化工学报 ›› 2025, Vol. 76 ›› Issue (6): 2886-2899.DOI: 10.11949/0438-1157.20241444

收稿日期:2024-12-13

修回日期:2025-01-15

出版日期:2025-06-25

发布日期:2025-07-09

通讯作者:

江锦波

作者简介:潘嘉阳(2000—),男,硕士研究生,211122020188@zjut.edu.cn

基金资助:

Jiayang PAN( ), Jinbo JIANG(

), Jinbo JIANG( ), Xudong PENG, Xiangkai MENG, Yi Ma

), Xudong PENG, Xiangkai MENG, Yi Ma

Received:2024-12-13

Revised:2025-01-15

Online:2025-06-25

Published:2025-07-09

Contact:

Jinbo JIANG

摘要:

随着石墨圆周密封向着低磨损、长寿命目标的发展,不同开槽结构动压型石墨圆周密封性能的高效、准确求解显得尤为重要。本文针对转子面开槽、静子面开槽和双面开槽三种开槽模式圆周密封结构,推导了适用于不同开槽模式圆周密封膜压分布求解的广义瞬态雷诺方程,基于动网格技术和有限体积法自主编程求解获得膜压分布和性能参数,并与商用软件模拟结果的求解精度和计算效率进行对比,在相同槽深条件下对比分析了三种开槽模式圆周密封的膜压分布和浮升力、泄漏率的时变特性,探讨了转速、入口压力和密封间隙等运行参数对三种开槽模式密封性能的影响规律。结果表明,相较于商用软件求解,相同面网格数下的圆周密封膜压分布自主编程计算结果吻合良好,但计算时间为5%~30%,计算效率显著提高;相较于单面开槽密封,双面开槽密封的时均浮升力和时均泄漏率均显著下降;因转子面与静子面螺旋槽相对位置变化,双面开槽密封的介质泄漏会出现反向回流和正向高泄漏周期波动的情况,弱化了密封封严特性和成膜特性。本文所提出基于广义瞬态雷诺方程的分层计算模型为不同开槽表面圆周密封的性能分析提供了新的方法。

中图分类号:

潘嘉阳, 江锦波, 彭旭东, 孟祥铠, 马艺. 双面开槽石墨圆周密封分层计算模型及开槽位置影响研究[J]. 化工学报, 2025, 76(6): 2886-2899.

Jiayang PAN, Jinbo JIANG, Xudong PENG, Xiangkai MENG, Yi Ma. Study on a layered computational model of double-sided graphite circumferential seal and the effect of grooved position[J]. CIESC Journal, 2025, 76(6): 2886-2899.

| 参数和单位 | 数值 | 参数和单位 | 数值 |

|---|---|---|---|

| 转子外径D /mm | 66 | 静子周向槽宽比θ2 /θ0 | 0.5 |

| 膜厚hm /μm | 3 | 转子螺旋角β1 /(°) | 45 |

| 槽深h /μm | 5 | 静子螺旋角β2 /(°) | 45 |

| 槽数 | 12 | 上游压力pin /MPa | 0.40 |

| 密封环轴向宽度l0 /mm | 10 | 下游压力pout /MPa | 0.10 |

| 轴向槽长比l1 /l0 | 0.6 | 转速n /(r/min) | 20000 |

| 密封环周期角度θ0 /(°) | 30 | 空气温度T /K | 300 |

| 转子周向槽宽比θ1 /θ0 | 0.5 | 空气黏度μ /(mPa·s) | 17.89 |

表1 石墨圆周密封性能分析计算初始参数

Table 1 Initial parameters for analysis of graphite circumferential seal performance

| 参数和单位 | 数值 | 参数和单位 | 数值 |

|---|---|---|---|

| 转子外径D /mm | 66 | 静子周向槽宽比θ2 /θ0 | 0.5 |

| 膜厚hm /μm | 3 | 转子螺旋角β1 /(°) | 45 |

| 槽深h /μm | 5 | 静子螺旋角β2 /(°) | 45 |

| 槽数 | 12 | 上游压力pin /MPa | 0.40 |

| 密封环轴向宽度l0 /mm | 10 | 下游压力pout /MPa | 0.10 |

| 轴向槽长比l1 /l0 | 0.6 | 转速n /(r/min) | 20000 |

| 密封环周期角度θ0 /(°) | 30 | 空气温度T /K | 300 |

| 转子周向槽宽比θ1 /θ0 | 0.5 | 空气黏度μ /(mPa·s) | 17.89 |

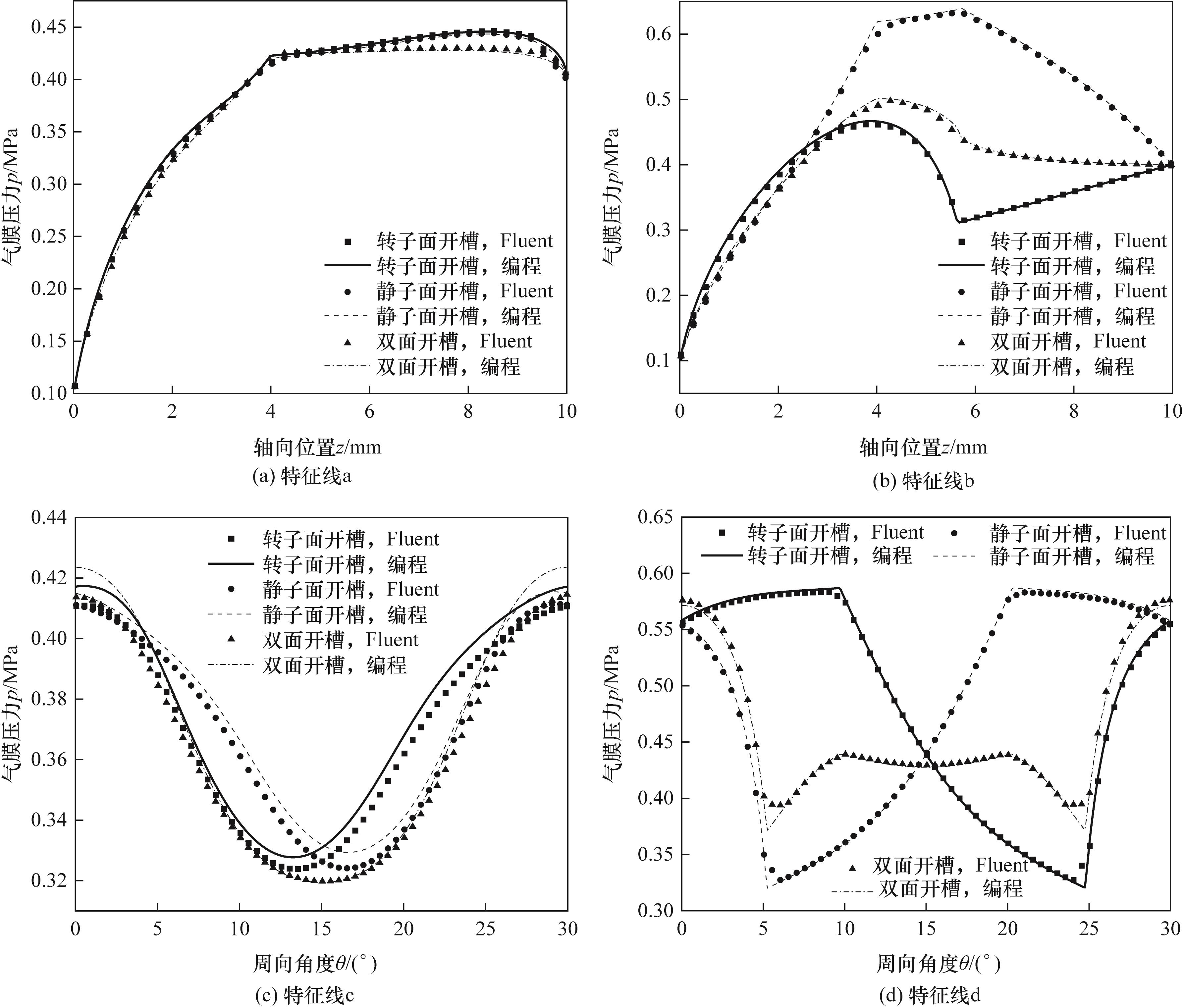

图7 不同开槽模式动压型圆周密封特征线膜压分布模拟值与计算值

Fig.7 Simulated and calculated values of characteristic line film pressure distribution of hydrodynamic circumferential seal in different slot modes

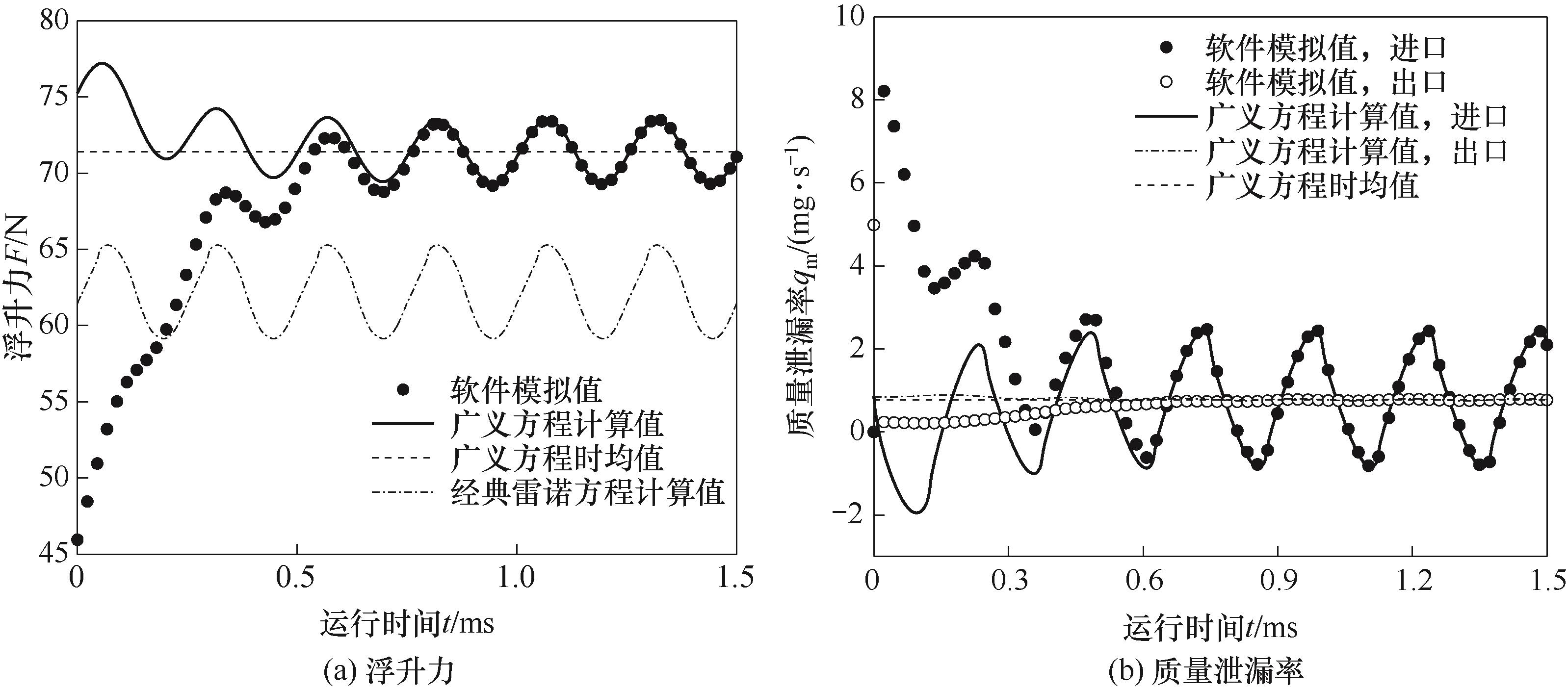

图8 双面开槽圆周密封浮升力与泄漏率时变曲线对比结果

Fig.8 Results of time-varying curve comparison between floating lift and leakage rate of a double-sided slotted circumferential seal

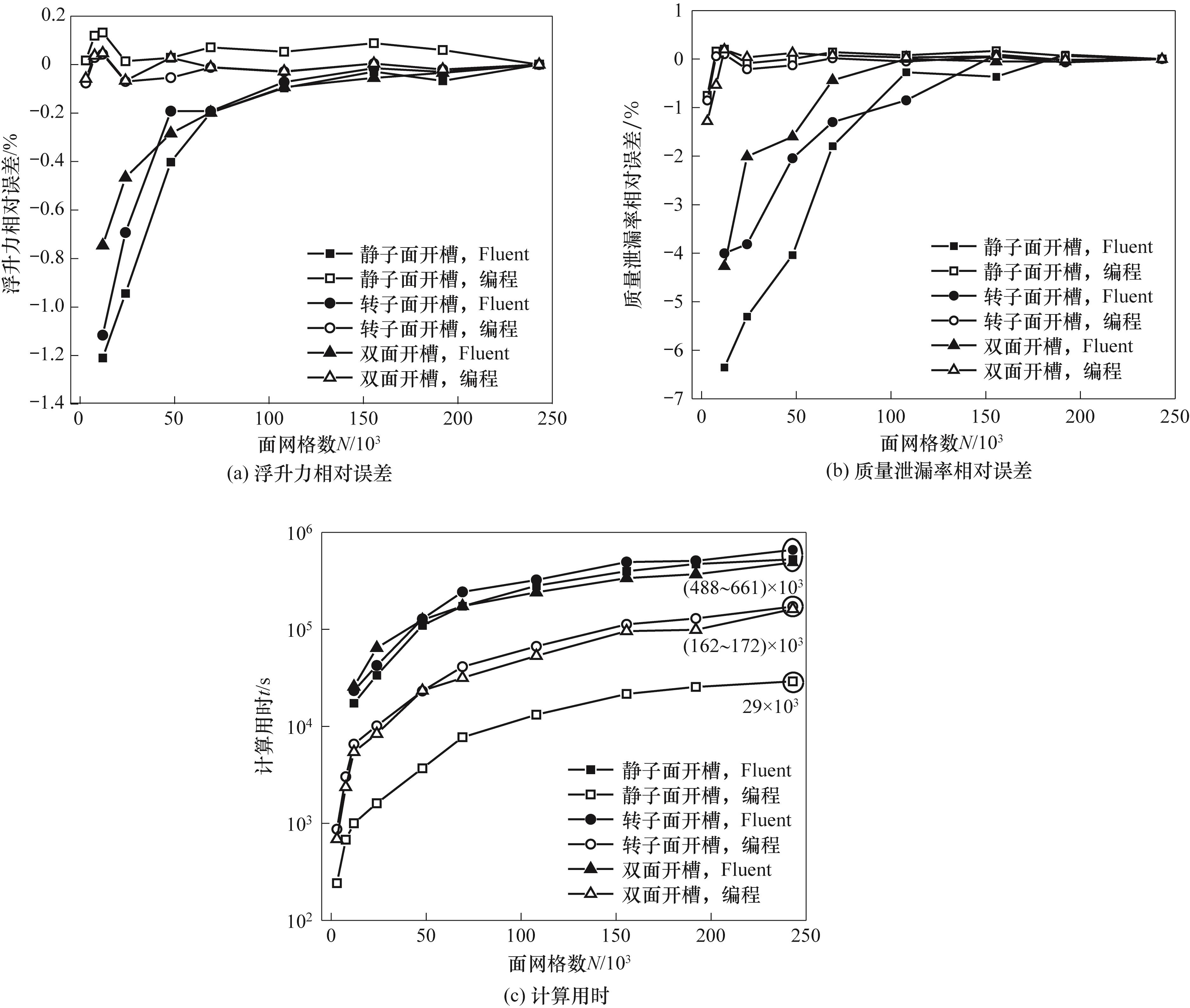

图9 不同面网格数下单面开槽和双面开槽圆周密封性能计算结果与计算时间

Fig.9 Calculation results and calculation time of single-side slotted and double-side slotted circular sealing performance under different face grid number

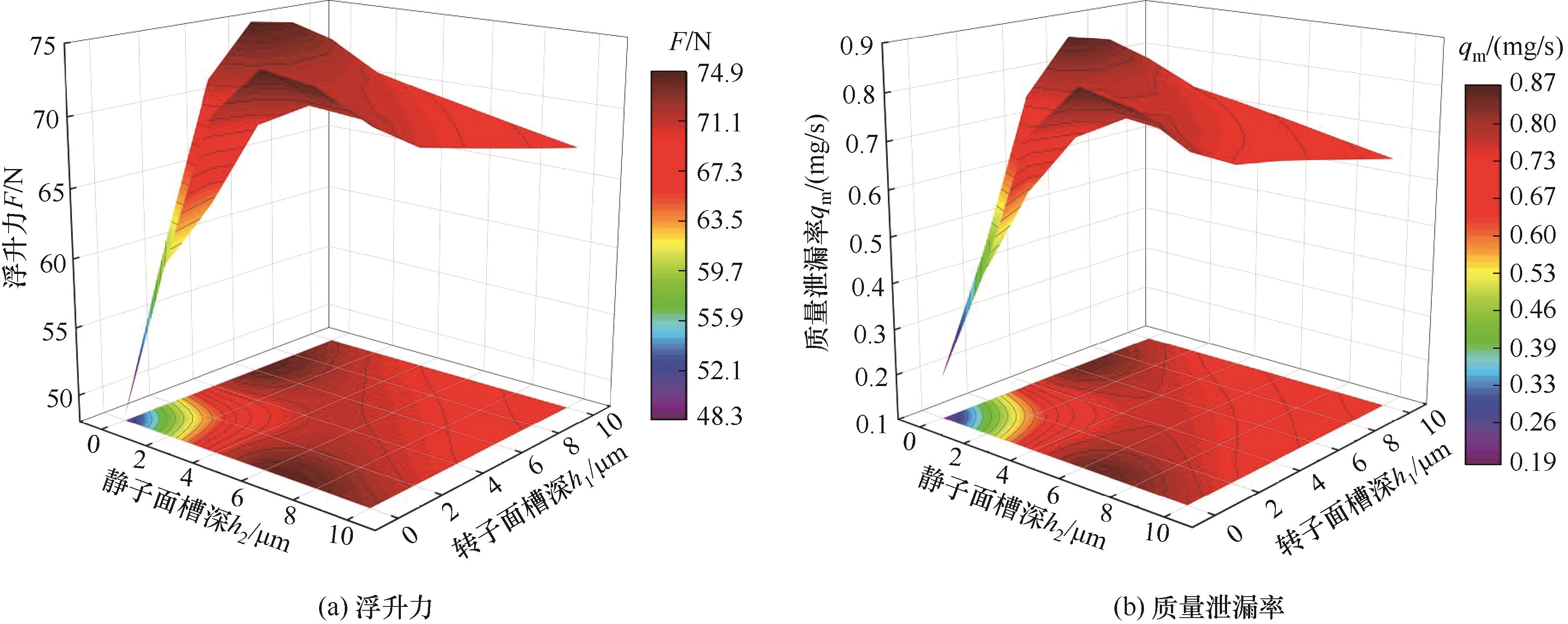

图12 不同转子面和静子面槽深条件下圆周密封的浮升力和泄漏率

Fig.12 Floating lift and leakage rate of the circular seal under different groove depths of rotor surface and stator surface

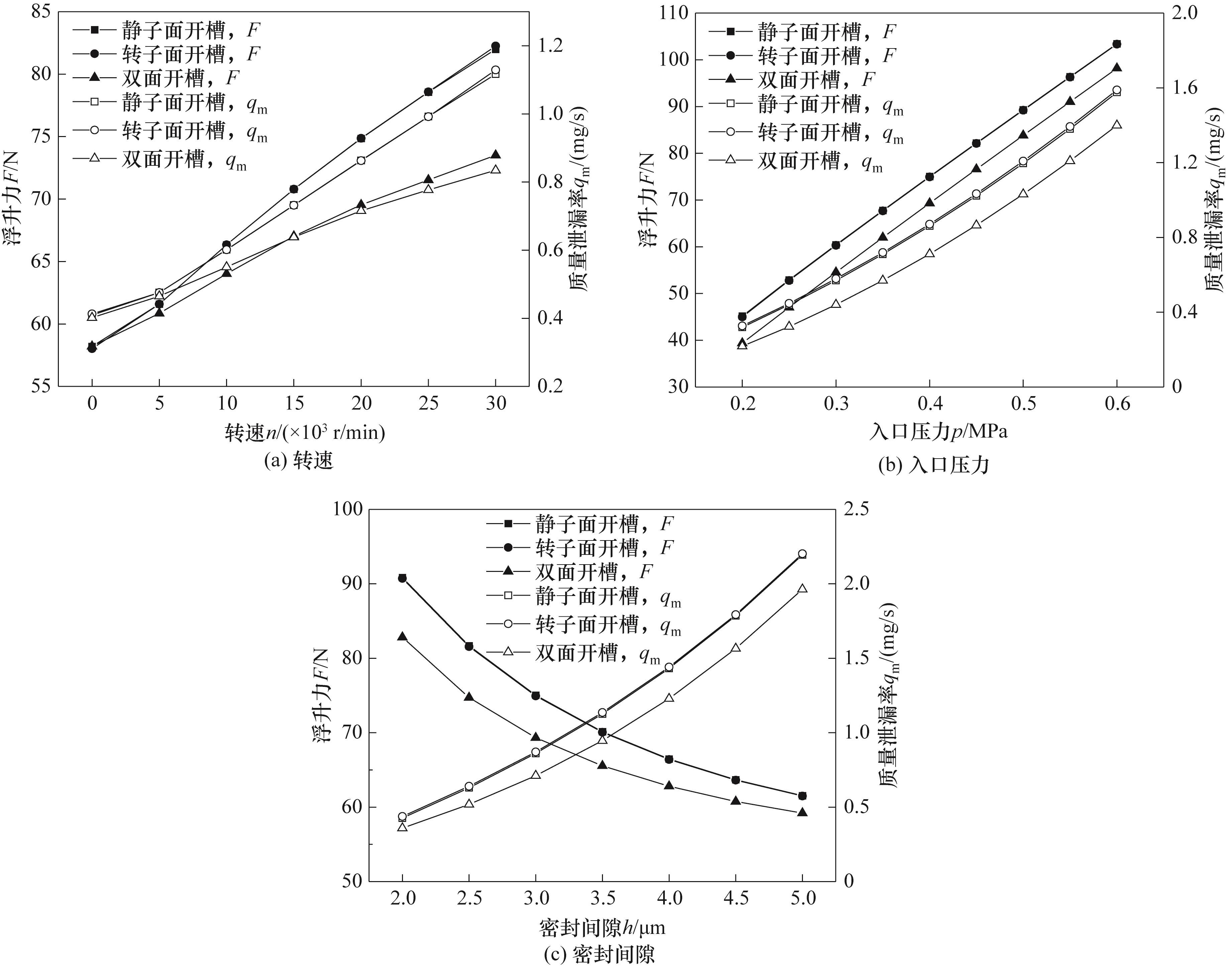

图13 工况参数对三种开槽模式圆周密封浮升力和泄漏率的影响

Fig.13 Influence of operating parameters on the floating lift and leakage rate of the circular seal with three grooving modes

| [1] | 李璐, 丁雪兴, 王蕊霞, 等. 力载荷下分瓣式碳环密封结构变形研究[J]. 润滑与密封, 2024, 49(6): 57-64. |

| Li L, Ding X X, Wang R X, et al. Research on deformation of split type carbon ring seal structure under force load[J]. Lubrication Engineering, 2024, 49(6): 57-64. | |

| [2] | 李璐. 新能源车用分瓣式碳环密封结构变形研究[D]. 兰州: 兰州理工大学, 2023. |

| Li L. Study on structural deformation of split carbon ring seal for new energy vehicles[D]. Lanzhou: Lanzhou University of Technology, 2023. | |

| [3] | Dahite S, Arghir M. Thermogasodynamic analysis of the segmented annular seal[J]. Journal of Tribology, 2021, 143(7): 072301. |

| [4] | Zheng X Q, la Pointe B, Sciutto S. Non-contacting carbon seal for high-temperature and large-diameter turbomachinery applications[J]. Advanced Materials Research, 2013, 744: 262-265. |

| [5] | 樊汝凤, 赵欢, 任国哲, 等. 转子微织构对圆周石墨密封滑油泄漏流动特性影响[J]. 航空动力学报, doi:10.13224/j.cnki.jasp.20240102 . |

| Fan R F, Zhao H, Ren G Z, et al. Influence of rotor micro-texture on leakage flow characteristic of lubricating oil in circumferential graphite seal[J]. Journal of Aerospace Power, doi:10.13224/j.cnki.jasp.20240102 . | |

| [6] | 陈滋新, 彭旭东, 赵文静, 等. 动压型分段式圆周密封变形特性及其调控策略研究[J]. 摩擦学学报, 2023, 43(2): 143-156. |

| Chen Z X, Peng X D, Zhao W J, et al. Deformation characteristics and control strategies of a dynamic segmented circumferential seal[J]. Tribology, 2023, 43(2): 143-156. | |

| [7] | 韩量宇, 赵欢, 常城, 等. 基于引气封油的轴承腔石墨密封系统滑油泄漏流动特性试验研究[J]. 航空学报, doi: 10.7527/S1000-6893.2024.31297 . |

| Han L Y, Zhao H, Chang C, et al. Numerical and experimental study on oil-air two-phase, eakage flow characteristics based on air-bleeding oil-sealing mode in seal clearance of bearing cavity[J]. Acta Aeronautica et Astronautica Sinica, doi: 10.7527/S1000-6893.2024.31297 . | |

| [8] | 谢仙赐, 赵欢, 王双, 等. 基于微分求积法的环瓣式浮环密封动压润滑特性理论研究[J]. 润滑与密封, 2024, 49(11): 35-40. |

| Xie X C, Zhao H, Wang S, et al. Theoretical study on hydrodynamic lubrication characteristics of segmented floating seal based on differential quadrature method[J]. Lubrication Engineering, 2024, 49(11): 35-40. | |

| [9] | Wang S, Sun D, Yang Z M, et al. Investigation of static and rotordynamic characteristics of the segmented annular seals based on the differential quadrature method[J]. Tribology International, 2024, 196: 109657. |

| [10] | Arghir M, Mariot A. Theoretical analysis of the static characteristics of the carbon segmented seal[J]. Journal of Tribology, 2017, 139(6): 062202. |

| [11] | Arghir M, Dahite S. Numerical analysis of lift generation in a radial segmented gas seal[C]//ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition. Phoenix, Arizona, USA, 2019. |

| [12] | Dahite S, Arghir M. Numerical modelling of a segmented annular seal with enhanced lift effects[J]. Mechanical Systems and Signal Processing, 2021, 152: 107455. |

| [13] | Jolly P, Arghir M, Kasahara H, et al. Experimental investigations on carbon segmented seals with smooth and pocketed pads[J]. Journal of Engineering for Gas Turbines and Power, 2025, 147(6): 061014. |

| [14] | Fourt E, Arghir M, Jolly P, et al. Experimental analysis of the leakage characteristics of three types of annular segmented seals[J]. Journal of Engineering for Gas Turbines and Power, 2023, 145(9): 091005. |

| [15] | Andasmas M, Gajan H, Amami L, et al. Impact of material on the sealing behaviour of radial segmented seals[J]. Tribology Online, 2024, 19(4): 287-297. |

| [16] | Li G Q, Zhang S, Kang Z, et al. Leakage and wear characteristics of carbon seals for aero-engines[J]. Chinese Journal of Aeronautics, 2022, 35(11): 389-400. |

| [17] | 周华宁, 李国庆, 王晨枫. 高线速度石墨密封多物理场耦合特性[J]. 润滑与密封, 2024, 49(3): 49-59. |

| Zhou H N, Li G Q, Wang C F. Multi physical field coupling characteristics of high speed graphite seals[J]. Lubrication Engineering, 2024, 49(3): 49-59. | |

| [18] | Dowson D. A generalized Reynolds equation for fluid-film lubrication[J]. International Journal of Mechanical Sciences, 1962, 4(2): 159-170. |

| [19] | Berthe D, Godet M. A more general form of Reynolds equation–Application to rough surfaces[J]. Wear, 1974, 27(3): 345-357. |

| [20] | Profito F J, Giacopini M, Zachariadis D C, et al. A general finite volume method for the solution of the Reynolds lubrication equation with a mass-conserving cavitation model[J]. Tribology Letters, 2015, 60(1): 18. |

| [21] | Profito F J, Zachariadis D C, Dini D. Partitioned fluid-structure interaction techniques applied to the mixed-elastohydrodynamic solution of dynamically loaded connecting-rod big-end bearings[J]. Tribology International, 2019, 140: 105767. |

| [22] | Ardah S, Profito F J, Reddyhoff T, et al. Advanced modelling of lubricated interfaces in general curvilinear grids[J]. Tribology International, 2023, 188: 108727. |

| [23] | Li Y, Ning Y Q, Zhang D S, et al. A model of hydrodynamic bearings with circumferential parallel arranged grooves[J]. Journal of Tribology, 2023, 145(10): 104102. |

| [24] | Lehn A, Schweizer B. Generalized Reynolds equation for fluid film problems with arbitrary boundary conditions: application to double-sided spiral groove thrust bearings[J]. Archive of Applied Mechanics, 2016, 86(4): 743-760. |

| [25] | Teng L M, Jiang J B, Peng X D, et al. Influence of surface grooving methods on steady and dynamic performance of spiral groove gas face seals[J]. Alexandria Engineering Journal, 2023, 64: 55-80. |

| [26] | Steijl R, Barakos G. Sliding mesh algorithm for CFD analysis of helicopter rotor–fuselage aerodynamics[J]. International Journal for Numerical Methods in Fluids, 2008, 58(5): 527-549. |

| [27] | 张凌新, 胡龙兵, 邵雪明. 滑移网格下泵内流场的非定常流计算[J]. 水动力学研究与进展(A辑), 2013, 28(1): 10-16. |

| Zhang L X, Hu L B, Shao X M. Computation of unsteady flow fields in a pump using sliding mesh method[J]. Chinese Journal of Hydrodynamics, 2013, 28(1): 10-16. | |

| [28] | Kang Y S, Sohn D, Kim J H, et al. A sliding mesh technique for the finite element simulation of fluid–solid interaction problems by using variable-node elements[J]. Computers & Structures, 2014, 130: 91-104. |

| [29] | 陈滋新. 氧涡轮泵氦气分段式圆周密封的变形特性研究[D]. 杭州: 浙江工业大学, 2022. |

| Chen Z X. Study on deformation characteristics of helium segmented circumferential seal of oxygen turbine pump[D]. Hangzhou: Zhejiang University of Technology, 2022. | |

| [30] | 江锦波, 彭新, 许文烜, 等. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| Jiang J B, Peng X, Xu W X, et al. Study on leakage characteristics and parameter influence of pump-out spiral groove oil-gas seal[J]. CIESC Journal, 2023, 74(6): 2538-2554. |

| [1] | 吴罗长, 杨泽宇, 颜建国, 朱旭涛, 陈阳, 王子辰. 微小方形通道内近超临界压力二氧化碳流动换热特性实验研究[J]. 化工学报, 2025, 76(4): 1583-1594. |

| [2] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [3] | 许婉婷, 许波, 王鑫, 陈振乾. 方形微通道内超临界CO2流动换热特性研究[J]. 化工学报, 2022, 73(4): 1534-1545. |

| [4] | 王彦红, 陆英楠, 李素芬, 东明. 周向非均匀加热水平圆管内超临界正癸烷换热特性[J]. 化工学报, 2021, 72(3): 1342-1353. |

| [5] | 颜建国, 朱凤岭, 郭鹏程, 罗兴锜. 高热流低流速条件下超临界CO2在小圆管内的对流传热特性[J]. 化工学报, 2019, 70(5): 1779-1787. |

| [6] | 陈汇龙, 李同, 任坤腾, 王彬, 赵斌娟. 端面变形对液体动压型机械密封液膜瞬态特性的影响[J]. 化工学报, 2017, 68(4): 1533-1541. |

| [7] | 白万金, 徐肖肖, 吴杨杨. 低质量流速下超临界CO2在管内冷却换热特性[J]. 化工学报, 2016, 67(4): 1244-1250. |

| [8] | 王淑香, 张伟, 牛志愿, 徐进良. 超临界压力下CO2在螺旋管内的混合对流换热[J]. CIESC Journal, 2013, 64(11): 3917-3926. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号