化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2294-2303.DOI: 10.11949/0438-1157.20241217

刘鑫1,3( ), 郑皓仁1,3, 陈强1, 丁静怡3, 黄康1,3(

), 郑皓仁1,3, 陈强1, 丁静怡3, 黄康1,3( ), 徐至2(

), 徐至2( )

)

收稿日期:2024-10-31

修回日期:2024-12-24

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

黄康,徐至

作者简介:刘鑫(1999—),男,博士研究生,liuxin@njtech.edu.cn

基金资助:

Xin LIU1,3( ), Haoren ZHENG1,3, Qiang CHEN1, Jingyi DING3, Kang HUANG1,3(

), Haoren ZHENG1,3, Qiang CHEN1, Jingyi DING3, Kang HUANG1,3( ), Zhi XU2(

), Zhi XU2( )

)

Received:2024-10-31

Revised:2024-12-24

Online:2025-05-25

Published:2025-06-13

Contact:

Kang HUANG, Zhi XU

摘要:

设计了用于全钒液流电池的纤维素纳米晶(CNC)掺杂的磺化聚醚醚酮(SPEEK)混合基质膜,CNC表面大量的羟基和磺酸基团使其具有良好的亲水性,这些基团的存在也能改善填料和聚合物之间的界面相容性。此外,CNC的高结晶度和高纵横比确保了膜在强酸性和强氧化性条件下高的稳定性以及良好的活性离子阻隔能力。同时其表面丰富的—OH基团与水分子以及SPEEK中丰富的—SO3H基团构建了高度互连的亲水离子纳米团簇,实现高达0.073 S·cm-1的质子传导率。使用其组装的电池在120 mA·cm-2的电流密度下电压效率(VE)可达88.7%,远远超过SPEEK膜(78.3%),表明SPEEK/CNC膜在全钒液流电池中具有良好的应用前景。

中图分类号:

刘鑫, 郑皓仁, 陈强, 丁静怡, 黄康, 徐至. 全钒液流电池用纤维素纳米晶掺杂混合基质膜[J]. 化工学报, 2025, 76(5): 2294-2303.

Xin LIU, Haoren ZHENG, Qiang CHEN, Jingyi DING, Kang HUANG, Zhi XU. Cellulose nanocrystals-doped hybrid matrix membranes for vanadium flow battery[J]. CIESC Journal, 2025, 76(5): 2294-2303.

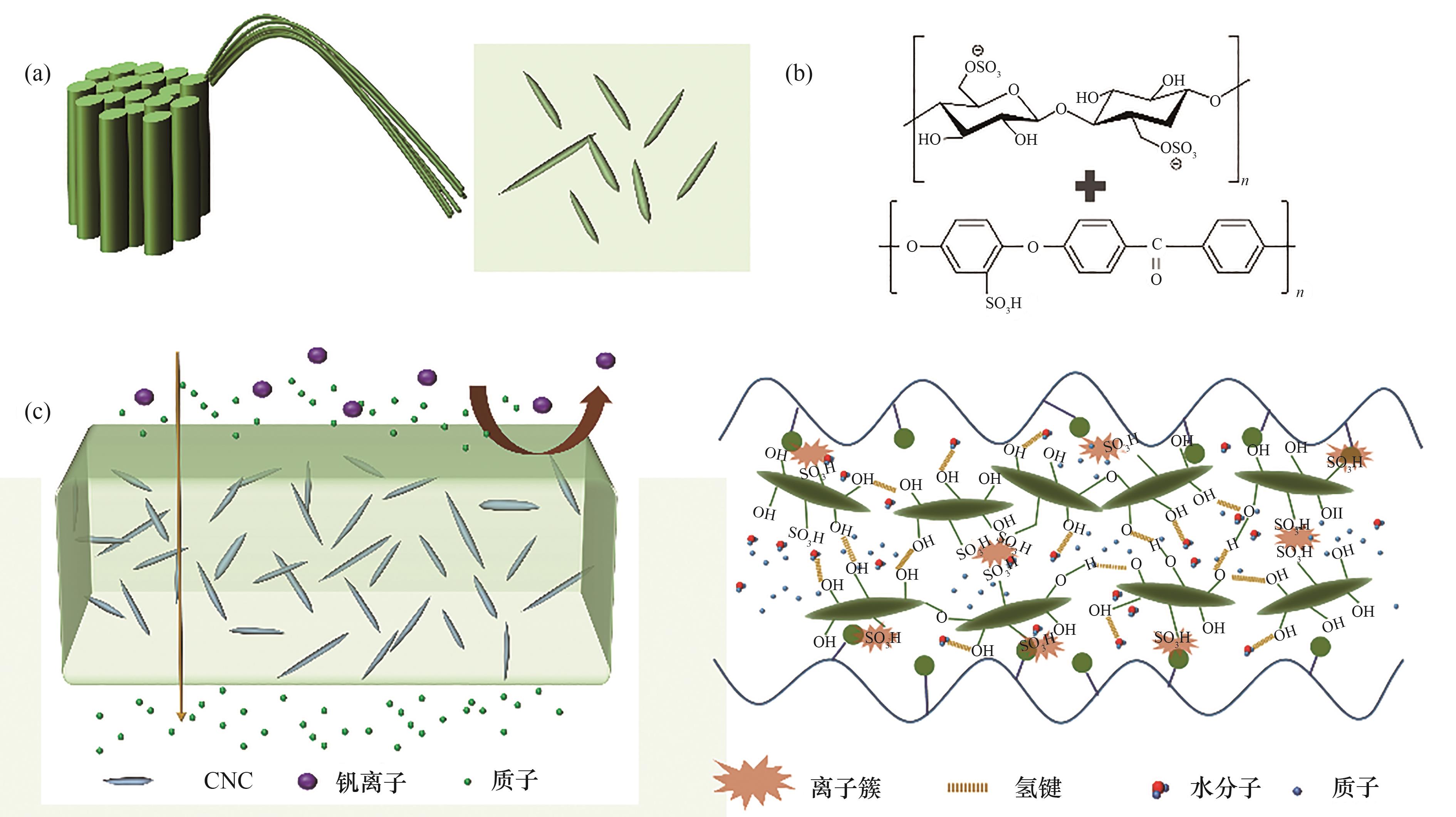

图1 SPEEK/CNC混合基质膜: (a) CNC来源;(b) CNC与SPEEK分子式;(c) SPEEK/CNC膜筛分与传质机理

Fig.1 SPEEK/CNC hybrid matrix membrane: (a) source of CNC; (b) molecular formula of CNC and SPEEK; (c) SPEEK/CNC membrane sieving and mass transfer mechanisms

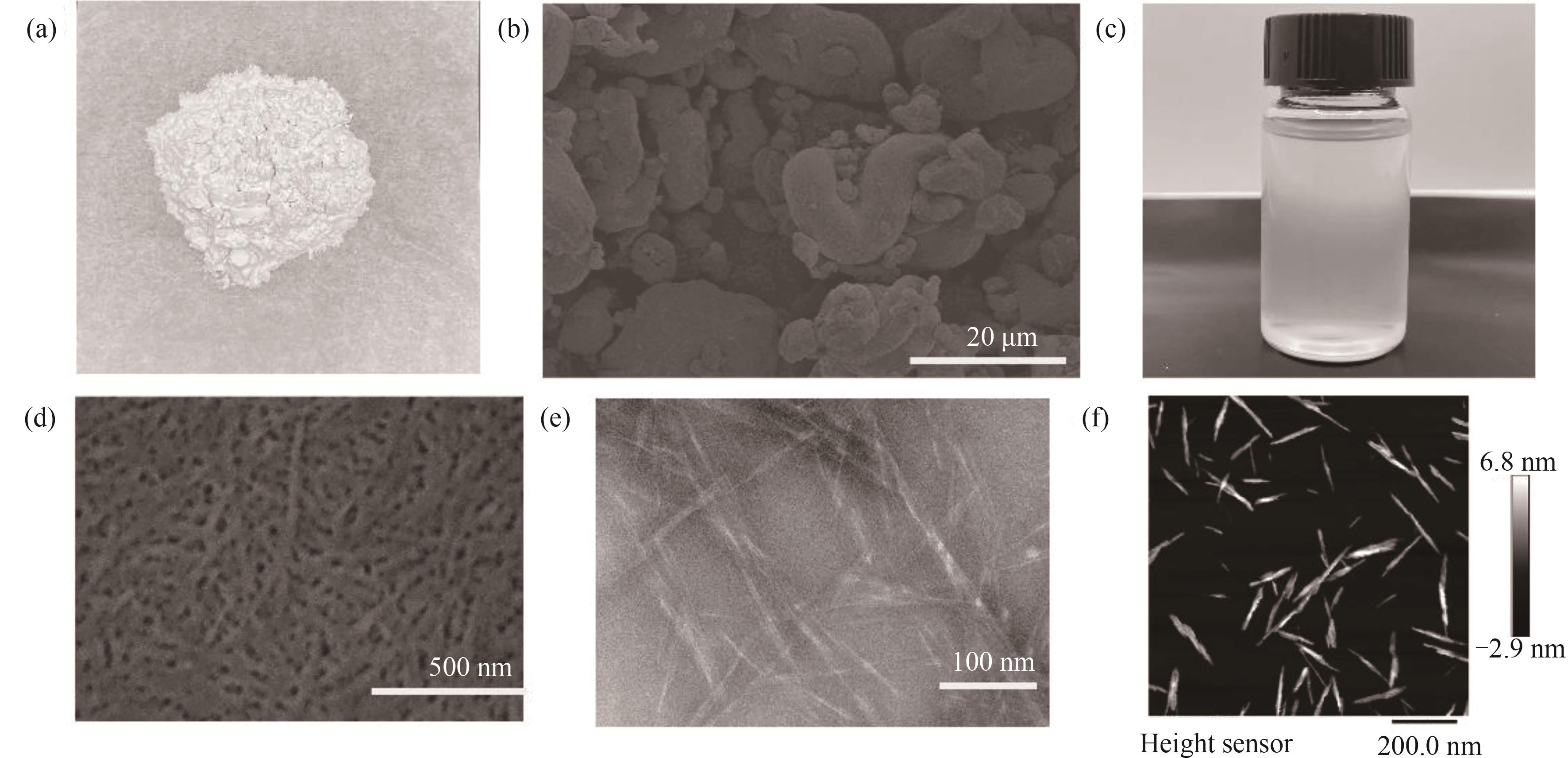

图2 CNC的形貌表征: (a) CNC粉末;(b) CNC粉末的SEM图像;(c) CNC的DMSO分散液;(d) CNC分散液的SEM图像;(e) CNC分散液的TEM图像;(f) CNC分散液的AFM图像

Fig.2 Topography characterization of CNC: (a) powder of CNC; (b) SEM image of CNC powder; (c) DMSO dispersion for CNC; (d) SEM image of CNC dispersion; (e) TEM image of CNC dispersion; (f) AFM image of CNC dispersion

图3 CNC的基本表征: (a) CNC的XPS谱图-S 2p;(b) CNC的Zeta电位图;(c) CNC的水流体力学直径图;(d) CNC的热重图;(e) CNC的XRD谱图;(f) CNC的红外光谱图

Fig.3 Basic characterization of CNC: (a) XPS spectrum of CNC-S 2p; (b) Zeta potential map of CNC; (c) hydrodynamic diameter diagram of CNC; (d) TGA of CNC; (e) XRD spectrum of CNC; (f) FTIR of CNC

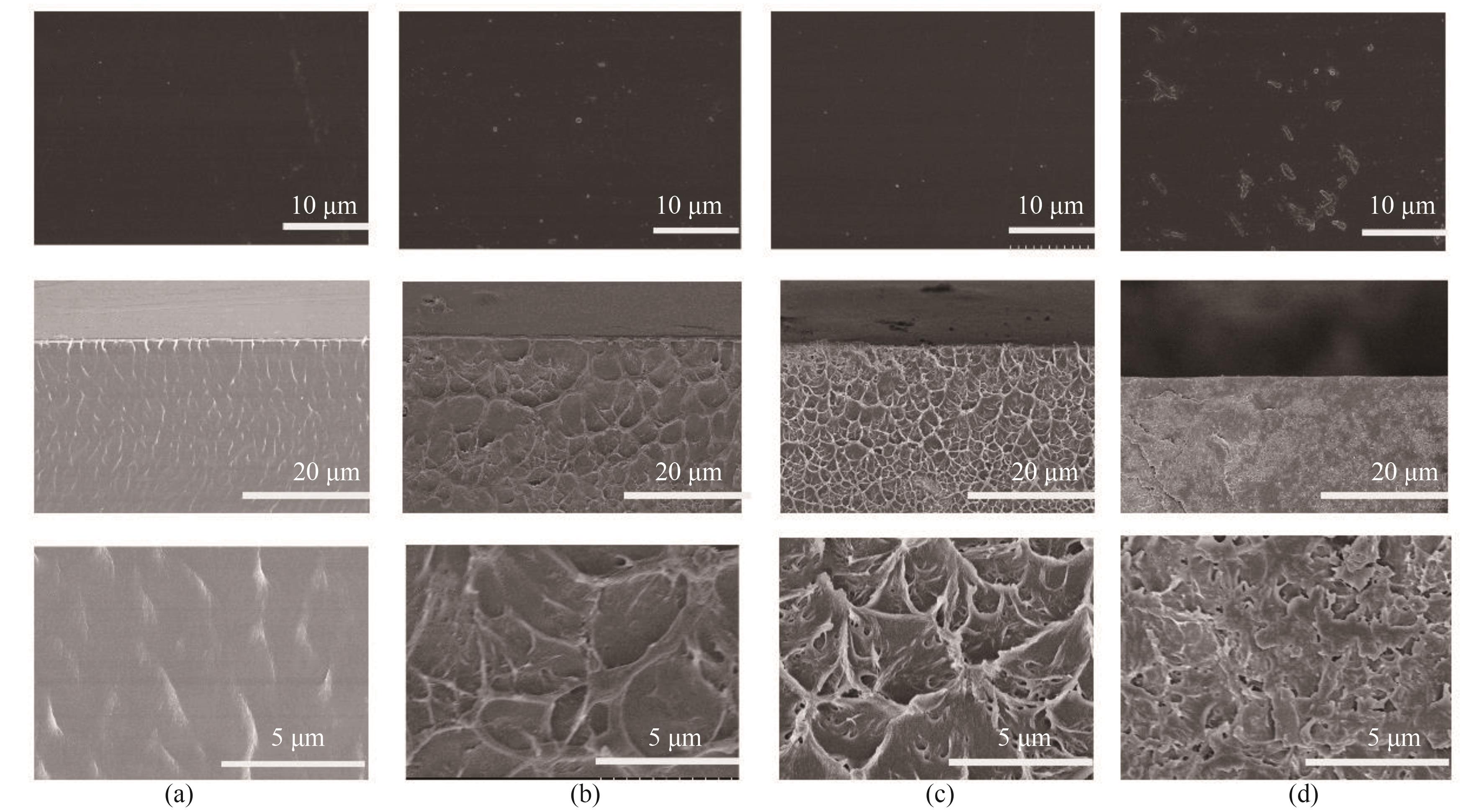

图5 不同CNC掺杂量的SEM图像: (a) SPEEK;(b) S/CNC-1;(c) S/CNC-3;(d) S/CNC-5

Fig.5 SEM images with different CNC doping amounts: (a) SPEEK; (b) S/CNC-1; (c) S/CNC-3; (d) S/CNC-5

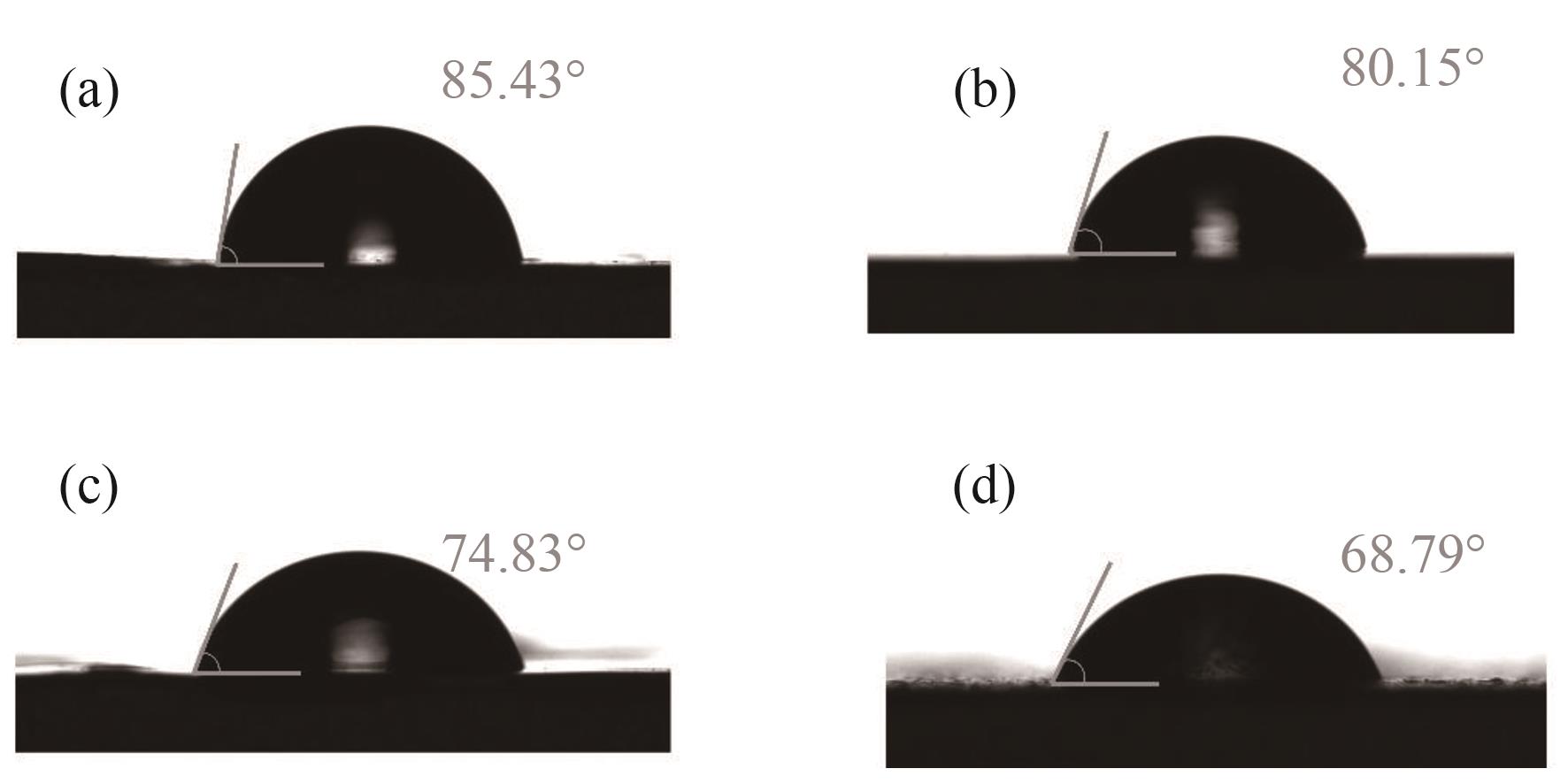

图6 不同CNC掺杂量的水接触角图像: (a) SPEEK;(b) S/CNC-1;(c) S/CNC-3;(d) S/CNC-5

Fig.6 Images of water contact angles with varying amounts of CNC doping: (a) SPEEK; (b) S/CNC-1; (c) S/CNC-3; (d) S/CNC-5

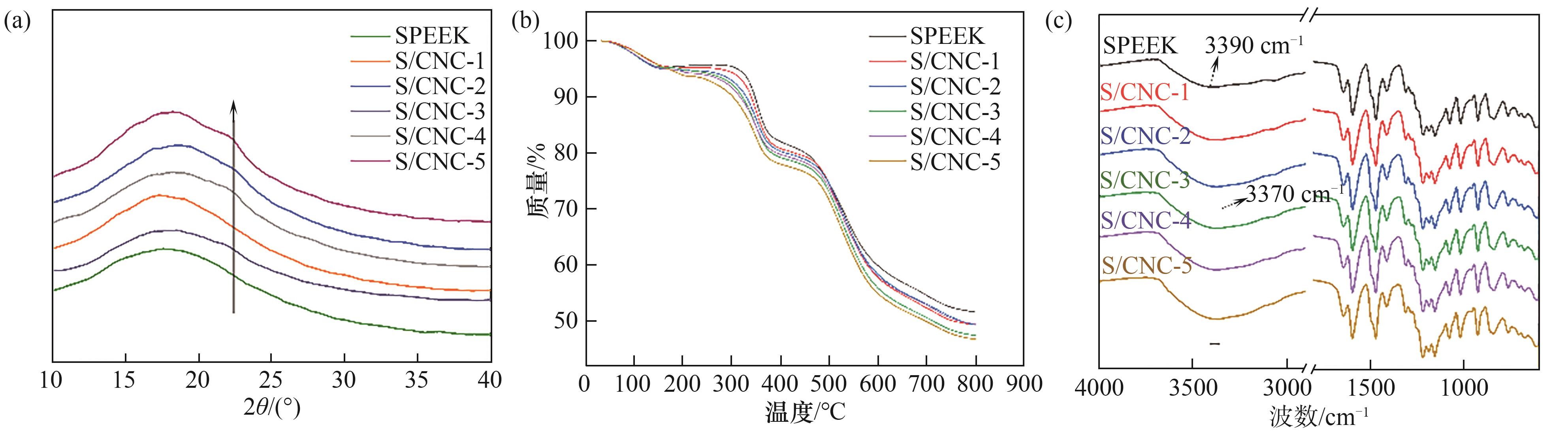

图7 不同CNC掺杂量的数据分析: (a)不同CNC掺杂量的XRD谱图;(b)不同CNC掺杂量的热重曲线;(c)不同CNC掺杂量的FTIR谱图

Fig.7 Data analysis of different CNC doping amounts: (a) XRD spectra of different CNC doping amount; (b) TGA curves for different CNC doping levels; (c) FTIR spectra of different CNC doping amounts

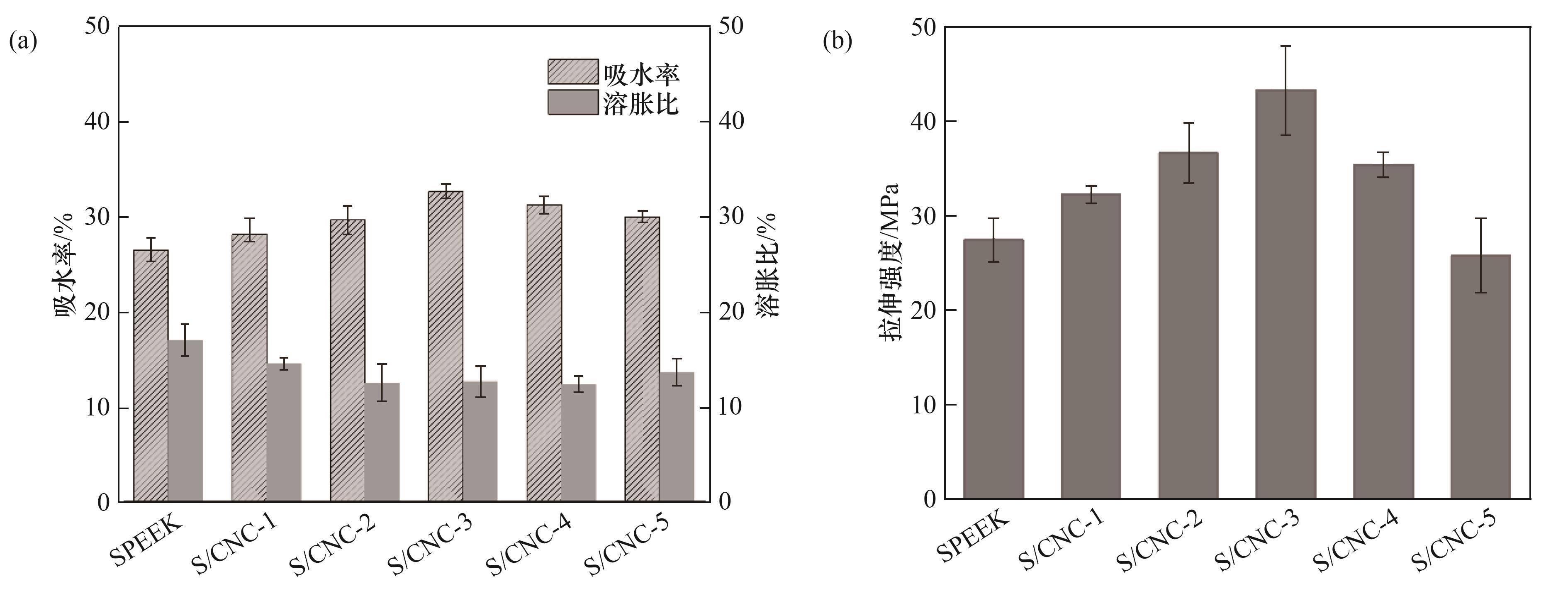

图8 不同膜的物理性能测试: (a) 吸水率与溶胀比;(b) 拉伸强度

Fig.8 Evaluation of physical properties of various membrane materials: (a) water absorption and swelling ratio; (b) tensile strength

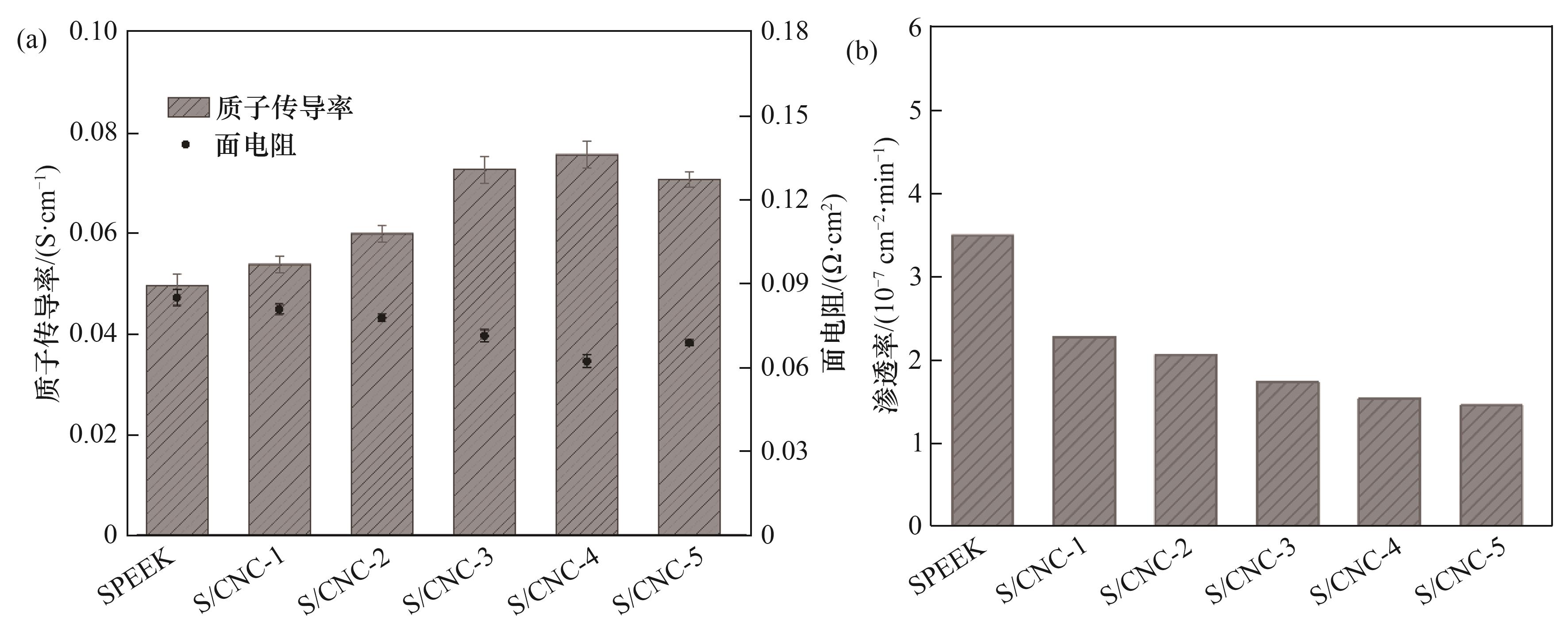

图9 SPEEK/CNC杂化膜与SPEEK的基础性能: (a) 质子传导率与面积电阻;(b) 钒离子渗透率

Fig.9 Basic properties of SPEEK/CNC hybrid membranes and SPEEK: (a) proton conductivity and area resistance; (b) vanadium ion permeability

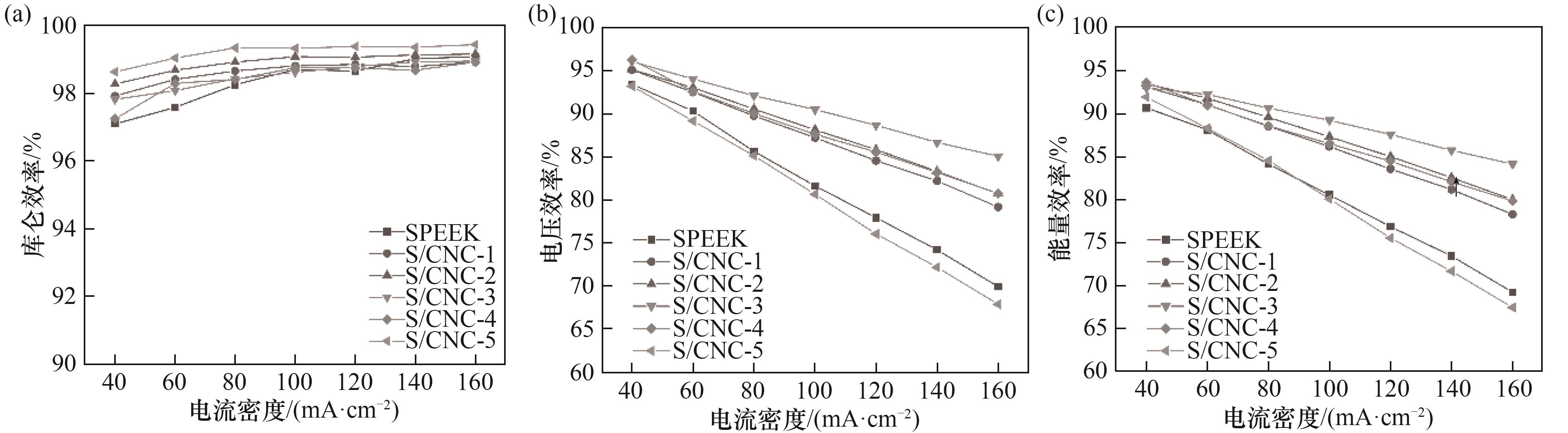

图10 不同膜的单电池性能: (a) 库仑效率;(b) 电压效率;(c) 能量效率

Fig.10 Performance of VFB single cells with different membranes: (a) coulombic efficiency; (b) voltage efficiency; (c) energy efficiency

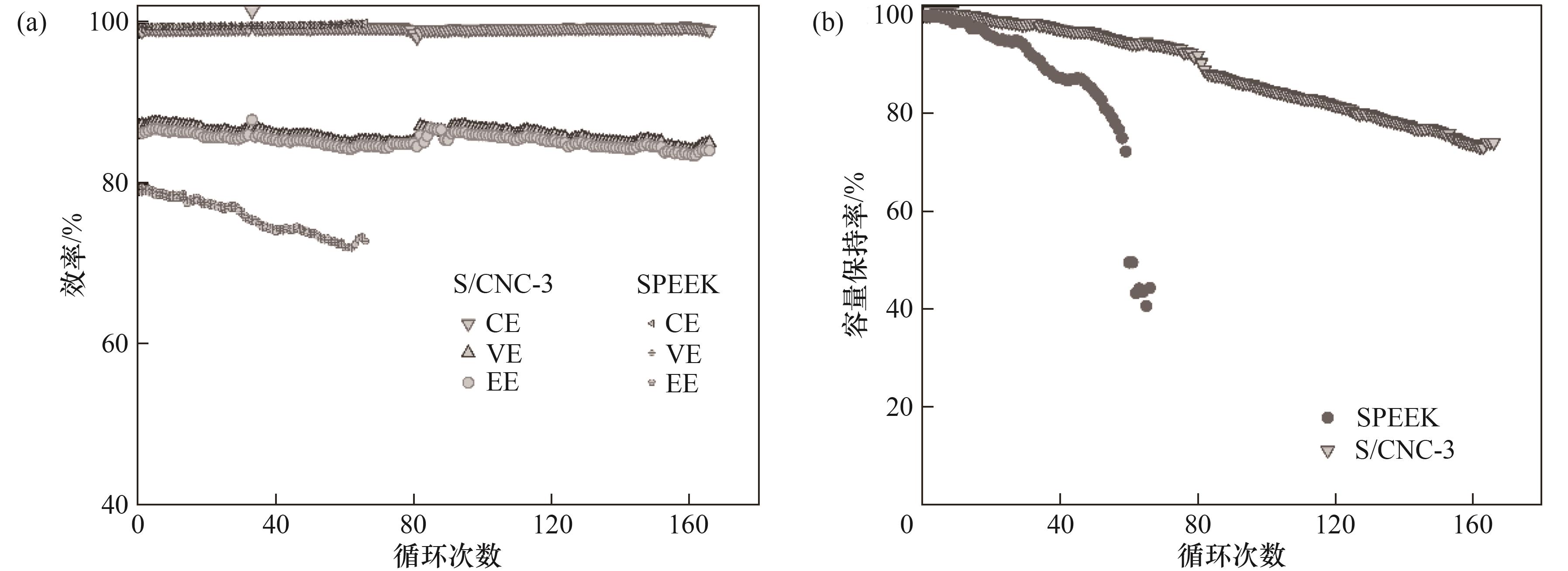

图12 SPEEK膜与S/CNC-3膜在120 mA·cm-2下的循环稳定性: (a) 120 mA·cm-2下的长循环稳定性;(b) 放电容量保持率

Fig.12 Cycling stability of SPEEK membrane along with S/CNC-3 membrane at 120 mA·cm-2: (a) cycling stability at 120 mA·cm-2; (b) discharge capacity retention

| 1 | Hunter C A, Penev M M, Reznicek E P, et al. Techno-economic analysis of long-duration energy storage and flexible power generation technologies to support high-variable renewable energy grids[J]. Joule, 2021, 5(8): 2077-2101. |

| 2 | Shan R, Reagan J, Castellanos S, et al. Evaluating emerging long-duration energy storage technologies[J]. Renewable and Sustainable Energy Reviews, 2022, 159: 112240. |

| 3 | Ouyang T C, Zhang M L, Qin P J, et al. Flow battery energy storage system for microgrid peak shaving based on predictive control algorithm[J]. Applied Energy, 2024, 356: 122448. |

| 4 | Kim J Q, So S, Kim H T, et al. Highly ordered ultrathin perfluorinated sulfonic acid ionomer membranes for vanadium redox flow battery[J]. ACS Energy Letters, 2021, 6(1): 184-192. |

| 5 | Kim D K, Yoon S J, Lee J, et al. Parametric study and flow rate optimization of all-vanadium redox flow batteries[J]. Applied Energy, 2018, 228: 891-901. |

| 6 | Zhang D Z, Huang K, Xia Y S, et al. Two-dimensional MFI-type zeolite flow battery membranes[J]. Angewandte Chemie International Edition, 2023, 62(43): e202310945. |

| 7 | Wu Y L, Wang Y X, Zhang D Z, et al. Crystallizing self-standing covalent organic framework membranes for ultrafast proton transport in flow batteries[J]. Angewandte Chemie International Edition, 2023, 62(50): e202313571. |

| 8 | 杜若晗, 逄博, 王宁, 等. 连续共价有机框架筛分复合膜及全钒电池性能[J]. 化工学报, 2022, 73(9): 4163-4172. |

| Du R H, Pang B, Wang N, et al. Continuous covalent organic framework composite membrane with size-sieving effect for vanadium flow battery[J]. CIESC Journal, 2022, 73(9): 4163-4172. | |

| 9 | Khataee A, Nederstedt H, Jannasch P, et al. Poly(arylene alkylene)s functionalized with perfluorosulfonic acid groups as proton exchange membranes for vanadium redox flow batteries[J]. Journal of Membrane Science, 2023, 671: 121390. |

| 10 | Dos Santos F B, McMichael P S, Whitbeck A, et al. Proton exchange membranes from sulfonated lignin nanocomposites for redox flow battery applications[J]. Small, 2024, 20(24): e2309459. |

| 11 | Wang R J, Yang L P, Li J, et al. High rate lithium slurry flow batteries enabled by an ionic exchange Nafion composite membrane incorporated with LLZTO fillers[J]. Nano Energy, 2023, 108: 108174. |

| 12 | Yang X B, Zhao L, Goh K, et al. A phosphotungstic acid coupled silica-Nafion composite membrane with significantly enhanced ion selectivity for vanadium redox flow battery[J]. Journal of Energy Chemistry, 2020, 41: 177-184. |

| 13 | Zhang D H, Yu W J, Zhang Y, et al. Reconstructing proton channels via Zr-MOFs realizes highly ion-selective and proton-conductive SPEEK-based hybrid membrane for vanadium flow battery[J]. Journal of Energy Chemistry, 2022, 75: 448-456. |

| 14 | Zhu H L. SPEEK scaling UP[J]. Joule, 2022, 6(4): 718-720. |

| 15 | Qiao L, Zhang H M, Lu W J, et al. Advanced porous membranes with slit-like selective layer for flow battery[J]. Nano Energy, 2018, 54: 73-81. |

| 16 | Lau W J, Ismail A F. Theoretical studies on the morphological and electrical properties of blended PES/SPEEK nanofiltration membranes using different sulfonation degree of SPEEK[J]. Journal of Membrane Science, 2009, 334(1/2): 30-42. |

| 17 | Chang N N, Yin Y B, Yue M, et al. A cost-effective mixed matrix polyethylene porous membrane for long-cycle high power density alkaline zinc-based flow batteries[J]. Advanced Functional Materials, 2019, 29(29): 1901674. |

| 18 | Wang Z G, Wang D, Zhang S X, et al. Interfacial design of mixed matrix membranes for improved gas separation performance[J]. Advanced Materials, 2016, 28(17): 3399-3405. |

| 19 | Zhang B, Dai X Y, Wei N N, et al. Fabrication of oriented MOF-based mixed matrix membrane via ion-induced synchronous synthesis[J]. Small, 2024, 20(11): e2305688. |

| 20 | Kim J, Fu Q, Xie K, et al. CO2 separation using surface-functionalized SiO2 nanoparticles incorporated ultra-thin film composite mixed matrix membranes for post-combustion carbon capture[J]. Journal of Membrane Science, 2016, 515: 54-62. |

| 21 | Ye J Y, Zhao X L, Ma Y L, et al. Hybrid membranes dispersed with superhydrophilic TiO2 nanotubes toward ultra-stable and high-performance vanadium redox flow batteries[J]. Advanced Energy Materials, 2020, 10(22): 1904041. |

| 22 | Pang R Z, Li X, Li J S, et al. Preparation and characterization of ZrO2/PES hybrid ultrafiltration membrane with uniform ZrO2 nanoparticles[J]. Desalination, 2014, 332(1): 60-66. |

| 23 | Yang Z Q, Wu Z J, Peh S B, et al. Mixed-matrix membranes containing porous materials for gas separation: from metal-organic frameworks to discrete molecular cages[J]. Engineering, 2023, 23: 40-55. |

| 24 | Li C, Jiang Y N, Wu Z H, et al. Mixed matrix membrane with penetrating subnanochannels: a versatile nanofluidic platform for selective metal ion conduction[J]. Angewandte Chemie International Edition, 2023, 62(2): e202215906. |

| 25 | Xie K, Fu Q, Webley P A, et al. MOF scaffold for a high-performance mixed-matrix membrane[J]. Angewandte Chemie International Edition, 2018, 57(28): 8597-8602. |

| 26 | Zhang Y H, Ma L, Lv Y Q, et al. Facile manufacture of COF-based mixed matrix membranes for efficient CO2 separation[J]. Chemical Engineering Journal, 2022, 430: 133001. |

| 27 | Qi A H, Li C E, Evans J D, et al. Self-sorting of interfacial compatibility in MOF-based mixed matrix membranes[J]. Angewandte Chemie International Edition, 2024, 63(24): e202400474. |

| 28 | Qian Q H, Wu A X, Chi W S, et al. Mixed-matrix membranes formed from imide-functionalized UiO-66-NH2 for improved interfacial compatibility[J]. ACS Applied Materials & Interfaces, 2019, 11(34): 31257-31269. |

| 29 | Wang Z H, Chen Z, Zheng Z D, et al. Nanocellulose-based membranes for highly efficient molecular separation[J]. Chemical Engineering Journal, 2023, 451: 138711. |

| 30 | Wang S, Li T, Chen C J, et al. Transparent, anisotropic biofilm with aligned bacterial cellulose nanofibers[J]. Advanced Functional Materials, 2018, 28(24): 1707491. |

| 31 | Melikoğlu A Y, Bilek S E, Cesur S. Optimum alkaline treatment parameters for the extraction of cellulose and production of cellulose nanocrystals from apple pomace[J]. Carbohydrate Polymers, 2019, 215: 330-337. |

| 32 | 王雨西, 高焕秋, 代笛菲, 等. 不同硫酸浓度水解制备纤维素纳米晶及其稳定Pickering乳液研究[J]. 食品与发酵工业, 2024, 50(9): 132-138. |

| Wang Y X, Gao H Q, Dai D F, et al. Preparation of cellulose nanocrystals by hydrolysis with different sulfuric acid concentrations and their stabilized Pickering emulsions[J]. Food and Fermentation Industries, 2024, 50(9): 132-138. | |

| 33 | Mukhopadhyay A, Cheng Z, Natan A, et al. Stable and highly ion-selective membrane made from cellulose nanocrystals for aqueous redox flow batteries[J]. Nano Letters, 2019, 19(12): 8979-8989. |

| 34 | Gu J, Catchmark J M, Kaiser E Q, et al. Quantification of cellulose nanowhiskers sulfate e sterification levels[J]. Carbohydrate Polymers, 2013, 92(2): 1809-1816. |

| 35 | Beh E S, De Porcellinis D, Gracia R L, et al. A neutral pH aqueous organic-organometallic redox flow battery with extremely high capacity retention[J]. ACS Energy Letters, 2017, 2(3): 639-644. |

| [1] | 顾栋, 皮行健, 张叠, 张瑛. 不同粒径CAU-1/PI混合基质膜的构建与H2/CO2分离性能研究[J]. 化工学报, 2025, 76(5): 2410-2418. |

| [2] | 丁相斐, 丘晓琳, 朱喜成, 张佳伟, 陈锦华. pH响应性气体渗透CNC/PBAT复合膜的制备与性能[J]. 化工学报, 2024, 75(3): 1040-1051. |

| [3] | 胡超, 董玉明, 张伟, 张红玲, 周鹏, 徐红彬. 浓硫酸活化五氧化二钒制备高浓度全钒液流电池正极电解液[J]. 化工学报, 2023, 74(S1): 338-345. |

| [4] | 裴仁花, 王永洪, 张新儒, 李晋平. 碳纳米管/环糊精金属有机骨架协同强化混合基质膜的CO2分离[J]. 化工学报, 2022, 73(9): 3904-3914. |

| [5] | 杜若晗, 逄博, 王宁, 崔福军, 郭明钢, 贺高红, 吴雪梅. 连续共价有机框架筛分复合膜及全钒电池性能[J]. 化工学报, 2022, 73(9): 4163-4172. |

| [6] | 于喆淼, 王志, 生梦龙, 邢广宇, 王纪孝. 界面聚合法制备用于脱氮提纯CH4的N2优先渗透ZIF-90/聚酰胺混合基质膜[J]. 化工学报, 2022, 73(7): 3273-3286. |

| [7] | 王立维, 王娟娟, 王永洪, 张新儒, 李晋平. 聚乙烯胺/Cu3(BTC)2-MMT-NH2混合基质膜的制备及气体传递性能[J]. 化工学报, 2022, 73(7): 3068-3077. |

| [8] | 毛恒, 王月, 王森, 刘伟民, 吕静, 陈甫雪, 赵之平. APTES改性ZIF-L/PEBA混合基质膜强化渗透汽化分离苯酚研究[J]. 化工学报, 2022, 73(3): 1389-1402. |

| [9] | 靳卓, 王永洪, 张新儒, 白雪, 李晋平. Pebax/a-MoS2/MIP-202混合基质膜的制备及CO2分离性能[J]. 化工学报, 2022, 73(10): 4527-4538. |

| [10] | 王艳芳,毛恒,蔡玮玮,张傲率,徐李昊,赵之平. ZIF-L/PDMS混合基质膜蒸气渗透耦合发酵强化乙醇生产效率的研究[J]. 化工学报, 2021, 72(10): 5226-5236. |

| [11] | 周毅,王永洪,张新儒,李晋平. PEBA/氮硫共掺杂多孔碳球混合基质膜的制备及CO2分离性能研究[J]. 化工学报, 2021, 72(10): 5237-5246. |

| [12] | 王维, 姜雪迎, 李悦, 苏丽萍, 邹昀, 童张法. 亲水型ZSM-5分子筛填充PVA膜及分离乙酸乙酯/水的应用[J]. 化工学报, 2020, 71(8): 3807-3818. |

| [13] | 朱乐, 齐亮, 姚克俭, 谢晓峰. 磁电复合场下正极钒离子的跨膜传质[J]. 化工学报, 2016, 67(S1): 148-158. |

| [14] | 李晨飞, 王树博, 谢晓峰, 张建文. 全钒液流电池石墨毡电极的Ga2O3修饰[J]. CIESC Journal, 2015, 66(S1): 277-281. |

| [15] | 张友, 王树博, 齐亮, 姚克俭. 协同场作用下钒离子在质子交换膜中的传质过程[J]. 化工学报, 2015, 66(S1): 81-88. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号