化工学报 ›› 2021, Vol. 72 ›› Issue (S1): 42-52.DOI: 10.11949/0438-1157.20200112

收稿日期:2020-10-09

修回日期:2020-10-17

出版日期:2021-06-20

发布日期:2021-06-20

通讯作者:

付凤艳

作者简介:付凤艳(1981—),女,博士,讲师,基金资助:Received:2020-10-09

Revised:2020-10-17

Online:2021-06-20

Published:2021-06-20

Contact:

FU Fengyan

摘要:

阴离子交换膜燃料电池(AEMFCs)因其具有环境友好、可使用非贵金属催化剂、电极反应速率快等特点而受到广泛关注。阴离子交换膜(AEMs)是AEMFCs的核心部件,其性质决定着燃料电池的性能、能量效率和使用寿命。从具有不同骨架结构的聚合物出发,介绍了聚苯醚、聚芳醚砜、聚烯烃和聚苯并咪唑等不同聚合物骨架结构的阴离子交换膜的制备、性能和应用,同时对具有不同聚合物骨架结构的阴离子交换膜在应用方面存在的问题及应用前景进行了评论和展望。

中图分类号:

付凤艳, 邢广恩. 碱性燃料电池用阴离子交换膜的研究进展[J]. 化工学报, 2021, 72(S1): 42-52.

FU Fengyan, XING Guang'en. Progress of polymer-based anion exchange membrane for alkaline fuel cell application[J]. CIESC Journal, 2021, 72(S1): 42-52.

图5 Suzuki偶联反应得到的含有三甲基苄铵的PSU的结构(a);氯甲基化得到的含有三甲基苄铵的PSU的结构(b)

Fig.5 The structure of trimethylbenzylammonium-functionalized polysulfone via Suzuki coupling reactions (a); The structure of trimethylbenzylammonium-functionalized polysulfone via chloromethylation route (b)

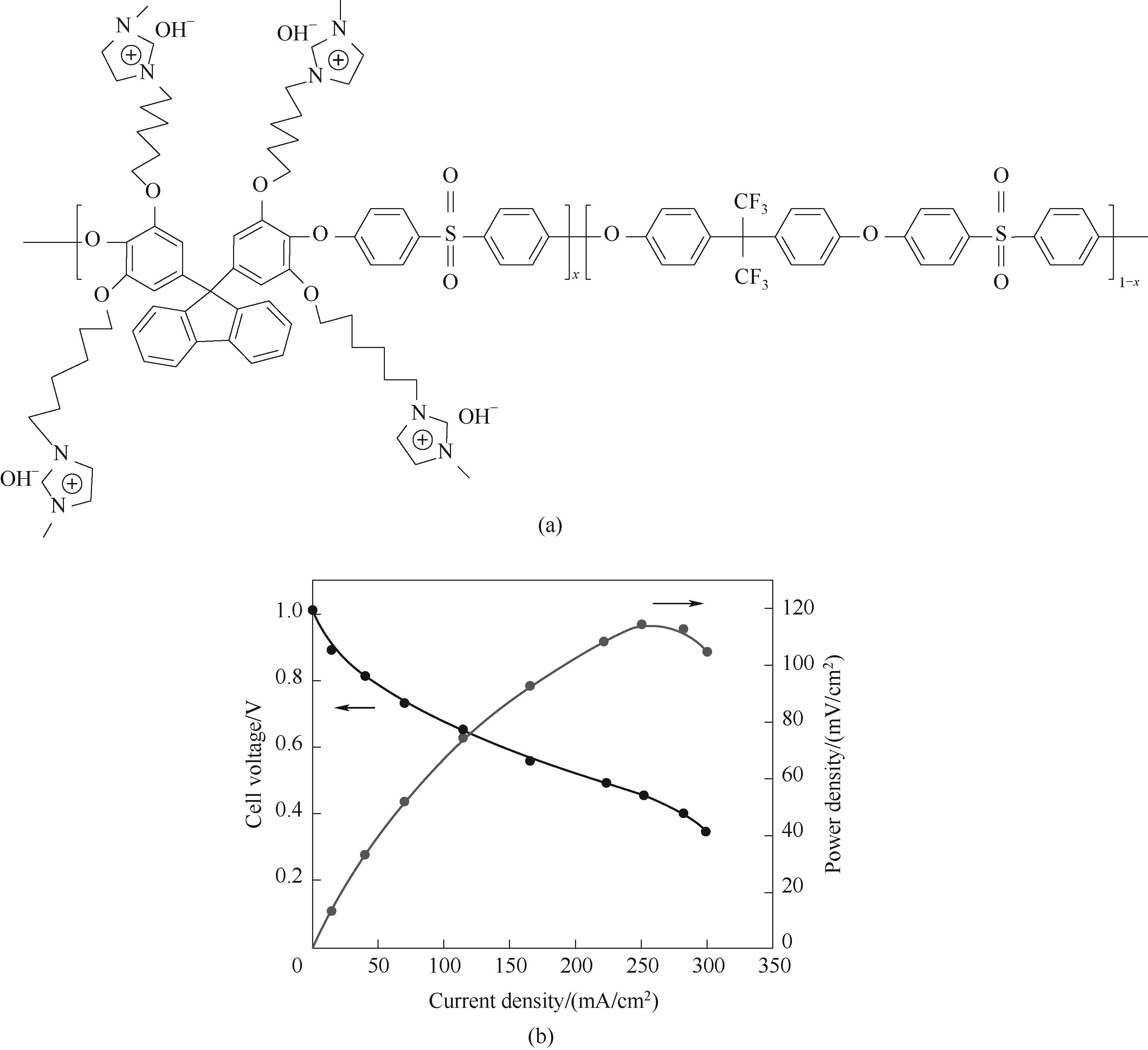

图6 阴离子交换膜ImPES-x的结构(a); ImPES-0.45膜的极化曲线(b) [32]

Fig.6 The structure of ImPES-x(a);Polarization curves of a H2/O2 fuel cell with ImPES-0.45 at 100% RH and 60℃(b) [32]

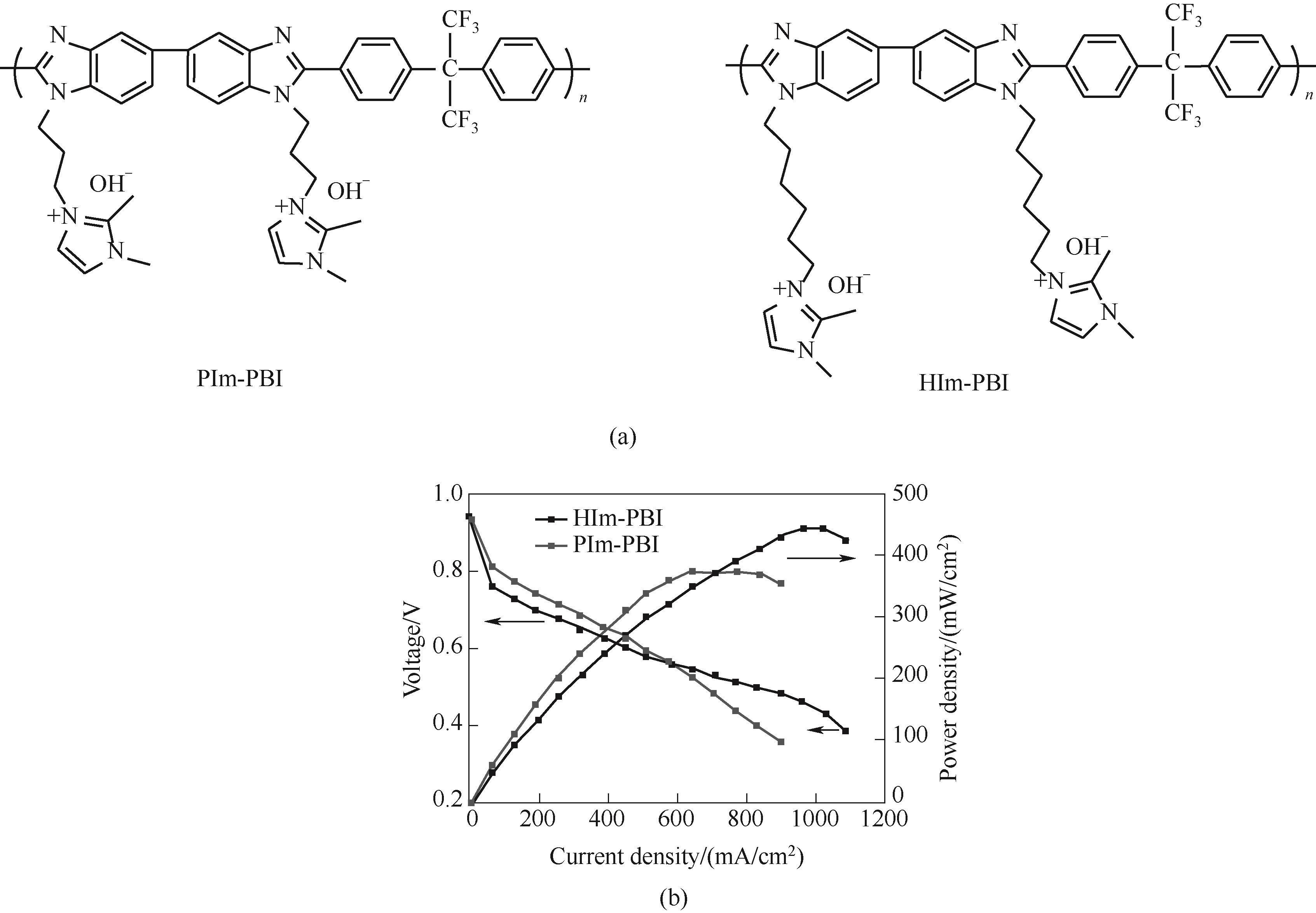

图8 PIm-PBI和HIm-PBI的结构(a); 60℃条件下HIm-PBI 和 PIm-PBI的极化曲线(b) [58]

Fig.8 The structure of PIm-PBI and HIm-PBI(a); Polarization curves of H2/O2 single cells with HIm-PBI and PIm-PBI at 60℃(b) [58]

| 1 | Merle G, Wessling M, Nijmeijer K. Anion exchange membranes for alkaline fuel cells: a review[J]. Journal of Membrane Science, 2011, 377(1/2): 1-35. |

| 2 | Matsumoto K, Fujigaya T, Yanagi H, et al. Very high performance alkali anion-exchange membrane fuel cells[J]. Advanced Functional Materials, 2011, 21(6): 1089-1094. |

| 3 | Kruusenberg I, Matisen L, Shah Q, et al. Non-platinum cathode catalysts for alkaline membrane fuel cells[J]. International Journal of Hydrogen Energy, 2012, 37(5): 4406-4412. |

| 4 | Maurya S, Shin S H, Kim Y, et al. A review on recent developments of anion exchange membranes for fuel cells and redox flow batteries[J]. RSC Advances, 2015, 5(47): 37206-37230. |

| 5 | Dekel D R. Review of cell performance in anion exchange membrane fuel cells[J]. Journal of Power Sources, 2018, 375: 158-169. |

| 6 | Meek K M, Nykaza J R, Elabd Y A. Alkaline chemical stability and ion transport in polymerized ionic liquids with various backbones and cations[J]. Macromolecules, 2016, 49(9): 3382-3394. |

| 7 | Zhang B Z, Kaspar R B, Gu S, et al. A new alkali-stable phosphonium cation based on fundamental understanding of degradation mechanisms[J]. ChemSusChem, 2016, 9(17): 2374-2379. |

| 8 | Gong X, Yan X M, Li T T, et al. Design of pendent imidazolium side chain with flexible ether-containing spacer for alkaline anion exchange membrane[J]. Journal of Membrane Science, 2017, 523: 216-224. |

| 9 | Cheng J, Yang G Q, Zhang K B, et al. Guanidimidazole-quanternized and cross-linked alkaline polymer electrolyte membrane for fuel cell application[J]. Journal of Membrane Science, 2016, 501: 100-108. |

| 10 | Sun Z, Pan J, Guo J N, et al. The alkaline stability of anion exchange membrane for fuel cell applications: the effects of alkaline media[J]. Advanced Science, 2018, 5(8): 1800065. |

| 11 | Mohanty A D, Bae C. Mechanistic analysis of ammonium cation stability for alkaline exchange membrane fuel cells[J]. J. Mater. Chem. A, 2014, 2(41): 17314-17320. |

| 12 | Jang H, Lee H S, Lee K S, et al. Facile fabrication of superomniphobic polymer hierarchical structures for directional droplet movement[J]. ACS Applied Materials & Interfaces, 2017, 9(11): 9213-9220. |

| 13 | Pan J, Han J J, Zhu L, et al. Cationic side-chain attachment to poly(phenylene oxide) backbones for chemically stable and conductive anion exchange membranes[J]. Chemistry of Materials, 2017, 29(12): 5321-5330. |

| 14 | Thomas O D, Soo K J, Peckham T J, et al. A stable hydroxide-conducting polymer[J]. Journal of the American Chemical Society, 2012, 134(26): 10753-10756. |

| 15 | Li N, Leng Y, Hickner M A, et al. Highly stable, anion conductive, comb-shaped copolymers for alkaline fuel cells[J]. Journal of the American Chemical Society, 2013, 135(27): 10124-10133. |

| 16 | Zeng L, Zhao T S. An effective strategy to increase hydroxide-ion conductivity through microphase separation induced by hydrophobic-side chains[J]. Journal of Power Sources, 2016, 303: 354-362. |

| 17 | Zhu Y, Ding L, Liang X, et al. Beneficial use of rotatable-spacer side-chains in alkaline anion exchange membranes for fuel cells[J]. Energy & Environmental Science, 2018, 11(12): 3472-3479. |

| 18 | Li N, Wang L, Hickner M. Cross-linked comb-shaped anion exchange membranes with high base stability[J]. Chemical Communications, 2014, 50(31): 4092-4095. |

| 19 | Zhu L, Zimudzi T J, Li N W, et al. Crosslinking of comb-shaped polymer anion exchange membranes via thiolene click chemistry[J]. Polymer Chemistry, 2016, 7(14): 2464-2475. |

| 20 | Hou J Q, Liu Y Z, Ge Q Q, et al. Recyclable cross-linked anion exchange membrane for alkaline fuel cell application[J]. Journal of Power Sources, 2018, 375: 404-411. |

| 21 | Wu L, Pan Q, Varcoe J R, et al. Thermal crosslinking of an alkaline anion exchange membrane bearing unsaturated side chains[J]. Journal of Membrane Science, 2015, 490: 1-8. |

| 22 | He Y B, Wu L, Pan J F, et al. A mechanically robust anion exchange membrane with high hydroxide conductivity[J]. Journal of Membrane Science, 2016, 504: 47-54. |

| 23 | Zhu L, Pan J, Christensen C M, et al. Functionalization of poly(2, 6-dimethyl-1,4-phenylene oxide)s with hindered fluorene side chains for anion exchange membranes[J]. Macromolecules, 2016, 49(9): 3300-3309. |

| 24 | Hibbs M R, Hickner M A, Alam T M, et al. Transport properties of hydroxide and proton conducting membranes[J]. Chemistry of Materials, 2008, 20(7): 2566-2573. |

| 25 | Yan J L, Hickner M A. Anion exchange membranes by bromination of benzylmethyl-containing poly(sulfone)s[J]. Macromolecules, 2010, 43(5): 2349-2356. |

| 26 | Wang X Q, Lin C X, Zhang Q G, et al. Anion exchange membranes from hydroxyl-bearing poly(ether sulfone)s with flexible spacers via ring-opening grafting for fuel cells[J]. International Journal of Hydrogen Energy, 2017, 42(30): 19044-19055. |

| 27 | Mohanty A D, Lee Y B, Zhu L, et al. Anion exchange fuel cell membranes prepared from C-H borylation and Suzuki coupling reactions[J]. Macromolecules, 2014, 47(6): 1973-1980. |

| 28 | Li N W, Zhang Q, Wang C Y, et al. Phenyltrimethylammonium functionalized polysulfone anion exchange membranes[J]. Macromolecules, 2012, 45(5): 2411-2419. |

| 29 | Peng J W, Liang M H, Liu Z C, et al. Poly(arylene ether sulfone) crosslinked networks with pillar[5]arene units grafted by multiple long-chain quaternary ammonium salts for anion exchange membranes[J]. Chemical Communications, 2020, 56(6): 928-931. |

| 30 | Wu W J, Wei B W, Feng J, et al. Synthesis and properties of symmetric side-chain quaternized poly(arylene ether sulfone)s for anion exchange membrane fuel cells[J]. Macromolecular Chemistry and Physics, 2018, 219(3): 1700416. |

| 31 | Lin B C, Qiu L H, Qiu B, et al. A soluble and conductive polyfluorene ionomer with pendant imidazolium groups for alkaline fuel cell applications[J]. Macromolecules, 2011, 44(24): 9642-9649. |

| 32 | Guo D, Lai A N, Lin C X, et al. Imidazolium-functionalized poly(arylene ether sulfone) anion-exchange membranes densely grafted with flexible side chains for fuel cells[J]. ACS Applied Materials & Interfaces, 2016, 8(38): 25279-25288. |

| 33 | Wang C Y, Zhou Y P, Xu C, et al. Synthesis and properties of new side-chain-type poly(arylene ether sulfone)s containing tri-imidazole cations as anion-exchange membranes[J]. International Journal of Hydrogen Energy, 2018, 43(45): 20739-20749. |

| 34 | Shen B, Pu H T. Fluorene-containing poly(arylene ether sulfone)s with imidazolium on flexible side chains for anion exchange membranes[J]. International Journal of Hydrogen Energy, 2019, 44(21): 11057-11065. |

| 35 | 刘磊, 褚晓萌, 李南文. 碱性燃料电池用聚烯烃类阴离子交换膜的研究进展[J]. 科学通报, 2019, 64(2): 123-133. |

| Liu L, Chu X M, Li N W. Recent development in polyolefin-based anion exchange membrane for fuel cell application[J]. Chinese Science Bulletin, 2019, 64(2): 123-133. | |

| 36 | Zha Y P, Disabb-Miller M L, Johnson Z D, et al. Metal-cation-based anion exchange membranes[J]. Journal of the American Chemical Society, 2012, 134(10): 4493-4496. |

| 37 | Clark T J, Robertson N J, Kostalik H A, et al. A ring-opening metathesis polymerization route to alkaline anion exchange membranes: development of hydroxide-conducting thin films from an ammonium-functionalized monomer[J]. Journal of the American Chemical Society, 2009, 131(36): 12888-12889. |

| 38 | You W, Hugar K M, Coates G W. Synthesis of alkaline anion exchange membranes with chemically stable imidazolium cations: unexpected cross-linked macrocycles from ring-fused ROMP monomers[J]. Macromolecules, 2018, 51(8): 3212-3218. |

| 39 | Zhu T, Xu S C, Rahman A, et al. Cationic metallo-polyelectrolytes for robust alkaline anion-exchange membranes[J]. Angewandte Chemie International Edition, 2018, 57(9): 2388-2392. |

| 40 | Dang H S, Jannasch P. Exploring different cationic alkyl side chain designs for enhanced alkaline stability and hydroxide ion conductivity of anion-exchange membranes[J]. Macromolecules, 2015, 48(16): 5742-5751. |

| 41 | Buggy N C, Du Y F, Kuo M C, et al. A polyethylene-based triblock copolymer anion exchange membrane with high conductivity and practical mechanical properties[J]. ACS Applied Polymer Materials, 2020, 2(3): 1294-1303. |

| 42 | Trant C, Hwang S, Bae C, et al. Synthesis and characterization of anion-exchange membranes using semicrystalline triblock copolymers in ordered and disordered states[J]. Macromolecules, 2020, 53(19): 8548-8561. |

| 43 | Wang J L, Wang X J, Zu D Y, et al. N3-adamantyl imidazolium cations: alkaline stability assessment and the corresponding comb-shaped anion exchange membranes[J]. Journal of Membrane Science, 2018, 545: 116-125. |

| 44 | Lin C X, Huang X L, Guo D, et al. Side-chain-type anion exchange membranes bearing pendant quaternary ammonium groups via flexible spacers for fuel cells[J]. Journal of Materials Chemistry A, 2016, 4(36): 13938-13948. |

| 45 | Li Y F, Liu Y, Savage A M, et al. Polyethylene-based block copolymers for anion exchange membranes[J]. Macromolecules, 2015, 48(18): 6523-6533. |

| 46 | Lin B C, Xu F, Su Y, et al. Facile preparation of anion-exchange membrane based on polystyrene-b-polybutadiene-b-polystyrene for the application of alkaline fuel cells[J]. Industrial & Engineering Chemistry Research, 2019, 58(49): 22299-22305. |

| 47 | Jeon J Y, Park S, Han J, et al. Synthesis of aromatic anion exchange membranes by Friedel–Crafts bromoalkylation and cross-linking of polystyrene block copolymers[J]. Macromolecules, 2019, 52(5): 2139-2147. |

| 48 | Jeon J Y, Tian D, Pagels M K, et al. Efficient preparation of styrene block copolymer anion exchange membranes via one-step Friedel–Crafts bromoalkylation with alkenes[J]. Organic Process Research & Development, 2019, 23(8): 1580-1586. |

| 49 | Zhang M, Shan C, Liu L, et al. Facilitating anion transport in polyolefin-based anion exchange membranes via bulky side chains[J]. ACS Applied Materials & Interfaces, 2016, 8(35): 23321-23330. |

| 50 | Park A M, Owczarczyk Z R, Garner L E, et al. Synthesis and characterization of perfluorinated anion exchange membranes[J]. ECS Transactions, 2017, 80(8): 957-966. |

| 51 | Wang J H, Gu S, Kaspar R B, et al. Stabilizing the imidazolium cation in hydroxide-exchange membranes for fuel cells[J]. ChemSusChem, 2013, 6(11): 2079-2082. |

| 52 | Henkensmeier D, Cho H, Brela M, et al. Anion conducting polymers based on ether linked polybenzimidazole (PBI-OO)[J]. International Journal of Hydrogen Energy, 2014, 39(6): 2842-2853. |

| 53 | Thomas O D, Soo K J W Y, Peckham T J, et al. Anion conducting poly(dialkyl benzimidazolium) salts[J]. Polymer Chemistry, 2011, 2(8): 1641. |

| 54 | Thomas O D, Soo K J, Peckham T J, et al. A stable hydroxide-conducting polymer[J]. Journal of the American Chemical Society, 2012, 134(26): 10753-10756. |

| 55 | Wright A G, Holdcroft S. Hydroxide-stable ionenes[J]. ACS Macro Letters, 2014, 3(5): 444-447. |

| 56 | Wright A G, Weissbach T, Holdcroft S. Poly(phenylene) and m-terphenyl as powerful protecting groups for the preparation of stable organic hydroxides[J]. Angewandte Chemie International Edition, 2016, 55(15): 4818-4821. |

| 57 | Ma H M, Zhu H, Wang Z M. Highly alkaline stable anion exchange membranes from nonplanar polybenzimidazole with steric hindrance backbone[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2019, 57(10): 1087-1096. |

| 58 | Lin B C, Xu F, Su Y, et al. Ether-free polybenzimidazole bearing pendant imidazolium groups for alkaline anion exchange membrane fuel cells application[J]. ACS Applied Energy Materials, 2020, 3(1): 1089-1098. |

| 59 | Sui Y Q, Hu H Y, Ueda M, et al. Mechanically robust poly[vinyl-(4-benzyl-N, N, N-trimethylammonium bromide) ketone]/polybenzimidazole blend membranes for anion conductive solid electrolytes[J]. Journal of Membrane Science, 2019, 572: 262-270. |

| 60 | Wang J, Wang J H, Zhang S B. Synthesis and characterization of cross-linked poly(arylene ether ketone) containing pendant quaternary ammonium groups for anion-exchange membranes[J]. Journal of Membrane Science, 2012, 415/416: 205-212. |

| 61 | Lai A N, Wang L S, Lin C X, et al. Benzylmethyl-containing poly(arylene ether nitrile) as anion exchange membranes for alkaline fuel cells[J]. Journal of Membrane Science, 2015, 481: 9-18. |

| 62 | Olsson J S, Pham T H, Jannasch P. Tuning poly(arylene piperidinium) anion-exchange membranes by copolymerization, partial quaternization and crosslinking[J]. Journal of Membrane Science, 2019, 578: 183-195. |

| 63 | Li L J, Zhang J J, Jiang T, et al. High ion conductivity and diffusivity in the anion exchange membrane enabled by tethering with multication strings on the poly(biphenyl alkylene) backbone[J]. ACS Appl. Energy Mater., 2020, 3(7): 6268-6279. |

| 64 | Tuan C M, Kim D. Anion-exchange membranes based on poly(arylene ether ketone) with pendant quaternary ammonium groups for alkaline fuel cell application[J]. Journal of Membrane Science, 2016, 511: 143-150. |

| 65 | Ghanem A F, El-Gendi A, Rehim M H A, et al. Hyperbranched polyester and its sodium titanate nanocomposites as proton exchange membranes for fuel cells[J]. RSC Advances, 2016, 6(38): 32245-32257. |

| 66 | Ge Q Q, Liu Y Z, Yang Z J, et al. Hyper-branched anion exchange membranes with high conductivity and chemical stability[J]. Chemical Communications, 2016, 52(66): 10141-10143. |

| 67 | Yang Q, Li L, Lin C X, et al. Hyperbranched poly(arylene ether ketone) anion exchange membranes for fuel cells[J]. Journal of Membrane Science, 2018, 560: 77-86. |

| 68 | Ren R, Zhang S M, Miller H A, et al. Facile preparation of an ether-free anion exchange membrane with pendant cyclic quaternary ammonium groups[J]. ACS Applied Energy Materials, 2019, 2(7): 4576-4581. |

| 69 | Chu J Y, Lee K H, Kim A R, et al. Study on the chemical stabilities of poly(arylene ether) random copolymers for alkaline fuel cells: effect of main chain structures with different monomer units[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(24): 20077-20087. |

| 70 | Liu W, Wang L L, Wang J L, et al. Preparation and characterization of high conductivity comb polymer anion exchange membranes[J]. European Polymer Journal, 2020, 122: 109379. |

| 71 | Han J J, Peng Y Q, Lin B C, et al. Hydrophobic side-chain attached polyarylether-based anion exchange membranes with enhanced alkaline stability[J]. ACS Applied Energy Materials, 2019, 2(11): 8052-8059. |

| 72 | Wang K F, Gao L, Liu J F, et al. Comb-shaped ether-free poly(biphenyl indole) based alkaline membrane[J]. Journal of Membrane Science, 2019, 588: 117216. |

| [1] | 徐子昂, 万磊, 刘凯, 王保国. 高稳定碱性离子膜分子设计研究进展[J]. 化工学报, 2021, 72(8): 3891-3906. |

| [2] | 刘璇, 马溢昌, 张秋根, 刘庆林. 富勒烯交联季铵化聚苯醚阴离子交换膜的制备[J]. 化工学报, 2021, 72(7): 3849-3855. |

| [3] | 刘元伟, 董晨初, 廖俊斌, 王超, 陈权, 沈江南. 不同侧链BPPO阴离子交换膜的制备及其抗污染性能[J]. 化工学报, 2021, 72(3): 1732-1741. |

| [4] | 王超, 潘能修, 鲁丹, 廖俊斌, 沈江南, 高从堦. 电渗析用季铵化聚氯乙烯均相阴离子交换膜的制备[J]. 化工学报, 2019, 70(4): 1620-1627. |

| [5] | 潘杰峰, 郑瑜, 丁金成, 施文慧, 沈江南, 高从堦. 膜法电容去离子技术用于水溶液中单/多价阴离子的分离[J]. 化工学报, 2018, 69(8): 3502-3508. |

| [6] | 姜玉良, 刘元伟, 韩波, 阮慧敏, 沈江南, 高从堦. PEI交联的PECH/nylon复合阴离子交换膜的制备及性能研究[J]. 化工学报, 2018, 69(6): 2744-2752. |

| [7] | 冯磊, 赵玉彬, 谢晓峰, 吕亚非. 可控型季铵化降冰片烯衍生物阴离子交换膜的制备[J]. 化工学报, 2015, 66(S2): 257-262. |

| [8] | 赵玉彬, 王树博, 赵阳, 谢晓峰, 张振琳. 降冰片烯类季铵型阴离子交换膜的制备[J]. CIESC Journal, 2015, 66(S1): 338-342. |

| [9] | 王文嫔, 王树博, 谢晓峰, 吕亚非, 黄绵延. 全钒液流电池用非氟咪唑型阴离子交换膜的制备[J]. 化工学报, 2013, 64(S1): 203-208. |

| [10] | 孙海翔, 李文轩, 李鹏, 曹敏, 孔瑛, 杨金荣. 动力锂离子二次电池聚偏氟乙烯隔膜的制备及性能表征[J]. 化工学报, 2013, 64(7): 2556-2564. |

| [11] | 王文晓1,2,尚玉明2,谢晓峰2,孟祥海1,刘植昌1. 化学交联胍基功能化阴离子交换膜的制备[J]. 化工学报, 2012, 63(S1): 235-239. |

| [12] | 董 锐,李远兵,张建勋,孙晓斌,马 磊,许 文. 季铵化羟乙基纤维素/季铵化聚乙烯醇共混阴离子交换膜的制备与表征[J]. 化工进展, 2012, 31(03): 612-616. |

| [13] | 徐敏1,2,尚玉明2,谢晓峰2,吕亚非1. 全钒液流电池用多氟聚噁二唑芳醚阴离子交换膜的制备[J]. 化工学报, 2011, 62(S2): 150-154. |

| [14] | 杨 春1,2,王海人1,王金海2,尚玉明2,谢晓峰2. 金属双极板在模拟直接甲醇碱性燃料电池环境中的电化学行为 [J]. CIESC Journal, 2010, 29(8): 1457-. |

| [15] | 胡拥军1,陈白珍2. 一种嵌段星形凝胶聚合物电解质的制备与性能 [J]. CIESC Journal, 2010, 29(7): 1263-. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号