化工学报 ›› 2019, Vol. 70 ›› Issue (7): 2737-2747.DOI: 10.11949/0438-1157.20190176

收稿日期:2019-03-03

修回日期:2019-04-29

出版日期:2019-07-05

发布日期:2019-07-05

通讯作者:

漆虹

作者简介:李秀秀(1993—),女,硕士研究生,<email>862421611@qq.com</email>

基金资助:

Xiuxiu LI( ),Yibin WEI,Zixuan XIE,Hong QI(

),Yibin WEI,Zixuan XIE,Hong QI( )

)

Received:2019-03-03

Revised:2019-04-29

Online:2019-07-05

Published:2019-07-05

Contact:

Hong QI

摘要:

以正辛基三乙氧基硅烷和乙醇分别作为改性剂和溶剂,采用接枝聚合法对平均孔径为500 nm的Al2O3膜和SiC膜进行疏水改性,考察了改性剂浓度、改性液温度和改性时间对膜表面疏水效果的影响,并对比了疏水改性前后两种陶瓷膜的表面性质及疏水改性后的油固分离性能,进行了反冲实验和稳定性测试。结果表明,两种陶瓷膜材料在改性剂浓度为0.2 mol·L-1,改性液温度为40℃,改性时间为12 h时,疏水改性效果最好,得到的疏水Al2O3膜和SiC膜的水接触角分别为134°±1°和140°±1°,经改性后的SiC膜的疏水效果优于Al2O3膜。在油固分离实验中,疏水Al2O3膜和SiC膜均对固体炭黑有良好的截留性能,但疏水改性对SiC膜的油品通量提升更为显著,两种膜的稳态通量分别为1134 L·m-2·h-1和1408 L·m-2·h-1。反冲操作对疏水SiC膜的通量恢复更有利。

中图分类号:

李秀秀, 魏逸彬, 谢子萱, 漆虹. Al2O3和SiC微滤膜的疏水改性及其油固分离性能研究[J]. 化工学报, 2019, 70(7): 2737-2747.

Xiuxiu LI, Yibin WEI, Zixuan XIE, Hong QI. Hydrophobic modification of Al2O3 and SiC microfiltration membranes for oil-solid separation[J]. CIESC Journal, 2019, 70(7): 2737-2747.

| Membrane | Porosity/% | Outer/inner diameter /mm | Effective membrane area/cm2 |

|---|---|---|---|

| Al2O3 | 30—35 | 12.8/8 | 24.2 |

| SiC | 30—35 | 12.8/8 | 24.2 |

表1 陶瓷膜规格参数

Table 1 Specification parameters of ceramic membranes

| Membrane | Porosity/% | Outer/inner diameter /mm | Effective membrane area/cm2 |

|---|---|---|---|

| Al2O3 | 30—35 | 12.8/8 | 24.2 |

| SiC | 30—35 | 12.8/8 | 24.2 |

| Membranes | Average pore size | WCA | Application | Ref. |

|---|---|---|---|---|

| Al2O3 | 0.76 μm | 133° | NaCl | [10] |

| TiO2-Al2O3 | 12.9 nm | 116° | NaCl | [24] |

| Al2O3 | 0.7 μm | 130° | NaCl | [25] |

| γ/α-Al2O3 | 5 nm | 134° | H2/CO2 | [26] |

| ZrO2 | 0.2 μm | 134° | W/O | [27] |

| Al2O3 | 0.5 μm | 134° | W/O | this work |

| SiC | 0.5 μm | 140° | W/O | this work |

表2 接枝聚合法制备疏水陶瓷膜的疏水性对比

Table 2 Comparison of hydrophobicity of hydrophobic ceramic membranes prepared via chemical grafting method

| Membranes | Average pore size | WCA | Application | Ref. |

|---|---|---|---|---|

| Al2O3 | 0.76 μm | 133° | NaCl | [10] |

| TiO2-Al2O3 | 12.9 nm | 116° | NaCl | [24] |

| Al2O3 | 0.7 μm | 130° | NaCl | [25] |

| γ/α-Al2O3 | 5 nm | 134° | H2/CO2 | [26] |

| ZrO2 | 0.2 μm | 134° | W/O | [27] |

| Al2O3 | 0.5 μm | 134° | W/O | this work |

| SiC | 0.5 μm | 140° | W/O | this work |

| Membranes | Mass loss(110—230℃)/% | n(-OH)/(mmol·g-1) |

|---|---|---|

| A-500 | 0.0197 | 0.0394 |

| A-500HB | 0.0154 | 0.0308 |

| S-500 | 0.0757 | 0.151 |

| S-500HB | 0.0128 | 0.0256 |

表3 改性前后陶瓷膜的质量损失以及—OH官能团含量

Table 3 Mass loss within 110—230℃ and hydroxyl group content of ceramic membranes before and after modification

| Membranes | Mass loss(110—230℃)/% | n(-OH)/(mmol·g-1) |

|---|---|---|

| A-500 | 0.0197 | 0.0394 |

| A-500HB | 0.0154 | 0.0308 |

| S-500 | 0.0757 | 0.151 |

| S-500HB | 0.0128 | 0.0256 |

| Ceramic membrane | Contact angle/(°) | Surface free energy/(mN·m-1) | ||||

|---|---|---|---|---|---|---|

| Water | Ethylene glycol | Diiodo-methane | Dispersive component | Non-dispersive component | Total | |

| A-500 | 23 | 24 | 19 | 42.3 | 7.67 | 50.0 |

| A-500HB | 134 | 55 | 39 | 36.6 | 3.01 | 39.6 |

| S-500 | 10 | 20 | 8 | 44.5 | 7.39 | 51.9 |

| S-500HB | 140 | 58 | 42 | 35.4 | 2.68 | 38.1 |

表4 改性前后陶瓷膜的接触角及表面自由能

Table 4 Contact angles and surface free energy of ceramic membranes before and after modification

| Ceramic membrane | Contact angle/(°) | Surface free energy/(mN·m-1) | ||||

|---|---|---|---|---|---|---|

| Water | Ethylene glycol | Diiodo-methane | Dispersive component | Non-dispersive component | Total | |

| A-500 | 23 | 24 | 19 | 42.3 | 7.67 | 50.0 |

| A-500HB | 134 | 55 | 39 | 36.6 | 3.01 | 39.6 |

| S-500 | 10 | 20 | 8 | 44.5 | 7.39 | 51.9 |

| S-500HB | 140 | 58 | 42 | 35.4 | 2.68 | 38.1 |

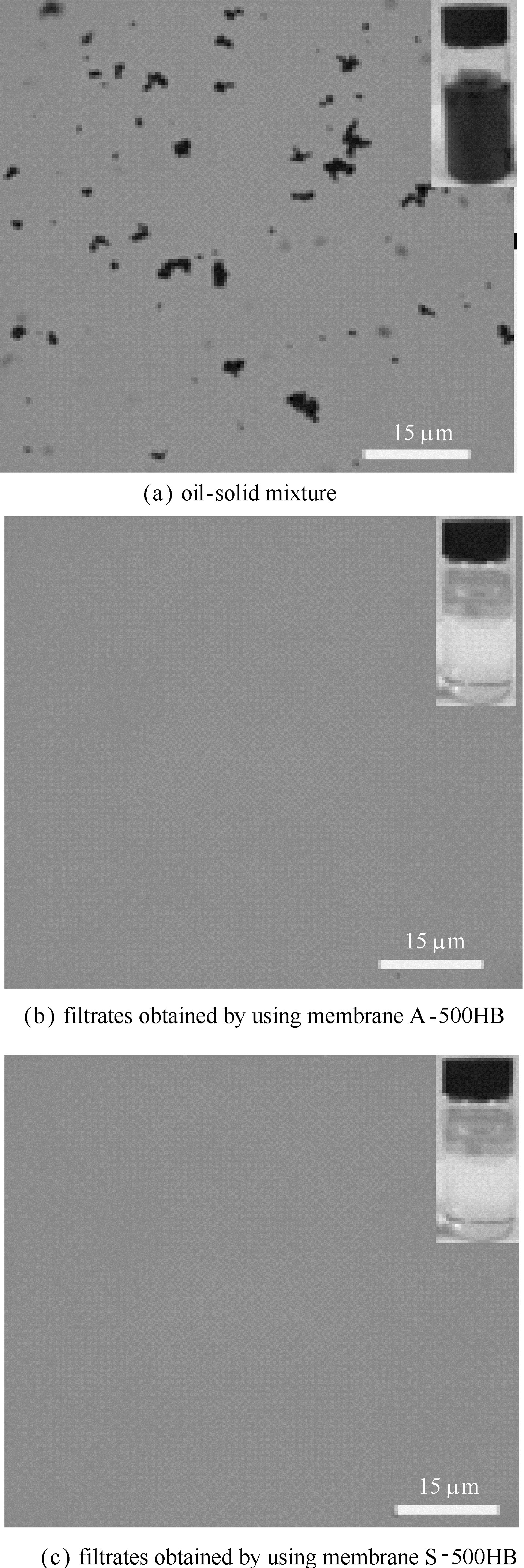

图12 经疏水陶瓷膜分离前后的原料液和渗透液光学照片

Fig.12 Optical photographs for oil-solid mixture (a), filtrates obtained by using membrane A-500HB (b) and filtrates obtained by using membrane S-500HB (c)

| 1 | 袁腾, 陈卓, 周显宏, 等. 基于超亲水超疏油原理的网膜及其在油水分离中的应用[J]. 化工学报, 2014, 65(6): 1943-1951. |

| YuanT, ChenZ, ZhouX H, et al. Coated mesh film based on superhydrophilic and superoleophobic principle and its application in oil-water separation[J]. CIESC Journal, 2014, 65(6): 1943-1951. | |

| 2 | WeiY B, QiH, GongX, et al. Specially wettable membranes for oil-water separation[J]. Advanced Materials Interfaces, 2018, 5(23): 1800576. |

| 3 | ChenX, LimJ F, XuY, et al. Operating conditions and feed composition on filtering emulsified oil using ceramic-hybrid membrane[J]. Ceramics International, 2016, 42(15): 17101-17109. |

| 4 | 张谨, 李俊俊, 纪晓声, 等. 利用混凝-超滤膜法研究乳化油水的分离过程[J]. 高校化学工程学报, 2017, 31(2): 449-455. |

| ZhangJ, LiJ J, JiX S, et al. Study on oil separation from oil/water emulsion via coagulation and ultrafiltration[J]. Journal of Chemical Engineering of Chinese Universities, 2017, 31(2): 449-455. | |

| 5 | 刘君腾, 卿伟华, 任钟旗, 等. 超疏水聚四氟乙烯丝网用于原油脱水的研究[J]. 高校化学工程学报, 2012, 26(4): 563-568. |

| LiuJ T, QingW H, RenZ Q, et al. The study of crude oil dehydration using super-hydrophobic PTFE-coated wire mesh[J]. Journal of Chemical Engineering of Chinese Universities, 2012, 26(4): 563-568. | |

| 6 | XuS, RenL F, ZhouQ, et al. Facile ZIF-8 functionalized hierarchical micronanofiber membrane for high-efficiency separation of water-in-oil emulsions[J]. Journal of Applied Polymer Science, 2018, 135(27): 46462. |

| 7 | CoutinhoC D M, ChiuM C, BassoR C, et al. State of art of the application of membrane technology to vegetable oils: a review[J]. Food Research International, 2009, 42(5/6): 536-550. |

| 8 | PadakiM, MuraliR S, AbdullahM S, et al. Membrane technology enhancement in oil-water separation: a review[J]. Desalination, 2015, 357(357): 197-207. |

| 9 | KhemakhemM, KhemakhemS, AmarR B. Emulsion separation using hydrophobic grafted ceramic membranes by[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2013, 436(35): 402-407. |

| 10 | RenC, FangH, GuJ Q, et al. Preparation and characterization of hydrophobic alumina planar membranes for water desalination[J]. Journal of the European Ceramic Society, 2015, 35(2): 723-730. |

| 11 | 李云, 胡浩威. 润湿性对纳米多孔陶瓷膜输运性能的影响[J]. 化工学报, 2017, 68(9): 3474-3481. |

| LiY, HuH W. Effect of wettability on nanoporous ceramic membrane for condensate transport performance[J]. CIESC Journal, 2017, 68(9): 3474-3481. | |

| 12 | KujawaJ, KujawskiW. Functionalization of ceramic metal oxide powders and ceramic membranes by perfluroalkylsilanes and alkylsilanes possessing different reactive groups physicochemical and tribological properties [J]. ACS Applied Materials & Interfaces, 2016, 8(11): 7509-7521. |

| 13 | KujawaJ, CerneauxS, KujawskiW, et al. Hydrophobic ceramic membranes for water desalination[J]. Applied Sciences, 2017, 7(4): 402. |

| 14 | GaoN W, FanY Q, QuanX J, et al. Modified ceramic membranes for low fouling separation of water-in-oil emulsions [J]. Journal of Materials Science, 2016, 51(13): 6379-6388. |

| 15 | AhmadN A, LeoC P, AhmadA L. Superhydrophobic alumina membrane by steam impingement: minimum resistance in microfiltration[J]. Separation and Purification Technology, 2013, 107(4): 187-194. |

| 16 | ZhangW B, ShiZ, ZhangF, et al. Superhydrophobic and superoleophilic PVDF membranes for effective separation of water-in-oil emulsions with high flux[J]. Advanced Materials, 2013, 25(14): 2071-2076. |

| 17 | BukhariS Z A, HaJ H, LeeJ, et al. Effect of different heat treatments on oxidation-bonded SiC membrane for water filtration[J]. Ceramics International, 2018, 44(12): 14251-14257. |

| 18 | 代小元, 沈凡, 戴武斌, 等. 碳化硅陶瓷膜处理工业废水的工艺特性研究[J]. 武汉工程大学学报, 2018, 40(3): 284-287. |

| DaiX Y, ShenF, DaiW B, et al. Process characteristics of industrial wastewater treatment with silicon carbide ceramic membrane[J]. Journal of Wuhan Institute of Technology, 2018, 40(3): 284-287. | |

| 19 | De WitP, KappertE J, LohausT, et al. Highly permeable and mechanically robust silicon carbide hollow fiber membranes[J]. Journal of Membrane Science, 2015, 475: 480-487. |

| 20 | 王新. 集成银丝SiC/PU复合加热膜的制备及性能分析[D]. 天津: 天津工业大学, 2014. |

| WangX. Preparation and performance analysis of integrated silver wire SiC/PU composite heating film[D]. Tianjin: Tianjin Polytechnic University, 2014. | |

| 21 | JacobD S, GedankenA. Effect of reaction parameters on the hydrolysis of tetramethyl orthosilicate and tetraethyl orthosilicate and their surface morphology in an ionic liquid[J]. Journal of the American Ceramic Society, 2010, 91(9): 3024-3030. |

| 22 | 陈奎, 张天云, 曹秀鸽, 等. γ-(2,3-环氧丙烷)丙基三甲氧基硅烷水解研究[J]. 化工新型材料, 2011, 39(9): 96-108. |

| ChenK, ZhangT Y, CaoX G. et al. Hydrolysis study on organic silicon oxygen alkyl GPTMS[J]. New Chemical Materials, 2011, 39(9): 96-108. | |

| 23 | CiobotaruI A, MajorI, VaireaunD I, et al. The determination of the optimum hydrolysis time for silane films deposition[J]. Applied Surface Science, 2016, 371: 275-280. |

| 24 | GaberA A, IbrahimD M, Abd-AimohsenF F, et al. Synthesis of alumina, titania, and alumina-titania hydrophobic membranes via sol-gel polymeric route[J]. Journal of Analytical Science and Technology, 2013, 4(1): 4-18. |

| 25 | FangH, GaoJ F, WangH T, et al. Hydrophobic porous alumina hollow fiber for water desalination via membrane distillation process [J]. Journal of Membrane Science, 2012, 403/404(6): 41-46. |

| 26 | 王煜琨, 韦奇, 张少康, 等. 碳氟基团修饰的多孔陶瓷膜润湿性、表面自由能及渗透性能的研究[J]. 膜科学与技术, 2018, 38(2): 52-59. |

| WangY K, WeiQ, ZhangS K, et al. Wettability, surface free energy and permeability of porous ceramic membranes silylated by fluorocarbon groups[J]. Membrane Science and Technology, 2018, 38(2): 52-59. | |

| 27 | GaoN W, LiM, JingW H, et al. Improving the filtration performance of ZrO2 membrane in non-polar organic solvents by surface hydrophobic modification[J]. Journal of Membrane Science, 2011, 375(1/2): 276-283. |

| 28 | EkS, RootA, PeussaM, et al. Determination of the hydroxyl group content in silica by thermogravimetry and a comparison with 1H MAS NMR results[J]. Thermochimica Acta, 2001, 379(1/2): 201-212. |

| 29 | KujawaJ, CerneauxS, KujawskiW. Characterization of the surface modification process of Al2O3, TiO2 and ZrO2 powders by PFAS molecules[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2014, 447(5): 14-22. |

| 30 | Van OssC J, ChaudhuryM K, GoodR J. Interfacial Lifshitz-van der Waals and polar interactions in macroscopic systems[J]. Chemical Reviews, 1988, 88(6): 927-941. |

| 31 | DingD, MaoH Y, ChenX F, et al. Underwater superoleophobic-underoil superhydrophobic Janus ceramic membrane with its switchable separation in oil/water emulsions[J]. Journal of Membrane Science, 2018, 565: 303-310. |

| 32 | WuJ, LingL, XieJ, et al. Surface modification of nanosilica with 3-mercaptopropyl trimethoxysilane: experimental and theoretical study on the surface interaction[J]. Chemical Physics Letters, 2014, 591: 227-232. |

| 33 | GaoN W, KeW, FanY Q, et al. Evaluation of the oleophilicity of different alkoxysilane modified ceramic membranes through wetting dynamic measurements[J]. Applied Surface Science, 2013, 283(14): 863-870. |

| 34 | 孟庆伟, 张峰, 陈璐, 等. 离子筛吸附与陶瓷膜耦合用于盐湖卤水提锂[J]. 化工学报, 2017, 68(5): 1899-1905. |

| MengQ W, ZhangF, ChenL, et al. Lithium recovery from qarham brine using adsorption-membrane separation hybrid system[J]. CIESC Journal, 2017, 68(5): 1899-1905. | |

| 35 | CaklJ, BauerI, DolečekP, et al. Effects of backflushing conditions on permeate flux in membrane crossflow microfiltration of oil emulsion[J]. Desalination, 2000, 127(2): 189-198. |

| [1] | 王思琪, 顾天宇, 陈献富, 王通, 李佳, 柯威, 李小锋, 范益群. 陶瓷膜用于杜仲叶提取液澄清的分离特性与膜污染机制研究[J]. 化工学报, 2023, 74(3): 1113-1125. |

| [2] | 陈献富, 王冬雨, 范益群, 邢卫红, 乔旭. 基于3D打印的多孔陶瓷膜研究进展[J]. 化工学报, 2023, 74(1): 105-115. |

| [3] | 马语峻, 刘向军. 多孔陶瓷膜烟气水分回收理论与模型研究[J]. 化工学报, 2022, 73(9): 4103-4112. |

| [4] | 李梦雨, 王冬祥, 郑晓阳, 徐桂转, 杜朝军, 常春. 粗甘油生物基聚氨酯材料的制备及吸附性能研究[J]. 化工学报, 2022, 73(5): 2270-2278. |

| [5] | 季超, 刘炜, 漆虹. 基于空冷的疏水陶瓷膜冷凝器用于烟气脱湿过程强化的实验研究[J]. 化工学报, 2022, 73(5): 2174-2182. |

| [6] | 陆鹏飞, 金志浩, 崔彦斌, 许光文, 武荣成. 原料粒度对合成碳化硅的影响研究[J]. 化工学报, 2021, 72(4): 2300-2308. |

| [7] | 周剑, 江倩, 杨怡, 冯厦厦, 仲兆祥, 邢卫红. 烧结助剂对低温制备碳化硅多孔陶瓷性能的影响[J]. 化工学报, 2021, 72(4): 2293-2299. |

| [8] | 滕达, 李铁林, 李昂, 安连锁, 沈国清, 张世平. 单通道陶瓷膜管低压透水性能实验分析[J]. 化工学报, 2020, 71(S1): 261-271. |

| [9] | 周鑫, 邱鸣慧, 罗平. 陶瓷膜接触器化学吸收氮氧化物的传质过程与阻力分析[J]. 化工学报, 2020, 71(8): 3652-3660. |

| [10] | 蒙真真, 武志红, 刘新伟, 王耀, 郑海康, 王宇斌. 竹节状碳化硅晶须吸波性能研究[J]. 化工学报, 2020, 71(4): 1889-1897. |

| [11] | 曹语, 王乐, 季超, 黄延召, 薛志磊, 陆剑鸣, 漆虹. 陶瓷膜冷凝器用于烟气脱白烟过程的中试研究[J]. 化工学报, 2019, 70(6): 2192-2201. |

| [12] | 李冬燕, 魏巍, 韩峰. 高温除尘碳化硅膜的制备及其抗腐蚀特性[J]. 化工学报, 2019, 70(1): 336-344. |

| [13] | 孟庆莹, 曹语, 黄延召, 王乐, 李丽, 牛淑锋, 漆虹. 过程参数对采用多孔陶瓷超滤膜回收烟气中余热和水性能的影响[J]. 化工学报, 2018, 69(6): 2519-2525. |

| [14] | 韩士贤, 高兴银, 符开云, 邱鸣慧, 范益群. 疏水性单管陶瓷膜接触器在SO2吸收中的应用[J]. 化工学报, 2017, 68(6): 2415-2422. |

| [15] | 孟庆伟, 张峰, 陈璐, 夏永生, 居沈贵, 邢卫红. 离子筛吸附与陶瓷膜耦合用于盐湖卤水提锂[J]. 化工学报, 2017, 68(5): 1899-1905. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号