化工学报 ›› 2021, Vol. 72 ›› Issue (4): 2038-2046.DOI: 10.11949/0438-1157.20201015

分析

分析

梁坤峰1( ),冯长振1,王莫然1,董彬1(

),冯长振1,王莫然1,董彬1( ),王林2,刘瑞见1

),王林2,刘瑞见1

收稿日期:2020-07-27

修回日期:2020-10-12

出版日期:2021-04-05

发布日期:2021-04-05

通讯作者:

董彬

作者简介:梁坤峰(1975—),男,博士,教授,基金资助:

LIANG Kunfeng1( ),FENG Changzhen1,WANG Moran1,DONG Bin1(

),FENG Changzhen1,WANG Moran1,DONG Bin1( ),WANG Lin2,LIU Ruijian1

),WANG Lin2,LIU Ruijian1

Received:2020-07-27

Revised:2020-10-12

Online:2021-04-05

Published:2021-04-05

Contact:

DONG Bin

摘要:

针对非共沸工质非线性复杂相变传热过程,基于高级 分析方法,推导出表征热泵系统性能的评估指标模型——温度匹配度(TMD),探讨了非共沸工质与换热流体之间的换热匹配特性,实验验证了模型的准确性与适用性。选用了三组不同温度滑移程度的非共沸工质(M1、M2、M3)为对象,探究了TMD与换热夹点、系统COP、

分析方法,推导出表征热泵系统性能的评估指标模型——温度匹配度(TMD),探讨了非共沸工质与换热流体之间的换热匹配特性,实验验证了模型的准确性与适用性。选用了三组不同温度滑移程度的非共沸工质(M1、M2、M3)为对象,探究了TMD与换热夹点、系统COP、 效率η以及换热器实际

效率η以及换热器实际 损占比ε之间的关系。结果表明:TMD越小,换热流体间的温度匹配越好,系统COP、

损占比ε之间的关系。结果表明:TMD越小,换热流体间的温度匹配越好,系统COP、 效率越大,换热器实际

效率越大,换热器实际 损占比越小,反之亦然;且当TMD最小时换热器内夹点总是出现在饱和气态点处。

损占比越小,反之亦然;且当TMD最小时换热器内夹点总是出现在饱和气态点处。

中图分类号:

梁坤峰, 冯长振, 王莫然, 董彬, 王林, 刘瑞见. 非共沸工质换热匹配特性影响热泵性能的高级 分析[J]. 化工学报, 2021, 72(4): 2038-2046.

分析[J]. 化工学报, 2021, 72(4): 2038-2046.

LIANG Kunfeng, FENG Changzhen, WANG Moran, DONG Bin, WANG Lin, LIU Ruijian. Advanced exergy analysis of heat pump performance affected by heat transfer matching characteristics of non-azeotropic refrigerants[J]. CIESC Journal, 2021, 72(4): 2038-2046.

| 工况 | 冷却水进口温度(Tw,in)/℃ | 冷却水出口温度(Tw,out)/℃ |

|---|---|---|

| 工况1 | 25 | 40 |

| 工况2 | 25 | 60 |

表1 计算工况

Table 1 Operating conditions

| 工况 | 冷却水进口温度(Tw,in)/℃ | 冷却水出口温度(Tw,out)/℃ |

|---|---|---|

| 工况1 | 25 | 40 |

| 工况2 | 25 | 60 |

| 第一组分的 质量分数 | 滑移温度/℃ | ||

|---|---|---|---|

| R600/R32 (M1) | R600/R134a(M2) | R245fa/R290(M3) | |

| 0.1 | 0.48 | 0 | 0.35 |

| 0.2 | 6.67 | 1.85 | 0.96 |

| 0.3 | 17.95 | 7.43 | 2.02 |

| 0.4 | 27.58 | 12.89 | 3.85 |

| 0.5 | 35.71 | 16.74 | 6.95 |

| 0.6 | 42.39 | 18.66 | 11.65 |

| 0.7 | 46.96 | 18.33 | 17.38 |

| 0.8 | 47.24 | 15.29 | 23.05 |

| 0.9 | 36.42 | 9.15 | 25.55 |

表2 三种非共沸工质的滑移温度

Table 2 Temperature glide of three non-azeotropic mixtures

| 第一组分的 质量分数 | 滑移温度/℃ | ||

|---|---|---|---|

| R600/R32 (M1) | R600/R134a(M2) | R245fa/R290(M3) | |

| 0.1 | 0.48 | 0 | 0.35 |

| 0.2 | 6.67 | 1.85 | 0.96 |

| 0.3 | 17.95 | 7.43 | 2.02 |

| 0.4 | 27.58 | 12.89 | 3.85 |

| 0.5 | 35.71 | 16.74 | 6.95 |

| 0.6 | 42.39 | 18.66 | 11.65 |

| 0.7 | 46.96 | 18.33 | 17.38 |

| 0.8 | 47.24 | 15.29 | 23.05 |

| 0.9 | 36.42 | 9.15 | 25.55 |

| 参数 | M1 | M2 | M3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.78 | 0.88 | 0.98 | 1.00 | 0.66 | 0.76 | 0.86 | 0.96 | 0.79 | 0.89 | 0.99 | 1.00 | |

| TMD | 3.56 | 3.32 | 2.38 | 2.62 | 2.43 | 2.35 | 2.14 | 2.49 | 2.88 | 2.92 | 2.39 | 2.62 |

| COP | 3.35 | 3.69 | 4.88 | 4.28 | 4.56 | 4.75 | 5.17 | 4.53 | 3.64 | 3.74 | 4.80 | 4.29 |

表3 不同工质占比下所对应的温度匹配度和COP

Table 3 TMD and COP corresponding to different mass fraction of working fluids

| 参数 | M1 | M2 | M3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.78 | 0.88 | 0.98 | 1.00 | 0.66 | 0.76 | 0.86 | 0.96 | 0.79 | 0.89 | 0.99 | 1.00 | |

| TMD | 3.56 | 3.32 | 2.38 | 2.62 | 2.43 | 2.35 | 2.14 | 2.49 | 2.88 | 2.92 | 2.39 | 2.62 |

| COP | 3.35 | 3.69 | 4.88 | 4.28 | 4.56 | 4.75 | 5.17 | 4.53 | 3.64 | 3.74 | 4.80 | 4.29 |

图4 工况1下三种工质的TMD与COP、循环温差变化趋势

Fig.4 Variation curves of TMD, COP and cyclic temperature difference under different working fluid mass fractions in condition 1

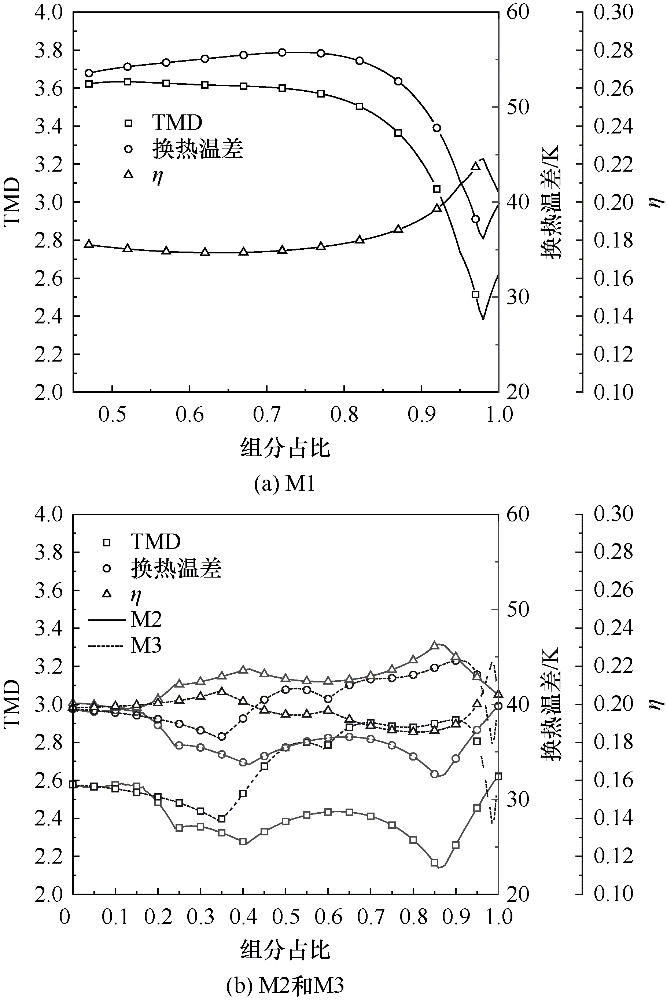

图6 工况1下三种工质的TMD与η、换热温差变化趋势

Fig.6 Variation curves of TMD, η and heat transfer temperature difference under different working fluid mass fractions in condition 1

| 文献 | 工作流体 | Pc/MPa | Pe/MPa | COP | TMD |

|---|---|---|---|---|---|

| [ | W1 | 1.69 | 0.60 | 5.36 | 2.51 |

| 1.88 | 0.59 | 4.68 | 2.65 | ||

| 2.09 | 0.59 | 4.20 | 2.76 | ||

| W2 | 1.33 | 0.46 | 5.41 | 2.56 | |

| 1.48 | 0.45 | 4.77 | 2.69 | ||

| 1.65 | 0.45 | 4.29 | 2.89 | ||

| [ | Z1 | 1.160 | 0.420 | 5.09 | 2.13 |

| 1.292 | 0.420 | 4.51 | 2.29 | ||

| 1.434 | 0.416 | 4.01 | 2.45 | ||

| Z2 | 1.716 | 0.654 | 4.97 | 2.02 | |

| 1.898 | 0.648 | 4.37 | 2.16 | ||

| 2.094 | 0.642 | 3.87 | 2.32 | ||

| [ | R134a/R245fa (0.1/0.9) | 1.51 | 0.41 | 3.94 | 2.79 |

| R134a/R245fa (0.2/0.8) | 1.76 | 0.48 | 3.92 | 2.83 | |

| R134a/R245fa (0.3/0.7) | 2.00 | 0.56 | 3.88 | 2.84 | |

| R134a/R245fa (0.4/0.6) | 2.26 | 0.64 | 3.77 | 2.86 |

表4 文献工质理论循环参数及相应的TMD

Table 4 The parameters in the literature and corresponding TMD

| 文献 | 工作流体 | Pc/MPa | Pe/MPa | COP | TMD |

|---|---|---|---|---|---|

| [ | W1 | 1.69 | 0.60 | 5.36 | 2.51 |

| 1.88 | 0.59 | 4.68 | 2.65 | ||

| 2.09 | 0.59 | 4.20 | 2.76 | ||

| W2 | 1.33 | 0.46 | 5.41 | 2.56 | |

| 1.48 | 0.45 | 4.77 | 2.69 | ||

| 1.65 | 0.45 | 4.29 | 2.89 | ||

| [ | Z1 | 1.160 | 0.420 | 5.09 | 2.13 |

| 1.292 | 0.420 | 4.51 | 2.29 | ||

| 1.434 | 0.416 | 4.01 | 2.45 | ||

| Z2 | 1.716 | 0.654 | 4.97 | 2.02 | |

| 1.898 | 0.648 | 4.37 | 2.16 | ||

| 2.094 | 0.642 | 3.87 | 2.32 | ||

| [ | R134a/R245fa (0.1/0.9) | 1.51 | 0.41 | 3.94 | 2.79 |

| R134a/R245fa (0.2/0.8) | 1.76 | 0.48 | 3.92 | 2.83 | |

| R134a/R245fa (0.3/0.7) | 2.00 | 0.56 | 3.88 | 2.84 | |

| R134a/R245fa (0.4/0.6) | 2.26 | 0.64 | 3.77 | 2.86 |

| 1 | 赵力. 一种非共沸循环工质与R22的性能对比实验[J]. 化工学报, 2004, 55(8): 1237-1242. |

| Zhao L. Comparison of performance between non-azeotropic mixtures working fluid and R22[J]. Journal of Chemical Industry and Engineering (China), 2004, 55(8): 1237-1242. | |

| 2 | Zhao P C, Zhao L, Ding G L, et al. Temperature matching method of selecting working fluids for geothermal heat pumps[J]. Applied Thermal Engineering, 2003, 23(2): 179-195. |

| 3 | 涂岱兴, 赵力, 王建立, 等. 二氧化碳逆循环中气体冷却器的传热窄点分布[J]. 机械工程学报, 2009, 45(9): 307-311. |

| Tu D X, Zhao L, Wang J L, et al. Distribution of heat transfer pinch point of gas cooler in CO2 inverse-cycle[J]. Journal of Mechanical Engineering, 2009, 45(9): 307-311. | |

| 4 | 赵鹏程, 赵力, 丁国良, 等. 二元混合工质与换热介质的温度匹配在热泵中的应用[J]. 太阳能学报, 2003, 24(2): 172-177. |

| Zhao P C, Zhao L, Ding G L, et al. Temperature matching between binary non-azeotropic mixtures and secondary heat transfer fluids in heat pumps[J]. Acta Energiae Solaris Sinica, 2003, 24(2): 172-177. | |

| 5 | 蒯大秋, 巴珍贵, 涂智勇. 制冷工质与热源匹配性能的理论分析与计算[J]. 湖南文理学院学报(自然科学版), 2005, 17(3): 23-25. |

| Kuai D Q, Ba Z G, Tu Z Y. The calculation and analyses on temperature matching performance between heat source and working fluids[J]. Journal of Hunan University of Arts and Science (Natural Science Edition), 2005, 17(3): 23-25. | |

| 6 | 蒯大秋, 马一太, 何绍书. 混合工质匹配性能的热力学分析[J]. 工程热物理学报, 2004, 25(1): 34-36. |

| Kuai D Q, Ma Y T, He S S. Thermodynamic analysis for matching performance between mixtures and heat sources[J]. Journal of Engineering Thermophysics, 2004, 25(1): 34-36. | |

| 7 | 王辉涛, 王华, 葛众, 等. 变温热源驱动非共沸混合工质ORC换热器温度匹配性能评价方法[J]. 昆明理工大学学报(自然科学版), 2014, 39(1): 58-62, 71. |

| Wang H T, Wang H, Ge Z, et al. A method to evaluate temperature matching performance of heat exchanger in variable-temperature heat source driving ORC with zeotropic refrigerant mixtures[J]. Journal of Kunming University of Science and Technology (Natural Science Edition), 2014, 39(1): 58-62, 71. | |

| 8 | 于超, 徐进良, 王华荣. 工质比热匹配对有机朗肯循环不可逆损失的影响[J]. 华北电力大学学报(自然科学版), 2016, 43(3): 69-75. |

| Yu C, Xu J L, Wang H R. Influence of heat capacity match between heat transfer fluids on irreversibility of organic Rankine cycle[J]. Journal of North China Electric Power University (Natural Science Edition), 2016, 43(3): 69-75. | |

| 9 | Zühlsdorf B, Jensen J K, Cignitti S, et al. Analysis of temperature glide matching of heat pumps with zeotropic working fluid mixtures for different temperature glides[J]. Energy, 2018, 153: 650-660. |

| 10 | Ju F J, Fan X W, Chen Y P, et al. Performance assessment of heat pump water heaters with R1233zd(E)/HCs binary mixtures[J]. Applied Thermal Engineering, 2017, 123: 1345-1355. |

| 11 | Guo H, Gong M Q, Qin X Y. Performance analysis of a modified subcritical zeotropic mixture recuperative high-temperature heat pump[J]. Applied Energy, 2019, 237: 338-352. |

| 12 | Cheng Z, Wang B L, Shi W X, et al. Numerical research on R32/R1234ze(E) air source heat pump under variable mass concentration[J]. International Journal of Refrigeration, 2017, 82: 1-10. |

| 13 | Larsen U, Nguyen T V, Knudsen T, et al. System analysis and optimisation of a Kalina split-cycle for waste heat recovery on large marine diesel engines[J]. Energy, 2014, 64: 484-494. |

| 14 | Bao J J, Zhang R X, Yuan T, et al. A simultaneous approach to optimize the component and composition of zeotropic mixture for power generation systems[J]. Energy Conversion and Management, 2018, 165: 354-362. |

| 15 | Chen J Y, Zhu K D, Huang Y S, et al. Evaluation of the ejector refrigeration system with environmentally friendly working fluids from energy, conventional exergy and advanced exergy perspectives[J]. Energy Conversion and Management, 2017, 148: 1208-1224. |

| 16 | Mehdizadeh-Fard M, Pourfayaz F, Mehrpooya M, et al. Improving energy efficiency in a complex natural gas refinery using combined pinch and advanced exergy analyses[J]. Applied Thermal Engineering, 2018, 137: 341-355. |

| 17 | Bühler F, Nguyen T V, Jensen J K, et al. Energy, exergy and advanced exergy analysis of a milk processing factory[J]. Energy, 2018, 162: 576-592. |

| 18 | Tsatsaronis G, Park M H. On avoidable and unavoidable exergy destructions and investment costs in thermal systems[J]. Energy Conversion and Management, 2002, 43(9/10/11/12): 1259-1270. |

| 19 | Zühlsdorf B, Meesenburg W, Ommen T S, et al. Improving the performance of booster heat pumps using zeotropic mixtures[J]. Energy, 2018, 154: 390-402. |

| 20 | Chen Y G. Pinch point analysis and design considerations of CO2 gas cooler for heat pump water heaters[J]. International Journal of Refrigeration, 2016, 69: 136-146. |

| 21 | 周颖艳, 杜小泽, 杨立军, 等. 吸收烟气余热的非共沸混合工质蒸发换热特性[J]. 中国电机工程学报, 2013, 33(8): 9-15, 4. |

| Zhou Y Y, Du X Z, Yang L J, et al. Heat transfer characteristics of zeotropic mixtures in an ORC evaporator heated by exhaust gas[J]. Proceedings of the CSEE, 2013, 33(8): 9-15, 4. | |

| 22 | Fartaj A, Ting D S K, Yang W W. Second law analysis of the transcritical CO2 refrigeration cycle[J]. Energy Conversion and Management, 2004, 45(13/14): 2269-2281. |

| 23 | Guo T, Wang H X, Zhang S J. Comparative analysis of CO2-based transcritical Rankine cycle and HFC245fa-based subcritical organic Rankine cycle using low-temperature geothermal source[J]. Science China Technological Sciences, 2010, 53(6): 1638-1646. |

| 24 | Zühlsdorf B, Jensen J K, Elmegaard B. Heat pump working fluid selection—economic and thermodynamic comparison of criteria and boundary conditions[J]. International Journal of Refrigeration, 2019, 98: 500-513. |

| 25 | Liu Z Y, Zhao L, Zhao X Z, et al. The occurrence of pinch point and its effects on the performance of high temperature heat pump[J]. Applied Energy, 2012, 97: 869-875. |

| 26 | Besbes K, Zoughaib A, De Carlan F, et al. Exergy based methodology for optimized integration of heat pumps in industrial processes[C]//15th International Refrigeration and Air Conditioning Conference. Purdue, 2014. |

| 27 | Yang J L, Ma Y T, Li M X, et al. Exergy analysis of transcritical carbon dioxide refrigeration cycle with an expander[J]. Energy, 2005, 30(7): 1162-1175. |

| 28 | 高攀. 基于温焓关系的中高温热泵非共沸工质的循环特性分析[D]. 天津: 天津大学, 2007. |

| Gao P. Investigation on cyclic characteristics of non-azeotropic mixtures in moderate and high temperature heat pumps according to the relation between temperature and enthalpy[D]. Tianjin: Tianjin University, 2007. | |

| 29 | 赵学政. 高温热泵工况下自然工质混合物两类传热窄点的实验研究[D]. 天津: 天津大学, 2010. |

| Zhao X Z. Experimental researches on two different heat transfer pinch points of non-azeotropic mixtures of natural refrigerants in high temperature heat pump[D]. Tianjin: Tianjin University, 2010. | |

| 30 | 孙利豪. 新工质中高温水源热泵系统优化研究[D]. 青岛: 青岛理工大学, 2018. |

| Sun L H. Study on thermal performance of new refrigerant in medium-high temperature water source heat pump[D]. Qingdao: Qingdao University of Tehcnology, 2018. | |

| 31 | 刘瑞见. 非共沸工质高温热泵系统研究[D]. 河南: 河南科技大学, 2020. |

| Liu R J. Research on high temperature heat pump system with non-azeotropic mixtures[D]. Henan: Henan University of Science and Technology, 2020. |

| [1] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [2] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [3] | 常明慧, 王林, 苑佳佳, 曹艺飞. 盐溶液蓄能型热泵循环特性研究[J]. 化工学报, 2023, 74(S1): 329-337. |

| [4] | 代宝民, 王启龙, 刘圣春, 张佳宁, 李鑫海, 宗凡迪. 非共沸工质辅助过冷CO2冷热联供系统的热力学性能分析[J]. 化工学报, 2023, 74(S1): 64-73. |

| [5] | 杨天阳, 邹慧明, 周晖, 王春磊, 田长青. -30℃电动汽车补气式CO2热泵制热性能实验研究[J]. 化工学报, 2023, 74(S1): 272-279. |

| [6] | 邹启宏, 李乾, 葛天舒. 基于多目标下的两级并联除湿热泵系统实验研究[J]. 化工学报, 2023, 74(S1): 265-271. |

| [7] | 雷博雯, 吴建华, 吴启航. R290低压比热泵高补气过热度循环研究[J]. 化工学报, 2023, 74(5): 1875-1883. |

| [8] | 董益秀, 王如竹. 高温热泵的循环、工质研究及应用展望[J]. 化工学报, 2023, 74(1): 133-144. |

| [9] | 卢沛, 罗向龙, 陈健勇, 杨智, 梁颖宗, 陈颖. 板式换热器及其热力系统的运行特性和高级 分析[J]. 化工学报, 2021, 72(S1): 512-519. 分析[J]. 化工学报, 2021, 72(S1): 512-519. |

| [10] | 汪谦旭, 刘益才, 梁恒, 李政, 赵祥乐. 融霜下落水对换热器除霜性能的影响[J]. 化工学报, 2021, 72(S1): 356-361. |

| [11] | 吴迪, 胡斌, 王如竹, 余京京, 林欣毅, 李子亮. 水工质热泵多种循环的理论研究与性能对比[J]. 化工学报, 2021, 72(S1): 236-243. |

| [12] | 罗介霖, 杨凯寅, 赵朕, 王勤, 陈光明. 低GWP混合工质回热热泵采暖性能[J]. 化工学报, 2021, 72(S1): 84-90. |

| [13] | 赵兰萍, 郭本涛, 杨志刚. 车用热泵内部冷凝器结构对性能的影响[J]. 化工学报, 2021, 72(9): 4616-4628. |

| [14] | 李晓宇, 徐宏阳, 代敏, 蔡姗姗. 热弥散对地埋管换热器全尺度传热的影响[J]. 化工学报, 2021, 72(5): 2547-2559. |

| [15] | 王宇波, 全贞花, 靖赫然, 王林成, 赵耀华. 多能互补协同蓄能系统热力学分析与运行优化[J]. 化工学报, 2021, 72(5): 2474-2483. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号