化工学报 ›› 2025, Vol. 76 ›› Issue (9): 4563-4577.DOI: 10.11949/0438-1157.20250394

李雪雯1( ), 王治红1(

), 王治红1( ), 高阳2, 吴明鸥3, 马文皓1, 谭仁敏1

), 高阳2, 吴明鸥3, 马文皓1, 谭仁敏1

收稿日期:2025-04-15

修回日期:2025-05-13

出版日期:2025-09-25

发布日期:2025-10-23

通讯作者:

王治红

作者简介:李雪雯(2001—),女,硕士研究生,2014432795@qq.com

Xuewen LI1( ), Zhihong WANG1(

), Zhihong WANG1( ), Yang GAO2, Ming'ou WU3, Wenhao MA1, Renmin TAN1

), Yang GAO2, Ming'ou WU3, Wenhao MA1, Renmin TAN1

Received:2025-04-15

Revised:2025-05-13

Online:2025-09-25

Published:2025-10-23

Contact:

Zhihong WANG

摘要:

针对天然气净化厂脱硫再生工段现有工艺再生能耗高、塔顶余热利用率低问题,本研究提出了基于机械蒸汽再压缩(MVR)热泵蒸馏改造方案。通过构建吸收-再生模拟系统,创新设计塔顶蒸汽经MVR系统增压升温后供给再沸器热源的闭式循环架构,形成余热品位提升与热能自平衡的新型再生模式。基于能效分析与过程能耗评估,针对压缩机、换热器等建立操作参数优化模型,开发含敏感性分析、响应面法与非支配排序遗传算法(NSGA-Ⅱ)的协同优化框架,构建以节能增效、减排降本为核心的多目标体系,并采用三级递进策略提升能效。结果显示,改造后硫化氢流量波动≤0.13%,再生单元能耗降低39.86%,碳排放强度下降30.66%。该方案为天然气净化低碳改造提供了创新路径,兼具经济与环境效益。

中图分类号:

李雪雯, 王治红, 高阳, 吴明鸥, 马文皓, 谭仁敏. 基于热泵技术的醇胺法脱硫再生系统多目标优化研究[J]. 化工学报, 2025, 76(9): 4563-4577.

Xuewen LI, Zhihong WANG, Yang GAO, Ming'ou WU, Wenhao MA, Renmin TAN. Multi-objective optimization of amine-based desulfurization regeneration system integrated with heat pump technology[J]. CIESC Journal, 2025, 76(9): 4563-4577.

| 参数 | 数值 | |

|---|---|---|

| 组成 | 甲烷 | 0.8692 |

| 乙烷 | 0.0393 | |

| 丙烷 | 0.0093 | |

| 异丁烷 | 0.0026 | |

| 正丁烷 | 0.0029 | |

| 异戊烷 | 0.0014 | |

| 正戊烷 | 0.0012 | |

| 正己烷 | 0.0018 | |

| H2O | 0.0122 | |

| 氮气 | 0.0016 | |

| H2S | 0.0172 | |

| CO2 | 0.0413 | |

| 温度/℃ | 25 | |

| 压力/kPa | 600.0 | |

| 摩尔流量/(kmol/h) | 1250.0 | |

| 质量流量/(kg/h) | 23583.8 | |

| 汽相分率 | 0.9932 | |

| 质量密度/(kg/m3) | 4.6751 | |

表1 原料天然气组成与关键参数

Table 1 Composition and key parameters of feed natural gas

| 参数 | 数值 | |

|---|---|---|

| 组成 | 甲烷 | 0.8692 |

| 乙烷 | 0.0393 | |

| 丙烷 | 0.0093 | |

| 异丁烷 | 0.0026 | |

| 正丁烷 | 0.0029 | |

| 异戊烷 | 0.0014 | |

| 正戊烷 | 0.0012 | |

| 正己烷 | 0.0018 | |

| H2O | 0.0122 | |

| 氮气 | 0.0016 | |

| H2S | 0.0172 | |

| CO2 | 0.0413 | |

| 温度/℃ | 25 | |

| 压力/kPa | 600.0 | |

| 摩尔流量/(kmol/h) | 1250.0 | |

| 质量流量/(kg/h) | 23583.8 | |

| 汽相分率 | 0.9932 | |

| 质量密度/(kg/m3) | 4.6751 | |

| 序号 | 目标函数 | 原始值 |

|---|---|---|

| 1 | 再生塔顶H2S质量流量Qm1/(kg/d) | 17505.7 |

| 2 | 流股换热器基本面积A/m2 | — |

| 3 | 碳排放水平(折合CO2质量流量)Qm2/(kg/d) | 17715.0 |

表2 目标函数及原始值

Table 2 Objective functions and baseline values

| 序号 | 目标函数 | 原始值 |

|---|---|---|

| 1 | 再生塔顶H2S质量流量Qm1/(kg/d) | 17505.7 |

| 2 | 流股换热器基本面积A/m2 | — |

| 3 | 碳排放水平(折合CO2质量流量)Qm2/(kg/d) | 17715.0 |

| 序号 | 决策变量 | 决策范围 |

|---|---|---|

| 1 | 再生塔进料温度Tin/℃ | 85~95 |

| 2 | 再生塔塔板数NDC | 18~22 |

| 3 | 再生塔进料位置FDC | -2~+2 |

表3 决策变量及范围

Table 3 Decision variables and ranges

| 序号 | 决策变量 | 决策范围 |

|---|---|---|

| 1 | 再生塔进料温度Tin/℃ | 85~95 |

| 2 | 再生塔塔板数NDC | 18~22 |

| 3 | 再生塔进料位置FDC | -2~+2 |

| 因素水平 | 决策变量 | ||

|---|---|---|---|

| Tin/℃ | NDC | FDC | |

| -1 | 85 | 18 | -2 |

| 0 | 90 | 20 | 0 |

| 1 | 95 | 22 | 2 |

表4 三因素水平

Table 4 Three-factor levels

| 因素水平 | 决策变量 | ||

|---|---|---|---|

| Tin/℃ | NDC | FDC | |

| -1 | 85 | 18 | -2 |

| 0 | 90 | 20 | 0 |

| 1 | 95 | 22 | 2 |

| 项目 | Qm1/(kg/d) | A/m2 | Qm2/(kg/d) | |||

|---|---|---|---|---|---|---|

| R2= 0.9768 | R2= 0.9983 | R2= 0.9997 | ||||

| F值 | p值 | F值 | p值 | F值 | p值 | |

| 模型 | 32.81 | <0.0001 | 459.19 | <0.0001 | 2248.33 | <0.0001 |

| a | 0.03 | 0.87 | 3485.95 | <0.0001 | 18964.47 | <0.0001 |

| b | 43.04 | 0.0003 | 41.39 | 0.0004 | 2.99 | 0.13 |

| c | 191.62 | <0.0001 | 135.84 | <0.0001 | 6.97 | 0.03 |

| ab | 0.04 | 0.85 | 0.16 | 0.70 | 4.65 | 0.07 |

| ac | 0.0002 | 0.99 | 0.69 | 0.43 | 11.83 | 0.01 |

| bc | 20.08 | 0.0030 | 5.03 | 0.06 | 1.50 | 0.26 |

| a2 | 0.14 | 0.72 | 451.12 | <0.0001 | 1230.85 | <0.0001 |

| b2 | 6.73 | 0.04 | 0.25 | 0.63 | 0.32 | 0.59 |

| c2 | 31.41 | 0.0008 | 3.70 | 0.10 | 0.19 | 0.67 |

| 差异性 | 0.3800 | 0.7800 | 70.9800 | 0.0006 | 34.6600 | 0.0030 |

表5 回归模型的ANOVA摘要

Table 5 Summary of analysis of variance (ANOVA) for the regression models

| 项目 | Qm1/(kg/d) | A/m2 | Qm2/(kg/d) | |||

|---|---|---|---|---|---|---|

| R2= 0.9768 | R2= 0.9983 | R2= 0.9997 | ||||

| F值 | p值 | F值 | p值 | F值 | p值 | |

| 模型 | 32.81 | <0.0001 | 459.19 | <0.0001 | 2248.33 | <0.0001 |

| a | 0.03 | 0.87 | 3485.95 | <0.0001 | 18964.47 | <0.0001 |

| b | 43.04 | 0.0003 | 41.39 | 0.0004 | 2.99 | 0.13 |

| c | 191.62 | <0.0001 | 135.84 | <0.0001 | 6.97 | 0.03 |

| ab | 0.04 | 0.85 | 0.16 | 0.70 | 4.65 | 0.07 |

| ac | 0.0002 | 0.99 | 0.69 | 0.43 | 11.83 | 0.01 |

| bc | 20.08 | 0.0030 | 5.03 | 0.06 | 1.50 | 0.26 |

| a2 | 0.14 | 0.72 | 451.12 | <0.0001 | 1230.85 | <0.0001 |

| b2 | 6.73 | 0.04 | 0.25 | 0.63 | 0.32 | 0.59 |

| c2 | 31.41 | 0.0008 | 3.70 | 0.10 | 0.19 | 0.67 |

| 差异性 | 0.3800 | 0.7800 | 70.9800 | 0.0006 | 34.6600 | 0.0030 |

| 参数 | 数值 |

|---|---|

| 种群大小 | 100 |

| 代数 | 200 |

| 停滞代数限制 | 200 |

| 函数容忍度 | 10-100 |

| 交叉比例 | 0.9 |

| 迁移比例 | 0.03 |

表6 gamultiobj的参数设置

Table 6 The parameter configuration for gamultiobj

| 参数 | 数值 |

|---|---|

| 种群大小 | 100 |

| 代数 | 200 |

| 停滞代数限制 | 200 |

| 函数容忍度 | 10-100 |

| 交叉比例 | 0.9 |

| 迁移比例 | 0.03 |

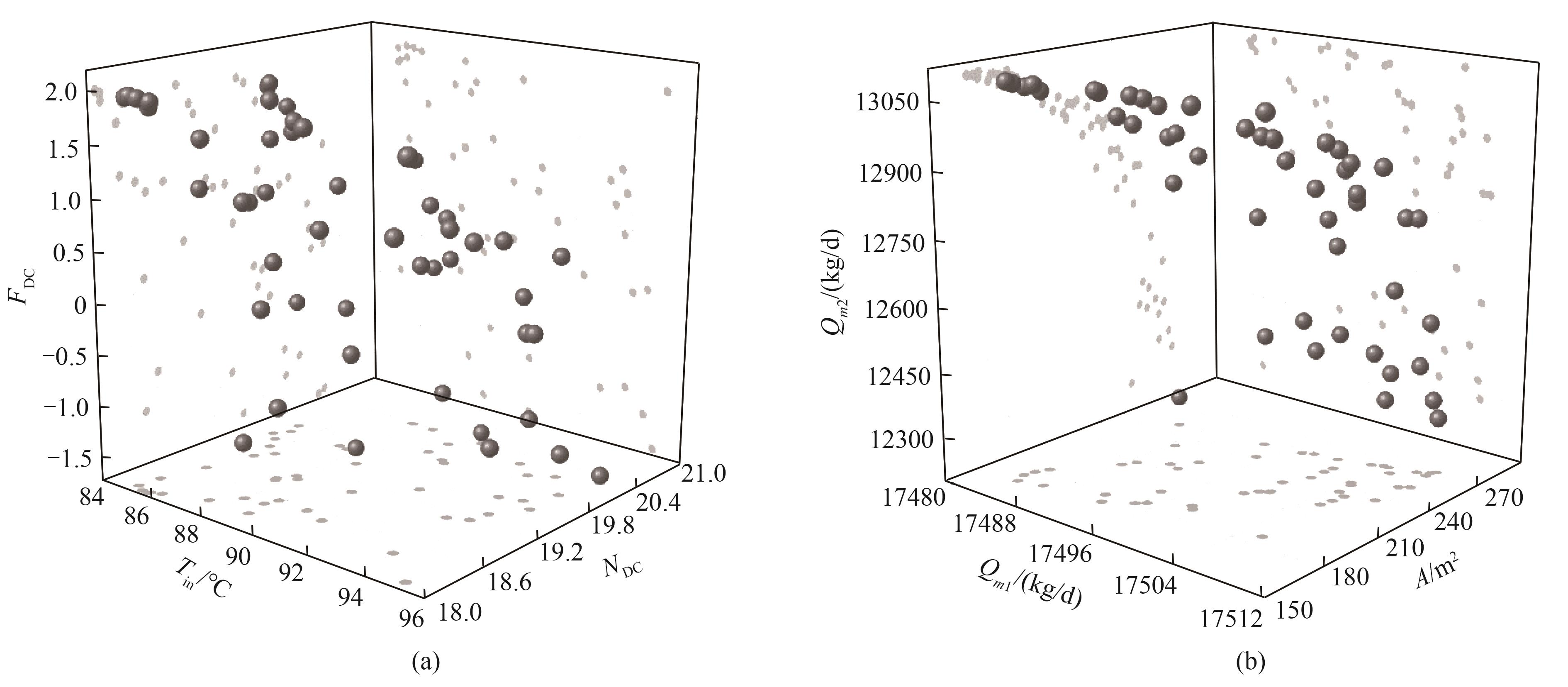

图13 (a)Pareto最优解决策变量的分布;(b)Pareto最优解的分布

Fig.13 (a) Distribution of decision variables for Pareto optimal solutions; (b) Distribution of Pareto optimal solutions

| 方案序号 | Qm1/(kg/d) | A/m2 | Qm2/(kg/d) | 平均误差/% | |||

|---|---|---|---|---|---|---|---|

| 预测值 | 实际值 | 预测值 | 实际值 | 预测值 | 实际值 | ||

| 1 | 17488.6 | 17493.7 | 200.9 | 194.3 | 12828.2 | 12939.7 | 1.43 |

| 2 | 17507.1 | 17506.8 | 238.2 | 236.2 | 12452.2 | 12436.3 | 0.33 |

| 3 | 17505.7 | 17493.2 | 202.5 | 207.5 | 12941.6 | 12751.3 | 1.32 |

| 4 | 17485.5 | 17483.6 | 218.9 | 219.6 | 12271.2 | 12282.8 | 0.14 |

| 5 | 17494.4 | 17500.2 | 150.2 | 152.8 | 13088.3 | 13091.7 | 0.59 |

表7 随机组平均误差分析

Table 7 Random group average error analysis

| 方案序号 | Qm1/(kg/d) | A/m2 | Qm2/(kg/d) | 平均误差/% | |||

|---|---|---|---|---|---|---|---|

| 预测值 | 实际值 | 预测值 | 实际值 | 预测值 | 实际值 | ||

| 1 | 17488.6 | 17493.7 | 200.9 | 194.3 | 12828.2 | 12939.7 | 1.43 |

| 2 | 17507.1 | 17506.8 | 238.2 | 236.2 | 12452.2 | 12436.3 | 0.33 |

| 3 | 17505.7 | 17493.2 | 202.5 | 207.5 | 12941.6 | 12751.3 | 1.32 |

| 4 | 17485.5 | 17483.6 | 218.9 | 219.6 | 12271.2 | 12282.8 | 0.14 |

| 5 | 17494.4 | 17500.2 | 150.2 | 152.8 | 13088.3 | 13091.7 | 0.59 |

| 项目 | 节约效益/(×104 CNY/a) | 新增成本/(×104 CNY) | 静态投资回收期/a | ||||

|---|---|---|---|---|---|---|---|

| 电费 | 热泵压缩机 | 流股换热器 | 设备安装费 | 合计 | |||

| 数值 | 54.6 | 86.7 | 22.3 | 32.9 | 14.3 | 156.2 | 3 |

表8 经济效益分析

Table 8 Economic benefit analysis

| 项目 | 节约效益/(×104 CNY/a) | 新增成本/(×104 CNY) | 静态投资回收期/a | ||||

|---|---|---|---|---|---|---|---|

| 电费 | 热泵压缩机 | 流股换热器 | 设备安装费 | 合计 | |||

| 数值 | 54.6 | 86.7 | 22.3 | 32.9 | 14.3 | 156.2 | 3 |

| [1] | Zheng W, Yang W L, Chen J F, et al. H2S induced in situ formation of recyclable metal sulfide-based sorbent for elemental mercury sequestration in natural gas[J]. Chemical Engineering Journal, 2024, 497: 154699. |

| [2] | Silva A M A, Britto de Faria A C, de Lima Ribeiro C, et al. Review of zeolite membranes for natural gas processing and treatment: state of the art and future perspectives[J]. Gas Science and Engineering, 2023, 117: 205056. |

| [3] | Zhao X, Ma X W, Chen B Y, et al. Challenges toward carbon neutrality in China: strategies and countermeasures[J]. Resources, Conservation and Recycling, 2022, 176: 105959. |

| [4] | Abdallah L, El-Shennawy T. Reducing carbon dioxide emissions from electricity sector using smart electric grid applications[J]. Journal of Engineering, 2013, 2013(1): 845051. |

| [5] | Bayoumy S H, El-Marsafy S M, Ahmed T S. Optimization of a saturated gas plant: meticulous simulation-based optimization—A case study[J]. Journal of Advanced Research, 2020, 22: 21-33. |

| [6] | Adib H, Kazerooni N, Falsafi A, et al. Prediction of sulfur content in propane and butane after gas purification on a treatment unit[J]. Oil & Gas Science and Technology, 2018, 73: 70. |

| [7] | Chew Y E, Putra Z A, Foo D C Y. Process simulation and optimisation for acid gas removal system in natural gas processing[J]. Journal of Natural Gas Science and Engineering, 2022, 107: 104764. |

| [8] | Cui X P, Lv W D, Ye H T, et al. Development of a selective sequential process for H2S enrichment and CO2 capture in aqueous MDEA solutions[J]. Journal of Cleaner Production, 2024, 478: 143858. |

| [9] | Moioli S, Giuffrida A, Romano M C, et al. Assessment of MDEA absorption process for sequential H2S removal and CO2 capture in air-blown IGCC plants[J]. Applied Energy, 2016, 183: 1452-1470. |

| [10] | Moioli S, Pellegrini L A, Romano M C, et al. Pre-combustion CO2 removal in IGCC plant by MDEA scrubbing: modifications to the process flowsheet for energy saving[J]. Energy Procedia, 2017, 114: 2136-2145. |

| [11] | Dara S, AlHammadi A A, Berrouk A S, et al. Carbon footprint reduction of acid gas enrichment units in hot climates: a techno-economic simulation study[J]. Journal of Cleaner Production, 2018, 201: 974-987. |

| [12] | Dai Y Y, Peng Y W, Qiu Y, et al. Techno-economic analysis of a novel two-stage flashing process for acid gas removal from natural gas[J]. Energies, 2019, 12(21): 4213. |

| [13] | Al-Amri A, Zahid U. Design modification of acid gas cleaning units for an enhanced performance in natural gas processing[J]. Energy & Fuels, 2020, 34(2): 2545-2552. |

| [14] | Liu G H, Zhu L, Cao W H, et al. New technique integrating hydrate-based gas separation and chemical absorption for the sweetening of natural gas with high H2S and CO2 contents[J]. ACS Omega, 2021, 6(40): 26180-26190. |

| [15] | Tang W T, Chien C K, Ward J D. A review of energy intensification strategies for distillation processes: cyclic operation, stacking, heat pumps, side-streams, dividing walls and beyond[J]. Separation and Purification Technology, 2025, 357: 130030. |

| [16] | Felbab N, Patel B, El-Halwagi M M, et al. Vapor recompression for efficient distillation(1): A new synthesis perspective on standard configurations[J]. AIChE Journal, 2013, 59(8): 2977-2992. |

| [17] | Kishimoto A, Kansha Y, Fushimi C, et al. Exergy recuperative CO2 gas separation in post-combustion capture[J]. Industrial & Engineering Chemistry Research, 2011, 50(17): 10128-10135. |

| [18] | Zhang K F, Liu Z L, Wang Y Y, et al. Flash evaporation and thermal vapor compression aided energy saving CO2 capture systems in coal-fired power plant[J]. Energy, 2014, 66: 556-568. |

| [19] | Waheed M A, Oni A O, Adejuyigbe S B, et al. Performance enhancement of vapor recompression heat pump[J]. Applied Energy, 2014, 114: 69-79. |

| [20] | Shakerian F, Kim K H, Szulejko J E, et al. A comparative review between amines and ammonia as sorptive media for post-combustion CO2 capture[J]. Applied Energy, 2015, 148: 10-22. |

| [21] | Oh S Y, Binns M, Cho H, et al. Energy minimization of MEA-based CO2 capture process[J]. Applied Energy, 2016, 169: 353-362. |

| [22] | Song C F, Liu Q L, Ji N, et al. Reducing the energy consumption of membrane-cryogenic hybrid CO2 capture by process optimization[J]. Energy, 2017, 124: 29-39. |

| [23] | Jang G G, Jung G S, Aye Meyer P, et al. Effective direct steam regeneration of bis-iminoguanidine solid sorbent used for carbon dioxide capture[J]. Chemical Engineering Journal, 2024, 495: 153469. |

| [24] | Mantingh J, Kiss A A. Enhanced process for energy efficient extraction of 1,3-butadiene from a crude C4 cut[J]. Separation and Purification Technology, 2021, 267: 118656. |

| [25] | Christopher C C E, Dutta A, Farooq S, et al. Process synthesis and optimization of propylene/propane separation using vapor recompression and self-heat recuperation[J]. Industrial & Engineering Chemistry Research, 2017, 56(49): 14557-14564. |

| [26] | Sajid M, Nazal M K, Ihsanullah, et al. Removal of heavy metals and organic pollutants from water using dendritic polymers based adsorbents: a critical review[J]. Separation and Purification Technology, 2018, 191: 400-423. |

| [27] | Witek-Krowiak A, Chojnacka K, Podstawczyk D, et al. Application of response surface methodology and artificial neural network methods in modelling and optimization of biosorption process[J]. Bioresource Technology, 2014, 160: 150-160. |

| [28] | Bowden G D, Pichler B J, Maurer A. A design of experiments (DoE) approach accelerates the optimization of copper-mediated 18F-fluorination reactions of arylstannanes[J]. Scientific Reports, 2019, 9: 11370. |

| [29] | Lu H N, Dong Q, Yan S, et al. Development of flexible grouting material for cement-stabilized macadam base using response surface and genetic algorithm optimization methodologies[J]. Construction and Building Materials, 2023, 409: 133823. |

| [30] | Ferreira S L C, Bruns R E, Ferreira H S, et al. Box-Behnken design: an alternative for the optimization of analytical methods[J]. Analytica Chimica Acta, 2007, 597(2): 179-186. |

| [31] | Emmerich M, Giotis A, Özdemir M, et al. Metamodel: assisted evolution strategies[M]//Parallel Problem Solving from Nature— PPSN Ⅶ. Berlin, Heidelberg: Springer Berlin Heidelberg, 2002: 361-370. |

| [32] | Hao Y Y, Zhao C L, Zhang Y Q, et al. Constrained multi-objective optimization problems: methodologies, algorithms and applications[J]. Knowledge-Based Systems, 2024, 299: 111998. |

| [33] | Wang T, Feng J C. Multi-objective joint optimization for concurrent execution of design-construction tasks in design-build mode[J]. Automation in Construction, 2023, 156: 105078. |

| [34] | Zhai C H, Wang J J, Tu Y L, et al. Robust optimization of 3D printing process parameters considering process stability and production efficiency[J]. Additive Manufacturing, 2023, 71: 103588. |

| [1] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [2] | 郭纪超, 徐肖肖, 孙云龙. 基于植物工厂中的CO2浓度气流模拟及优化研究[J]. 化工学报, 2025, 76(S1): 237-245. |

| [3] | 石一帆, 柯钢, 陈浩, 黄孝胜, 叶芳, 李成娇, 郭航. 大型高低温环境实验室温度控制仿真[J]. 化工学报, 2025, 76(S1): 268-280. |

| [4] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [5] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [6] | 马爱华, 赵帅, 王林, 常明慧. 太阳能吸收制冷循环动态特性仿真方法研究[J]. 化工学报, 2025, 76(S1): 318-325. |

| [7] | 黄琮琪, 邵双全. 液冷数据中心余热驱动的压缩-吸收式制冷系统特性研究[J]. 化工学报, 2025, 76(S1): 326-335. |

| [8] | 何婷, 张开, 林文胜, 陈利琼, 陈家富. 沼气超临界压力低温脱碳-液化耦合流程研究[J]. 化工学报, 2025, 76(S1): 418-425. |

| [9] | 沙鑫权, 胡然, 丁磊, 蒋珍华, 吴亦农. 空间用单机两级有阀线性压缩机研制及测试[J]. 化工学报, 2025, 76(S1): 114-122. |

| [10] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [11] | 蒋智洪, 雷骞, 朱引军, 雷志刚, 陈洪林. 三聚甲醛体系物性模型和提浓工艺研究[J]. 化工学报, 2025, 76(9): 4872-4881. |

| [12] | 刘璐, 王文玥, 王腾, 王太, 董新宇, 汤建成, 王少恒. 基于双混合工质深冷的氢液化工艺优化与分析[J]. 化工学报, 2025, 76(9): 4933-4943. |

| [13] | 田鹏, 张忠林, 任超, 孟国超, 郝晓刚, 刘叶刚, 侯起旺, ABUDULA Abuliti, 官国清. 基于自热再生的一种低温甲醇洗工艺建模与优化[J]. 化工学报, 2025, 76(9): 4601-4612. |

| [14] | 郭旭, 贾继宁, 姚克俭. 基于优化CNN-BiLSTM神经网络的间歇精馏过程建模[J]. 化工学报, 2025, 76(9): 4613-4629. |

| [15] | 王杰, 林渠成, 张先明. 基于分解算法的混合气体多级膜分离系统全局优化[J]. 化工学报, 2025, 76(9): 4670-4682. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号