化工学报 ›› 2025, Vol. 76 ›› Issue (7): 3626-3638.DOI: 10.11949/0438-1157.20241418

收稿日期:2024-12-06

修回日期:2025-02-14

出版日期:2025-07-25

发布日期:2025-08-13

通讯作者:

孙金菊

作者简介:龚宇(1996—),男,硕士研究生,助理工程师,gy.gongyu@qq.com

Yu GONG1( ), Shengli WANG2, Jinju SUN3(

), Shengli WANG2, Jinju SUN3( ), Kuo HAI1, Wen HUANG1

), Kuo HAI1, Wen HUANG1

Received:2024-12-06

Revised:2025-02-14

Online:2025-07-25

Published:2025-08-13

Contact:

Jinju SUN

摘要:

微型多级压缩机充气系统的体积小、质量轻、输出压力高,可广泛应用于各种场景。以往的研究多集中于单级压缩机或单气瓶的数值模型,本研究基于热力学、流体力学、传热学、材料力学及压缩机原理等多学科理论,构建了涵盖“气缸-级间流道-储气瓶”的多级往复式压缩机充气系统热力学模型。该模型可用于预测和分析压缩机的全动态工作过程以及系统充瓶时间。模拟了多级压缩机充气系统的瞬态加压加注过程,模型能够准确反映气缸、气阀、流道和储气瓶的动态工作特性。深入分析了影响系统充气时间的关键因素,结果表明,缸内换热和中间冷却对充瓶时间的影响较小,但对压缩机效率有显著影响;压缩机进气参数对充瓶时间有明显影响,其中进气压力的影响较为显著;泄漏对充瓶时间和压缩机效率均有显著影响。

中图分类号:

龚宇, 王胜利, 孙金菊, 海阔, 黄文. 微型多级压缩机充气系统的热力学模型及规律探究[J]. 化工学报, 2025, 76(7): 3626-3638.

Yu GONG, Shengli WANG, Jinju SUN, Kuo HAI, Wen HUANG. Thermodynamic model and exploration of micro multi-stage compressor inflation system[J]. CIESC Journal, 2025, 76(7): 3626-3638.

| 级数 | 缸径/mm | 活塞行程/mm | 吸气阀喉部直径/mm | 排气阀喉部直径/mm | 压力范围/MPa |

|---|---|---|---|---|---|

| 1级 | 50 | 15 | 7 | 6.5 | 0.07~0.90 |

| 2级 | 20 | 15 | 6 | 5.5 | 0.6~5.5 |

| 3级 | 7.5 | 15 | 4 | 3 | 5.0~40.0 |

表1 多级压缩机的设计参数

Table 1 Design parameters of multi-stage compressor

| 级数 | 缸径/mm | 活塞行程/mm | 吸气阀喉部直径/mm | 排气阀喉部直径/mm | 压力范围/MPa |

|---|---|---|---|---|---|

| 1级 | 50 | 15 | 7 | 6.5 | 0.07~0.90 |

| 2级 | 20 | 15 | 6 | 5.5 | 0.6~5.5 |

| 3级 | 7.5 | 15 | 4 | 3 | 5.0~40.0 |

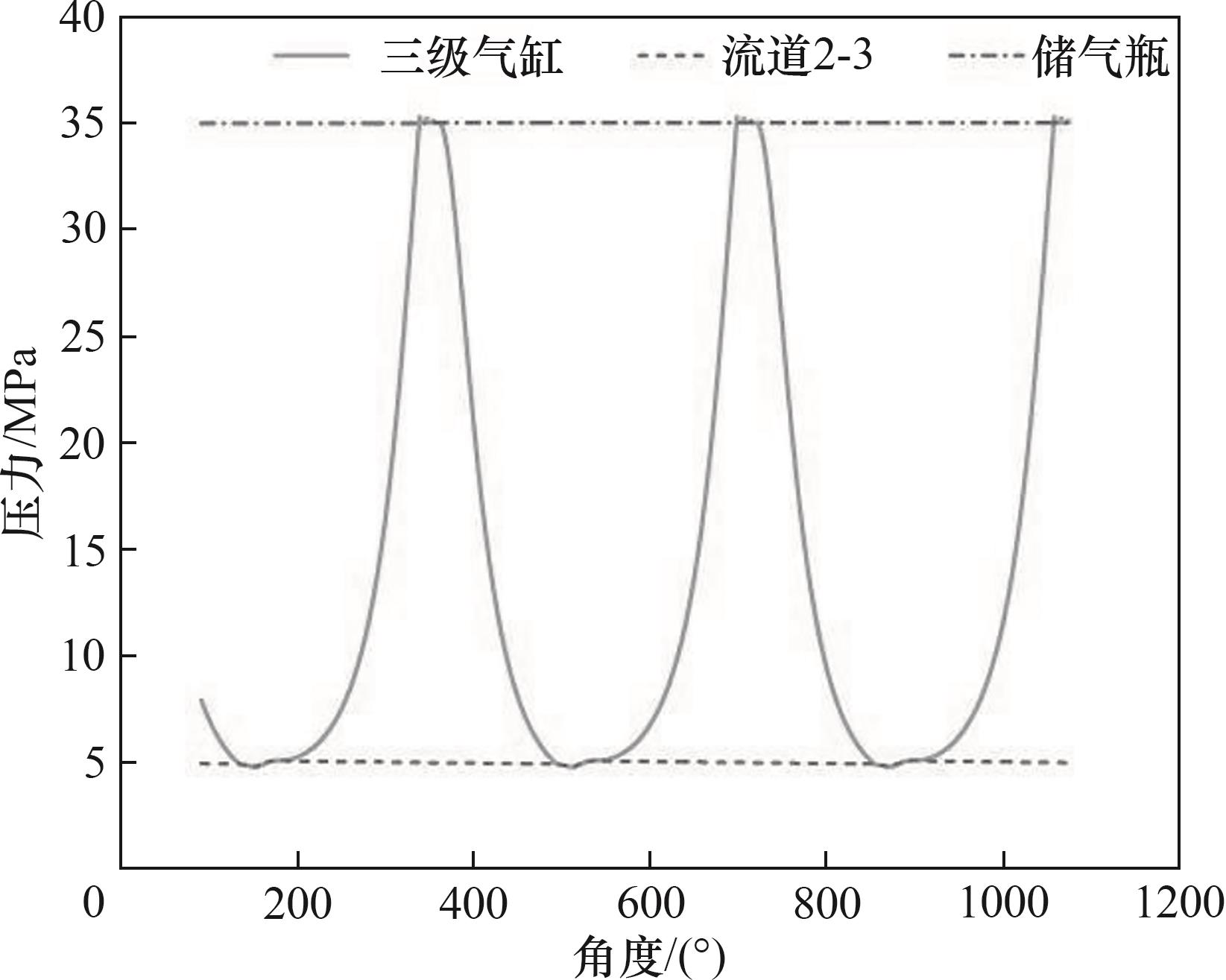

图5 300 ml储气瓶充气过程最后几个循环中第三级气缸的压力变化

Fig.5 The pressure change of the third stage cylinder during the last few cycles of the 300 ml gas cylinder inflation process

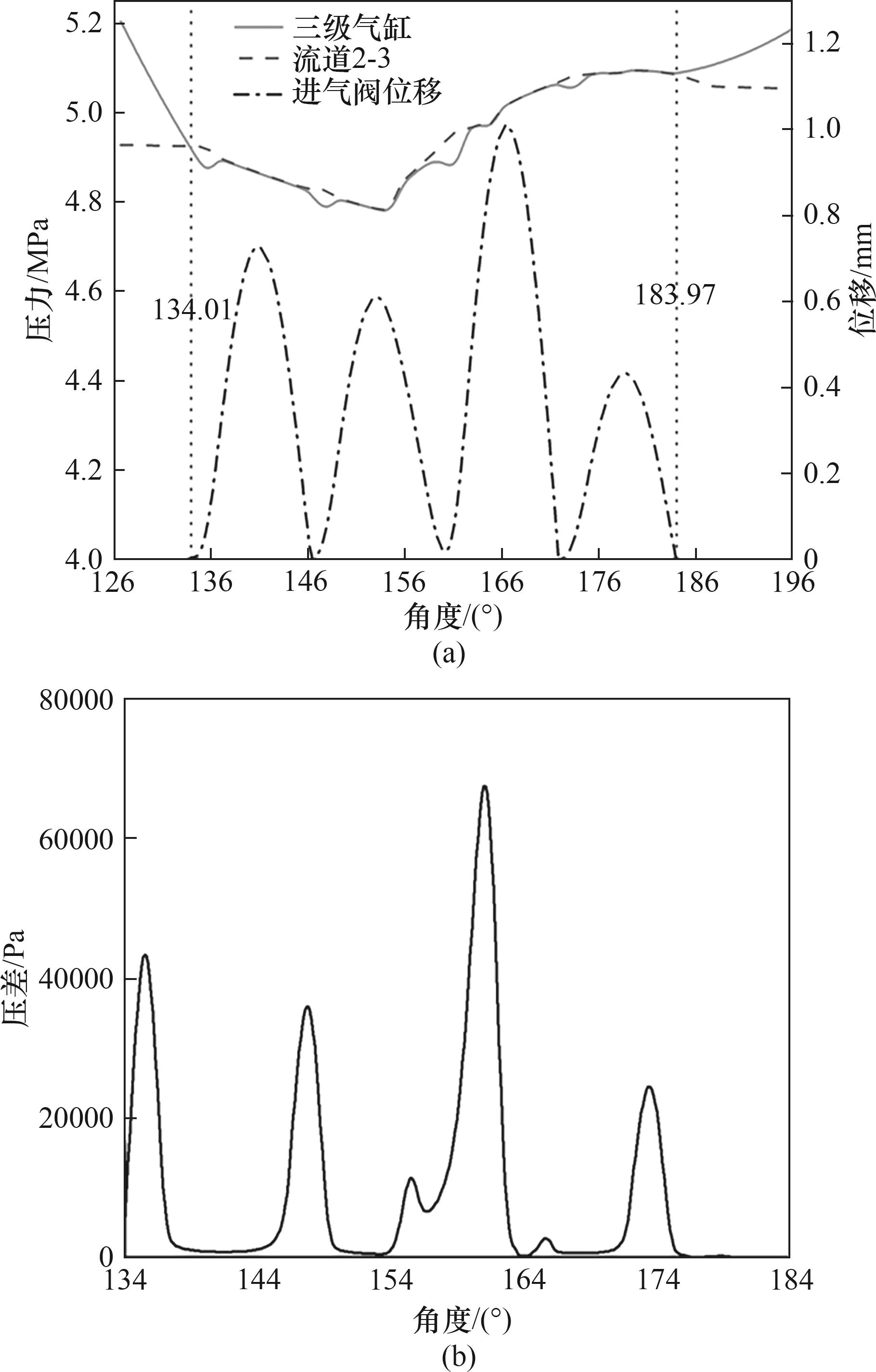

图6 第三级气缸吸气过程中的(a)压力、进气阀位移和(b)流道2-3与三级气缸间的压力差

Fig.6 (a) Pressure, intake valve displacement, and (b) pressure difference between passage 2-3 and the third stage cylinder during the intake process of the third stage cylinder

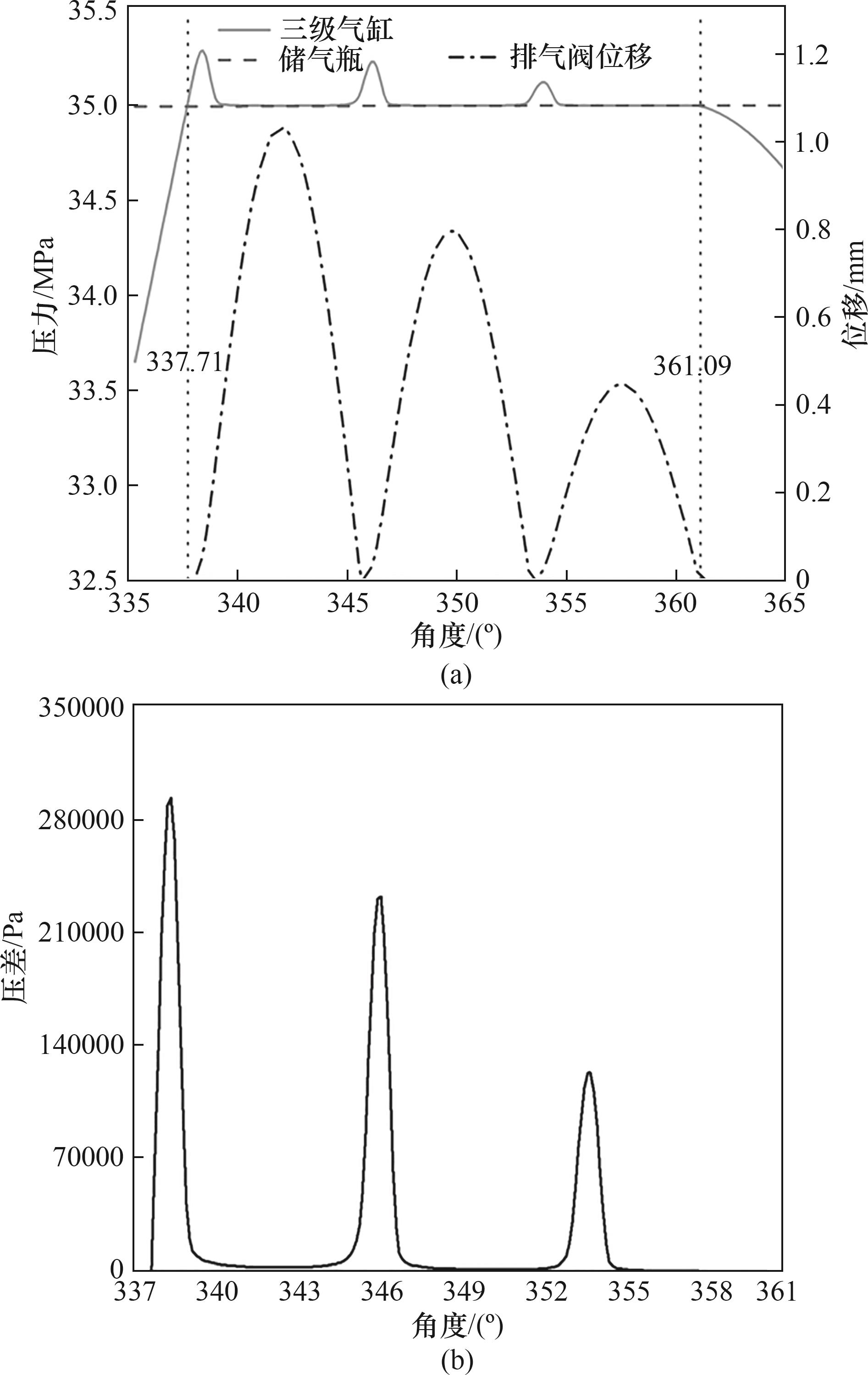

图7 第三级气缸排气过程中的(a)压力、排气阀位移和(b)三级气缸与储气瓶间的压力差

Fig.7 (a) Pressure and displacement of exhaust valve, and (b) pressure difference between the third stage cylinder and the gas cylinder during the exhaust process of the third stage cylinder

| 转速/(r/min) | 充瓶时间/s | 流道1-2温度/K | 流道2-3温度/K | 储气瓶温度/K |

|---|---|---|---|---|

| 600 | 545.415 | 511.628 | 618.321 | 713.149 |

| 900 | 364.613 | 513.807 | 621.865 | 727.377 |

| 1200 | 278.759 | 515.120 | 625.840 | 737.866 |

| 1500 | 224.446 | 517.563 | 626.892 | 745.643 |

表2 没有级间冷却时的计算结果

Table 2 Results without inter stage cooling

| 转速/(r/min) | 充瓶时间/s | 流道1-2温度/K | 流道2-3温度/K | 储气瓶温度/K |

|---|---|---|---|---|

| 600 | 545.415 | 511.628 | 618.321 | 713.149 |

| 900 | 364.613 | 513.807 | 621.865 | 727.377 |

| 1200 | 278.759 | 515.120 | 625.840 | 737.866 |

| 1500 | 224.446 | 517.563 | 626.892 | 745.643 |

| [1] | Deng Y P, Liu Y S, Li F, et al. Research on sealing performance in high pressure oil-free miniature air compressor[C]//Asme/bath Symposium on Fluid Power & Motion Control. Sarasota, Florida, USA, 2017: V001T01A023. |

| [2] | Luo Y X, Wang X Y. Exergy analysis on throttle reduction efficiency based on real gas equations[J]. Energy, 2010, 35(1): 181-187. |

| [3] | 郁永章. 往复活塞压缩机[M]. 西安: 西安交通大学出版社, 2009. |

| Yu Y Z. Reciprocating Piston Compressor[M]. Xi'an: Xi'an Jiaotong University Press, 2009. | |

| [4] | 周依霖, 游歩东, 柯尊荣, 等. 新型多级回转式空气压缩机的研究[J]. 液压与气动, 2014, 38(9): 100-103. |

| Zhou Y L, You B D, Ke Z R, et al. A new multistage rotary air compressor[J]. Chinese Hydraulics & Pneumatics, 2014, 38(9): 100-103. | |

| [5] | Deng Y P, Miao N, Wu D F, et al. A new high-pressure clearance seal with flexible laddered piston assembly in oil-free miniature compressor for potential hydrogen applications and investigation on its dynamic sealing efficiency[J]. International Journal of Hydrogen Energy, 2019, 44(45): 24856-24866. |

| [6] | Saadat-Targhi M, Khadem J, Farzaneh-Gord M. Thermodynamic analysis of a CNG refueling station considering the reciprocating compressor[J]. Journal of Natural Gas Science and Engineering, 2016, 29: 453-461. |

| [7] | Tuhovcak J, Hejcik J, Jicha M. Comparison of heat transfer models for reciprocating compressor[J]. Applied Thermal Engineering, 2016, 103: 607-615. |

| [8] | Heidari M, Mortazavi M, Rufer A. Design, modeling and experimental validation of a novel finned reciprocating compressor for isothermal compressed air energy storage applications[J]. Energy, 2017, 140: 1252-1266. |

| [9] | Lohn S K, Pereira E L L. Numerical investigation of the gas leakage through the piston-cylinder clearance of reciprocating compressors[C]// 22nd International Compressor Engineering Conference. Purdue, 2014: 2295. |

| [10] | Sun S Y, Ren T R. New method of thermodynamic computation for a reciprocating compressor: computer simulation of working process[J]. International Journal of Mechanical Sciences, 1995, 37(4): 343-353. |

| [11] | Manepatil S, Tiwari A. Fault diagnosis of reciprocating compressor using pressure pulsations[C]// International Compressor Engineering Conference. West Lafayette, Indiana, USA, 2006: 1819. |

| [12] | Ma Y, Gan Y N, Peng X Y, et al. Modeling of a reciprocating compressor for transcriticla CO2 heat pumps[C]//The 22nd International Congress of Refrigeration. Beijing, China, 2007: IC R07-E2-814. |

| [13] | Farzaneh-Gord M, Jannatabadi M. Simulation of single acting natural gas reciprocating expansion engine based on ideal gas model[J]. Journal of Natural Gas Science and Engineering, 2014, 21: 669-679. |

| [14] | Farzaneh-Gord M, Niazmand A, Deymi-Dashtebayaz M, et al. Thermodynamic analysis of natural gas reciprocating compressors based on real and ideal gas models[J]. International Journal of Refrigeration, 2015, 56: 186-197. |

| [15] | Liang K, Stone R, Davies G, et al. Modelling and measurement of a moving magnet linear compressor performance[J]. Energy, 2014, 66: 487-495. |

| [16] | Farzaneh-Gord M, Niazmand A, Deymi-Dashtebayaz M, et al. Effects of natural gas compositions on CNG (compressed natural gas) reciprocating compressors performance[J]. Energy, 2015, 90: 1152-1162. |

| [17] | Roskosch D, Venzik V, Atakan B. Thermodynamic model for reciprocating compressors with the focus on fluid dependent efficiencies[J]. International Journal of Refrigeration, 2017, 84: 104-116. |

| [18] | Liang K. Analysis of oil-free linear compressor operated at high pressure ratios for household refrigeration[J]. Energy, 2018, 151: 324-331. |

| [19] | Woschni G. A universally applicable equation for the instantaneous heat transfer coefficient in the internal combustion engine[C]//SAE Technical Paper Series. SAE International, 1967: 670931. |

| [20] | Annand W J D, Ma T H. Second paper: instantaneous heat transfer rates to the cylinder head surface of a small compression-ignition engine[J]. Proceedings of the Institution of Mechanical Engineers, 1970, 185(1): 976-987. |

| [21] | Adair R, Qvale E, Pearson J T. Instantaneous heat transfer to the cylinder wall in reciprocating compressors[C]// International Compressor Engineering Conference. West Lafayette, Indiana, USA, 1972: 86. |

| [22] | Disconzi F P, Deschamps C J, Pereira E L. Development of an in-cylinder heat transfer correlation for reciprocating compressors[C]//International Compressor Engineering Conference. West Lafayette, Indiana, USA, 2012: 2103. |

| [23] | Ferreira R, Lilie D E B. Evaluation of the leakage through the clearance between piston and cylinder in hermetic compressors[C]//International Compressor Engineering Conference. West Lafayette, Indiana, USA, 1984: 424. |

| [24] | Zuk J, Smith P J. Computer Program for Viscous, Isothermal Compressible Flow Across a Sealing Dam with Small Tilt Angle[M]. Washington, D.C.: National Aeronautics and Space Administration, 1969: 4-9. |

| [25] | Braga V M, Deschamps C J. Numerical analysis of gas leakage in the piston-cylinder clearance of reciprocating compressors considering compressibility effects[J]. IOP Conference Series: Materials Science and Engineering, 2017, 232: 012006. |

| [26] | 慕光宇, 王枫, 米小珍. 压缩机舌簧排气阀运动模型对比及动态特性影响因素分析[J]. 西安交通大学学报, 2017, 51(9): 69-76. |

| Mu G Y, Wang F, Mi X Z. Comparison of motion models of reciprocating compressor discharge reed valve and analysis for factors affecting dynamic characteristics[J]. Journal of Xi'an Jiaotong University, 2017, 51(9): 69-76. | |

| [27] | 马晶晶, 孙金菊, 樊宏周, 等. 限制器型线对舌簧阀动态应力影响的数值研究[J]. 工程热物理学报, 2022, 43(6): 1528-1534. |

| Ma J J, Sun J J, Fan H Z, et al. Numerical investigation of reed-type valve dynamic stress with different lift limiter shapes[J]. Journal of Engineering Thermophysics, 2022, 43(6): 1528-1534. | |

| [28] | Elhaj M, Gu F, Ball A D, et al. Numerical simulation and experimental study of a two-stage reciprocating compressor for condition monitoring[J]. Mechanical Systems and Signal Processing, 2008, 22(2): 374-389. |

| [29] | Lee S J, Shim J, Kim K C. Development of capacity modulation compressor based on a two stage rotary compressor (part Ⅰ): Modeling and simulation of compressor performance[J]. International Journal of Refrigeration, 2015, 54: 22-37. |

| [30] | Deng Y P, Liu Y S, Miao N, et al. Analysis on clearance seals in miniature multistage swash plate compressor considering piston motion effects[C]//CSAA/IET International Conference on Aircraft Utility Systems. Guiyang, China: Institution of Engineering and Technology, 2018: 6. |

| [31] | Liu Y S, Miao N, Deng Y P, et al. Efficiency evaluation of a miniature multi-stage compressor under insufficient inter-stage cooling conditions[J]. International Journal of Refrigeration, 2019, 97: 169-179. |

| [32] | Kountz K. Modeling the fast fill process in natural gas vehicle storage cylinders[C]//Institute of Gas Technology. Chicago, USA, 1994. |

| [33] | Farzaneh-Gord M. Compressed natural gas—single reservoir filling process[J]. International Gas Engineering and Management, 2008, 48(6): 16-18. |

| [34] | Farzaneh-Gord M, Deymi-Dashtebayaz M, Rahbari H R, et al. Effects of storage types and conditions on compressed hydrogen fuelling stations performance[J]. International Journal of Hydrogen Energy, 2012, 37(4): 3500-3509. |

| [35] | 王增丽, 申迎峰, 王振波, 等. 舰船用星型压缩机并联充气过程的理论研究[J]. 流体机械, 2017, 45(5): 26-31. |

| Wang Z L, Shen Y F, Wang Z B, et al. Theoretical study of the parallel inflatable process for star type compressor used in ships and warships[J]. Fluid Machinery, 2017, 45(5): 26-31. | |

| [36] | Pérez-Segarra C D, Rigola J, Sòria M, et al. Detailed thermodynamic characterization of hermetic reciprocating compressors[J]. International Journal of Refrigeration, 2005, 28(4): 579-593. |

| [1] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [2] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [3] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [4] | 臧子晴, 李修真, 谈莹莹, 刘晓庆. 分凝器对两级分离自复叠制冷循环特性影响研究[J]. 化工学报, 2025, 76(S1): 17-25. |

| [5] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [6] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [7] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [8] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [9] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [10] | 李银龙, 刘国强, 晏刚. 分馏与闪蒸分离耦合自复叠制冷循环性能分析[J]. 化工学报, 2025, 76(S1): 26-35. |

| [11] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [12] | 孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296. |

| [13] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [14] | 朱腾飞, 刘晔. 低GWP制冷剂在新能源汽车空调应用性能分析[J]. 化工学报, 2025, 76(S1): 343-350. |

| [15] | 吴迪, 胡斌, 姜佳彤. R1233zd(E)高温热泵实验研究与应用分析[J]. 化工学报, 2025, 76(S1): 377-383. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号