化工学报 ›› 2025, Vol. 76 ›› Issue (11): 6066-6076.DOI: 10.11949/0438-1157.20250259

• 能源和环境工程 • 上一篇

收稿日期:2025-03-17

修回日期:2025-04-07

出版日期:2025-11-25

发布日期:2025-12-19

通讯作者:

张大全

作者简介:程闻笛(1993—),男,硕士,工程师,2119671460@qq.com

Wendi CHENG1( ), Daquan ZHANG2(

), Daquan ZHANG2( )

)

Received:2025-03-17

Revised:2025-04-07

Online:2025-11-25

Published:2025-12-19

Contact:

Daquan ZHANG

摘要:

国内外市场对绿色电能的极大需求,使大型工商业储能系统投入广泛应用,但电池存在热稳定性差、高温条件下副反应增加且易突发热失控的问题。为了更有效地将电池组的工作温度控制在最适宜温度区间20

中图分类号:

程闻笛, 张大全. 储能电池包的热特性数值研究[J]. 化工学报, 2025, 76(11): 6066-6076.

Wendi CHENG, Daquan ZHANG. Numerical study of thermal characteristics of energy storage battery packs[J]. CIESC Journal, 2025, 76(11): 6066-6076.

| Contents | Value |

|---|---|

| Nominal capacity/(A·h) | 280 |

| Mass/kg | 5.5 |

| Energy density/(W·h/kg) | |

| Direct current internal resistance/mΩ | 0.50 (10 s,25℃,25% SOC) |

| Dimensions (width×thickness×height)/mm | 173.8 |

| Charging cut-off voltage/V | 3.65 |

| Discharge cut-off voltage/V | 2.5 |

表1 半固态锂电池规格参数

Table 1 Specifications of semi-solid lithium batteries

| Contents | Value |

|---|---|

| Nominal capacity/(A·h) | 280 |

| Mass/kg | 5.5 |

| Energy density/(W·h/kg) | |

| Direct current internal resistance/mΩ | 0.50 (10 s,25℃,25% SOC) |

| Dimensions (width×thickness×height)/mm | 173.8 |

| Charging cut-off voltage/V | 3.65 |

| Discharge cut-off voltage/V | 2.5 |

| Type | Density/(kg/m3) | Specific heat/( | Thermal conductivity/( |

|---|---|---|---|

| Cell | 2152 | 1051.1 | λth=1.04, λw,λh=21.05 |

| Liquid cooling plate | 2680 | 880 | 237 |

| Thermal silica gel | 2420 | 967 | 2.1 |

| Coolant | 1065 | 3394 | 0.419 |

| PC board | 1200 | 1340 | 0.194 |

表2 电池包各主要部件物性参数

Table 2 Physical property parameters of main components of battery pack

| Type | Density/(kg/m3) | Specific heat/( | Thermal conductivity/( |

|---|---|---|---|

| Cell | 2152 | 1051.1 | λth=1.04, λw,λh=21.05 |

| Liquid cooling plate | 2680 | 880 | 237 |

| Thermal silica gel | 2420 | 967 | 2.1 |

| Coolant | 1065 | 3394 | 0.419 |

| PC board | 1200 | 1340 | 0.194 |

| SOC | Internal resistance/mΩ | |||||||

|---|---|---|---|---|---|---|---|---|

| -20℃ | -10℃ | 0℃ | 10℃ | 25℃ | 35℃ | 45℃ | 55℃ | |

| 0 | — | — | — | — | — | — | — | — |

| 5 | 5.34 | 3.66 | 1.73 | 1.24 | 0.57 | 0.46 | 0.34 | 0.23 |

| 10 | 5.05 | 3.47 | 1.63 | 1.18 | 0.53 | 0.43 | 0.33 | 0.22 |

| 15 | 4.75 | 3.29 | 1.56 | 1.13 | 0.51 | 0.42 | 0.32 | 0.23 |

| 20 | 4.46 | 3.11 | 1.50 | 1.09 | 0.49 | 0.40 | 0.32 | 0.23 |

| 25 | 4.17 | 2.93 | 1.45 | 1.06 | 0.47 | 0.39 | 0.31 | 0.23 |

| 30 | 3.88 | 2.76 | 1.41 | 1.03 | 0.46 | 0.39 | 0.31 | 0.23 |

| 35 | 3.64 | 2.59 | 1.38 | 1.00 | 0.45 | 0.38 | 0.30 | 0.23 |

| 40 | 3.43 | 2.46 | 1.34 | 0.98 | 0.44 | 0.37 | 0.30 | 0.23 |

| 45 | 3.24 | 2.33 | 1.32 | 0.96 | 0.43 | 0.37 | 0.30 | 0.23 |

| 50 | 3.14 | 2.24 | 1.29 | 0.94 | 0.43 | 0.36 | 0.29 | 0.23 |

| 55 | 3.12 | 2.20 | 1.27 | 0.93 | 0.42 | 0.36 | 0.29 | 0.23 |

| 60 | 3.09 | 2.18 | 1.25 | 0.92 | 0.42 | 0.36 | 0.29 | 0.23 |

| 65 | 3.05 | 2.15 | 1.24 | 0.91 | 0.43 | 0.37 | 0.30 | 0.23 |

| 70 | 3.01 | 2.13 | 1.23 | 0.91 | 0.42 | 0.36 | 0.30 | 0.23 |

| 75 | 2.97 | 2.10 | 1.22 | 0.90 | 0.41 | 0.35 | 0.29 | 0.23 |

| 80 | 2.93 | 2.07 | 1.21 | 0.89 | 0.41 | 0.35 | 0.29 | 0.23 |

| 85 | 2.88 | 2.04 | 1.19 | 0.87 | 0.40 | 0.34 | 0.29 | 0.23 |

| 90 | 2.83 | 2.00 | 1.17 | 0.86 | 0.39 | 0.34 | 0.28 | 0.23 |

| 95 | 2.79 | 1.97 | 1.16 | 0.85 | 0.39 | 0.33 | 0.28 | 0.23 |

| 100 | 2.77 | 1.97 | 1.17 | 0.86 | 0.39 | 0.34 | 0.29 | 0.23 |

表3 10 s脉冲放电内阻

Table 3 10 s pulse discharge internal resistance

| SOC | Internal resistance/mΩ | |||||||

|---|---|---|---|---|---|---|---|---|

| -20℃ | -10℃ | 0℃ | 10℃ | 25℃ | 35℃ | 45℃ | 55℃ | |

| 0 | — | — | — | — | — | — | — | — |

| 5 | 5.34 | 3.66 | 1.73 | 1.24 | 0.57 | 0.46 | 0.34 | 0.23 |

| 10 | 5.05 | 3.47 | 1.63 | 1.18 | 0.53 | 0.43 | 0.33 | 0.22 |

| 15 | 4.75 | 3.29 | 1.56 | 1.13 | 0.51 | 0.42 | 0.32 | 0.23 |

| 20 | 4.46 | 3.11 | 1.50 | 1.09 | 0.49 | 0.40 | 0.32 | 0.23 |

| 25 | 4.17 | 2.93 | 1.45 | 1.06 | 0.47 | 0.39 | 0.31 | 0.23 |

| 30 | 3.88 | 2.76 | 1.41 | 1.03 | 0.46 | 0.39 | 0.31 | 0.23 |

| 35 | 3.64 | 2.59 | 1.38 | 1.00 | 0.45 | 0.38 | 0.30 | 0.23 |

| 40 | 3.43 | 2.46 | 1.34 | 0.98 | 0.44 | 0.37 | 0.30 | 0.23 |

| 45 | 3.24 | 2.33 | 1.32 | 0.96 | 0.43 | 0.37 | 0.30 | 0.23 |

| 50 | 3.14 | 2.24 | 1.29 | 0.94 | 0.43 | 0.36 | 0.29 | 0.23 |

| 55 | 3.12 | 2.20 | 1.27 | 0.93 | 0.42 | 0.36 | 0.29 | 0.23 |

| 60 | 3.09 | 2.18 | 1.25 | 0.92 | 0.42 | 0.36 | 0.29 | 0.23 |

| 65 | 3.05 | 2.15 | 1.24 | 0.91 | 0.43 | 0.37 | 0.30 | 0.23 |

| 70 | 3.01 | 2.13 | 1.23 | 0.91 | 0.42 | 0.36 | 0.30 | 0.23 |

| 75 | 2.97 | 2.10 | 1.22 | 0.90 | 0.41 | 0.35 | 0.29 | 0.23 |

| 80 | 2.93 | 2.07 | 1.21 | 0.89 | 0.41 | 0.35 | 0.29 | 0.23 |

| 85 | 2.88 | 2.04 | 1.19 | 0.87 | 0.40 | 0.34 | 0.29 | 0.23 |

| 90 | 2.83 | 2.00 | 1.17 | 0.86 | 0.39 | 0.34 | 0.28 | 0.23 |

| 95 | 2.79 | 1.97 | 1.16 | 0.85 | 0.39 | 0.33 | 0.28 | 0.23 |

| 100 | 2.77 | 1.97 | 1.17 | 0.86 | 0.39 | 0.34 | 0.29 | 0.23 |

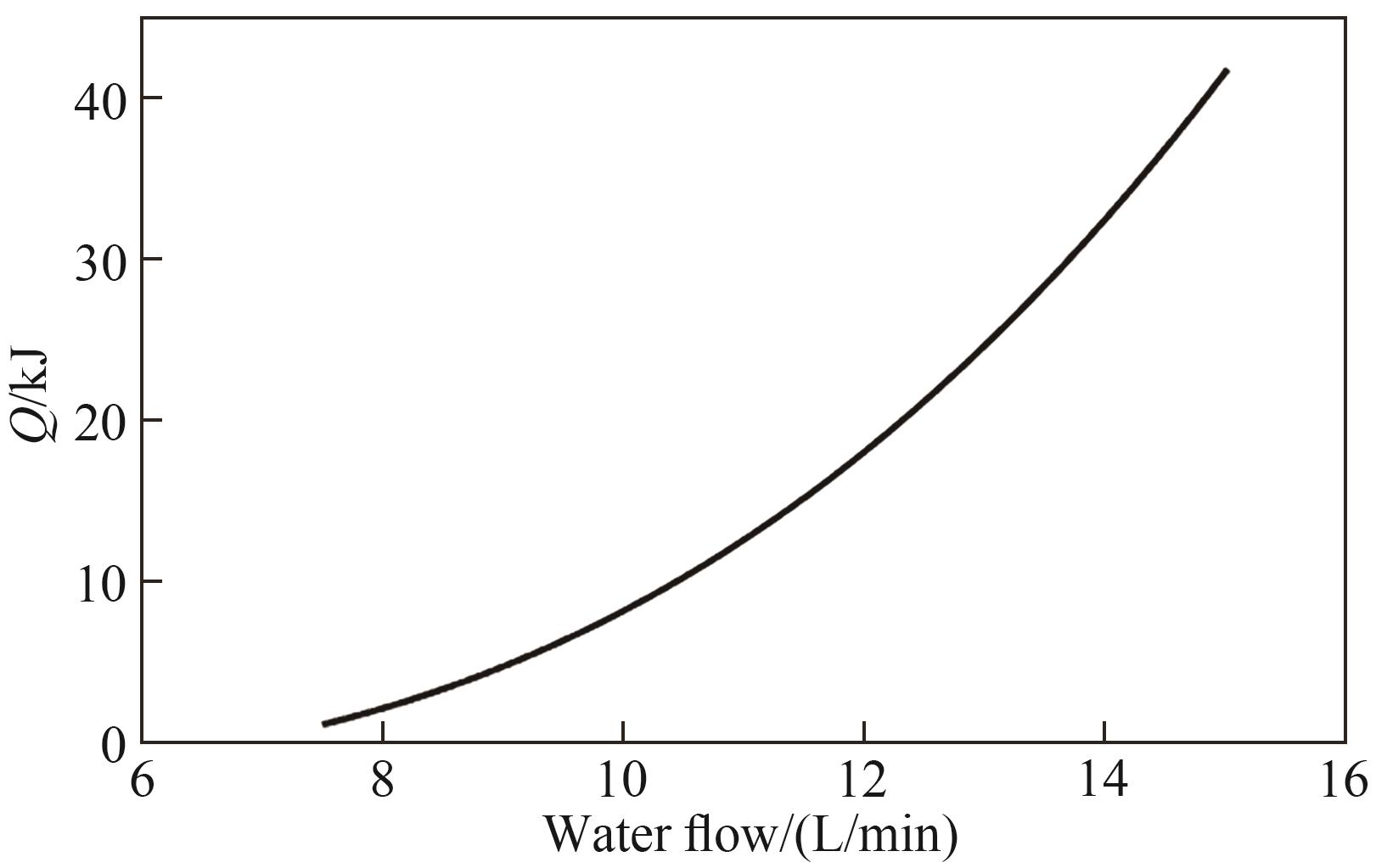

图16 不同水流量对应的液冷系统放电截止时刻能耗变化

Fig.16 shows changes in energy consumption of liquid cooling system at moment of discharge cutoff corresponding to different water flow rates

| [1] | Mustafa J. Numerical investigation of the effect of inlet dimensions air duct and distance of battery packs for thermal management of three lithium-ion battery packs[J]. Journal of Energy Storage, 2022, 48: 103959. |

| [2] | Yang H, Liu N H, Gu M J, et al. Optimized design of novel serpentine channel liquid cooling plate structure for lithium-ion battery based on discrete continuous variables[J]. Applied Thermal Engineering, 2025, 264: 125502. |

| [3] | Liu Z Y, Xiong C F, Du X F. Research on the optimization control strategy of a battery thermal management system based on serpentine liquid cooling combined with phase change material[J]. Journal of Power Sources, 2025, 630: 236127. |

| [4] | Dai H S, Yang C X, Zhang F, et al. Transient heat dissipation performance investigation on the battery thermal management system based on S-CO2 immersion cooling[J]. Energy, 2025, 318:134656. |

| [5] | Wang G L, Gu L, Li Y, et al. Optimization of guide plates and orifice plates on thermal management of battery energy storage system[J]. Applied Thermal Engineering, 2024, 253: 123794. |

| [6] | Hai T, Awatef A, Azher M A, et al. Three-dimensional numerical study of the effect of an air-cooled system on thermal management of a cylindrical lithium-ion battery pack with two different arrangements of battery cells[J]. Journal of Power Sources, 2022,50:232117. |

| [7] | Wu C X, Sun Y L, Tang H, et al. A review on the liquid cooling thermal management system of lithium-ion batteries[J]. Applied Energy, 2024, 375: 124173. |

| [8] | Sarvar-Ardeh S, Rafee R, Rashidi S. Enhancing the performance of liquid-based battery thermal management system by porous substrate minichannel[J]. Journal of Energy Storage, 2023, 71:108142. |

| [9] | 刘周斌, 朱涛, 姜巍, 等. 储能锂离子电池包冷却系统的数值模拟与结构优化[J]. 中国电力, 2023, 56(10): 202-210. |

| Liu Z B, Zhu T, Jiang W, et al. Simulation analysis and structure optimization of cooling system for energy storage lithium-ion battery pack[J]. Electric Power, 2023, 56(10): 202-210. | |

| [10] | 张子惠, 韩东, 熊佳明, 等. MVR降膜式储能电池间接液冷系统设计及性能分析[J]. 节能技术, 2024, 42(6): 523-529. |

| Zhang Z H, Han D, Xiong J M, et al. Process design and performance analysis of an indirect liquid-cooling system based on mechanical vapor recompression(MVR) falling film evaporation for energy storage battery[J]. Energy Conservation Technology, 2024, 42(6): 523-529. | |

| [11] | Lin X W, Zhou Z F, Li M X, et al. Exploration on the liquid-based energy storage battery system from system design, parametric optimization, and control strategy[J]. Renewable Energy, 2024, 237: 121904. |

| [12] | Wei W H, Luo Z, Qiao S X, et al. Analysis and design of module-level liquid cooling system for rectangular Li-ion batteries[J]. International Journal of Heat and Mass Transfer, 2024, 225:125435. |

| [13] | Thakur A K, Ahmed M S, Kang H, et al. Critical review on internal and external battery thermal management systems for fast charging applications[J]. Advanced Energy Materials, 2023, 13(11): 2202944. |

| [14] | Ashkboos P, Yousefi A, Houshfar E. Design improvement of thermal management for Li-ion battery energy storage systems[J]. Sustainable Energy Technologies and Assessments, 2021, 44: 101094. |

| [15] | Feng Y, Zhou L M, Ma H, et al. Challenges and advances in wide-temperature rechargeable lithium batteries[J]. Energy & Environmental Science, 2022, 15(5): 1711-1759. |

| [16] | 钱亨, 刘剑, 霍玉雷. 扰流结构对电池热管理系统的传热特性研究[J]. 储能科学与技术, 2024, 13(11): 3889-3897. |

| Qian H, Liu J, Huo Y L. Heat transfer characteristics of lithium-ion battery thermal management system with spoiler structure[J]. Energy Storage Science and Technology, 2024, 13(11): 3889-3897. | |

| [17] | 张新宇, 罗声豪, 吴颖欣, 等. 复合相变材料用于锂离子电池热管理和热失控防护研究进展[J]. 储能科学与技术, 2025, 14(3): 1040-1053. |

| Zhang X Y, Luo S H, Wu Y X, et al. Research progress of composite phase change materials for thermal management and thermal runaway protection of lithium ion batteries[J]. Energy Storage Science and Technology, 2025, 14(3): 1040-1053. | |

| [18] | Jouhara H, Khordehgah N, Serey N, et al. Applications and thermal management of rechargeable batteries for industrial applications[J]. Energy, 2019, 170: 849-861. |

| [19] | Liu Z Q, Cao M, Li J H, et al. Performance analysis and comparison study of liquid cooling-based shell-and-tube battery thermal management systems[J]. Journal of Energy Storage, 2024, 80:110234. |

| [20] | Feng X H, Li Z Z, Gu F S, et al. Structural design and optimization of air-cooled thermal management system for lithium-ion batteries based on discrete and continuous variables[J]. Journal of Energy Storage, 2024, 86: 111202. |

| [21] | 郭鹏宇, 王铭民, 许栋栋, 等. 调峰和调频工况下磷酸铁锂电池组的冷却研究[J]. 低温与超导, 2024, 52(3): 88-95. |

| Guo P Y, Wang M M, Xu D D, et al. Study on cooling of Lithium iron phosphate battery under peak shaving and frequency modulation conditions[J]. Cryogenics & Superconductivity, 2024, 52(3): 88-95. | |

| [22] | Cheng W M, Chen M Y, Ouyang D X, et al. Investigation of the thermal performance and heat transfer characteristics of the lithium-ion battery module based on an oil-immersed cooling structure[J]. Journal of Energy Storage, 2024, 79: 110184. |

| [23] | Liu S, Liu Y, Gu H C, et al. Experimental study of the cooling performance of γ-Al2O3/heat transfer fluid nanofluid for power batteries[J]. Journal of Energy Storage, 2023, 72: 108476. |

| [24] | Lin X W, Shi M Y, Zhou Z F, et al. Multi-objective topology optimization design of liquid-based cooling plate for 280 Ah prismatic energy storage battery thermal management[J]. Energy Conversion and Management, 2025, 325: 119440. |

| [25] | Wu C T, Yuan X L, Kong B B, et al. Innovative liquid cooling channel enhanced battery thermal management (BTM) structure based on stepwise optimization method[J]. Journal of Energy Storage, 2024, 81: 110485. |

| [26] | 李岳峰, 徐卫潘, 韦银涛, 等. 储能锂电池包浸没式液冷系统散热设计及热仿真分析[J]. 储能科学与技术, 2024, 13(10): 3534-3544. |

| Li Y F, Xu W P, Wei Y T, et al. Thermal design and simulation analysis of an immersing liquid cooling system for lithium-ions battery packs in energy storage applications[J]. Energy Storage Science and Technology, 2024, 13(10): 3534-3544. | |

| [27] | 王罗亚, 吴超, 殷文倩, 等. 适用多工况的储能电池液冷系统优化设计及分析[J]. 电源技术, 2024, 48(12): 2434-2443. |

| Wang L Y, Wu C, Yin W Q, et al. Optimization design and analysis of liquid cooling system for energy storage battery with multiple working conditions[J]. Chinese Journal of Power Sources, 2024, 48(12): 2434-2443. | |

| [28] | Xiao J S, Zhang X, Bénard P, et al. Fin structure and liquid cooling to enhance heat transfer of composite phase change materials in battery thermal management system[J]. Energy Storage, 2023, 5(6): e453. |

| [29] | Gan H L, Tian J A, Qiu H R, et al. Thermal performance of symmetrical double-spiral channel liquid cooling plate based battery thermal management for energy storage system[J]. Applied Thermal Engineering, 2025, 263: 125399. |

| [30] | Liu S J, Wang Y, Liu Q, et al. Thermal equalization design for the battery energy storage system (BESS) of a fully electric ship[J]. Energy, 2024, 312: 133611. |

| [31] | Yao F D, Guan X, Chen Q R, et al. Research on thermal management system of lithium-ion battery with a new type of spider web liquid cooling channel and phase change materials[J]. Journal of Energy Storage, 2024, 81: 110447. |

| [1] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [2] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [3] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [4] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [5] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [6] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [7] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [8] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [9] | 刘奕扬, 邢志祥, 刘烨铖, 彭明, 李玉洋, 李云浩, 沈宁舟. 加氢站液氢泄漏扩散特性与安全监测数值模拟研究[J]. 化工学报, 2025, 76(9): 4694-4708. |

| [10] | 黄正宗, 刘科成, 李泽方, 曾平生, 刘永富, 闫红杰, 刘柳. 锌精馏炉砖砌式换热室数值模拟与场协同优化[J]. 化工学报, 2025, 76(9): 4425-4439. |

| [11] | 陈昇, 李子争, 苗超, 白学刚, 李飞, 刘家璇, 李天天, 杨爽, 吕蓉蓉, 王江云. 大尺度密集场景高危氯气非均匀湍流扩散特性三维CFD模拟[J]. 化工学报, 2025, 76(9): 4630-4643. |

| [12] | 王一飞, 李玉星, 欧阳欣, 赵雪峰, 孟岚, 胡其会, 殷布泽, 郭雅琦. 基于裂尖减压特性的CO2管道断裂扩展数值计算[J]. 化工学报, 2025, 76(9): 4683-4693. |

| [13] | 贾志勇, 沈宪琨, 蓝晓程, 王铁峰. 气体密度对高压流态化影响的CFD-DEM模拟[J]. 化工学报, 2025, 76(9): 4383-4397. |

| [14] | 段炼, 周星睿, 袁文君, 陈飞. 连续相速度脉动对微通道内聚合物液滴生成和形貌的影响规律[J]. 化工学报, 2025, 76(9): 4578-4585. |

| [15] | 杨开源, 陈锡忠. 颗粒破碎的离散元及有限离散元模拟方法比较[J]. 化工学报, 2025, 76(9): 4398-4411. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号