化工学报 ›› 2021, Vol. 72 ›› Issue (4): 2132-2138.DOI: 10.11949/0438-1157.20200899

游洋1( ),刘应书1,杨雄1,吴晓永1,赵春雨1,王正1,侯环宇2,李子宜1(

),刘应书1,杨雄1,吴晓永1,赵春雨1,王正1,侯环宇2,李子宜1( )

)

收稿日期:2020-07-06

修回日期:2020-10-23

出版日期:2021-04-05

发布日期:2021-04-05

通讯作者:

李子宜

作者简介:游洋(1995—),男,硕士研究生,基金资助:

YOU Yang1( ),LIU Yingshu1,YANG Xiong1,WU Xiaoyong1,ZHAO Chunyu1,WANG Zheng1,HOU Huanyu2,LI Ziyi1(

),LIU Yingshu1,YANG Xiong1,WU Xiaoyong1,ZHAO Chunyu1,WANG Zheng1,HOU Huanyu2,LI Ziyi1( )

)

Received:2020-07-06

Revised:2020-10-23

Online:2021-04-05

Published:2021-04-05

Contact:

LI Ziyi

摘要:

合理高效的吸附工艺是决定吸附法净化和回收烟气中NOx工业可行性的关键工艺环节。提出一种通过外部补充气体实现固定床循环体空间内多次循环解吸NOx的新型吸附工艺(GVTSA)。基于该工艺,采用Na-ZSM-5分子筛作为吸附剂,以某钢厂烧结机脱硫后烟气为原料(组分)进行了NOx吸附回收实验研究。结果表明,GVTSA工艺相较传统吸附工艺(TSA工艺、VSA工艺)可获取更高的NOx回收量,在优选条件下(220℃,-50 kPa),NOx回收率达到90%,解吸气中NO2浓度由原料气的36 mg·m-3提升到2%以上,NOx循环吸附量可达0.10 mmol·g-1,16次吸脱附循环稳定。研究结果可为烟气NOx治理与资源化工业应用提供参考。

中图分类号:

游洋, 刘应书, 杨雄, 吴晓永, 赵春雨, 王正, 侯环宇, 李子宜. 面向烟气NOx净化与回收的新型吸附工艺[J]. 化工学报, 2021, 72(4): 2132-2138.

YOU Yang, LIU Yingshu, YANG Xiong, WU Xiaoyong, ZHAO Chunyu, WANG Zheng, HOU Huanyu, LI Ziyi. A new adsorption process for flue gas NOx purification and recovery[J]. CIESC Journal, 2021, 72(4): 2132-2138.

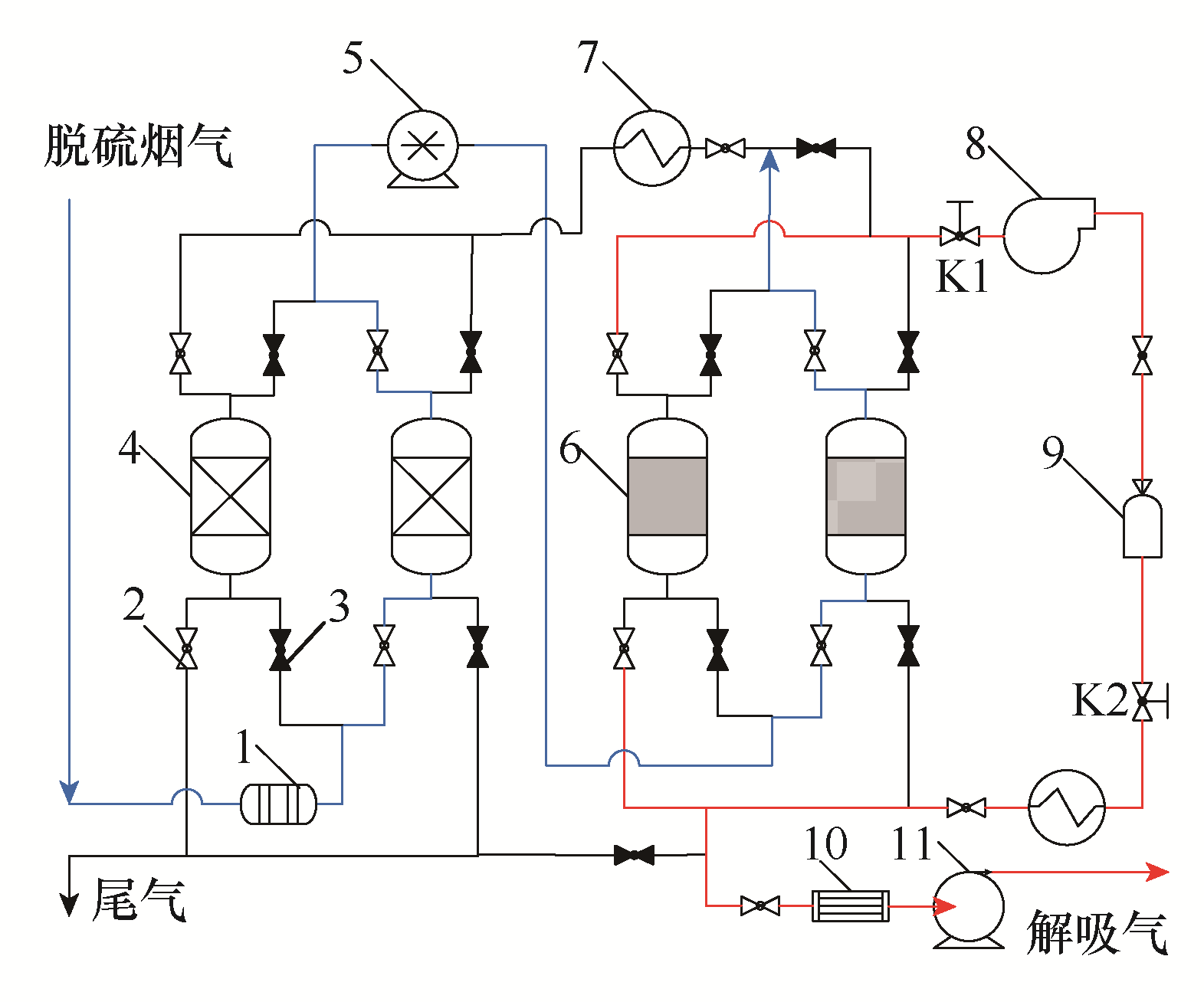

图1 NOx吸附分离回收现场实验设备及工艺(蓝色路线:吸附流程;红色路线:解吸流程)1—过滤器;2—阀门开启;3—阀门关闭;4—脱水塔;5—增压泵;6—脱硝塔;7—换热器;8—循环鼓风机;9—储气罐;10—冷却器;11—真空泵

Fig.1 Field test equipment and process of NOx adsorption separation and recycling (blue line: adsorption process; red line: desorption process)

| 位置 | 烟气温度/℃ | RH/% | O2/% | CO2/% | CO/% | NO/ (mg·m-3) | NO2/(mg·m-3) |

|---|---|---|---|---|---|---|---|

| 过滤前 | 126 | — | 13.7 | 5.1 | 0.6 | 376±12 | 48±2 |

| 脱水前 | 40 | 100 | 13.7 | 5.1 | 0.6 | 376±12 | 40±2 |

| 脱硝前 | 35 | <1 | 13.5 | ~4.6 | 0.6 | 366±12 | 36±2 |

表1 现场实验不同位置的烟气条件

Table 1 Information about flue gases at different locations of field experiment

| 位置 | 烟气温度/℃ | RH/% | O2/% | CO2/% | CO/% | NO/ (mg·m-3) | NO2/(mg·m-3) |

|---|---|---|---|---|---|---|---|

| 过滤前 | 126 | — | 13.7 | 5.1 | 0.6 | 376±12 | 48±2 |

| 脱水前 | 40 | 100 | 13.7 | 5.1 | 0.6 | 376±12 | 40±2 |

| 脱硝前 | 35 | <1 | 13.5 | ~4.6 | 0.6 | 366±12 | 36±2 |

| 参数 | 小塔 | 大塔 |

|---|---|---|

| 脱硝塔内径/cm | 3 | 8 |

| 脱硝塔高度/cm | 26 | 220 |

| 填装体积Va/L | 0.184 | 11.1 |

| 吸附剂质量/g | 70 | 5000 |

| 堆积密度/(kg·m-3) | 381 | 452 |

| 烟气流量/(L·min-1) | 1 | 65 |

| 烟气温度/℃ | 308 | 308 |

| 环境温度/℃ | 298 | 298 |

| 空速/h-1 | 326.6 | 352.6 |

| 空塔流速/(m·s-1) | 0.0236 | 0.2156 |

| 循环流量/(L·min-1) | 0.3 | 20 |

| 单次循环补充气量/L | 1 | 65 |

| 循环次数 | 1~3 | 1~3 |

| 前期吹扫气流量/(L·min-1) | 0.2 | 13 |

| 前期吹扫时间/min | 10 | 10 |

| 后期吹扫气流量/(L·min-1) | 0.5 | 35 |

表2 大、小规模现场实验参数

Table 2 Experimental parameters of larger and smaller tower field tests

| 参数 | 小塔 | 大塔 |

|---|---|---|

| 脱硝塔内径/cm | 3 | 8 |

| 脱硝塔高度/cm | 26 | 220 |

| 填装体积Va/L | 0.184 | 11.1 |

| 吸附剂质量/g | 70 | 5000 |

| 堆积密度/(kg·m-3) | 381 | 452 |

| 烟气流量/(L·min-1) | 1 | 65 |

| 烟气温度/℃ | 308 | 308 |

| 环境温度/℃ | 298 | 298 |

| 空速/h-1 | 326.6 | 352.6 |

| 空塔流速/(m·s-1) | 0.0236 | 0.2156 |

| 循环流量/(L·min-1) | 0.3 | 20 |

| 单次循环补充气量/L | 1 | 65 |

| 循环次数 | 1~3 | 1~3 |

| 前期吹扫气流量/(L·min-1) | 0.2 | 13 |

| 前期吹扫时间/min | 10 | 10 |

| 后期吹扫气流量/(L·min-1) | 0.5 | 35 |

| 1 | Gholami F, Tomas M, Gholami Z, et al. Technologies for the nitrogen oxides reduction from flue gas: a review[J]. Sci. Total. Environ., 2020, 714: 136712. |

| 2 | Giampiccolo A, Tobaldi D M, Leonardi S G, et al. Sol gel graphene/TiO2 nanoparticles for the photocatalytic-assisted sensing and abatement of NO2[J]. Appl. Catal. B, 2019, 243: 183-194. |

| 3 | Resitoglu I A, Keskin A. Hydrogen applications in selective catalytic reduction of NOx emissions from diesel engines[J]. Int. J. Hydrogen Energy, 2017, 42(36): 23389-23394. |

| 4 | Liu J, Luo X, Yao S, et al. Influence of flue gas recirculation on the performance of incinerator-waste heat boiler and NOx emission in a 500 t/d waste-to-energy plant[J]. Waste Manage., 2020, 105: 450-456. |

| 5 | Yamamoto Y, Yamamoto H, Takada D, et al. Simultaneous removal of NOx and SOx from flue gas of a glass melting furnace using a combined ozone injection and semi-dry chemical process[J]. Ozone-Sci. Eng., 2016, 38(3): 211-218. |

| 6 | Ren F, Tian X, Ren Y L, et al. Nitrogen dioxide-catalyzed aerobic oxidation of benzyl alcohols under cocatalyst and acid-free conditions[J]. Catal. Commun., 2017, 101: 98-101. |

| 7 | Nesbitt H, Browne G, Odonovan K, et al. Nitric oxide up-regulates RUNX2 in LNCaP prostate tumours: implications for tumour growth in vitro and in vivo[J]. J. Cell Physiol., 2016, 231(2): 473-482. |

| 8 | Choi S, Drese J H, Jones C W, et al. Adsorbent materials for carbon dioxide capture from large anthropogenic point sources[J]. ChemSusChem, 2009, 2(9): 796-854. |

| 9 | Mohapatro S, Rajanikanth B S. Cascaded cross flow DBD-adsorbent technique for NOxabatement in diesel engine exhaust, IEEE Trans[J]. Dielectr. Electr. Insul., 2010, 17: 1543-1550. |

| 10 | Selleri T, Gramigni F, Nova I, et al. NO oxidation on Fe- and Cu-zeolites mixed with BaO/Al2O3: free oxidation regime and relevance for the NH3-SCR chemistry at low temperature[J]. Appl. Catal. B, 2018, 225: 324-331. |

| 11 | Breedon M, Spencer M, Miura N. The adsorption of NO on YSZ(111) and oxygen-enriched YSZ(111) surfaces[J]. Chem. Phys. Lett., 2014, 593: 61-68. |

| 12 | Shirahama N, Moon S H, Choi K, et al. Mechanistic study on adsorption and reduction of NO2 over activated carbon fibers[J]. Carbon, 2002, 40(4): 2605-2611. |

| 13 | Wang X, Hanson J C, Kwak J H, et al. Cation movements during dehydration and NO2 desorption in a Ba-Y, FAU zeolite: an in situ time-resolved X-ray diffraction study[J]. J. Phys. Chem. C, 2013, 117(8): 3915-3922. |

| 14 | Li J, Han X, Zhang X, et al. Capture of nitrogen dioxide and conversion to nitric acid in a porous metal–organic framework[J]. Nat. Chem., 2019, 11(12): 1085-1090. |

| 15 | Li Y, Liu W, Yan R, et al. Hierarchical three-dimensionally ordered macroporous Fe-V binary metal oxide catalyst for low temperature selective catalytic reduction of NOxfrom marine diesel engine exhaust[J]. Appl. Catal. B, 2020, 268: 118455. |

| 16 | Liu H, Zhang Z, Xu Y, et al. Adsorption-oxidation reaction mechanism of NO on Na-ZSM-5 molecular sieves with a high Si/Al ratio at ambient temperature[J]. Chin. J. Catal., 2010, 31(9/10): 1233-1241. |

| 17 | Liu L, Li Z, Liu S, et al. Effect of exhaust gases of exhaust gas recirculation(EGR) coupling lean-burn gasoline engine on NOx purification of lean NOx trap(LNT) [J]. Mech. Syst. Signal Pr., 2017, 87: 195-213. |

| 18 | Yoshida K, Rajanikanth B S, Okubo M, et al. NOx reduction and desorption studies under electric discharge plasma using a simulated gas mixture: a case study on the effect of corona electrodes[J]. Plasma Sci. Technol., 2019, 11(3): 327-333. |

| 19 | Ghouma I, Jeguirim M, Dorge S, et al. Activated carbon prepared by physical activation of olive stones for the removal of NO2 at ambient temperature[J]. C. R. Chim., 2015, 18(1): 63-74. |

| 20 | Machida M, Yoshii A, Kijima T. Temperature swing adsorption of NOx over ZrO2-based oxides[J]. Int. J. Inorg. Mater., 2000, 2(5): 413-417. |

| 21 | Matsuok S, Kodama T, Kumagai M, et al. Development of adsorption process for NOx recycling in a reprocessing plant[J]. J. Nucl. Sci. Technol., 2003, 40(6): 410-416. |

| 22 | Yoshida K. The effect of NO pre-oxidizing in a temperature-swing-adsorption system for diesel NOx after treatment—mechanisms to enhance its performance[J]. J. Taiwan Inst. Chem. Eng., 2018, 86: 141-147. |

| 23 | Saleman T L, Li G, Rufford T E, et al. Capture of low grade methane from nitrogen gas using dual-reflux pressure swing adsorption[J]. Chem. Eng. J., 2015, 281: 739-748. |

| 24 | Han Z, Wang D, Jiang P, et al. Enhanced removal and recovery of binary mixture of n-butyl acetate and p-xylene by temperature swing-vacuum pressure swing hybrid adsorption process[J]. Process Saf. Environ. Prot., 2020, 135: 273-281. |

| 25 | Zhang W, Yahiro H, Mizuno N, et al. Removal of nitrogen monoxide on copper ion-exchanged zeolites by pressure swing adsorption[J]. Langmuir, 1993, 9(9): 2337-2343. |

| 26 | Zhang Z, John D A, Jiang B, et al. NO oxidation by microporous zeolites: isolating the impact of pore structure to predict NO conversion[J]. Appl. Catal. B, 2015, 163(2): 573-583. |

| 27 | Lee Y, Park J, Jun S, et al. NOx adsorption-temperature programmed desorption and surface molecular ions distribution by activated carbon with chemical modification[J]. Carbon, 2004, 42(1): 59-69. |

| 28 | Silas K, Ghani W, Choong T, et al. Carbonaceous materials modified catalysts for simultaneous SO2/NOx removal from flue gas: a review[J]. Catalysis Reviews, 2018, 61(1): 134-161. |

| 29 | Paolo D. SO2 and NOx adsorption properties of activated carbons obtained from a pitch containing iron derivatives[J]. Carbon, 2001, 39(14): 2173-2179. |

| 30 | Yu H, Xie Q. Discussion on reducing abrasion loss of active coke in dry-type desulfurization and denitrification technology [J]. Mining Engineering, 2018, 16(2): 37-39. |

| 31 | Szanyi J, Kwak J, Peden C. The effect of water on the adsorption of NO2 in Na- and Ba-Y, FAU zeolites: a combined FTIR and TPD investigation[J]. J. Phys. Chem. B, 2004, 108: 3746-3753. |

| 32 | Seredych M, Bashkova S, Pietrzak R, et al. Interactions of NO2 and NO with carbonaceous adsorbents containing silver nanoparticles[J]. Langmuir, 2010, 26(12): 9457-9464. |

| 33 | Szanyi J, Kwak J H, Moline R A, et al. The adsorption of NO2 and the NO + O2 reaction on Na-Y, FAU: an in situ FTIR investigation[J]. Phys. Chem. Chem. Phys., 2003, 5(18): 4045-4051. |

| 34 | Delachaux F, Vallières C, Monnier H, et al. Experimental study of NO and NO2 adsorption on a fresh or dried NaY zeolite: influence of the gas composition by breakthrough curves measurements[J]. Adsorption, 2019, 25(1): 95-103. |

| 35 | Liu L, Jin S, Ko K, et al. Alkyl-functionalization of (3-aminopropyl) triethoxysilane-grafted zeolite beta for carbon dioxide capture in temperature swing adsorption[J]. Chem. Eng. J., 2020, 382: 122834. |

| [1] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [2] | 车睿敏, 郑文秋, 王小宇, 李鑫, 许凤. 基于离子液体的纤维素均相加工研究进展[J]. 化工学报, 2023, 74(9): 3615-3627. |

| [3] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [4] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [5] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [6] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [7] | 卫雪岩, 钱勇. 微米级铁粉燃料中低温氧化反应特性及其动力学研究[J]. 化工学报, 2023, 74(6): 2624-2638. |

| [8] | 肖忠良, 尹碧露, 宋刘斌, 匡尹杰, 赵亭亭, 刘成, 袁荣耀. 废旧锂离子电池回收工艺研究进展及其安全风险分析[J]. 化工学报, 2023, 74(4): 1446-1456. |

| [9] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| [10] | 潘煜, 王子航, 王佳韵, 王如竹, 张华. 基于可得然-氯化锂复合吸附剂的除湿换热器热湿性能研究[J]. 化工学报, 2023, 74(3): 1352-1359. |

| [11] | 许万, 陈振斌, 张慧娟, 牛昉昉, 火婷, 刘兴盛. 线性温敏性聚合物嵌段调控的 |

| [12] | 鲁文静, 李先锋. 液流电池多孔离子传导膜研究进展[J]. 化工学报, 2023, 74(1): 192-204. |

| [13] | 黄宽, 马永德, 蔡镇平, 曹彦宁, 江莉龙. 油脂催化加氢转化制备第二代生物柴油研究进展[J]. 化工学报, 2023, 74(1): 380-396. |

| [14] | 刘坤, 尹远, 耿文强, 夏昊天. 不同操作参数下介质阻挡放电的固氮性能研究及机理分析[J]. 化工学报, 2022, 73(9): 4045-4053. |

| [15] | 马语峻, 刘向军. 多孔陶瓷膜烟气水分回收理论与模型研究[J]. 化工学报, 2022, 73(9): 4103-4112. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号