化工学报 ›› 2025, Vol. 76 ›› Issue (11): 5739-5752.DOI: 10.11949/0438-1157.20250465

• 专栏:能源利用过程中的多相流与传热 • 上一篇

刘雨晗1( ), 王创创1, 鲜麟2, 赵凯1, 种道彤1, 赵全斌1(

), 王创创1, 鲜麟2, 赵凯1, 种道彤1, 赵全斌1( )

)

收稿日期:2025-04-30

修回日期:2025-06-26

出版日期:2025-11-25

发布日期:2025-12-19

通讯作者:

赵全斌

作者简介:刘雨晗(1998—),女,博士研究生,liu_yuhan@stu.xjtu.edu.cn

基金资助:

Yuhan LIU1( ), Chuangchuang WANG1, Lin XIAN2, Kai ZHAO1, Daotong CHONG1, Quanbin ZHAO1(

), Chuangchuang WANG1, Lin XIAN2, Kai ZHAO1, Daotong CHONG1, Quanbin ZHAO1( )

)

Received:2025-04-30

Revised:2025-06-26

Online:2025-11-25

Published:2025-12-19

Contact:

Quanbin ZHAO

摘要:

小型反应堆的灵活稳定调控对于其安全运行具有重要意义,其中直流蒸汽发生器二次侧进出口阀门开度调节是二回路系统调控的重要途径之一,对阀门扰动引起的套管式蒸汽发生器动态特性进行研究对于优化阀门调控策略具有重要意义。基于vPower系统动态仿真平台搭建了一、二回路耦合换热的小型反应堆二回路动态模型,研究了套管式直流蒸汽发生器二次侧在入口与出口阀门阶跃扰动工况下主蒸汽参数及轴向参数的动态响应特性及机制。研究结果表明:入口阀门扰动对主蒸汽参数的影响显著大于出口阀门,在±10%、±15%和±20%开度扰动范围内,入口阀门对主蒸汽流量、压力、温度的影响幅度分别为出口阀门的2.09~14.09倍、1.78~6.67倍、-1.67~-14.38倍;同时,发现了蒸汽发生器内部两相流及蒸汽区对流量和压力的明显缓冲作用,进出口阀门在阶跃扰动时由于压力和流量响应速度不同导致超调,而OTSG的缓冲作用导致该超调仅发生在阀门附近;此外,进出口阀门扰动下,各设备局部压降占比及蒸汽发生器内部焓升速率的变化规律不同,导致入口阀门和出口阀门扰动对蒸汽发生器内部压力和主蒸汽温度的影响规律呈现相反趋势。研究成果对于蒸汽发生器二回路运行调控策略具有重要指导意义。

中图分类号:

刘雨晗, 王创创, 鲜麟, 赵凯, 种道彤, 赵全斌. 套管式直流蒸汽发生器二次侧阀门扰动下的动态特性研究[J]. 化工学报, 2025, 76(11): 5739-5752.

Yuhan LIU, Chuangchuang WANG, Lin XIAN, Kai ZHAO, Daotong CHONG, Quanbin ZHAO. Dynamic response characteristics of once-through steam generator secondary side under valve disturbances[J]. CIESC Journal, 2025, 76(11): 5739-5752.

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 管束数量/根 | 665 | 一次侧冷却剂流量/(kg·s-1) | 126.2 |

| 换热段有效长度/m | 2.15 | 冷却剂入口温度/℃ | 319.5 |

| 外管外径/mm | 13 | 冷却剂出口温度/℃ | 286.5 |

| 外管内径/mm | 10 | 一次侧压力/MPa | 15.0 |

| 内管外径/mm | 8 | 给水流量/(kg·s-1) | 10.3 |

| 内管内径/mm | 6 | 给水温度/℃ | 140.0 |

| 管束排列节距/mm | 13.8 | 蒸汽温度/℃ | 285.0 |

| 总换热功率/MW | 24.1 | 蒸汽压力/MPa | 4.01 |

表1 单台套管式直流蒸汽发生器设计参数

Table 1 Design parameters of the casing OTSG

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 管束数量/根 | 665 | 一次侧冷却剂流量/(kg·s-1) | 126.2 |

| 换热段有效长度/m | 2.15 | 冷却剂入口温度/℃ | 319.5 |

| 外管外径/mm | 13 | 冷却剂出口温度/℃ | 286.5 |

| 外管内径/mm | 10 | 一次侧压力/MPa | 15.0 |

| 内管外径/mm | 8 | 给水流量/(kg·s-1) | 10.3 |

| 内管内径/mm | 6 | 给水温度/℃ | 140.0 |

| 管束排列节距/mm | 13.8 | 蒸汽温度/℃ | 285.0 |

| 总换热功率/MW | 24.1 | 蒸汽压力/MPa | 4.01 |

| 区域 | 起始判据 | 传热系数计算关联式 |

|---|---|---|

| 预热区 | — | |

| 过冷沸腾区 | ||

| 饱和沸腾区 | ||

| 缺液区 | ||

| 过热区 |

表2 二次侧流动区域分区判据及传热系数计算关联式

Table 2 Boundary criterion of flow region and heat transfer coefficient correlation of the secondary side

| 区域 | 起始判据 | 传热系数计算关联式 |

|---|---|---|

| 预热区 | — | |

| 过冷沸腾区 | ||

| 饱和沸腾区 | ||

| 缺液区 | ||

| 过热区 |

| 二回路系统参数 | 设计值 | 计算值 | 误差 |

|---|---|---|---|

| 主汽压/MPa | 4.01 | 4.01 | 0.00% |

| 主汽温/℃ | 288.00 | 288.06 | 0.02% |

| 给水流量/(kg∙s-1) | 165.77 | 166.52 | 0.45% |

| 给水温度/℃ | 139.90 | 138.99 | 0.65% |

| 热功率/MW | 385.30 | 388.12 | 0.73% |

| 汽机功率/MW | 127.52 | 126.64 | 0.69% |

表3 二回路热力系统计算误差

Table 3 Simulation error of the secondary loop thermodynamic system

| 二回路系统参数 | 设计值 | 计算值 | 误差 |

|---|---|---|---|

| 主汽压/MPa | 4.01 | 4.01 | 0.00% |

| 主汽温/℃ | 288.00 | 288.06 | 0.02% |

| 给水流量/(kg∙s-1) | 165.77 | 166.52 | 0.45% |

| 给水温度/℃ | 139.90 | 138.99 | 0.65% |

| 热功率/MW | 385.30 | 388.12 | 0.73% |

| 汽机功率/MW | 127.52 | 126.64 | 0.69% |

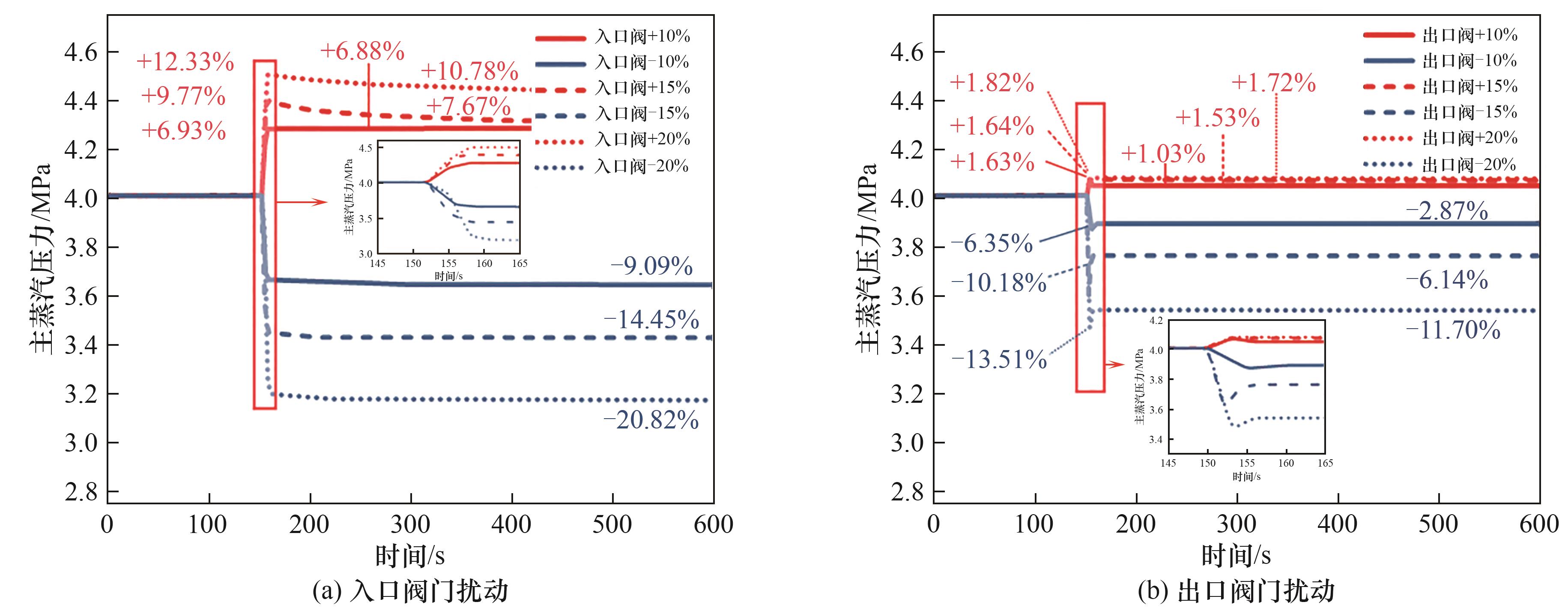

图6 入口及出口阀门阶跃扰动±10%、±15%和±20%下主蒸汽压力动态变化特性

Fig.6 Dynamic characteristics of main steam pressure under ±10%, ±15%, ±20% step disturbance of inlet and outlet valves

| 阀门扰动 | 流量 | 压力 | 温度 |

|---|---|---|---|

| 入口阀+10% | +0.12% | +0.04% | 0 |

| 入口阀+15% | +0.03% | +1.97% | -0.05% |

| 入口阀+20% | +0.04% | +1.42% | -0.07% |

| 入口阀-10% | -0.11% | -0.01% | +0.01% |

| 入口阀-15% | -0.25% | -0.03% | 0 |

| 入口阀-20% | -0.22% | -0.09% | +0.01% |

| 出口阀+10% | +0.80% | +0.59% | +0.03% |

| 出口阀+15% | +0.61% | +0.12% | +0.04% |

| 出口阀+20% | +0.62% | +0.11% | +0.04% |

| 出口阀-10% | -0.84% | -0.53% | -0.10% |

| 出口阀-15% | -5.51% | -4.31% | -0.03% |

| 出口阀-20% | -2.76% | -2.05% | -0.06% |

表4 入口阀门及出口阀门扰动±10%、±15%和±20%时主蒸汽流量、压力及温度超调量

Table 4 The overshoot of the main steam mass flow rate, pressure and temperature under the inlet valve and outlet valve disturbance by ±10%, ±15% and ±20%

| 阀门扰动 | 流量 | 压力 | 温度 |

|---|---|---|---|

| 入口阀+10% | +0.12% | +0.04% | 0 |

| 入口阀+15% | +0.03% | +1.97% | -0.05% |

| 入口阀+20% | +0.04% | +1.42% | -0.07% |

| 入口阀-10% | -0.11% | -0.01% | +0.01% |

| 入口阀-15% | -0.25% | -0.03% | 0 |

| 入口阀-20% | -0.22% | -0.09% | +0.01% |

| 出口阀+10% | +0.80% | +0.59% | +0.03% |

| 出口阀+15% | +0.61% | +0.12% | +0.04% |

| 出口阀+20% | +0.62% | +0.11% | +0.04% |

| 出口阀-10% | -0.84% | -0.53% | -0.10% |

| 出口阀-15% | -5.51% | -4.31% | -0.03% |

| 出口阀-20% | -2.76% | -2.05% | -0.06% |

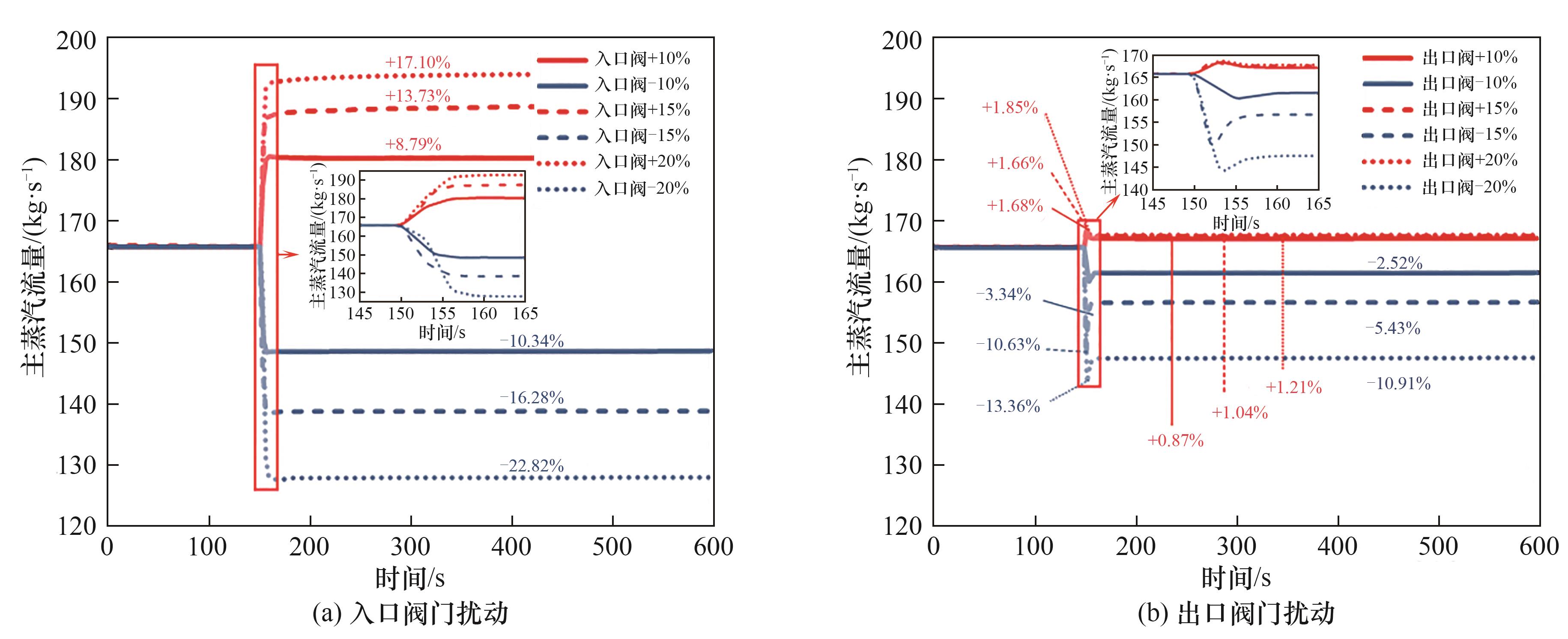

图7 入口及出口阀门阶跃扰动±10%、±15%和±20%下主蒸汽流量动态变化特性

Fig.7 Dynamic characteristics of main steam mass flow rate under ±10%, ±15%, ±20% step disturbance of inlet and outlet valves

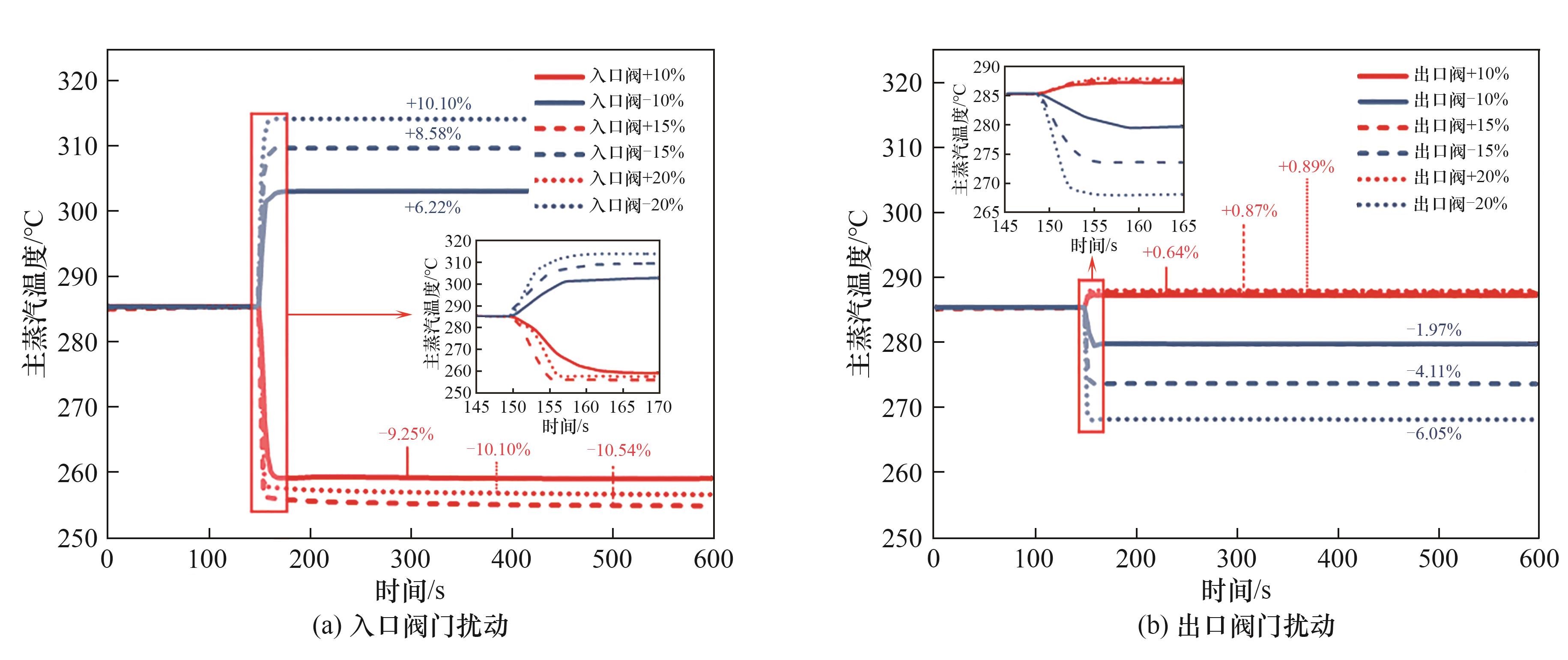

图8 入口及出口阀门阶跃扰动±10%、±15%和±20%下主蒸汽温度动态变化特性

Fig.8 Dynamic characteristics of main steam temperature under ±10%, ±15%, ±20% step disturbance of inlet and outlet valves

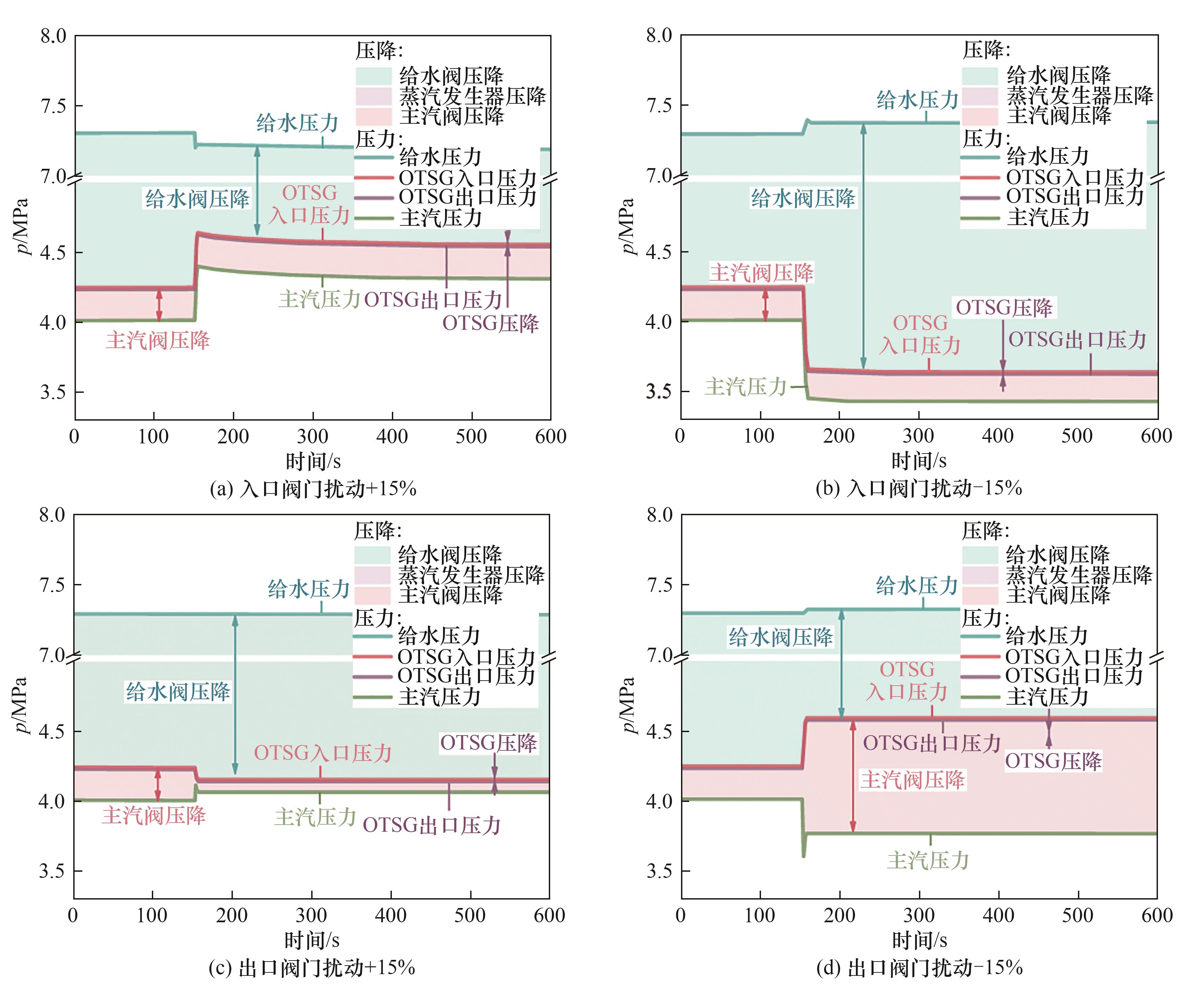

图9 入口及出口阀门阶跃扰动±15%时二次侧阻力特性

Fig.9 Dynamic characteristics of pressure drop of secondary loop under ±15% step disturbance of the inlet and outlet valves

| 工况 | 总压降/MPa | 入口给水阀压降/MPa | 入口给水阀压降占比/% | OTSG 压降/MPa | OTSG压降占比/% | 出口主汽阀压降/MPa | 出口主汽阀压降占比/% |

|---|---|---|---|---|---|---|---|

| 初始工况 | 3.27 | 3.04 | 92.86 | 16.65×10-3 | 0.51 | 0.22 | 6.63 |

| 入口阀+10% | 2.95 | 2.71 | 91.96 | 16.46×10-3 | 0.56 | 0.22 | 7.42 |

| 入口阀+15% | 2.87 | 2.62 | 91.39 | 17.29×10-3 | 0.60 | 0.23 | 8.01 |

| 入口阀+20% | 2.75 | 2.51 | 91.13 | 17.17×10-3 | 0.62 | 0.23 | 8.19 |

| 入口阀-10% | 3.69 | 3.46 | 93.92 | 15.71×10-3 | 0.43 | 0.21 | 5.61 |

| 入口阀-15% | 3.94 | 3.73 | 94.64 | 15.75×10-3 | 0.40 | 0.20 | 4.96 |

| 入口阀-20% | 4.22 | 4.02 | 95.27 | 14.72×10-3 | 0.35 | 0.18 | 4.35 |

| 出口阀+10% | 3.24 | 3.10 | 95.69 | 16.43×10-3 | 0.51 | 0.12 | 3.76 |

| 出口阀+15% | 3.22 | 3.11 | 96.38 | 16.82×10-3 | 0.52 | 0.10 | 3.09 |

| 出口阀+20% | 3.22 | 3.12 | 96.85 | 16.53×10-3 | 0.51 | 0.08 | 2.58 |

| 出口阀-10% | 3.41 | 2.90 | 84.87 | 15.52×10-3 | 0.45 | 0.50 | 14.63 |

| 出口阀-15% | 3.56 | 2.73 | 76.68 | 15.41×10-3 | 0.43 | 0.81 | 22.88 |

| 出口阀-20% | 3.81 | 2.42 | 63.48 | 13.68×10-3 | 0.36 | 1.38 | 36.12 |

表5 入口及出口扰动为±10%、±15%和±20%时入口阀、OTSG及出口阀压降

Table 5 Pressure drop of inlet valve, OTSG, and outlet valve under the ±10%, ±15%, ±20% disturbance of inlet and outlet valves

| 工况 | 总压降/MPa | 入口给水阀压降/MPa | 入口给水阀压降占比/% | OTSG 压降/MPa | OTSG压降占比/% | 出口主汽阀压降/MPa | 出口主汽阀压降占比/% |

|---|---|---|---|---|---|---|---|

| 初始工况 | 3.27 | 3.04 | 92.86 | 16.65×10-3 | 0.51 | 0.22 | 6.63 |

| 入口阀+10% | 2.95 | 2.71 | 91.96 | 16.46×10-3 | 0.56 | 0.22 | 7.42 |

| 入口阀+15% | 2.87 | 2.62 | 91.39 | 17.29×10-3 | 0.60 | 0.23 | 8.01 |

| 入口阀+20% | 2.75 | 2.51 | 91.13 | 17.17×10-3 | 0.62 | 0.23 | 8.19 |

| 入口阀-10% | 3.69 | 3.46 | 93.92 | 15.71×10-3 | 0.43 | 0.21 | 5.61 |

| 入口阀-15% | 3.94 | 3.73 | 94.64 | 15.75×10-3 | 0.40 | 0.20 | 4.96 |

| 入口阀-20% | 4.22 | 4.02 | 95.27 | 14.72×10-3 | 0.35 | 0.18 | 4.35 |

| 出口阀+10% | 3.24 | 3.10 | 95.69 | 16.43×10-3 | 0.51 | 0.12 | 3.76 |

| 出口阀+15% | 3.22 | 3.11 | 96.38 | 16.82×10-3 | 0.52 | 0.10 | 3.09 |

| 出口阀+20% | 3.22 | 3.12 | 96.85 | 16.53×10-3 | 0.51 | 0.08 | 2.58 |

| 出口阀-10% | 3.41 | 2.90 | 84.87 | 15.52×10-3 | 0.45 | 0.50 | 14.63 |

| 出口阀-15% | 3.56 | 2.73 | 76.68 | 15.41×10-3 | 0.43 | 0.81 | 22.88 |

| 出口阀-20% | 3.81 | 2.42 | 63.48 | 13.68×10-3 | 0.36 | 1.38 | 36.12 |

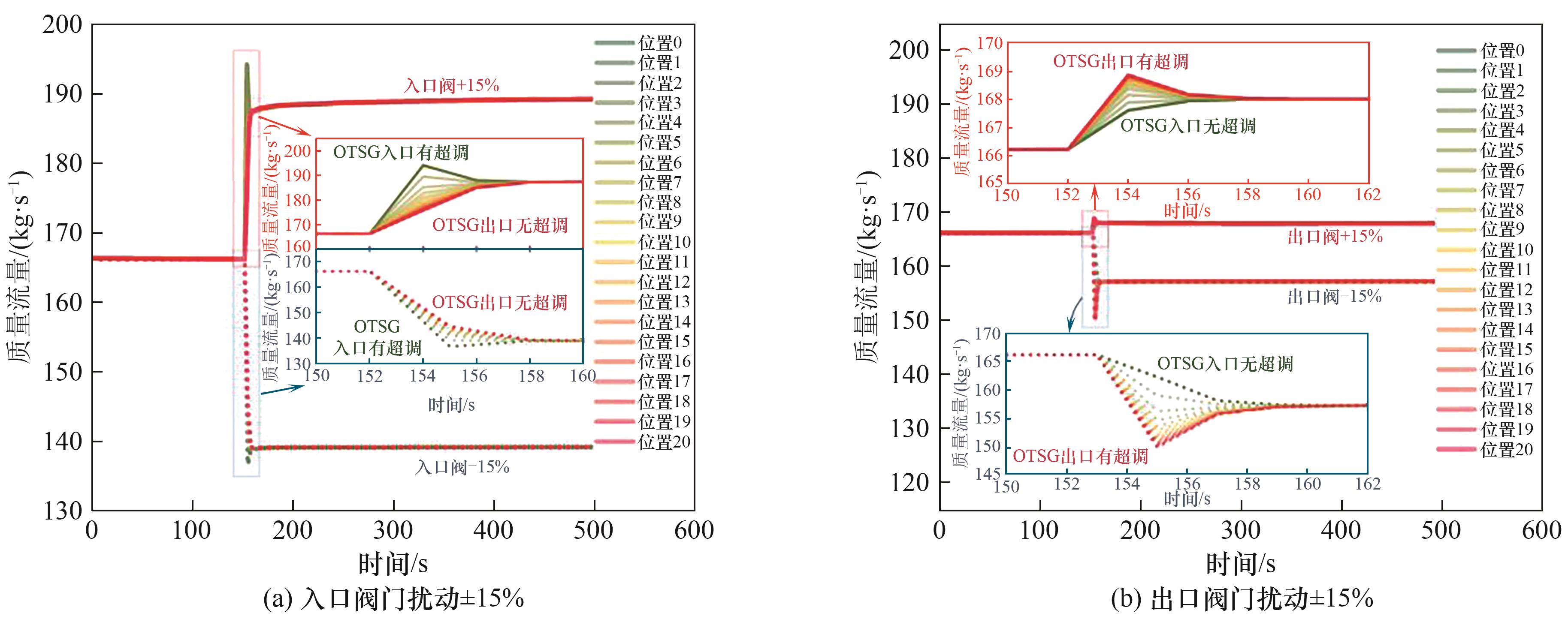

图10 入口及出口阀门阶跃扰动±15%时二次侧不同节点位置质量流量的动态特性

Fig.10 Dynamic characteristics of local mass flow rate of OTSG under ±15% step disturbance of the inlet and outlet valves

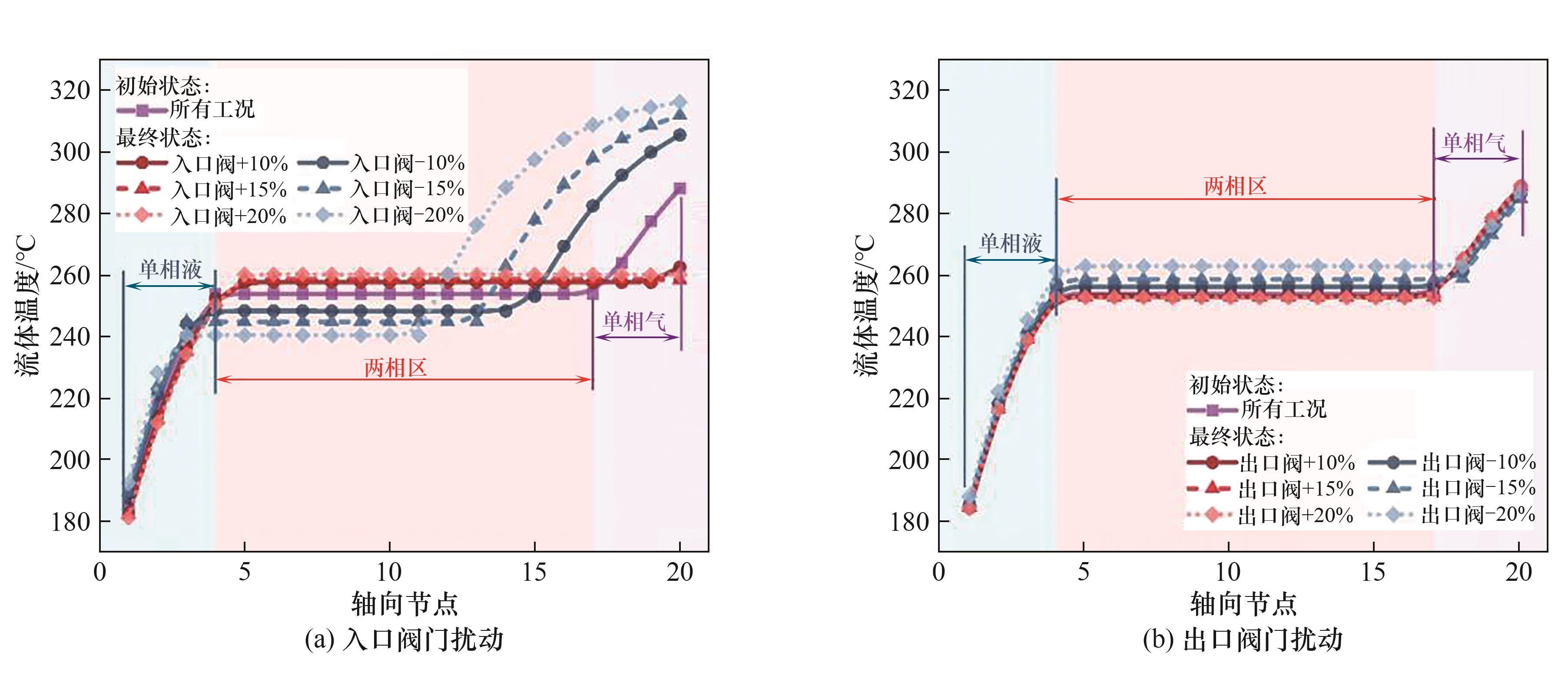

图11 入口及出口阀门阶跃扰动时二次侧轴向流体温度稳态及动态特性

Fig.11 Dynamic and statistic characteristics of local fluid temperature of OTSG under step disturbance of the inlet and outlet valves

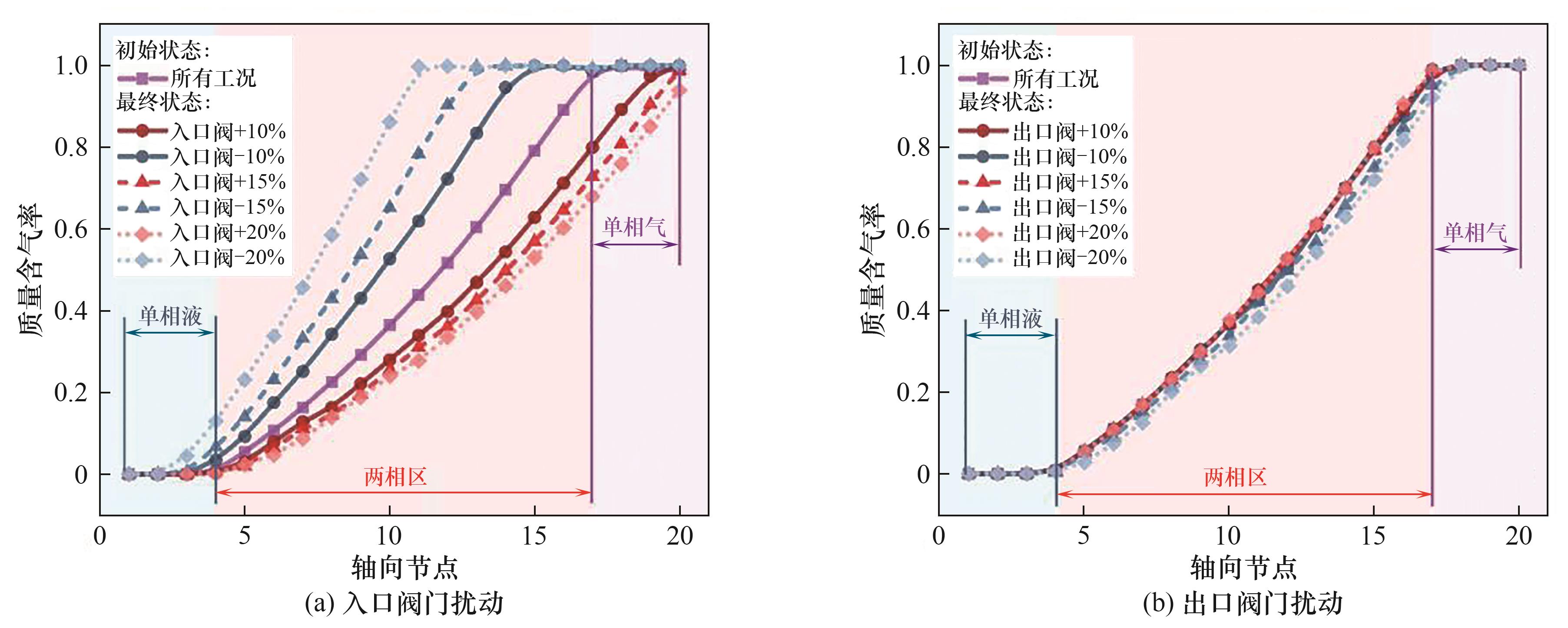

图12 入口及出口阀门阶跃扰动时二次侧轴向质量含气率动态及稳态特性

Fig.12 Dynamic and statistic characteristics of local vapor quality of OTSG under step disturbance of the inlet and outlet valves

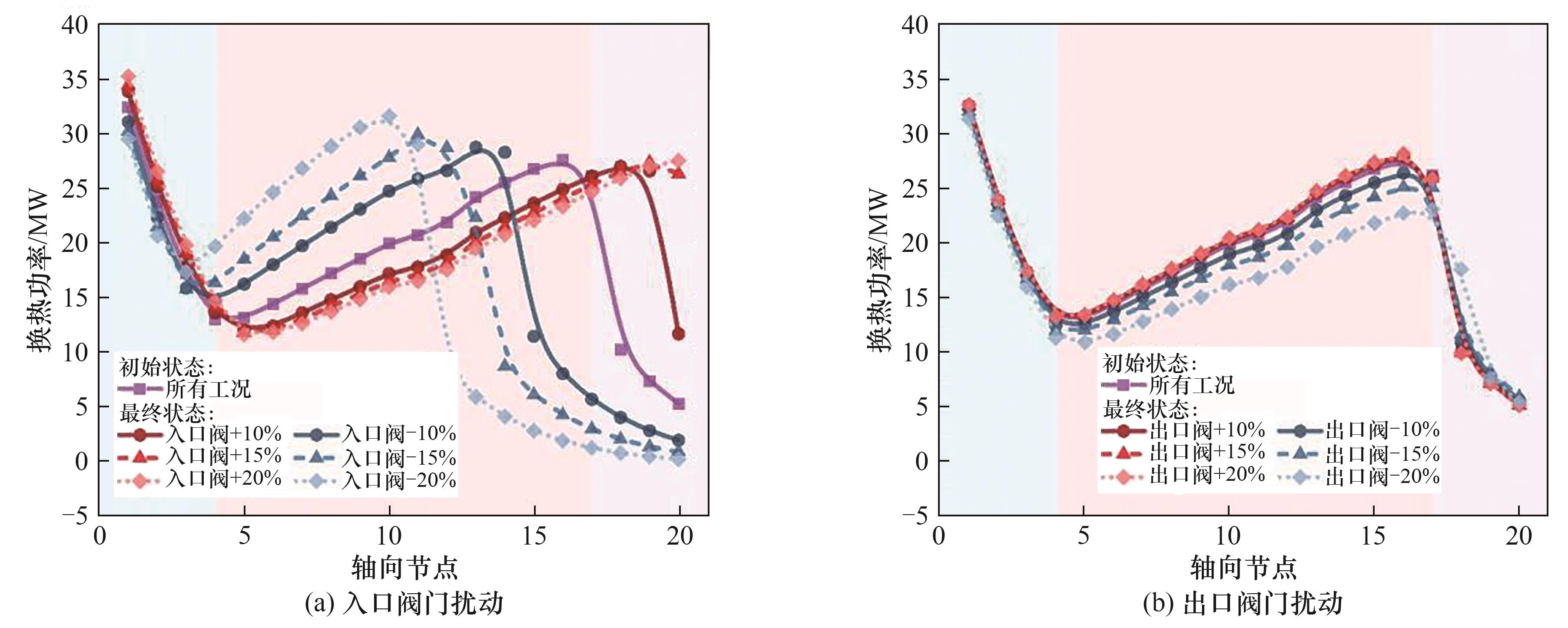

图13 入口及出口阀门阶跃扰动时二次侧轴向换热功率稳态及动态特性

Fig.13 Dynamic and statistic characteristics of local heat load of OTSG under step disturbance of the inlet and outlet valves

| 阀门开度 | 平均局部换热功率稳态相对变化量 | |||||

|---|---|---|---|---|---|---|

| 入口阀门 | 出口阀门 | |||||

| 单相液 | 两相区 | 单相气 | 单相液 | 两相区 | 单相气 | |

| +10% | +5.45% | -13.72% | — | +0.39% | +1.77% | -2.22% |

| +15% | +8.79% | -17.17% | — | +0.46% | +2.21% | -2.86% |

| +20% | +11.79% | -19.41% | — | +0.54% | +2.47% | -2.95% |

| -10% | -6.32% | +24.23% | -62.26% | -1.16% | -4.81% | +6.49% |

| -15% | -8.03% | +41.77% | -82.32% | -2.41% | -9.87% | +12.51% |

| -20% | -11.49% | +61.83% | -94.64% | -5.69% | -18.64% | +3.03% |

表6 入口及出口阀门扰动±10%、±15%和±20%时各区域平均局部换热功率稳态相对变化量

Table 6 Relative difference of average heat load for different flow regions under the ±10%, ±15%, ±20% disturbance of inlet and outlet valves

| 阀门开度 | 平均局部换热功率稳态相对变化量 | |||||

|---|---|---|---|---|---|---|

| 入口阀门 | 出口阀门 | |||||

| 单相液 | 两相区 | 单相气 | 单相液 | 两相区 | 单相气 | |

| +10% | +5.45% | -13.72% | — | +0.39% | +1.77% | -2.22% |

| +15% | +8.79% | -17.17% | — | +0.46% | +2.21% | -2.86% |

| +20% | +11.79% | -19.41% | — | +0.54% | +2.47% | -2.95% |

| -10% | -6.32% | +24.23% | -62.26% | -1.16% | -4.81% | +6.49% |

| -15% | -8.03% | +41.77% | -82.32% | -2.41% | -9.87% | +12.51% |

| -20% | -11.49% | +61.83% | -94.64% | -5.69% | -18.64% | +3.03% |

| [1] | 王鑫, 赵钢, 曲新鹤, 等. 某小型模块化反应堆核电站二回路系统变工况特性[J]. 清华大学学报(自然科学版), 2024, 64(1): 155-163. |

| Wang X, Zhao G, Qu X H, et al. Investigating the off-design performance of the secondary circuit system in a small modular reactor nuclear power plant[J]. Journal of Tsinghua University (Science and Technology), 2024, 64(1): 155-163. | |

| [2] | 孔夏明, 王苇, 孟海波, 等. 直流蒸汽发生器启动系统动态特性仿真[J]. 舰船科学技术, 2013, 35(10): 56-59. |

| Kong X M, Wang W, Meng H B, et al. Simulation study of dynamic characteristic of start-up system for once-through steam generator[J]. Ship Science and Technology, 2013, 35(10): 56-59. | |

| [3] | 朱一虎. 螺旋管式直流蒸汽发生器建模与控制策略研究[D]. 哈尔滨: 哈尔滨工程大学, 2023. |

| Zhu Y H. Modeling and control strategy research of helical tube once-through steam generator[D]. Harbin: Harbin Engineering University, 2023. | |

| [4] | 彭敏俊. 船舶核动力装置[M]. 北京: 原子能出版社, 2009. |

| Peng M J. Ship Nuclear Power Plant[M]. Beijing: Atomic Press, 2009. | |

| [5] | 丁训慎. 核电厂蒸汽发生器设计中的安全问题[J]. 核安全, 2005, 4(2): 1-6, 15. |

| Ding X S. The design safety of steam generators in NPP[J]. Nuclear Safety, 2005, 4(2): 1-6, 15. | |

| [6] | 熊扬恒. 核电站蒸汽发生器研究设计中的几个问题[J]. 核动力工程, 1994, 15(4): 319-322, 333. |

| Xiong Y H. Several problems in the research and design to the steam generator of the nuclear power plant[J]. Nuclear Power Engineering, 1994, 15(4): 319-322, 333. | |

| [7] | 戴饶棋, 段天英, 刘勇, 等. 钠冷快堆直流蒸汽发生器建模与仿真研究[J]. 节能技术, 2023, 41(4): 362-366. |

| Dai R Q, Duan T Y, Liu Y, et al. Study on modeling and simulation of once-through steam generator in sodium-cooled fast reactors[J]. Energy Conservation Technology, 2023, 41(4): 362-366. | |

| [8] | 王寒雨. 套管式直流蒸汽发生器建模与特性分析[D]. 南京: 东南大学, 2022. |

| Wang H Y. Modeling and characteristic analysis of casing once-through steam generator[D]. Nanjing: Southeast University, 2022. | |

| [9] | 王楠. 基于隐式差分格式的直流蒸汽发生器动态性能研究[D]. 哈尔滨: 哈尔滨工程大学, 2022. |

| Wang N. Research on dynamic performance of once through steam generator based on implicit scheme[D]. Harbin: Harbin Engineering University, 2022. | |

| [10] | 许余, 皇甫泽玉, 胥建群, 等. 直流蒸汽发生器动态特性与小破口故障仿真研究[J]. 核动力工程, 2021, 42(2): 161-167. |

| Xu Y, Huangfu Z Y, Xu J Q, et al. Simulation research on dynamic characteristics and small break fault of once-through steam generator[J]. Nuclear Power Engineering, 2021, 42(2): 161-167. | |

| [11] | 许余, 皇甫泽玉, 胥建群, 等. 直流蒸汽发生器建模与仿真研究[J]. 核动力工程, 2021, 42(1): 154-160. |

| Xu Y, Huangfu Z Y, Xu J Q, et al. Research on modeling and simulation of once-through steam generator[J]. Nuclear Power Engineering, 2021, 42(1): 154-160. | |

| [12] | 魏巍. 600 MW钠冷快堆蒸汽发生器仿真研究[D]. 哈尔滨: 哈尔滨工程大学, 2019. |

| Wei W. Simulation of 600 MW sodium-cooled fast reactor steam generator[D]. Harbin: Harbin Engineering University, 2019. | |

| [13] | 丁宏达. 考虑流动阻力的直流蒸汽发生器换热性能仿真[D]. 哈尔滨: 哈尔滨工程大学, 2018. |

| Ding H D. Simulation of heat transfer performance of once-through steam generator with flow resistance is considered[D]. Harbin: Harbin Engineering University, 2018. | |

| [14] | 薄琳, 孙宝芝, 干依燃, 等. 一次扰动下直流蒸汽发生器动态换热性能仿真[J]. 化工学报, 2018, 69(S1): 64-71. |

| Bo L, Sun B Z, Gan Y R, et al. Simulation of heat transfer performance of once-through steam generator under primary side disturbance[J]. CIESC Journal, 2018, 69(S1): 64-71. | |

| [15] | 张羽, 孙宝芝, 童铁峰. 运行条件对蒸汽发生器热工参数影响的仿真研究[J]. 原子能科学技术, 2015, 49(12): 2157-2163. |

| Zhang Y, Sun B Z, Tong T F. Simulation research of impact of operating condition on thermal parameters in steam generator[J]. Atomic Energy Science and Technology, 2015, 49(12): 2157-2163. | |

| [16] | Zhang G L, Zhang Y, Yang Y L, et al. Dynamic heat transfer performance study of steam generator based on distributed parameter method[J]. Annals of Nuclear Energy, 2014, 63: 658-664. |

| [17] | Zhu J Y, Guo Y, Zhang Z J. Dynamic simulation of once-through steam generator with concentric annuli tube[J]. Annals of Nuclear Energy, 2012, 50: 185-198. |

| [18] | 朱景艳, 张志俭, 郭赟. 套管式直流蒸汽发生器动态实时仿真研究[J]. 原子能科学技术, 2011, 45(8): 937-940, 942. |

| Zhu J Y, Zhang Z J, Guo Y. Dynamic real-time simulation research on once-through steam generator with concentric annuli tube[J]. Atomic Energy Science and Technology, 2011, 45(8): 937-940, 942. | |

| [19] | 刘建阁, 彭敏俊, 张志俭, 等. 套管式直流蒸汽发生器负荷跟随动态特性分析[J]. 原子能科学技术, 2010, 44(2): 175-182. |

| Liu J G, Peng M J, Zhang Z J, et al. Load following dynamic characteristic analysis of casing once-through steam generator[J]. Atomic Energy Science and Technology, 2010, 44(2): 175-182. | |

| [20] | 李海鹏, 黄晓津, 张良驹. 螺旋管式直流蒸汽发生器的集总参数动态模型[J]. 原子能科学技术, 2008, 42(8): 729-733. |

| Li H P, Huang X J, Zhang L J. Lumped parameter dynamic model of helical coiled once-through steam generator[J]. Atomic Energy Science and Technology, 2008, 42(8): 729-733. | |

| [21] | 黄晓津, 冯元琨, 郭人俊. HTR-10螺旋管式直流蒸汽发生器的动态数学模型[J]. 高技术通讯, 2001, 11(1): 96-99, 93. |

| Huang X J, Feng Y K, Guo R J. Dynamic mathematical model of helical coils of steam generator of HTR-10[J]. High Technology Letters, 2001, 11(1): 96-99, 93. | |

| [22] | 郭海红. 蒸汽发生器工作过程动态仿真[D]. 哈尔滨: 哈尔滨工程大学, 2007. |

| Guo H H. Working process dynamic simulation of steam generator[D]. Harbin: Harbin Engineering University, 2007. | |

| [23] | 张伟, 边信黔, 夏国清. 套管式直流蒸汽发生器动态特性仿真研究[J]. 核科学与工程, 2006, 26(2): 103-107. |

| Zhang W, Bian X Q, Xia G Q. Simulation study of dynamic characteristic of once-through steam generator in annuli tube[J]. Chinese Journal of Nuclear Science and Engineering, 2006, 26(2): 103-107. | |

| [24] | Bai X, Wei Y Z, Zhang R, et al. Operation Scheme analysis of a multipurpose small modular reactor under cogeneration condition based on a once-through steam generator dynamic model[J]. Applied Thermal Engineering, 2024, 257: 124264. |

| [25] | Wan J S, Xie J Y, Wang P F, et al. Control system design for the once-through steam generator of lead-bismuth cooled reactor based on classical control theory[J]. Annals of Nuclear Energy, 2022, 175: 109214. |

| [26] | Li C, Yu R, Yu W M, et al. Pressure control of once-through steam generator using proximal policy optimization algorithm[J]. Annals of Nuclear Energy, 2022, 175: 109232. |

| [27] | Tao M, Ke Z W, Li X L, et al. The research of the model-free adaptive control method of once-through steam generator in nuclear power[C]//2017 25th International Conference on Nuclear Engineering. Shanghai, China, 2017. |

| [28] | 陶文铨. 传热学[M]. 5版. 北京: 高等教育出版社, 2019. |

| Tao W Q. Heat Transfer[M]. 5th ed. Beijing: Higher Education Press, 2019. | |

| [29] | Bergles A E, Rohsenow W M. The determination of forced-convection surface-boiling heat transfer[J]. Journal of Heat Transfer, 1964, 86(3): 365-372. |

| [30] | Jens W H, Lottes P A. Analysis of heat transfer, burnout, pressure drop and density data for high pressure water[R]. Chicago: Argonne National Laboratory, 1951. |

| [31] | Chen J C. Correlation for boiling heat transfer to saturated fluids in convective flow[J]. Industrial & Engineering Chemistry Process Design and Development, 1966, 5(3): 322-329. |

| [32] | 吴鸽平, 吴埃敏, 郭贇, 等. 环形窄缝通道内流动沸腾干涸点的研究[J]. 西安交通大学学报, 2004, 38(7): 686-689, 697. |

| Wu G P, Wu A M, Guo Y, et al. Experimental research on dryout point of flow boiling in narrow annular channel[J]. Journal of Xi'an Jiaotong University, 2004, 38(7): 686-689, 697. | |

| [33] | Groeneveld D C, Delorme G G J. Prediction of thermal non-equilibrium in the post-dryout regime[J]. Nuclear Engineering and Design, 1976, 36(1): 17-26. |

| [34] | The Babcock & Wilcox Company. Steam: Its Generation and Use[M]. Akron: The Babcock & Wilcox Company, 2011. |

| [35] | 孔夏明, 王苇, 孟海波, 等. 负荷扰动下直流蒸汽发生器蒸汽压力控制仿真[J]. 舰船科学技术, 2013, 35(2): 68-71. |

| Kong X M, Wang W, Meng H B, et al. Simulation research on pressure control of main steam in once through steam generator load disturbance[J]. Ship Science and Technology, 2013, 35(2): 68-71. | |

| [36] | Li H P, Huang X J, Zhang L J. A lumped parameter dynamic model of the helical coiled once-through steam generator with movable boundaries[J]. Nuclear Engineering and Design, 2008, 238(7): 1657-1663. |

| [37] | 吴青阳, 李根, 刘明, 等. 核能水电联产系统的变负荷动态特性与灵活运行控制策略优化研究[J]. 动力工程学报, 2025, 45(4): 582-591. |

| Wu Q Y, Li G, Liu M, et al. Research on dynamic characteristics and flexible operation control strategy optimization of nuclear power and water cogeneration system[J]. Journal of Chinese Society of Power Engineering, 2025, 45(4): 582-591. |

| [1] | 任现超, 谷雅秀, 段少斌, 贾文竹, 李汉林. 翅片式椭圆套管蒸发式冷凝器传热传质性能实验研究[J]. 化工学报, 2025, 76(S1): 75-83. |

| [2] | 袁琳慧, 王瑜. 单服务器浸没射流式液冷系统散热性能[J]. 化工学报, 2025, 76(S1): 160-169. |

| [3] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [4] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [5] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [6] | 孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296. |

| [7] | 马爱华, 赵帅, 王林, 常明慧. 太阳能吸收制冷循环动态特性仿真方法研究[J]. 化工学报, 2025, 76(S1): 318-325. |

| [8] | 吴成云, 孙浩然. 民用飞机空调系统性能仿真与燃油代偿损失研究[J]. 化工学报, 2025, 76(S1): 351-359. |

| [9] | 肖鑫, 杨耿, 王云峰. 基于TRNSYS的太阳能梯级蓄热热泵系统模拟[J]. 化工学报, 2025, 76(S1): 393-400. |

| [10] | 王三一, 黄文来. 电化学合成氨流程建模与优化[J]. 化工学报, 2025, 76(9): 4474-4486. |

| [11] | 周轶磊, 李智, 彭鑫. 基于代理模型的连续重整反应过程自优化控制结构设计[J]. 化工学报, 2025, 76(9): 4499-4511. |

| [12] | 罗海梅, 王泓, 孙照明, 尹艳华. 同向双螺杆传热系数计算模型的分析与验证[J]. 化工学报, 2025, 76(9): 4809-4823. |

| [13] | 胡金琦, 闵春华, 李小龙, 范元鸿, 王坤. 振动叶片耦合柔性板强化流体混沌混合与传热研究[J]. 化工学报, 2025, 76(9): 4824-4837. |

| [14] | 吴林凯, 林志敏, 王良璧. 基于热质传递效应的准稳态结霜模型改进及数值验证[J]. 化工学报, 2025, 76(8): 4004-4016. |

| [15] | 佘海龙, 胡光忠, 崔晓钰, 柳忠彬, 彭帝, 李航. 不同节流工质下叠层微通道分布式节流制冷器性能研究[J]. 化工学报, 2025, 76(8): 4017-4029. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号