化工学报 ›› 2025, Vol. 76 ›› Issue (11): 6077-6085.DOI: 10.11949/0438-1157.20250237

• 材料化学工程与纳米技术 • 上一篇

林星月1( ), 徐秀彬1(

), 徐秀彬1( ), 李鑫2, 韦林洁1, 王灏1, 姚希2(

), 李鑫2, 韦林洁1, 王灏1, 姚希2( ), 吴旭1(

), 吴旭1( )

)

收稿日期:2025-03-11

修回日期:2025-04-10

出版日期:2025-11-25

发布日期:2025-12-19

通讯作者:

徐秀彬,姚希,吴旭

作者简介:林星月(2000—),女,硕士研究生,1613902089@qq.com

基金资助:

Xingyue LIN1( ), Xiubin XU1(

), Xiubin XU1( ), Xin LI2, Linjie WEI1, Hao WANG1, Xi YAO2(

), Xin LI2, Linjie WEI1, Hao WANG1, Xi YAO2( ), Xu WU1(

), Xu WU1( )

)

Received:2025-03-11

Revised:2025-04-10

Online:2025-11-25

Published:2025-12-19

Contact:

Xiubin XU, Xi YAO, Xu WU

摘要:

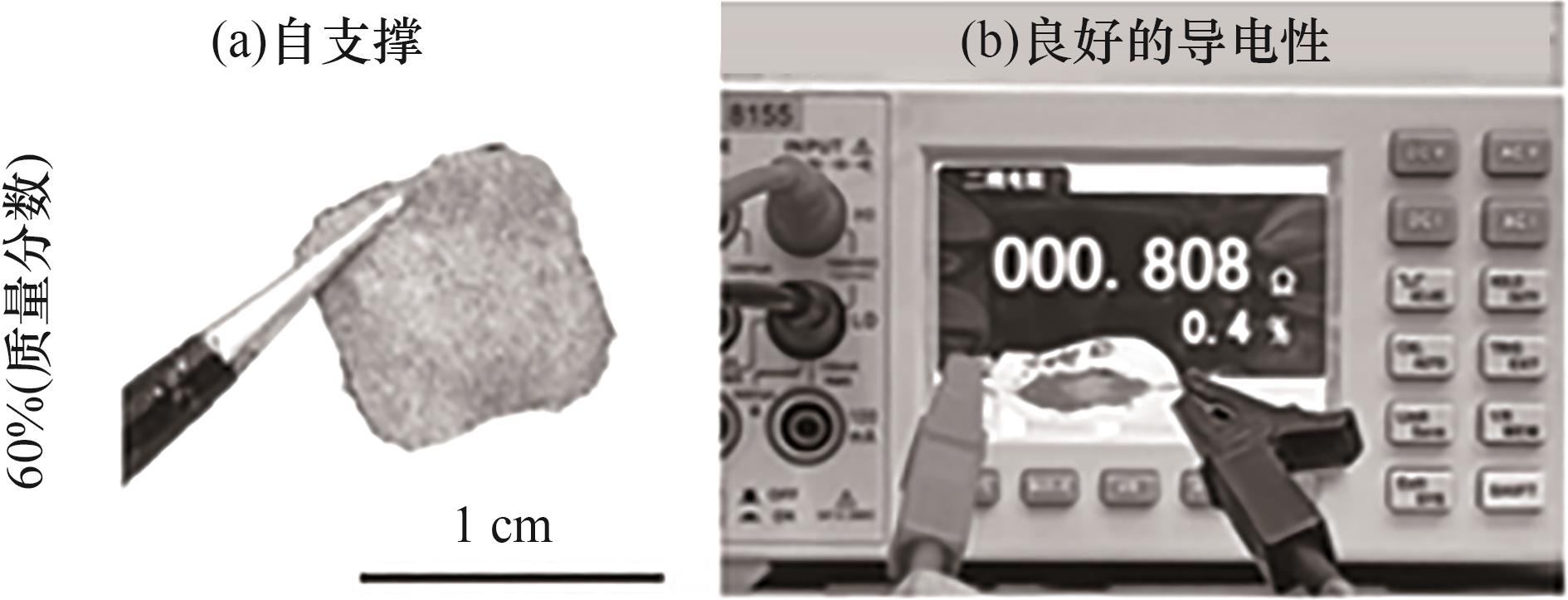

通过无溶剂搅拌策略将液态金属(LM)与β-环糊精(CD)复合制备液态金属/β-环糊精(LM/CD)复合物,并以此为引发剂引发丙烯酰胺(AAm)单体共聚,成功合成具有梯度LM/CD分布的水凝胶。CD的疏水空腔可包封LM液滴,其表面羟基通过配位作用与LM形成物理锚定,结合空间位阻效应抑制颗粒团聚,在搅拌转速2000 r/min、时间30 min条件下可有效分散60%(质量分数)的LM,LM/CD可形成具有自支撑性与导电性的片层结构。通过敲击诱导LM定向析出使LM/CD水凝胶底部电阻发生变化,电化学测试表明,LM/CD水凝胶底面电阻与敲击次数呈线性关系,可以实现仿生记忆功能且在压缩-释放循环中电阻保持稳定。与传统导电聚合物改性水凝胶相比,该材料兼具高导电性(底面电阻0.808 Ω)、优异力学性能及稳定的记忆行为,为智能仿生材料设计提供了新思路。

中图分类号:

林星月, 徐秀彬, 李鑫, 韦林洁, 王灏, 姚希, 吴旭. 液态金属/环糊精复合仿生记忆水凝胶[J]. 化工学报, 2025, 76(11): 6077-6085.

Xingyue LIN, Xiubin XU, Xin LI, Linjie WEI, Hao WANG, Xi YAO, Xu WU. Liquid metal/cyclodextrin composite biomimetic memory hydrogel[J]. CIESC Journal, 2025, 76(11): 6077-6085.

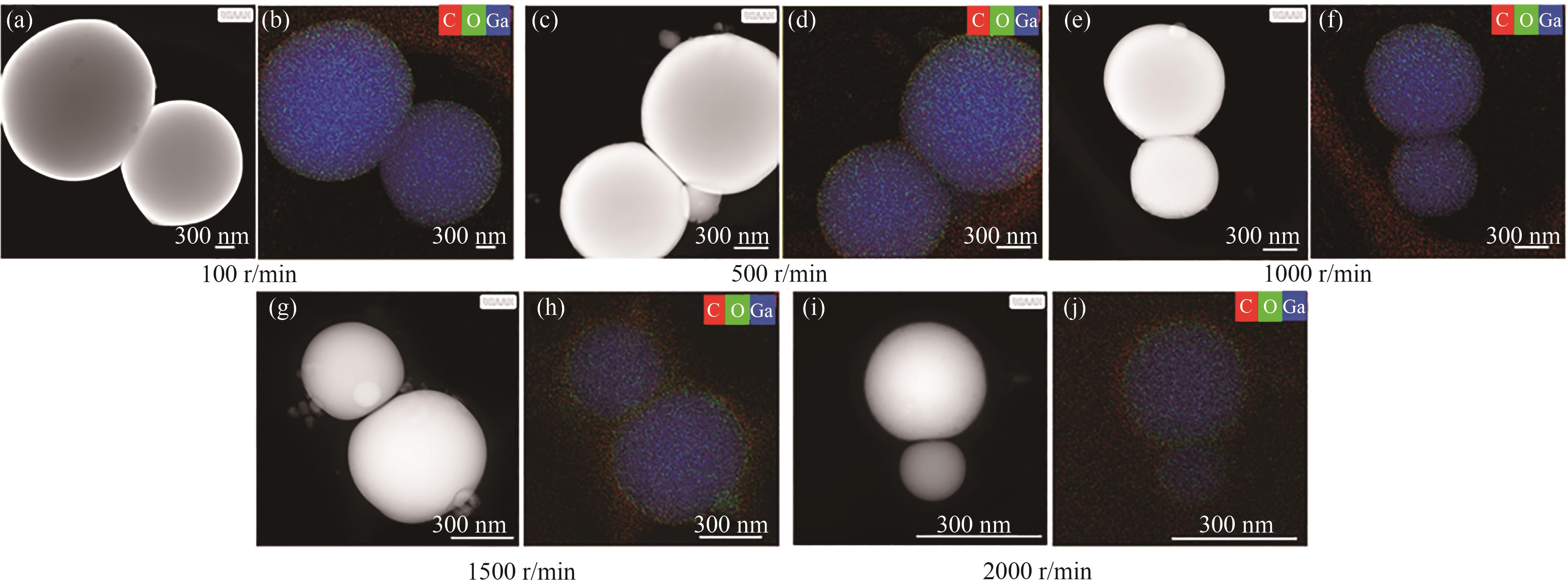

图3 不同搅拌转速下LM/CD 60复合物的TEM图像及对应的EDS元素映射图

Fig.3 TEM images and corresponding EDS element mapping diagrams of LM/CD 60 composites at different stirring speeds

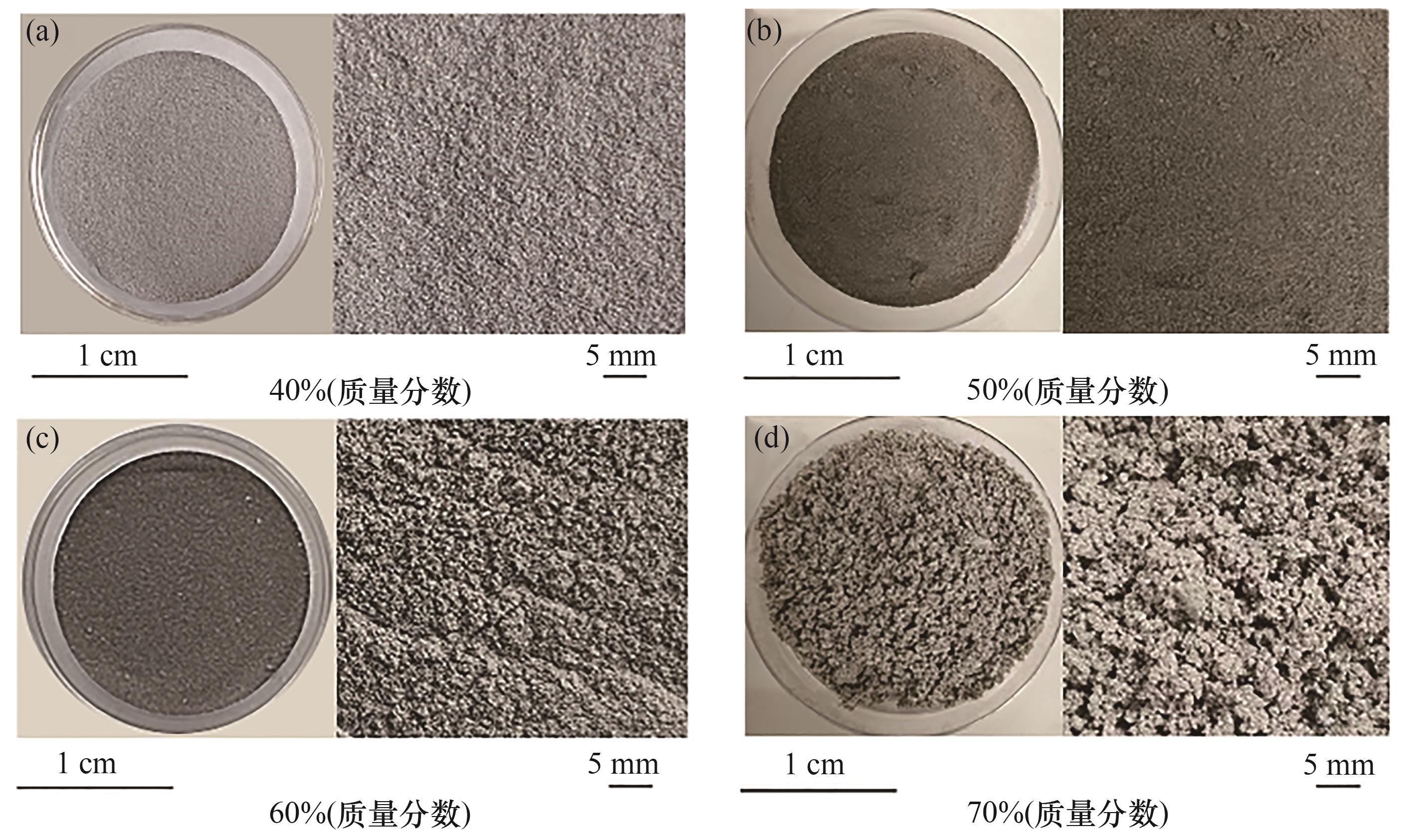

图4 转速为2000 r/min时LM/CD 40 (a)、 LM/CD 50 (b)、LM/CD 60 (c)、LM/CD 70 (d)复合材料及其局部放大电子图像

Fig.4 LM/CD 40 (a), LM/CD 50 (b), LM/CD 60 (c), and LM/CD 70 (d) composites and their partially enlarged electron images at a rotation speed of 2000 r/min

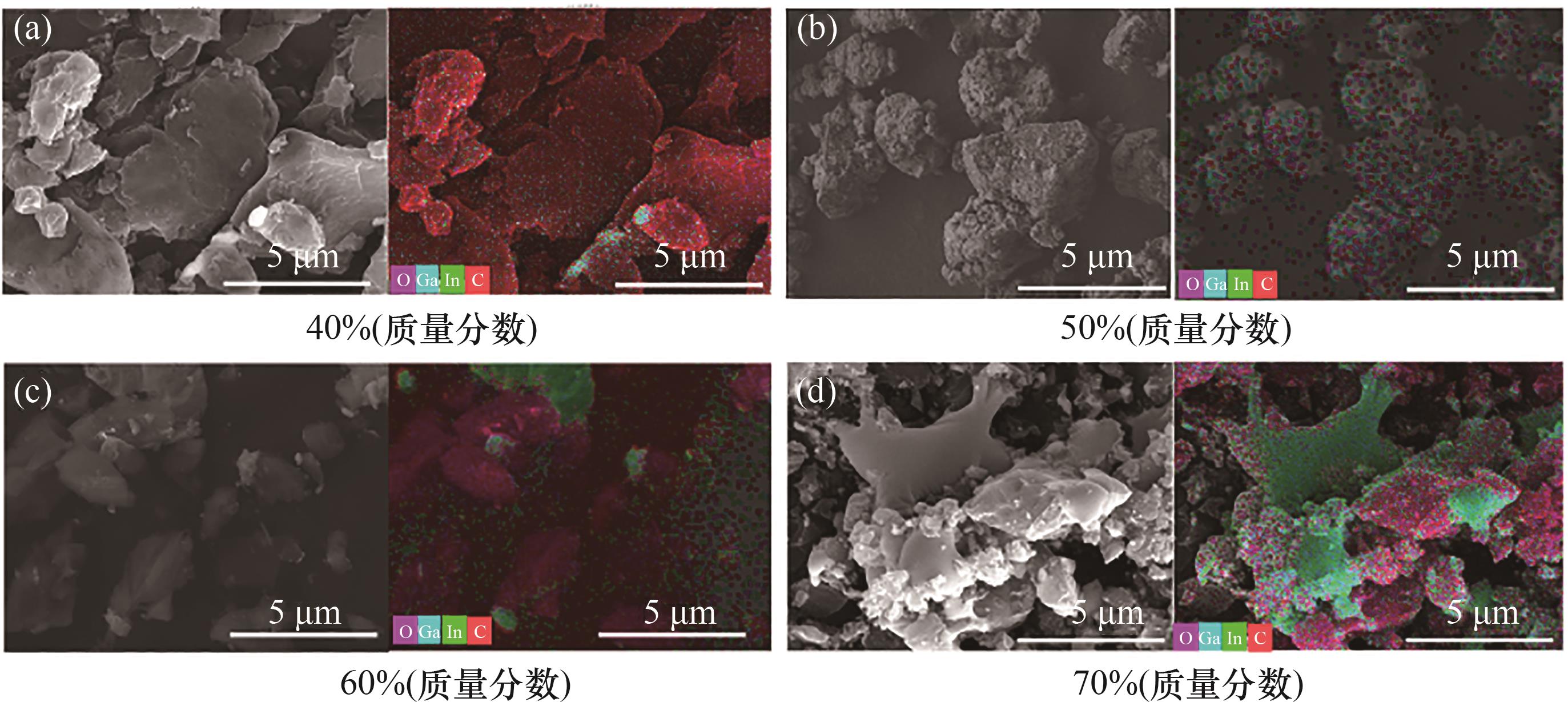

图5 转速为2000 r/min时LM/CD 40 (a)、LM/CD 50 (b)、LM/CD 60 (c)、LM/CD 70 (d)复合材料的扫描电子显微镜(SEM)谱图以及对应的元素映射图(EDS)

Fig.5 SEM images of LM/CD 40 (a), LM/CD 50 (b), LM/CD 60 (c), LM/CD 70 (d) composites with 2000 r/min, as well as corresponding EDS images

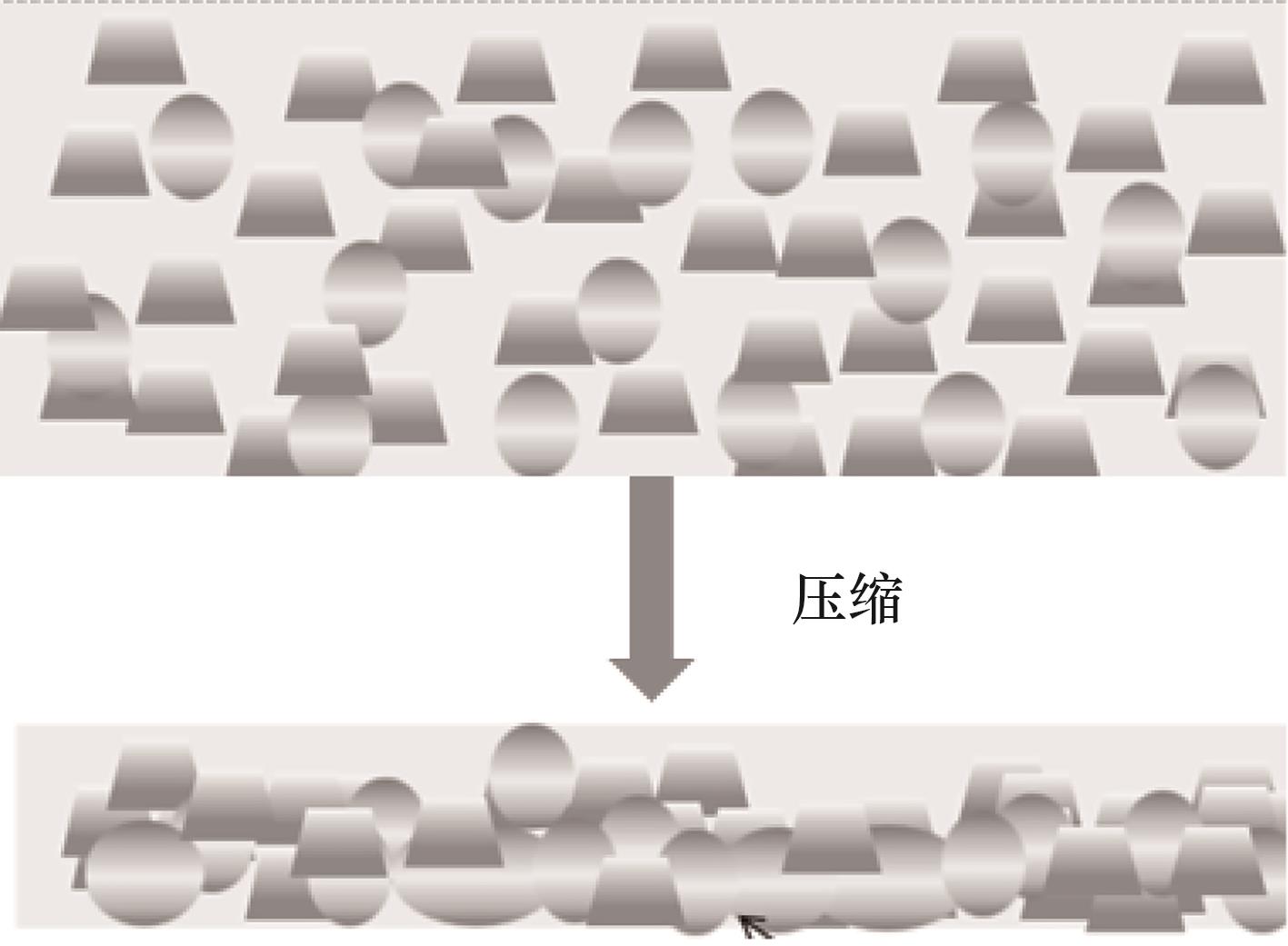

图7 自支撑薄膜导电原理示意图(圆形代表LM,梯形代表CD)

Fig.7 Schematic diagram of principle of self-supporting film conductivity (circle represents LM, and trapezoid represents CD)

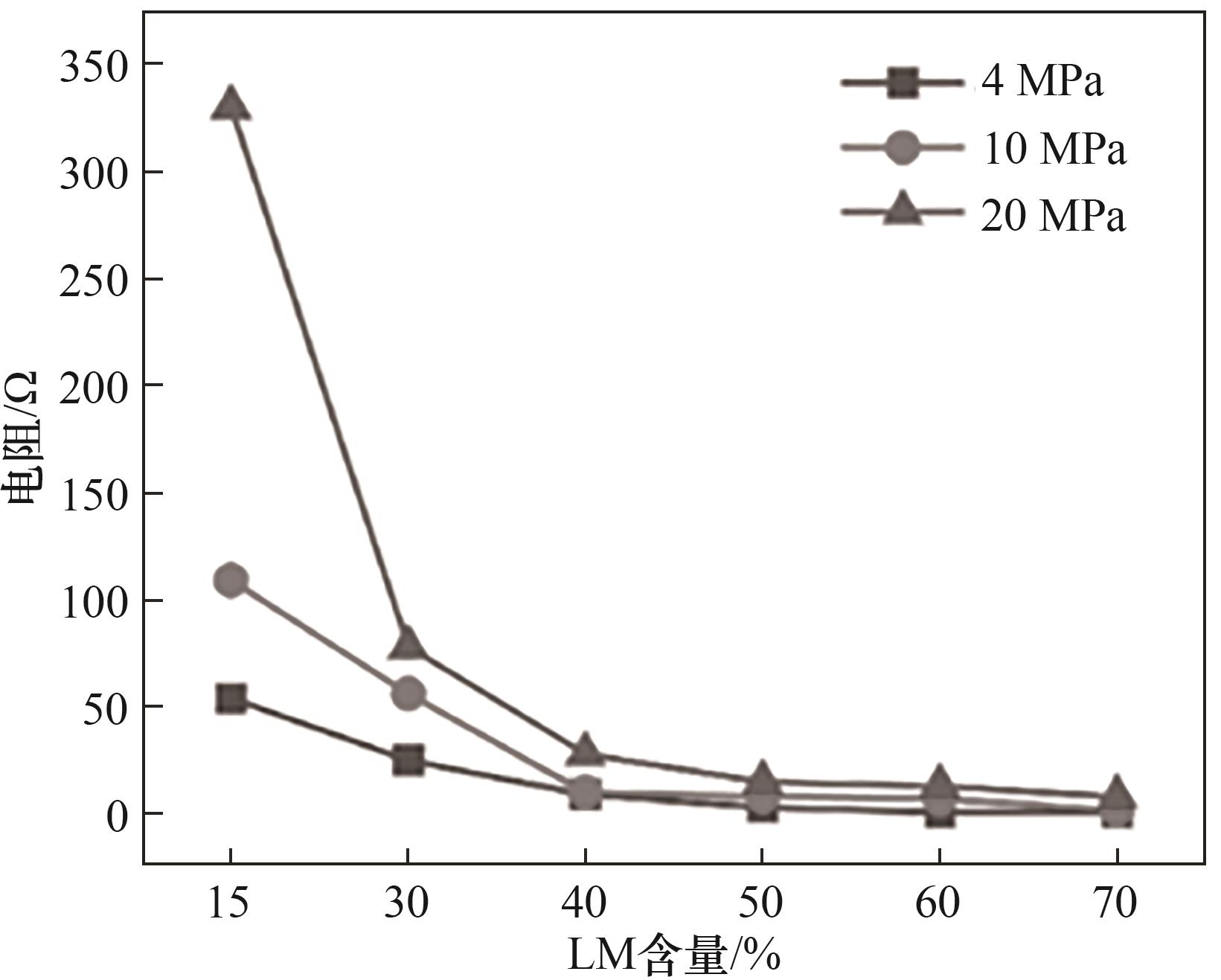

图8 不同LM含量的LM/CD在不同压力下制备的片层导电性能

Fig.8 Electrical conductivity of layered materials compressed under different pressures, composed of LM/CD with varying liquid metal contents

图9 LM/CD 60在4 MPa压力下的自支撑能力(a)以及片层良好的导电性(b)

Fig.9 Illustrates self-supporting capability (a) and good lamellar conductivity (b) of LM/CD 60 under a pressure of 4 MPa

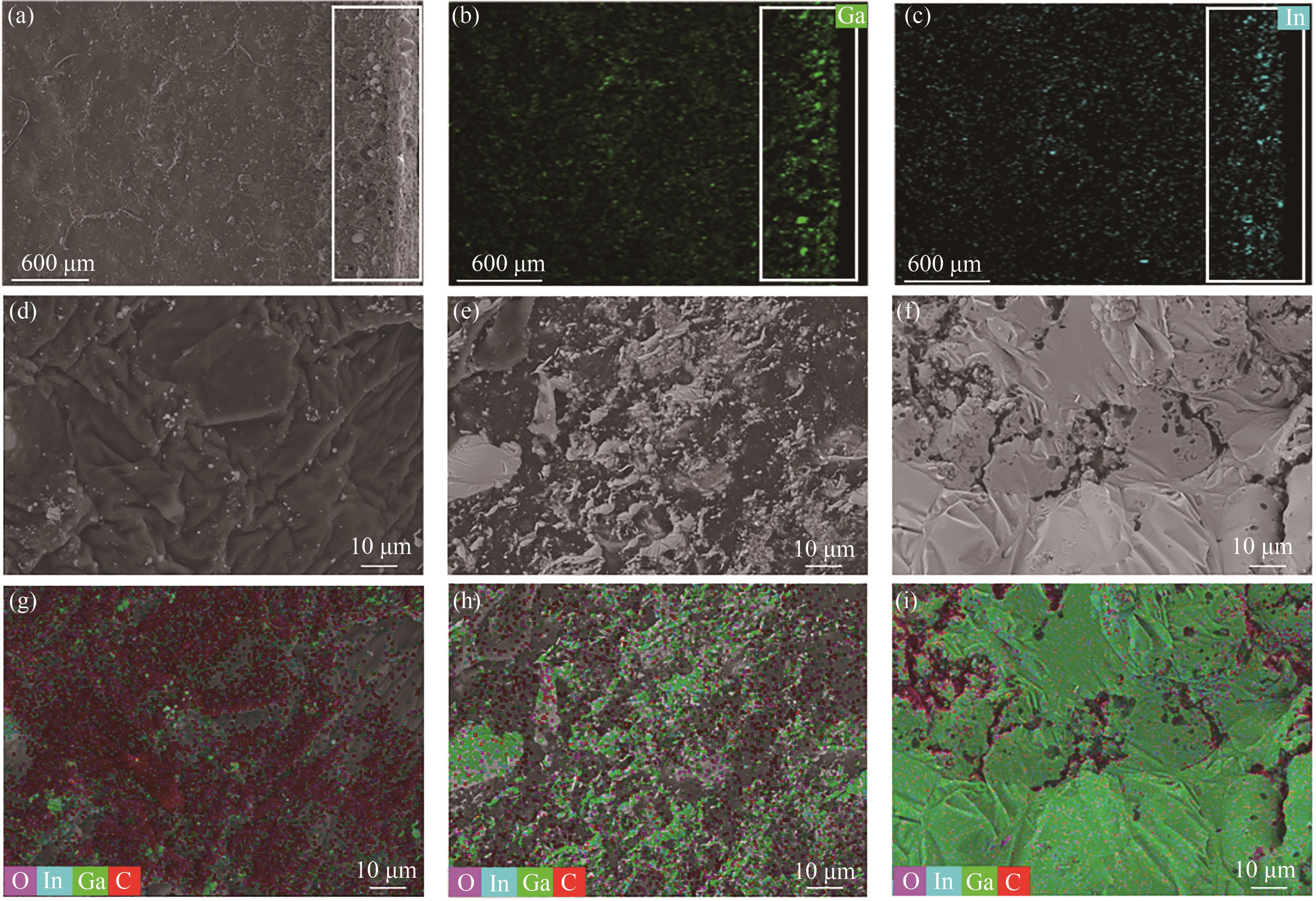

图12 LM/CD水凝胶元素分布分析:(a)凝胶截面二次电子像,(b)镓元素映射图和(c)铟元素映射图;(d)凝胶上表面二次电子像,(e)对应的元素(氧、铟、镓、碳)映射图;(f)凝胶下表面(原始)二次电子像,(g)对应的元素(氧、铟、镓、碳)映射图;(h)凝胶下表面敲击300次后的二次电子像,(i)对应的元素(氧、铟、镓、碳)映射图

Fig.12 Elemental distribution analysis of LM/CD organogel: (a) cross-sectional secondary electron image of gel, and (b) gallium (Ga) and (c) indium (In) elemental mappings, respectively; (d) secondary electron image of upper gel surface, and (e) corresponding elemental mappings (O, In, Ga, C); (f) secondary electron image of pristine lower gel surface, and (g) corresponding elemental mappings (O, In, Ga, C); (h) secondary electron image of lower gel surface after 300 cycles of tapping, and (i) corresponding elemental mappings (O, In, Ga, C)

| 元素 | 含量/%(质量分数) | |

|---|---|---|

| 上表面 | 下表面 | |

| C | 60.83 | 41.98 |

| O | 35.16 | 20.12 |

| Ga | 3.44 | 28.58 |

| In | 0.57 | 9.32 |

| 总量 | 100.00 | 100.00 |

表1 水凝胶上表面和下表面的EDS元素含量

Table 1 Elemental composition of top surface and bottom surface of hydrogel by EDS

| 元素 | 含量/%(质量分数) | |

|---|---|---|

| 上表面 | 下表面 | |

| C | 60.83 | 41.98 |

| O | 35.16 | 20.12 |

| Ga | 3.44 | 28.58 |

| In | 0.57 | 9.32 |

| 总量 | 100.00 | 100.00 |

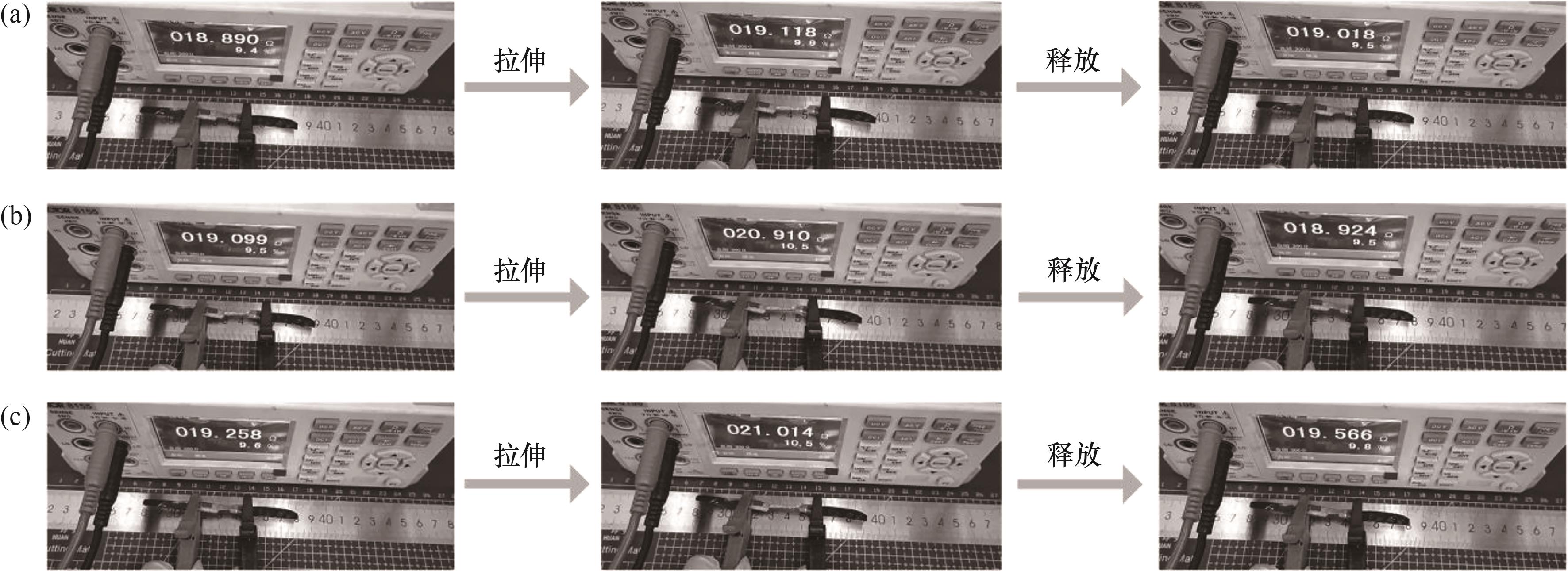

图13 水凝胶在拉伸和释放条件下电阻的恢复情况:拉伸-释放的电阻变化图(a) 3次循环拉伸后; (b) 6次循环拉伸后; (c) 10次循环拉伸后(a) after 3 stretching cycles; (b) after 6 stretching cycles; (c) after 10 stretching cycles

Fig.13 Resistance recovery of hydrogels under stretching and releasing conditions: a graph showing resistance changes during stretching and releasing

| [1] | Kim M S, Almuslem A S, Babatain W, et al. Beyond flexible: unveiling the next era of flexible electronic systems[J]. Advanced Materials, 2024, 36(51): 2406424. |

| [2] | Wang M X, Xiao X, Siddika S, et al. Glassy gels toughened by solvent[J]. Nature, 2024, 631(8020): 313-318. |

| [3] | Huang J C, Qiu L T, Ni C J, et al. Shape memory polymers with patternable recovery onset regulated by light[J]. Advanced Materials, 2024, 36(39): 2408324. |

| [4] | Liu Y J, Song Y Z, Wu P Y. Self-evolving hierarchical hydrogel fibers with circadian rhythms and memory functions[J]. Advanced Materials, 2024, 36(32): 2404506. |

| [5] | Li L, Ai Z T, Wu J F, et al. A robust polyaniline hydrogel electrode enables superior rate capability at ultrahigh mass loadings[J]. Nature Communications, 2024, 15(1): 6591. |

| [6] | He H M, Li H, Pu A Y, et al. Hybrid assembly of polymeric nanofiber network for robust and electronically conductive hydrogels[J]. Nature Communications, 2023, 14(1): 759. |

| [7] | Xie X J, Xu Z G, Yu X, et al. Liquid-in-liquid printing of 3D and mechanically tunable conductive hydrogels[J]. Nature Communications, 2023, 14(1): 4289. |

| [8] | Wang Z, Xu X Y, Zhang K, et al. Continuous phase separation induced tough hydrogel fibers with ultrahigh conductivity for multidimensional soft electronics[J]. Advanced Functional Materials, 2025, 35(3): 2413478. |

| [9] | Wan B L, Liu N N, Zhang Z, et al. Water-dispersible and stable polydopamine coated cellulose nanocrystal-MXene composites for high transparent, adhesive and conductive hydrogels[J]. Carbohydrate Polymers, 2023, 314: 120929. |

| [10] | Eivazzadeh-Keihan R, Bahojb Noruzi E, Chidar E, et al. Applications of carbon-based conductive nanomaterials in biosensors[J]. Chemical Engineering Journal, 2022, 442: 136183. |

| [11] | Liu B C, Wang Y, Miao Y, et al. Hydrogen bonds autonomously powered gelatin methacrylate hydrogels with super-elasticity, self-heal and underwater self-adhesion for sutureless skin and stomach surgery and E-skin[J]. Biomaterials, 2018, 171: 83-96. |

| [12] | Song X P, Wang X R, Zhang J, et al. A tunable self-healing ionic hydrogel with microscopic homogeneous conductivity as a cardiac patch for myocardial infarction repair[J]. Biomaterials, 2021, 273: 120811. |

| [13] | Liang Y P, Qiao L P, Qiao B W, et al. Conductive hydrogels for tissue repair[J]. Chemical Science, 2023, 14(12): 3091-3116. |

| [14] | Bernard F, Dargère D, Rechavi O, et al. Quantitative analysis of C. elegans transcripts by nanopore direct-cDNA sequencing reveals terminal hairpins in non trans-spliced mRNAs[J]. Nature Communications, 2023, 14(1): 1229. |

| [15] | Liu S L, Zhang W T, He J Z, et al. Fabrication techniques and sensing mechanisms of textile-based strain sensors: from spatial 1D and 2D perspectives[J]. Advanced Fiber Materials, 2024, 6(1): 36-67. |

| [16] | Dickey M D. Stretchable and soft electronics using liquid metals[J]. Advanced Materials, 2017, 29(27): 1606425. |

| [17] | Lin Z W, Qiu X W, Cai Z, et al. High internal phase emulsions gel ink for direct-ink-writing 3D printing of liquid metal[J]. Nature Communications, 2024, 15(1): 4806. |

| [18] | Jiang H J, Yuan B, Guo H T, et al. Malleable, printable, bondable, and highly conductive MXene/liquid metal plasticine with improved wettability[J]. Nature Communications, 2024, 15(1): 6138. |

| [19] | Li X K, Li M J, Zong L, et al. Liquid metal droplets wrapped with polysaccharide microgel as biocompatible aqueous ink for flexible conductive devices[J]. Advanced Functional Materials, 2018, 28(39): 1804197. |

| [20] | Alizadeh N, Nazari F. Thymol essential oil/β-cyclodextrin inclusion complex into chitosan nanoparticles: improvement of thymol properties in vitro studies[J]. Journal of Molecular Liquids, 2022, 346: 118250. |

| [21] | Wang Q, Ji X Y, Liu X, et al. Viscoelastic metal-in-water emulsion gel via host-guest bridging for printed and strain-activated stretchable electrodes[J]. ACS Nano, 2022, 16(8): 12677-12685. |

| [22] | Dickey M D, Chiechi R C, Larsen R J, et al. Eutectic gallium-indium (EGaIn): a liquid metal alloy for the formation of stable structures in microchannels at room temperature[J]. Advanced Functional Materials, 2008, 18(7): 1097-1104. |

| [23] | Chen W F, Tang Q Q, Zhong W J, et al. Directly printable and adhesive liquid metal ink for wearable devices[J]. Advanced Functional Materials, 2025, 35(1): 2411647. |

| [24] | Osborne T, Rhymer D, Werner D, et al. Investigating the impact of impeller geometry for a stirred mill using the discrete element method: effect of pin number and thickness[J]. Powder Technology, 2023, 428: 118810. |

| [25] | Wu S N, Zhang Y T, Li G W, et al. Simple, fast, and energy saving: room temperature synthesis of high-entropy alloy by liquid-metal-mediated mechanochemistry[J]. Matter, 2025, 8(3): 101986. |

| [26] | Qin Z Y, Jiang Q B, Zou Y C, et al. Synthesis of nanosized γ-cyclodextrin metal-organic frameworks as carriers of limonene for fresh-cut fruit preservation based on polycaprolactone nanofibers[J]. Small, 2024, 20(29): 2400399. |

| [27] | Topuz F, Uyar T. Advances in the development of cyclodextrin-based nanogels/microgels for biomedical applications: drug delivery and beyond[J]. Carbohydrate Polymers, 2022, 297: 120033. |

| [28] | Yu R H, Wu L, Yang Z H, et al. Dynamic liquid metal-microfiber interlocking enables highly conductive and strain-insensitive metastructured fibers for wearable electronics[J]. Advanced Materials, 2025, 37(6): 2415268. |

| [29] | Zheng Y, Liu H, Yan L, et al. Lignin-based encapsulation of liquid metal particles for flexible and high-efficiently recyclable electronics[J]. Advanced Functional Materials, 2024, 34(7): 2310653. |

| [30] | Zhang Y, Wang Z, Wang S T, et al. Dynamic-wetting liquid metal thin layer induced via surface oxygen-containing functional groups[J]. ACS Nano, 2025, 19(4): 4913-4923. |

| [31] | Liu W L, Ye J C, Wang Y L, et al. Multimodal antibacterial E-skin patch driven by oxidative stress for real-time wound-status monitoring and integrated treatment of chronic wounds[J]. Advanced Functional Materials, 2025, 35(22): 2424698. |

| [32] | Gong J P, Katsuyama Y, Kurokawa T, et al. Double-network hydrogels with extremely high mechanical strength[J]. Advanced Materials, 2003, 15(14): 1155-1158. |

| [33] | Haraguchi K, Takehisa T. Nanocomposite hydrogels: a unique organic-inorganic network structure with extraordinary mechanical, optical, and swelling/de-swelling properties[J]. Advanced Materials, 2002, 14(16): 1120-1124. |

| [34] | Zhang Q T, Lu H D, Yun G L, et al. A laminated gravity-driven liquid metal-doped hydrogel of unparalleled toughness and conductivity[J]. Advanced Functional Materials, 2024, 34(31): 2308113. |

| [1] | 段炼, 周星睿, 袁文君, 陈飞. 连续相速度脉动对微通道内聚合物液滴生成和形貌的影响规律[J]. 化工学报, 2025, 76(9): 4578-4585. |

| [2] | 叶鑫煌, 薛嘉豪, 赵玉来. 可聚型Gemini表面活性剂的制备、表征及其稳定高内相乳液的研究[J]. 化工学报, 2025, 76(8): 4331-4340. |

| [3] | 张晓晨, 鲁中山, 郭腾, 桂恒, 宋红兵, 肖盟. 一株端羟基聚丁二烯降解菌的筛选及降解机理研究[J]. 化工学报, 2025, 76(8): 4205-4216. |

| [4] | 赵美, 甘雨欣, 赵绍磊, 杨令, 王亭杰. 硅橡胶用纳米二氧化硅表面有机修饰及补强机理研究进展[J]. 化工学报, 2025, 76(7): 3125-3136. |

| [5] | 孙传付, 胡桂林, 曹俊杰, 左启斌, 陈媚, 夏玉珍. 梯度孔分布ZnO-GA锂离子电池负极材料研究[J]. 化工学报, 2025, 76(7): 3710-3718. |

| [6] | 乔亮, 李尚, 刘新亮, 王明, 张沛, 侯影飞. 三元共聚物稠油降黏剂的合成及分子模拟研究[J]. 化工学报, 2025, 76(7): 3686-3695. |

| [7] | 马谌睿, 王翔, 宋民航, 敬军, 吴琼, 黄云. 氯化法钛白氧化反应器内颗粒碰撞行为及生成演化过程理论分析[J]. 化工学报, 2025, 76(7): 3316-3324. |

| [8] | 王珺仪, 夏章讯, 景粉宁, 王素力. 基于重整气的高温聚合物电解质膜燃料电池电化学阻抗谱弛豫时间分布研究[J]. 化工学报, 2025, 76(7): 3509-3520. |

| [9] | 郭乃胜, 朱小波, 王双, 陈平, 褚召阳, 王志臣. 聚氨酯改性沥青高低温性能及影响因素的研究进展[J]. 化工学报, 2025, 76(6): 2505-2523. |

| [10] | 李长宇, 曾强, 肖杰, 张阳杰, 张政, 林元华. PVDF对LATP基固态电解质膜界面修饰研究[J]. 化工学报, 2025, 76(6): 2974-2982. |

| [11] | 高冰冰, 许诺, 白云翔, 张春芳, 杨永强, 董亮亮. 氦气分离聚合物膜[J]. 化工学报, 2025, 76(5): 2119-2135. |

| [12] | 李家顺, 李旺, 秦祖赠, 苏通明, 谢新玲, 纪红兵. 聚酰亚胺增强木质纤维素纳米纤丝气凝胶制备及其油水分离性能研究[J]. 化工学报, 2025, 76(5): 2169-2185. |

| [13] | 李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357. |

| [14] | 陆艳秋, 狄扬, 石文博, 殷聪聪, 汪勇. 基于新型有机多孔聚合物的智能响应膜研究进展[J]. 化工学报, 2025, 76(5): 2101-2118. |

| [15] | 翟紫航, 蒋杰, 李锦锦, 赵玲, 奚桢浩. 基于2,5-呋喃二甲酸的三元无规共聚酯PBSF的制备与性能[J]. 化工学报, 2025, 76(2): 868-878. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号