CIESC Journal ›› 2023, Vol. 74 ›› Issue (12): 4792-4809.DOI: 10.11949/0438-1157.20230874

• Reviews and monographs • Previous Articles Next Articles

Shuo LI1,2( ), Zhepeng ZHAO2, Zhengwei CUI2(

), Zhepeng ZHAO2, Zhengwei CUI2( ), Guanming YUAN1,2(

), Guanming YUAN1,2( ), Bin XU2

), Bin XU2

Received:2023-08-23

Revised:2023-12-11

Online:2024-02-19

Published:2023-12-25

Contact:

Zhengwei CUI, Guanming YUAN

李烁1,2( ), 赵哲鹏2, 崔正威2(

), 赵哲鹏2, 崔正威2( ), 袁观明1,2(

), 袁观明1,2( ), 许斌2

), 许斌2

通讯作者:

崔正威,袁观明

作者简介:李烁(2000—),男,硕士研究生,lishuo2030@163.com

基金资助:CLC Number:

Shuo LI, Zhepeng ZHAO, Zhengwei CUI, Guanming YUAN, Bin XU. Characteristic, structure, preparation and applications of soft and hard carbons[J]. CIESC Journal, 2023, 74(12): 4792-4809.

李烁, 赵哲鹏, 崔正威, 袁观明, 许斌. 软/硬炭的特性、结构、制备及应用[J]. 化工学报, 2023, 74(12): 4792-4809.

Add to citation manager EndNote|Ris|BibTeX

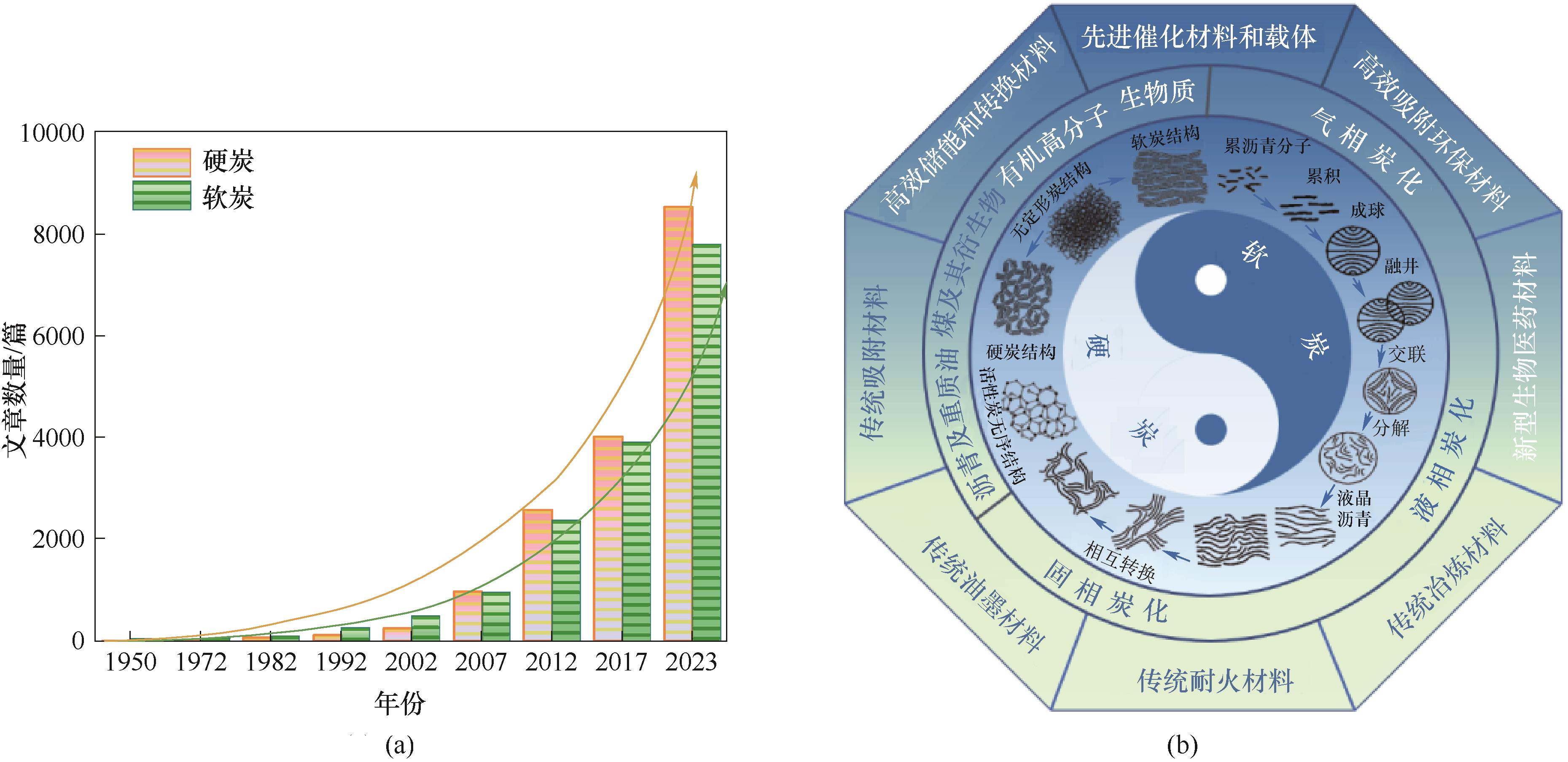

Fig.1 (a) Numbers of published articles on soft and hard carbons indexed by Web of Science; (b) Structure characteristics and applications of soft and hard carbons

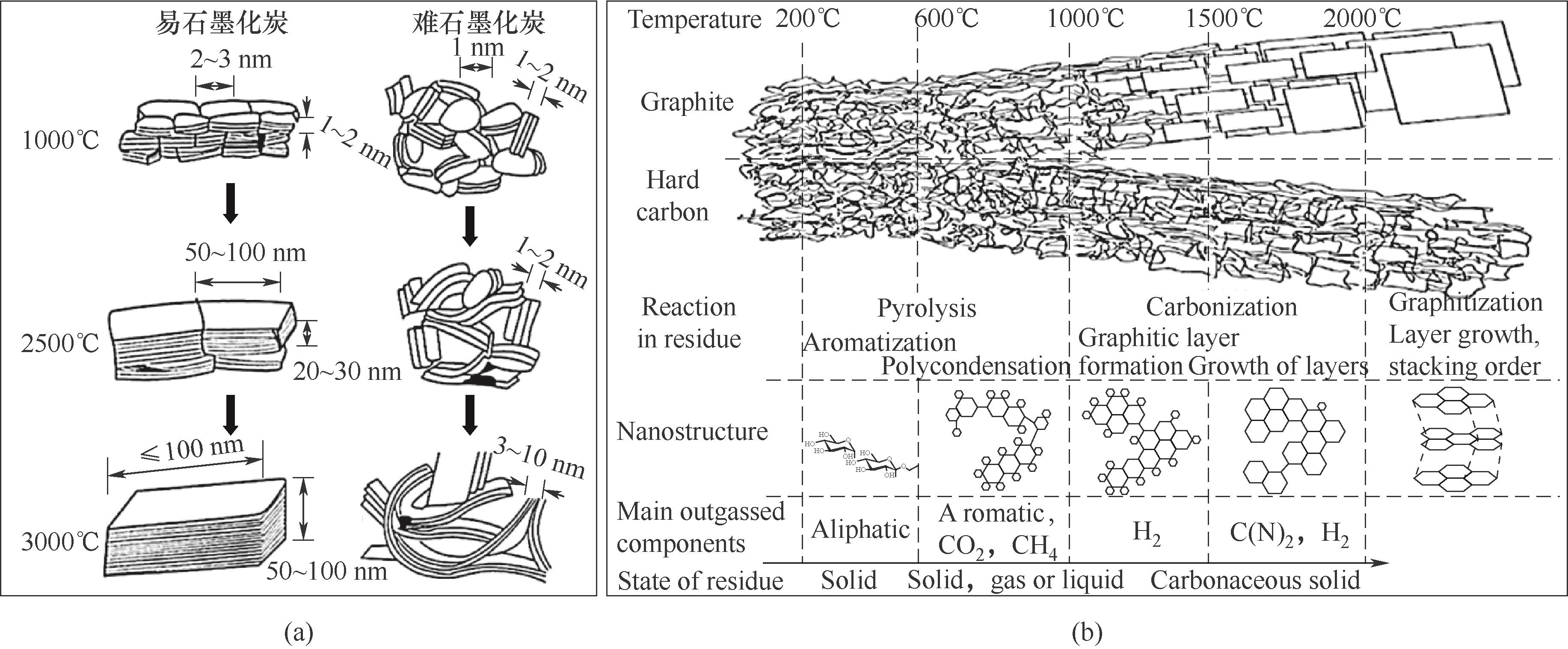

Fig.3 (a) Typical structure models of various carbon materials[32]; (b) Microcrystal structure characteristics of graphite, graphitizable soft carbon and non-graphitizable hard carbon[37-38]

Fig.8 (a) Structural changes of hardly and easily graphitized carbons during graphitization[83]; (b) Formation of hard carbon and its structure evolution as a function of temperature[84-85]

| 项目 | 软炭 | 硬炭 |

|---|---|---|

| 结构特性 | 结构较为密实、硬度较小,石墨微晶较大、排列较为有序, 易石墨化、缺陷较少 | 以多孔结构为主、硬度相对较大,石墨微晶较小、排列相对无序,难石墨化、缺陷较多 |

微观结构 |  |  |

| 代表种类 | 石油焦、针状焦、中间相炭微球、沥青基泡沫炭、中间相 沥青基碳纤维、气相热解炭(石墨) | 树脂(酚醛树脂、糠醛树脂等)炭、有机聚合物(聚丙烯腈、聚乙烯醇等)热解炭、生物质热解炭、炭黑(乙炔黑) |

| 原 料 | 石油沥青、煤沥青、重质油、稠环芳烃等 | 生物质、有机高分子聚合物、改性沥青、煤及其衍生物等 |

| 制备方法 | 气相炭化、液相炭化(主)、固相炭化 | 热解炭化、水热炭化、活化处理、氧化交联、静电纺丝、模板法 |

| 传统应用 | 导热材料、石墨电极、导电填料、耐磨材料、密封材料、 增强材料 | 传统燃料、绝热材料、染料、耐火材料、电极材料、吸附剂 |

| 新兴应用 | 新型电池、超级电容器、电极材料、复合材料等 | 高效吸附材料、储氢材料、储能材料、新型电极、催化剂及载体等 |

Table 1 Comprehensive comparison of soft and hard carbons in structure, preparation, properties and applications

| 项目 | 软炭 | 硬炭 |

|---|---|---|

| 结构特性 | 结构较为密实、硬度较小,石墨微晶较大、排列较为有序, 易石墨化、缺陷较少 | 以多孔结构为主、硬度相对较大,石墨微晶较小、排列相对无序,难石墨化、缺陷较多 |

微观结构 |  |  |

| 代表种类 | 石油焦、针状焦、中间相炭微球、沥青基泡沫炭、中间相 沥青基碳纤维、气相热解炭(石墨) | 树脂(酚醛树脂、糠醛树脂等)炭、有机聚合物(聚丙烯腈、聚乙烯醇等)热解炭、生物质热解炭、炭黑(乙炔黑) |

| 原 料 | 石油沥青、煤沥青、重质油、稠环芳烃等 | 生物质、有机高分子聚合物、改性沥青、煤及其衍生物等 |

| 制备方法 | 气相炭化、液相炭化(主)、固相炭化 | 热解炭化、水热炭化、活化处理、氧化交联、静电纺丝、模板法 |

| 传统应用 | 导热材料、石墨电极、导电填料、耐磨材料、密封材料、 增强材料 | 传统燃料、绝热材料、染料、耐火材料、电极材料、吸附剂 |

| 新兴应用 | 新型电池、超级电容器、电极材料、复合材料等 | 高效吸附材料、储氢材料、储能材料、新型电极、催化剂及载体等 |

| 1 | Michio I, Kang F. Materials Science and Engineering of Carbon: Fundamentals[M]. Beijing: Tsinghua University Press, 2014. |

| 2 | Xiang R. Atomic precision manufacturing of carbon nanotube—a perspective[J]. International Journal of Extreme Manufacturing, 2022, 4(2): 023001. |

| 3 | Su D S, Siglinda P, Gabriele C. Nanocarbons for the development of advanced catalysts[J]. Chemical Reviews, 2013, 113(8): 5782-5816. |

| 4 | Borchardt L, Zhu Q L, Casco M E, et al. Toward a molecular design of porous carbon materials[J]. Materials Today, 2017, 20(10): 592-610. |

| 5 | He H N, He J, Yu H B, et al. Dual-interfering chemistry for soft-hard carbon translation toward fast and durable sodium storage[J]. Advanced Energy Materials, 2023, 13(16): 2300357. |

| 6 | 胡梦菲, 黄丽萍, 李贺, 等. 锂/钠离子电池硬碳负极材料的研究进展[J]. 无机材料学报, 2023. DOI: 10.15541/jim20230365 . |

| Hu M F, Huang L P, Li H, et al. Research progress on hard carbon anode for Li/Na-ion batteries[J]. Journal of Inorganic Materials, 2023. DOI: 10.15541/jim20230365 . | |

| 7 | Qiu G J, Ning M, Zhang M L, et al. Flexible hard-soft carbon heterostructure based on mesopore confined carbonization for ultrafast and highly durable sodium storage[J]. Carbon, 2023, 205: 310-320. |

| 8 | Cheng B S, Li X, Xu H Q, et al. Strengthen synergistic effect of soft carbon and hard carbon toward high-performance anode for K-ion battery[J]. ACS Applied Materials & Interfaces, 2022, 14(28): 31879-31888. |

| 9 | Zhang H R, Zhu M X, Zhou J P. Hard-soft carbon with tailored graphitization for high performance supercapacitors[J]. Journal of Energy Storage, 2023, 66: 107406. |

| 10 | Chen S H, Kuang Q A, Fan H J. Dual-carbon batteries: materials and mechanism[J]. Small, 2020, 16(40): 2002803. |

| 11 | He L T, Wang D H, Zhu T L, et al. Pyrolysis recycling of pig manure biochar adsorption material for decreasing ammonia nitrogen in biogas slurry[J]. Science of the Total Environment, 2023, 881: 163315. |

| 12 | Gao W C, He W, Zhang J, et al. Effects of biochar-based materials on nickel adsorption and bioavailability in soil[J]. Scientific Reports, 2023, 13(1): 5880. |

| 13 | Jeon S, Farooq A, Lee I H, et al. Green conversion of wood plastic composites: a study on gasification with an activated bio-char catalyst[J]. International Journal of Hydrogen Energy, 2023. DOI: 10.1016/j.ijhydene.2023.05.127 . |

| 14 | Zhang J W, Mariska S, Pap S, et al. Enhanced separation capacity of carbonaceous materials (hydrochar, biochar, and activated carbon) toward potential toxic metals through grafting copolymerization[J]. Separation and Purification Technology, 2023, 320: 124229. |

| 15 | Infurna G, Caruso G, Dintcheva N T. Sustainable materials containing biochar particles: a review[J]. Polymers, 2023, 15(2): 343. |

| 16 | Wang L G, Wang D S, Li Y D. Single-atom catalysis for carbon neutrality[J]. Carbon Energy, 2022, 4(6): 1021-1079. |

| 17 | 张思伟, 张俊, 吴思达, 等. 钠离子电池用碳负极材料研究进展[J]. 化学学报, 2017, 75(2): 163-172. |

| Zhang S W, Zhang J, Wu S D, et al. Research advances of carbon-based anode materials for sodium-ion batteries[J]. Acta Chimica Sinica, 2017, 75(2): 163-172. | |

| 18 | Cheng D J, Zhou X Q, Hu H Y, et al. Electrochemical storage mechanism of sodium in carbon materials: a study from soft carbon to hard carbon[J]. Carbon, 2021, 182: 758-769. |

| 19 | Nandi P, Patnaik A, Subramaniam C. Synergising hard-carbon and soft-carbon interactions for delivering metal-free microscale supercapacitors with high specific energy and rapid power delivery[J]. Journal of Energy Storage, 2023, 73: 109157. |

| 20 | Biscoe J, Warren B E. An X-ray study of carbon black[J]. Journal of Applied Physics, 1942, 13(6): 364-371. |

| 21 | Franklin R E. Crystallite growth in graphitizing and non-graphitizing carbons[J]. Proceedings of the Royal Society of London. A: Mathematical and Physical Sciences, 1951, 209(1097): 196-218. |

| 22 | Mrozowski S. Proceedings of the First and Second Conferences on Carbon[M]. University of Buffalo: Waverly Press, 1956: 31. |

| 23 | Brooks J D, Taylor G H. Formation of graphitizing carbons from the liquid phase[J]. Nature, 1965, 206(4985): 697-699. |

| 24 | Maire J, Mehring J. Graphitization of soft carbons[J]. Chemistry and Physics of Carbon, 1970, 6: 125-190. |

| 25 | Marsh H, Walker P L. The formation of graphitizable carbons via mesophase: chemical and kinetic considerations[J]. Chemistry and Physics of Carbon, 1979, 15: 229-286. |

| 26 | Köchling K, McEnaney B, Müller S, et al. International committee for characterization and terminology of carbon “first publication of 14 further tentative definitions”[J]. Carbon, 1985, 23: 246-247. |

| 27 | Marsh H. Introduction to Carbon Science[M]. London: Butterworths, 1989. |

| 28 | Mochida I, Ku C H, Korai Y. Anodic performance and insertion mechanism of hard carbons prepared from synthetic isotropic pitches[J]. Carbon, 2001, 39(3): 399-410. |

| 29 | Michio I, Kang F. Carbon Materials Science and Engineering: From Fundamentals to Application[M]. Beijing: Tsinghua University Press, 2006. |

| 30 | 国家市场监督管理总局,国家标准化管理委员会. 软炭: GB∕T 38824—2020 [S]. 北京: 中国标准出版社, 2020. |

| State Administration for Market Regulation, National Standardization Administration. Soft Carbon: GB∕T 38824—2020 [S]. Beijing: Standards Press of China, 2020. | |

| 31 | 国家市场监督管理总局,国家标准化管理委员会. 硬炭: GB∕T 43114—2023 [S]. 北京: 中国标准出版社, 2023. |

| State Administration for Market Regulation, National Standardization Administration. Hard carbon: GB∕T 43114—2023 [S]. Beijing: Standards Press of China, 2023. | |

| 32 | Wang G, Yu M H, Feng X L. Carbon materials for ion-intercalation involved rechargeable battery technologies[J]. Chemical Society Reviews, 2021, 50(4): 2388-2443. |

| 33 | Zhang S, Liu Q F, Zhang H, et al. Structural order evaluation and structural evolution of coal derived natural graphite during graphitization[J]. Carbon, 2020, 157: 714-723. |

| 34 | Novoselov K S, Geim A A, Morozov S V, et al. Electric field effect in atomically thin carbon films[J]. Science, 2004, 306(5696): 666-669. |

| 35 | Ijima S. Helical microtubules of graphitic carbon[J]. Nature, 1991, 354(6348): 56-58. |

| 36 | 梁大明, 孙仲超. 煤基炭材料[M]. 北京: 化学工业出版社, 2011. |

| Liang D M, Sun Z C. Coal-Based Carbon Material[M]. Beijing: Chemical Industry Press, 2011. | |

| 37 | Nishi Y. The development of lithium ion secondary batteries[J]. The Chemical Record, 2001, 1(5): 406-413. |

| 38 | Crabtree G, Kócs E A, Trahey L. The energy-storage frontier: lithium-ion batteries and beyond[J]. MRS Bulletin, 2015, 40(12): 1067-1078. |

| 39 | 王成扬. 碳质中间相理论与应用[M]. 北京: 科学出版社, 2015: 100-101. |

| Wang C Y. Theory and Application of Carbonaceous Mesophase[M]. Beijing: Science Press, 2015: 100-101. | |

| 40 | Marsh H, Walker Jr P L. The effects of impregnation of coal by alkali salts upon carbonization properties[J]. Fuel Processing Technology, 1979, 2(1): 61-75. |

| 41 | Fujimoto K I, Mochida I, Todo Y, et al. Mechanism of puffing and the role of puffing inhibitors in the graphitization of electrodes from needle cokes[J]. Carbon, 1989, 27(6): 909-917. |

| 42 | Lee J S, Kim Y K, Hwang J Y, et al. Carbon nanosheets by the graphenization of ungraphitizable isotropic pitch molecules[J]. Carbon, 2017, 121: 479-489. |

| 43 | 王绍清, 王小令, 沙吉顿, 等. 煤石墨化:结构和差异性演化[J]. 煤炭学报, 2022, 47(12): 4300-4312. |

| Wang S Q, Wang X L, Sha J D, et al. Coal graphitization: structures and their differential evolution[J]. Journal of China Coal Society, 2022, 47(12): 4300-4312. | |

| 44 | Xie L J, Tang C, Bi Z H, et al. Hard carbon anodes for next-generation Li-ion batteries: review and perspective[J]. Advanced Energy Materials, 2021, 11(38): 2101650. |

| 45 | 肖国庆, 勾黎敏, 丁冬海. 超级电容器用PVDC基碳电极的研究现状[J]. 材料导报, 2018, 32(19): 3309-3317. |

| Xiao G Q, Gou L M, Ding D H. A state-of-the-art review on PVDC-based carbon electrode for supercapacitors[J]. Materials Review, 2018, 32(19): 3309-3317. | |

| 46 | 杨翠云, 杨成浩. 钠离子电池硬炭负极材料的研究进展[J]. 高等学校化学学报, 2023, 44(5): 162-177. |

| Yang C Y, Yang C H. Recent progress of hard carbon anode materials for sodium ion batteries[J]. Chemical Journal of Chinese Universities, 2023, 44(5): 162-177. | |

| 47 | Jenkins G M, Kawamura K, Ban L L. Formation and structure of polymeric carbons[J]. Proceedings of the Royal Society of London A: Mathematical and Physical Sciences, 1972, 327(1571): 501-517. |

| 48 | Harris P J F. Structure of non-graphitising carbons[J]. International Materials Reviews, 1997, 42(5): 206-218. |

| 49 | Shiraishi M. Introduction to Carbon Materials[M]. Tokyo: Carbon Society of Japan, 1984: 29-40. |

| 50 | Ban L L, Crawford D, Marsh H. Lattice-resolution electron microscopy in structural studies of non-graphitizing carbons from polyvinylidene chloride (PVDC)[J]. Journal of Applied Crystallography, 1975, 8(4): 415-420. |

| 51 | Harris P J F. Non-graphitizing carbons[M]//Encyclopedia of Materials: Science and Technology. Amsterdam: Elsevier, 2001: 6197-6202. |

| 52 | Michio I, Kang F. Materials Science and Engineering of Carbon: Characterization[M]. Beijing: Tsinghua University Press, 2017. |

| 53 | 张保法. 化学气相沉积中的气相生长碳纤维[J]. 材料工程, 2015, 43(11): 9-12. |

| Zhang B F. Vapor grown carbon fibers produced in chemical vapor deposition[J]. Journal of Materials Engineering, 2015, 43(11): 9-12. | |

| 54 | Shen Q L, Song Q, Xiao C X, et al. Ultrahigh thermal conductive graphite film via the in situ construction of aligned nanographene skeleton using chemical vapor deposition[J]. Journal of Materials Science & Technology, 2023, 148: 1-9. |

| 55 | Brooks J D, Taylor G H. The formation of graphitizing carbons from the liquid phase[J]. Carbon, 1965, 3(2): 185-193. |

| 56 | 杨桃, 刘犇, 宋燕, 等. 高温煤沥青中间相热转化行为[J]. 新型炭材料, 2019, 34(6): 546-551. |

| Yang T, Liu B, Song Y, et al. Formation and transformation behavior of mesophase from three high softening-point pitches[J]. New Carbon Materials, 2019, 34(6): 546-551. | |

| 57 | Marsh H. Carbon Mesophase[M]//Encyclopedia of Materials: Science and Technology. Amsterdam: Elsevier, 2001: 926-931. |

| 58 | Mochida I, Ku C H, Yoon S H, et al. Anodic performance and mechanism of mesophase-pitch-derived carbons in lithium ion batteries[J]. Journal of Power Sources, 1998, 75(2): 214-222. |

| 59 | Guo J G, Lu S C, Xie J R, et al. Preparation of mesophase pitch with domain textures by molecular regulation of ethylene tar pitch for boosting the performance of its carbon materials[J]. Journal of Analytical and Applied Pyrolysis, 2023, 170: 105932. |

| 60 | Zhang Z C, Lou B, Zhao N, et al. Co-carbonization behavior of the blended heavy oil and low temperature coal tar for the preparation of needle coke[J]. Fuel, 2021, 302: 121139. |

| 61 | Serp P. Carbon[M]//Comprehensive Inorganic Chemistry Ⅱ. Amsterdam: Elsevier, 2013: 323-369. |

| 62 | Hunter R D, Ramírez-Rico J, Schnepp Z. Iron-catalyzed graphitization for the synthesis of nanostructured graphitic carbons[J]. Journal of Materials Chemistry A, 2022, 10(9): 4489-4516. |

| 63 | Murakami M, Tatami A, Tachibana M. Fabrication of high quality and large area graphite thin films by pyrolysis and graphitization of polyimides[J]. Carbon, 2019, 145: 23-30. |

| 64 | Wu S Y, Zhang S Y, Wang C W, et al. High-strength charcoal briquette preparation from hydrothermal pretreated biomass wastes[J]. Fuel Processing Technology, 2018, 171: 293-300. |

| 65 | Chen C, Huang Y, Lu M W, et al. Tuning morphology, defects and functional group types in hard carbon via phosphorus doped for rapid sodium storage[J]. Carbon, 2021, 183: 415-427. |

| 66 | Zhang Y Y, Zhang J C, Chen K D, et al. Engineering banana-peel-derived biochar for the rapid adsorption of tetracycline based on double chemical activation[J]. Resources, Conservation and Recycling, 2023, 190: 106821. |

| 67 | 邵健, 冯军宗, 柳凤琦, 等. 酚醛树脂基炭微球结构调控与功能化制备研究进展[J]. 化工学报, 2022, 73(9): 3787-3801. |

| Shao J, Feng J Z, Liu F Q, et al. Research progress on structural modulation and functionalized preparation of phenolic resin-based carbon microspheres[J]. CIESC Journal, 2022, 73(9): 3787-3801. | |

| 68 | Li W, Wang G H, Sui W J, et al. Facile and scalable preparation of cage-like mesoporous carbon from lignin-based phenolic resin and its application in supercapacitor electrodes[J]. Carbon, 2022, 196: 819-827. |

| 69 | Yun H, Kim Y J, Bin Kim S, et al. Preparation of copper-loaded porous carbons through hydrothermal carbonization and ZnCl2 activation and their application to selective CO adsorption: experimental and DFT calculation studies[J]. Journal of Hazardous Materials, 2022, 426: 127816. |

| 70 | 李鹏, 张致远, 周群宗, 等. 煤沥青/聚丙烯腈基活性碳纤维无纺布的制备及电化学性能[J]. 煤炭学报, 2023, 48(2): 1028-1036. |

| Li P, Zhang Z Y, Zhou Q Z, et al. Preparation of coal pitch/polyacrylonitrile based activated carbon fiber film and investigation on its electrochemical performance[J]. Journal of China Coal Society, 2023, 48(2): 1028-1036. | |

| 71 | Lu Y X, Zhao C L, Qi X G, et al. Pre-oxidation-tuned microstructures of carbon anodes derived from pitch for enhancing Na storage performance[J]. Advanced Energy Materials, 2018, 8(27): 1800108. |

| 72 | Cao Y M, Li S P, Yang Z P, et al. Template-directing coupled with chemical activation methodology-derived hexagon-like porous carbon electrode with outstanding compatibility to electrolytes and low-temperature performance[J]. ACS Applied Materials & Interfaces, 2021, 13(7): 8206-8218. |

| 73 | Zhao C, Ge L C, Mai L H, et al. Preparation and performance of coal-based activated carbon based on an orthogonal experimental study[J]. Energy, 2023, 274: 127353. |

| 74 | 樊丽华, 王晓柳, 侯彩霞, 等. 褐煤基活性炭和无灰煤基活性炭性能对比研究[J]. 功能材料, 2017, 48(1): 1244-1248. |

| Fan L H, Wang X L, Hou C X, et al. Research on performance comparison of lignite-activated carbon and hypercoal-activated carbon[J]. Journal of Functional Materials, 2017, 48(1): 1244-1248. | |

| 75 | 岳晓明, 吴雅俊, 张双全, 等. 物理化学两步活化法制备煤基活性炭电极材料[J]. 中国矿业大学学报, 2017, 46(4): 888-894. |

| Yue X M, Wu Y J, Zhang S Q, et al. Preparation of coal-based activated carbon electrodes by two steps of physical-chemical activation[J]. Journal of China University of Mining & Technology, 2017, 46(4): 888-894. | |

| 76 | Tian H Y, Pan J, Zhu D Q, et al. Innovative one-step preparation of activated carbon from low-rank coals activated with oxidized pellets[J]. Journal of Cleaner Production, 2021, 313: 127877. |

| 77 | Mochizuki Y, Tsubouchi N. Preparation of pelletized coke by co-carbonization of caking coal and pyrolyzed char modified with tar produced during pyrolysis of woody biomass[J]. Fuel Processing Technology, 2019, 193: 328-337. |

| 78 | Tan H, Du X Q, Zhou R, et al. Rational design of microstructure and interphase enables high-capacity and long-life carbon anodes for potassium ion batteries[J]. Carbon, 2021, 176: 383-389. |

| 79 | Xu R, Yi Z L, Song M X, et al. Boosting sodium storage performance of hard carbons by regulating oxygen functionalities of the cross-linked asphalt precursor[J]. Carbon, 2023, 206: 94-104. |

| 80 | Oberlin A. Carbonization and graphitization[J]. Carbon, 1984, 22(6): 521-541. |

| 81 | Yan F, Long X Y, Cui Z W, et al. Stretching modification on mesophase-pitch-based fibers during carbonization process: from laboratory batch experiments to pilot continuous production[J]. Carbon, 2022, 197: 52-64. |

| 82 | Oberlin A, Terriere G. Graphitization studies of anthracites by high resolution electron microscopy[J]. Carbon, 1975, 13(5): 367-376. |

| 83 | 大谷杉郎, 大谷朝男. 碳纤维入门[M]. 吕健, 译. 中国金属学会炭素材料学会, 吉林炭素厂, 1983: 55. |

| Otani S, Oya A. Introduction to Carbon Fibers[M]. Lyv J, trans. Chinese Society of Metals and Carbon Materials Society; Jilin Carbon Plant, 1983: 55. | |

| 84 | Dou X W, Hasa I, Saurel D, et al. Hard carbons for sodium-ion batteries: structure, analysis, sustainability, and electrochemistry[J]. Materials Today, 2019, 23: 87-104. |

| 85 | Marsh H, Rodríguez-Reinoso F. Activated Carbon[M]. Amsterdam: Elsevier, 2006: 13-86. |

| 86 | Li Z F, Bommier C, Chong Z S, et al. Mechanism of Na-ion storage in hard carbon anodes revealed by heteroatom doping[J]. Advanced Energy Materials, 2017, 7(18): 1602894. |

| 87 | 王博阳, 夏吉利, 董晓玲, 等. 不同变质程度煤衍生硬炭的储钠行为研究[J]. 化工学报, 2021, 72(11): 5738-5750. |

| Wang B Y, Xia J L, Dong X L, et al. Study on sodium storage behavior of hard carbons derived from coal with different grades of metamorphism[J]. CIESC Journal, 2021, 72(11): 5738-5750. | |

| 88 | 郭行, 韩纹莉, 董晓玲, 等. 调控炭化过程优化煤基硬炭负极储钠性能[J]. 化工学报, 2022, 73(4): 1794-1806. |

| Guo H, Han W L, Dong X L, et al. Adjusting carbonization process to optimize sodium storage performance of coal-based hard carbon anode[J]. CIESC Journal, 2022, 73(4): 1794-1806. | |

| 89 | Qiu S, Xiao L F, Sushko M L, et al. Manipulating adsorption-insertion mechanisms in nanostructured carbon materials for high-efficiency sodium ion storage[J]. Advanced Energy Materials, 2017, 7(17): 1700403. |

| 90 | Liu S Y, Shao W L, Zhang W S, et al. Regulating microstructures of soft carbon anodes by terminations of Ti3C2T x MXene toward fast and stable sodium storage[J]. Nano Energy, 2021, 87: 106097. |

| 91 | Qi Y R, Lu Y X, Liu L L, et al. Retarding graphitization of soft carbon precursor: from fusion-state to solid-state carbonization[J]. Energy Storage Materials, 2020, 26: 577-584. |

| 92 | Kipling J J, Sherwood J N, Shooter P V, et al. Factors influencing the graphitization of polymer carbons[J]. Carbon, 1964, 1(3): 315-320. |

| 93 | Wang J, Yan L, Liu B H, et al. A solvothermal pre-oxidation strategy converting pitch from soft carbon to hard carbon for enhanced sodium storage[J]. Chinese Chemical Letters, 2023, 34(4): 107526. |

| 94 | Xie F, Xu Z, Jensen A C S, et al. Hard–soft carbon composite anodes with synergistic sodium storage performance[J]. Advanced Functional Materials, 2019, 29(24): 1901072. |

| 95 | Yin X P, Zhao Y F, Wang X A, et al. Modulating the graphitic domains of hard carbons derived from mixed pitch and resin to achieve high rate and stable sodium storage[J]. Small, 2022, 18(5): 2105568. |

| 96 | Li Y M, Hu Y S, Li H, et al. A superior low-cost amorphous carbon anode made from pitch and lignin for sodium-ion batteries[J]. Journal of Materials Chemistry A, 2016, 4(1): 96-104. |

| 97 | Jin Z, Zuo X H, Long X Y, et al. Accelerating the oxidative stabilization of pitch fibers and improving the physical performance of carbon fibers by modifying naphthalene-based mesophase pitch with C9 resin[J]. Journal of Analytical and Applied Pyrolysis, 2021, 154: 105009. |

| 98 | Qiu D, Cao T F, Zhang J, et al. Precise carbon structure control by salt template for high performance sodium-ion storage[J]. Journal of Energy Chemistry, 2019, 31: 101-106. |

| 99 | He X X, Zhao J H, Lai W H, et al. Soft-carbon-coated, free-standing, low-defect, hard-carbon anode to achieve a 94% initial coulombic efficiency for sodium-ion batteries[J]. ACS Applied Materials & Interfaces, 2021, 13(37): 44358-44368. |

| 100 | 郑雁军, 崔立山, 崔晓龙, 等. 高附加值石油焦新材料[J]. 新型炭材料, 2006, 21(1): 90-96. |

| Zheng Y J, Cui L S, Cui X L, et al. High value-added advanced materials based on petroleum coke[J]. New Carbon Materials, 2006, 21(1): 90-96. | |

| 101 | 李同起, 王成扬. 碳质中间相形成机理研究[J]. 新型炭材料, 2005, 20(3): 278-285. |

| Li T Q, Wang C Y. The formation mechanism of carbonaceous mesophase[J]. New Carbon Materials, 2005, 20(3): 278-285. | |

| 102 | Wang B, Peng Y, Yuan F, et al. A comprehensive review of carbons anode for potassium-ion battery: fast kinetic, structure stability and electrochemical[J]. Journal of Power Sources, 2021, 484: 229244. |

| 103 | Xue Y C, Gao M Y, Wu M R, et al. A promising hard carbon-soft carbon composite anode with boosting sodium storage performance[J]. ChemElectroChem, 2020, 7(19): 4010-4015. |

| 104 | 潘广宏, 赵永彬, 张开周, 等. 高功率锂离子电池软/硬复合碳负极材料[J]. 储能科学与技术, 2017, 6(1): 94-100. |

| Pan G H, Zhao Y B, Zhang K Z, et al. High power soft/hard carbon composite anode for rechargeable lithium-ion battery[J]. Energy Storage Science and Technology, 2017, 6(1): 94-100. | |

| 105 | 禹兴海, 罗齐良, 潘剑, 等. 一种生物炭基柔性固态超级电容器的制备及性能研究[J]. 化工学报, 2019, 70(9): 3590-3600. |

| Yu X H, Luo Q L, Pan J, et al. Preparation and properties of flexible supercapacitor based on biochar and solid gel-electrolyte[J]. CIESC Journal, 2019, 70(9): 3590-3600. | |

| 106 | Li X W, Zhang H Y, Zhao B, et al. Preparation of hydrogen storage carbon materials using bio-oil heavy components as carbon-containing precursor[J]. Fuel Processing Technology, 2020, 203: 106386. |

| 107 | Zhang W J, Jing P, Du J, et al. Interfacial-interaction-induced fabrication of biomass-derived porous carbon with enhanced intrinsic active sites[J]. Chinese Journal of Catalysis, 2022, 43(8): 2231-2239. |

| 108 | Jia Y, Yao X D. Defects in carbon-based materials for electrocatalysis: synthesis, recognition, and advances[J]. Accounts of Chemical Research, 2023, 56(8): 948-958. |

| 109 | Guo X J, Gao G, Remón J, et al. Selective hydrogenation of vanillin to vanillyl alcohol over Pd, Pt, and Au catalysts supported on an advanced nitrogen-containing carbon material produced from food waste[J]. Chemical Engineering Journal, 2022, 440: 135885. |

| 110 | Xiong Y, Dong J C, Huang Z Q, et al. Single-atom Rh/N-doped carbon electrocatalyst for formic acid oxidation[J]. Nature Nanotechnology, 2020, 15(5): 390-397. |

| 111 | Sundar D, Liu C H, Anandan S, et al. Photocatalytic CO2 conversion into solar fuels using carbon-based materials—a review[J]. Molecules, 2023, 28(14): 5383. |

| 112 | Han L L, Song S J, Liu M J, et al. Stable and efficient single-atom Zn catalyst for CO2 reduction to CH4 [J]. Journal of the American Chemical Society, 2020, 142(29): 12563-12567. |

| 113 | Wang M R, Cai Y P, Zhou B H, et al. Removal of PFASs from water by carbon-based composite photocatalysis with adsorption and catalytic properties: a review[J]. Science of the Total Environment, 2022, 836: 155652. |

| 114 | Xiong S, Tang R D, Gong D X, et al. Environmentally-friendly carbon nanomaterials for photocatalytic hydrogen production[J]. Chinese Journal of Catalysis, 2022, 43(7): 1719-1748. |

| 115 | Zhou J H, Li X S, Yuan J, et al. Efficient degradation and toxicity reduction of tetracycline by recyclable ferroferric oxide doped powdered activated charcoal via peroxymonosulfate (PMS) activation[J]. Chemical Engineering Journal, 2022, 441: 136061. |

| 116 | Wu F F, Chen L, Hu P, et al. Industrial alkali lignin-derived biochar as highly efficient and low-cost adsorption material for Pb(Ⅱ) from aquatic environment[J]. Bioresource Technology, 2021, 322: 124539. |

| 117 | Wang A, Chen W, Liu S Y, et al. Layered porous carbon material derived from food residues and its application for elemental mercury adsorption in flue gas[J]. Fuel, 2023, 335: 126876. |

| 118 | Wang J Y, Fan D Z, Zhang L Z, et al. Lignin-derived hierarchical porous carbon with high surface area and interconnected pores for efficient antibiotics adsorption[J]. Chemical Engineering Journal, 2023, 454: 139789. |

| 119 | Sun Z W, Lu F, Cheng J J, et al. Haemostatic bioactivity of novel schizonepetae spica carbonisata-derived carbon dots via platelet counts elevation[J]. Artificial Cells, Nanomedicine, and Biotechnology, 2018, 46(sup3): S308-S317. |

| 120 | Kaur T, Thirugnanam A. Effect of porous activated charcoal reinforcement on mechanical and in-vitro biological properties of polyvinyl alcohol composite scaffolds[J]. Journal of Materials Science & Technology, 2017, 33(7): 734-743. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||