemistry A, 2020, 8(17): 8503-8517. |

| 82 | Mishra A, Li T Y, Li F X, et al. Oxygen vacancy creation energy in Mn-containing perovskites: an effective indicator for chemical looping with oxygen uncoupling[J]. Chemistry of Materials, 2018, 31(3):689-98. |

| 83 | Galinsky N, Mishra A, Zhang J, et al. Ca1-xAxMnO3 (A = Sr and Ba) perovskite based oxygen carriers for chemical looping with oxygen uncoupling (CLOU)[J]. Applied Energy, 2015, 157: 358-367. |

| 84 | Maiti D, Hare B J, Daza Y A, et al. Earth abundant perovskite oxides for low temperature CO2 conversion[J]. Energy & Environmental Science, 2018, 11(3): 648-659. |

| 85 | Ezbiri M, Allen K M, Gàlvez M E, et al. Design principles of perovskites for thermochemical oxygen separation[J]. ChemSusChem, 2015, 8(11): 1966-1971. |

| [1] | Chao HU, Yuming DONG, Wei ZHANG, Hongling ZHANG, Peng ZHOU, Hongbin XU. Preparation of high-concentration positive electrolyte of vanadium redox flow battery by activating vanadium pentoxide with highly concentrated sulfuric acid [J]. CIESC Journal, 2023, 74(S1): 338-345. |

| [2] | Zhenghao JIN, Lijie FENG, Shuhong LI. Energy and exergy analysis of a solution cross-type absorption-resorption heat pump using NH3/H2O as working fluid [J]. CIESC Journal, 2023, 74(S1): 53-63. |

| [3] | Pan LI, Junyang MA, Zhihao CHEN, Li WANG, Yun GUO. Effect of the morphology of Ru/α-MnO2 on NH3-SCO performance [J]. CIESC Journal, 2023, 74(7): 2908-2918. |

| [4] | Xiaowen ZHOU, Jie DU, Zhanguo ZHANG, Guangwen XU. Study on the methane-pulsing reduction characteristics of Fe2O3-Al2O3 oxygen carrier [J]. CIESC Journal, 2023, 74(6): 2611-2623. |

| [5] | Yongyao SUN, Qiuying GAO, Wenguang ZENG, Jiaming WANG, Yifei CHEN, Yongzhe ZHOU, Gaohong HE, Xuehua RUAN. Design and optimization of membrane-based integration process for advanced utilization of associated gases in N2-EOR oilfields [J]. CIESC Journal, 2023, 74(5): 2034-2045. |

| [6] | Qian LIU, Yu CAO, Qi ZHOU, Jingshan MU, Wei LI. Design of Ziegler-Natta catalyst modified with pore structure and preparation of UHMWPE with high impact resistance and low entanglement [J]. CIESC Journal, 2023, 74(3): 1092-1101. |

| [7] | Hao CHEN, Yijuan TIAN, Xuejun QUAN, Ziwen JIANG, Gang LI. Decomposition behaviour of chromite in the HCl-HF system [J]. CIESC Journal, 2023, 74(3): 1161-1174. |

| [8] | Nini YUAN, Tuo GUO, Hongcun BAI, Yurong HE, Yongning YUAN, Jingjing MA, Qingjie GUO. Reaction process of CH4 on the surface of Fe2O3/Al2O3 oxygen carrier in chemical looping combustion: ReaxFF-MD simulation [J]. CIESC Journal, 2022, 73(9): 4054-4061. |

| [9] | Yuehui HOU, Xuan LIU, Yingjiang LIAN, Mei HAN, Chaoqun YAO, Guangwen CHEN. Synthesis process of trinitrophloroglucinol in an ultrasonic microreactor [J]. CIESC Journal, 2022, 73(8): 3597-3607. |

| [10] | Chengyi AI, Jinshuo QIAO, Zhenhuan WANG, Wang SUN, Kening SUN. Investigation on PrBaFe2O6-δ anode material with in-situ FeNi nanoparticle in direct carbon solid oxide fuel cell [J]. CIESC Journal, 2022, 73(8): 3708-3719. |

| [11] | Chenyang ZHOU, Ying JIA, Yuemin ZHAO, Yong ZHANG, Zhijie FU, Yuqing FENG, Chenlong DUAN. Intensification of dry dense medium fluidization separation process from a mesoscale perspective [J]. CIESC Journal, 2022, 73(6): 2452-2467. |

| [12] | Mengxi LIU, Yiping FAN, Zihan YAN, Xiuying YAO, Chunxi LU. Regulation and industrial application of gas jet hydrodynamic behavior in a feedstock injection zone of a riser [J]. CIESC Journal, 2022, 73(6): 2496-2513. |

| [13] | Xiaoshan DONG, Jian LI, Beibei YAN, Guanyi CHEN. Research progress of perovskite catalysts in thermochemical utilization of biomass [J]. CIESC Journal, 2022, 73(2): 504-520. |

| [14] | Baowen WANG, Gang ZHANG, Tongqing LIU, Weiguang LI, Mengjia WANG, Deshun LIN, Jingjing MA. Research on chemical looping reforming of CH4 by CeO2 doped CuFe2O4 oxygen carrier coupled with CO2 thermocatalytic reduction [J]. CIESC Journal, 2022, 73(12): 5414-5426. |

| [15] | ZHANG Yashuang, LI Hong, CONG Haifeng, HAN Hongming, LI Xingang, GAO Xin. Numerical simulation of microwave-enhanced spiral liquid-bridge falling film evaporator [J]. CIESC Journal, 2021, 72(S1): 227-235. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||