• •

周晴晴1( ), 项良顺1(

), 项良顺1( ), 国海超2, 肖辉1, 赵好阳1, 姜媛媛1, 韦芳芳1, 杨东辉1, 屠芳芳1, 张育红1, 相佳媛1

), 国海超2, 肖辉1, 赵好阳1, 姜媛媛1, 韦芳芳1, 杨东辉1, 屠芳芳1, 张育红1, 相佳媛1

收稿日期:2025-09-03

修回日期:2025-11-08

出版日期:2025-12-19

通讯作者:

项良顺

作者简介:周晴晴(1996—),女,硕士研究生,软包电芯研发工程师,zhou_qingqing@foxmail.com

基金资助:

Qingqing Zhou1( ), Liangshun Xiang1(

), Liangshun Xiang1( ), Haichao Guo2, Hui Xiao1, Haoyang Zhao1, Yuanyuan Jiang1, Fangfang Wei1, Donghui Yang1, Fangfang Tu1, Yuhong Zhang1, Jiayuan Xiang1

), Haichao Guo2, Hui Xiao1, Haoyang Zhao1, Yuanyuan Jiang1, Fangfang Wei1, Donghui Yang1, Fangfang Tu1, Yuhong Zhang1, Jiayuan Xiang1

Received:2025-09-03

Revised:2025-11-08

Online:2025-12-19

Contact:

Liangshun Xiang

摘要:

大尺寸软包锂离子电池存在结构变形风险,其常用的聚丙烯(PP)隔膜因易褶皱,可能引发极片黑斑及析锂缺陷。本研究以50 Ah叠片式软包动力电池为载体,系统研究了聚甲基丙烯酸甲酯(PMMA)基涂胶材料对PP基膜在生产制造及电化学性能方面的改进效果。结果表明,PP基膜表面均匀分布的PMMA胶层在有效维持锂离子传输所需多孔结构的同时,显著优化了物性参数。此外,采用PMMA涂胶隔膜的极芯经冷压处理后整体机械强度提高,隔膜与极片贴合紧密,焊接与封装短路率分别从5.37%和0.49%降至0.02%及0%,极片界面和电芯外观显著改善。与基膜组相比,涂胶隔膜组电芯基准容量提升约2.5%,高温放电容量提升约1%–2%,1.0C充电恒流比和1.5C放电容量分别增加约0.6%和1%,常温与高温循环500周后容量保持率分别提升约5%和3.2%。研究结果为下一代高性能锂离子电池的设计与制造提供了新的解决思路。

中图分类号:

周晴晴, 项良顺, 国海超, 肖辉, 赵好阳, 姜媛媛, 韦芳芳, 杨东辉, 屠芳芳, 张育红, 相佳媛. PMMA涂胶隔膜对软包锂离子电池制程及性能影响研究[J]. 化工学报, DOI: 10.11949/0438-1157.20250994.

Qingqing Zhou, Liangshun Xiang, Haichao Guo, Hui Xiao, Haoyang Zhao, Yuanyuan Jiang, Fangfang Wei, Donghui Yang, Fangfang Tu, Yuhong Zhang, Jiayuan Xiang. Influence of PMMA Adhesive-Separator on the Manufacturing Process and Performance of Pouch Lithium-ion Battery[J]. CIESC Journal, DOI: 10.11949/0438-1157.20250994.

| 参数 | 设计值 | |

|---|---|---|

| 正极 | 负极 | |

| 面密度/g/m2 | 380 | 171 |

| 压实密度/g/cm3 | 2.48 | 1.55 |

| 箔材厚度/µm | 12+1+1 | 4.5 |

| 极芯厚度/mm | 9.8±0.3 | |

| 电池厚度/mm | 10.8±0.3 | |

| 单位面积负极容量/正极容量(N/P) | 1.15 | |

| 注液量/g | 168±2 | |

| 设计容量/Ah | 50 | |

| 电池长×宽/mm | 252×161 | |

表1 电池设计参数

Table 1 Design parameters of battery

| 参数 | 设计值 | |

|---|---|---|

| 正极 | 负极 | |

| 面密度/g/m2 | 380 | 171 |

| 压实密度/g/cm3 | 2.48 | 1.55 |

| 箔材厚度/µm | 12+1+1 | 4.5 |

| 极芯厚度/mm | 9.8±0.3 | |

| 电池厚度/mm | 10.8±0.3 | |

| 单位面积负极容量/正极容量(N/P) | 1.15 | |

| 注液量/g | 168±2 | |

| 设计容量/Ah | 50 | |

| 电池长×宽/mm | 252×161 | |

| 测试项 | PP隔膜 | 涂胶隔膜 |

|---|---|---|

| 厚度/µm | 16 | 16 |

| 透气度/s/100 ml | 240 | 262 |

| 接触角/° | 54.4° | 37.4° |

| 吸液率ρ/% | 339.4 | 808.5 |

| 离子电导率σ/10-4 S/cm | 2.92 | 10.73 |

| 针刺强度/gf | 221 | 337 |

| MD拉伸强度/kgf/cm² | 1650 | 2011 |

| TD拉伸强度/kgf/cm² | 150 | 154 |

| MD热收缩90 ℃/12 h/% | 3.0 | 0.8 |

| TD热收缩90 ℃/12 h/% | 0.2 | 0 |

| MD热收缩130 ℃/0.5 h/% | 3.5 | 1.0 |

| TD热收缩130 ℃/0.5 h/% | 0.15 | 0 |

表2 PP隔膜和涂胶隔膜物性对比

Table 2 Comparison of physical properties of PP separator and adhesive-separator

| 测试项 | PP隔膜 | 涂胶隔膜 |

|---|---|---|

| 厚度/µm | 16 | 16 |

| 透气度/s/100 ml | 240 | 262 |

| 接触角/° | 54.4° | 37.4° |

| 吸液率ρ/% | 339.4 | 808.5 |

| 离子电导率σ/10-4 S/cm | 2.92 | 10.73 |

| 针刺强度/gf | 221 | 337 |

| MD拉伸强度/kgf/cm² | 1650 | 2011 |

| TD拉伸强度/kgf/cm² | 150 | 154 |

| MD热收缩90 ℃/12 h/% | 3.0 | 0.8 |

| TD热收缩90 ℃/12 h/% | 0.2 | 0 |

| MD热收缩130 ℃/0.5 h/% | 3.5 | 1.0 |

| TD热收缩130 ℃/0.5 h/% | 0.15 | 0 |

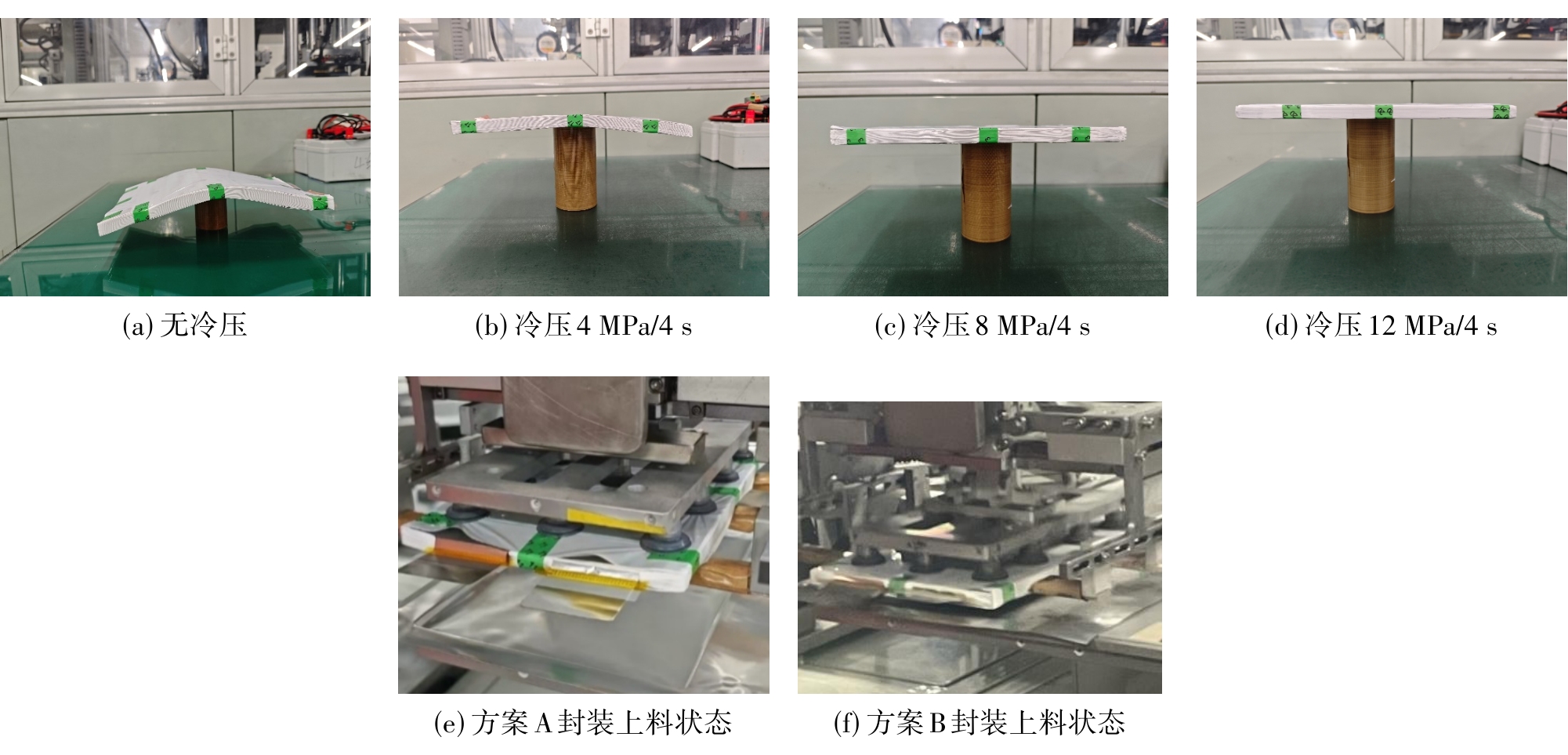

图2 不同冷压条件极芯状态 (a-d); 不同方案极芯封装上料状态 (e-f)

Fig.2 Battery core coil states under different cold pressing conditions (a-d); Battery core packaging status of different schemes (e-f)

| 参数 | 冷压前 | 冷压后 |

|---|---|---|

| 透气值/s/100 ml | 262 | 267 |

表3 8MPa/4 s冷压前后涂胶隔膜的透气值对比

Table 3 Comparison of the air permeability values of the adhesive-separator before and after cold pressing at 8 MPa/4 s

| 参数 | 冷压前 | 冷压后 |

|---|---|---|

| 透气值/s/100 ml | 262 | 267 |

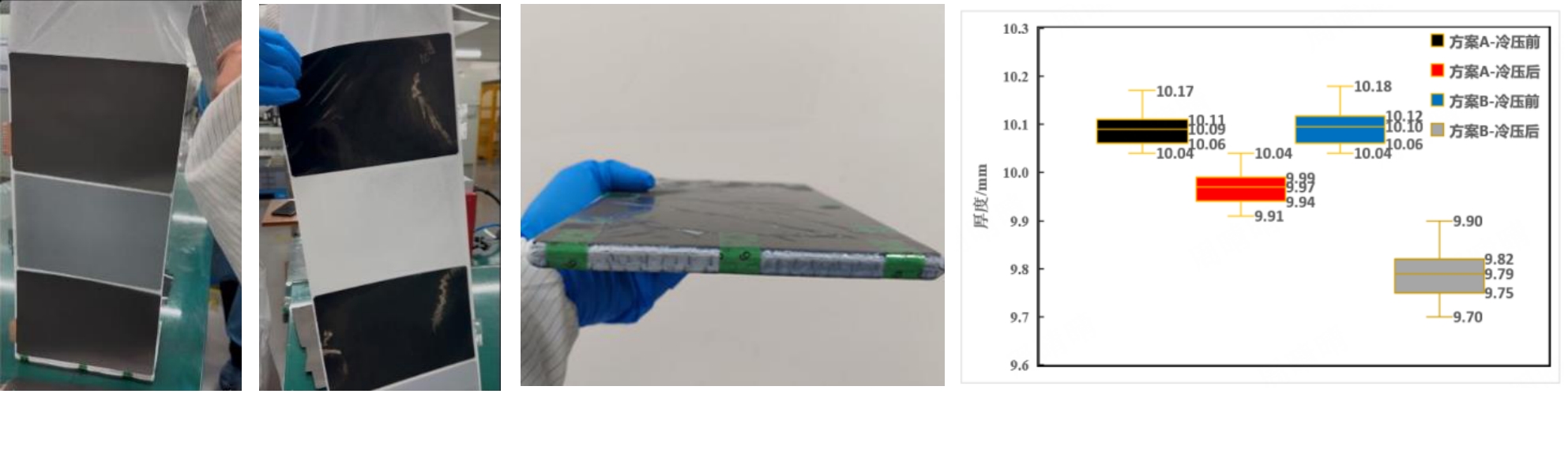

图3 冷压后负极片与隔膜粘结状态 (a);冷压后正极片与隔膜粘结状态 (b);电解液浸润24 h后极芯状态 (c);极芯冷压前后厚度变化 (d)注:(a) (b) (c) (d)

Fig.3 The bonding state between the negative electrode sheet and the separator after cold pressing (a); The bonding state between the positive electrode sheet and the separator after cold pressing (b); The core wound state (c) after 24 hours of electrolyte immersion; Thickness change of the core before and after cold pressing (d)

| 参数 | PP隔膜 | 涂胶隔膜 |

|---|---|---|

| 总产出数量/Pcs | 10000 | |

| 焊接前短路数量/Pcs | 537 | 2 |

| 焊接前短路率/% | 5.37 | 0.02 |

| 封装短路数量/Pcs | 49 | 0 |

| 封装短路率/% | 0.49 | 0.00 |

表4 电池装配不良对比

Table 4 Comparison of poor battery assembly

| 参数 | PP隔膜 | 涂胶隔膜 |

|---|---|---|

| 总产出数量/Pcs | 10000 | |

| 焊接前短路数量/Pcs | 537 | 2 |

| 焊接前短路率/% | 5.37 | 0.02 |

| 封装短路数量/Pcs | 49 | 0 |

| 封装短路率/% | 0.49 | 0.00 |

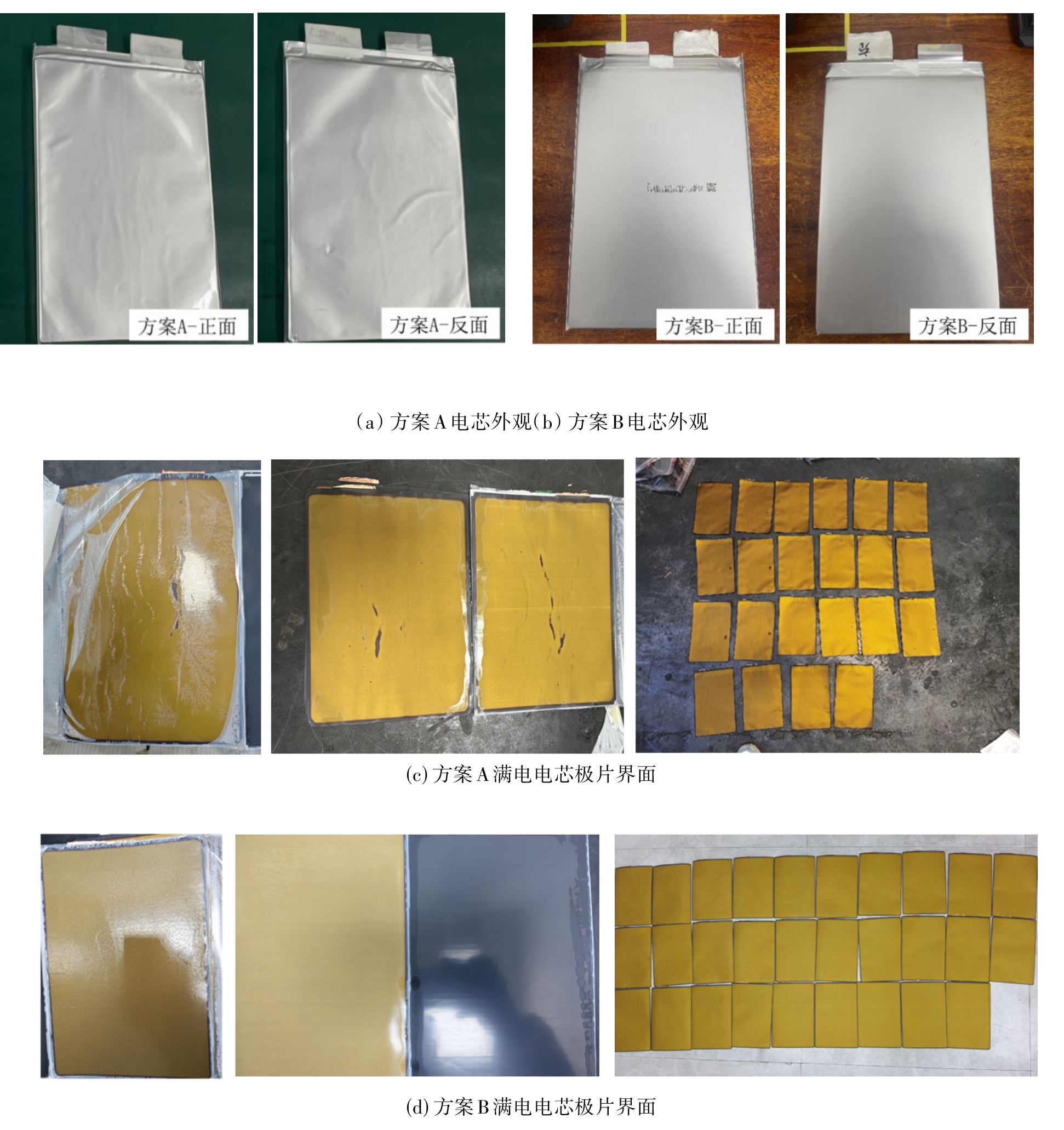

图4 方案A和方案B电芯外观 (a,b) 和满电极片界面对比 (c,d)

Fig.4 Comparison of the appearance of battery cells (a,b) and the interface of full electrode sheets (c,d) between Scheme A and Scheme B

| 测试项 | 方案A | 方案B | |

|---|---|---|---|

| 一步克容量mAh/g | 138.5 | 138.7 | |

| 三步克容量mAh/g | 142.5 | 142.9 | |

| 基准容量/Ah | 51.8 | 52.5 | |

| 倍率充电恒流比/% | 0.33C | 98.9、99.2 | 99.0、99.0 |

| 0.5C | 98.5、98.6 | 98.9、99.0 | |

| 1.0C | 97.2、97.1 | 97.7、97.8 | |

| 倍率充电温升/℃ | 0.33C | 1.5、1.9 | 1.9、2.0 |

| 0.5C | 2.4、2.6 | 2.1、2.2 | |

| 1.0C | 8.6、8.8 | 5.7、6.0 | |

| 倍率放电容量比率/% | 0.5C | 98.8、98.8 | 99.1、99.1 |

| 1.0C | 96.9、96.6 | 97.6、97.7 | |

| 1.5C | 96.6、96.3 | 97.5、97.3 | |

| 倍率放电温升/℃ | 0.5C | 3.7、3.7 | 3.9、3.0 |

| 1.0C | 6.5、7.0 | 7.3、5.6 | |

| 1.5C | 11.9、12.3 | 11.0、13.0 | |

| 55 ℃容量比率/% | 101.4、101.4 | 102.3、103.0 | |

| -10 ℃容量比率/% | 80.6、87.3 | 79.6、86.7 | |

| 60 ℃荷电容量比率/% | 96.6、96.5 | 96.5、96.6 | |

| 25 ℃荷电容量比率/% | 97.0、97.1 | 97.4、97.8 | |

表5 电化学性能测试数据

Table 5 Test data of electrochemical properties

| 测试项 | 方案A | 方案B | |

|---|---|---|---|

| 一步克容量mAh/g | 138.5 | 138.7 | |

| 三步克容量mAh/g | 142.5 | 142.9 | |

| 基准容量/Ah | 51.8 | 52.5 | |

| 倍率充电恒流比/% | 0.33C | 98.9、99.2 | 99.0、99.0 |

| 0.5C | 98.5、98.6 | 98.9、99.0 | |

| 1.0C | 97.2、97.1 | 97.7、97.8 | |

| 倍率充电温升/℃ | 0.33C | 1.5、1.9 | 1.9、2.0 |

| 0.5C | 2.4、2.6 | 2.1、2.2 | |

| 1.0C | 8.6、8.8 | 5.7、6.0 | |

| 倍率放电容量比率/% | 0.5C | 98.8、98.8 | 99.1、99.1 |

| 1.0C | 96.9、96.6 | 97.6、97.7 | |

| 1.5C | 96.6、96.3 | 97.5、97.3 | |

| 倍率放电温升/℃ | 0.5C | 3.7、3.7 | 3.9、3.0 |

| 1.0C | 6.5、7.0 | 7.3、5.6 | |

| 1.5C | 11.9、12.3 | 11.0、13.0 | |

| 55 ℃容量比率/% | 101.4、101.4 | 102.3、103.0 | |

| -10 ℃容量比率/% | 80.6、87.3 | 79.6、86.7 | |

| 60 ℃荷电容量比率/% | 96.6、96.5 | 96.5、96.6 | |

| 25 ℃荷电容量比率/% | 97.0、97.1 | 97.4、97.8 | |

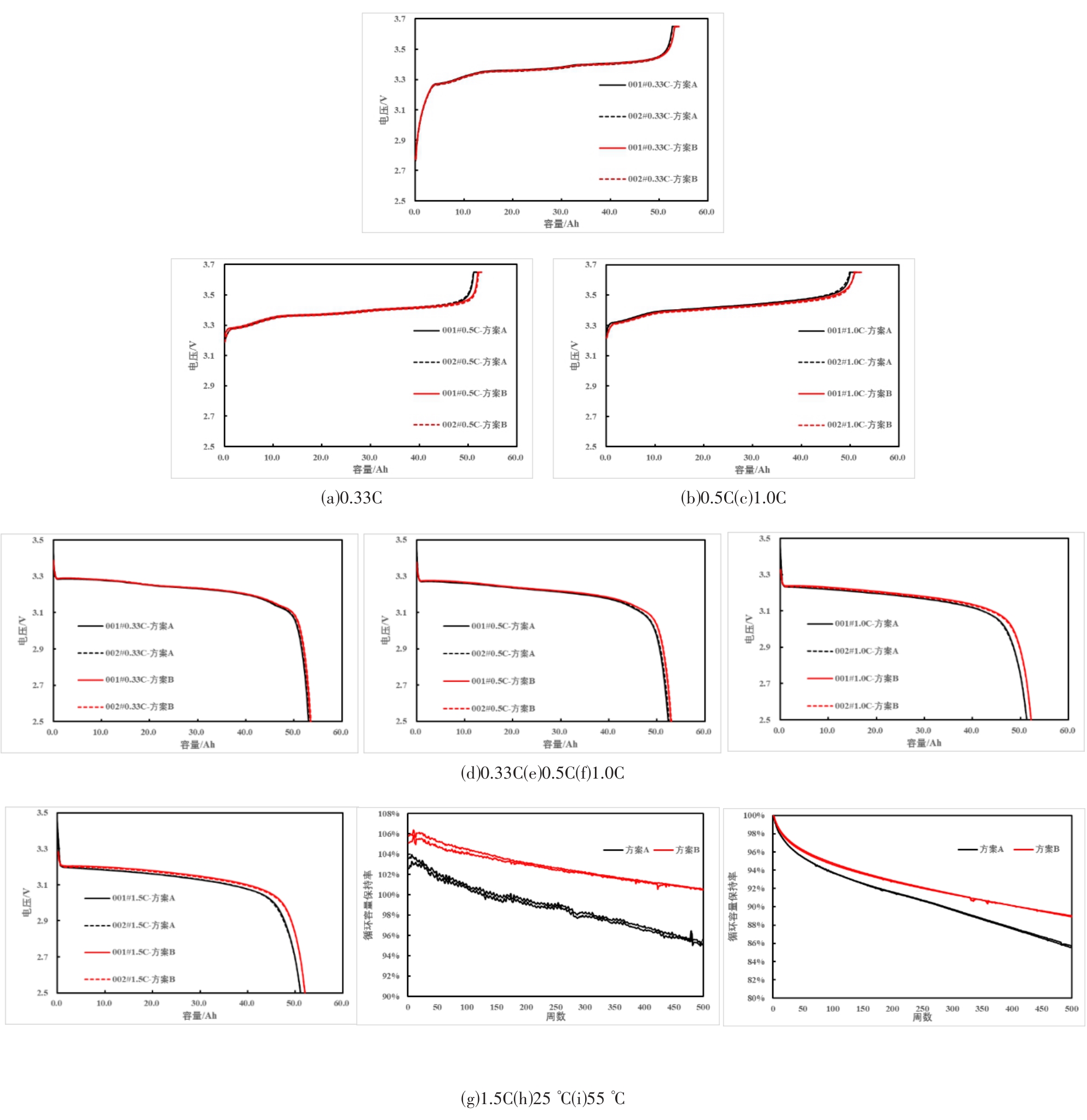

图6 方案A和方案B电芯倍率充电曲线对比 (a-c);方案A和方案B电芯倍率放电曲线对比 (d-g);方案A和方案B电芯不同温度循环性能对比 (h,i)

Fig.6 Comparison of battery rate charging curves between scheme A and B (a-c); Comparison of battery rate discharge curves between scheme A and B (d-g); Comparison of battery cycling performance at different temperatures in scheme A and scheme B (h- i)

| [1] | 吴超, 王罗亚, 袁子杰, 等. 液冷散热技术在电化学储能系统中的研究进展[J]. 储能科学与技术, 2024, 13(10): 3596-3612. |

| Wu C, Wang L Y, Yuan Z J, et al. Research progress in liquid cooling and heat dissipation technologies for electrochemical energy storage systems[J]. Energy Storage Science and Technology, 2024, 13(10): 3596-3612. | |

| [2] | 李琪, 黎平安, 刘泽通, 等. 同轴静电纺丝构筑微/纳米结构隔膜与电极材料用于锂离子电池: 从原理到应用[J]. 物理化学学报, 2024, 40(10): 35-41. |

| Li Q, Li P A, Liu Z T, et al. Fabricating micro/nanostructured separators and electrode materials by coaxial electrospinning for lithium-ion batteries: from fundamentals to applications[J]. Acta Physico-Chimica Sinica, 2024, 40(10): 35-41. | |

| [3] | Lagadec M F, Zahn R, Wood V. Characterization and performance evaluation of lithium-ion battery separators[J]. Nature Energy, 2019, 4(1): 16-25. |

| [4] | Lingappan N, Lee W, Passerini S, et al. A comprehensive review of separator membranes in lithium-ion batteries[J]. Renewable and Sustainable Energy Reviews, 2023, 187: 113726. |

| [5] | 孙文浩, 田君, 张锟, 等. 锂离子电池用高热稳定性新型隔膜的研究新进展[J]. 化工学报, 2025, 76(6): 2524-2543. |

| Sun W H, Tian J, Zhang K, et al. New development of novel separators with high thermal stability for lithium-ion batteries[J]. CIESC Journal, 2025, 76(6): 2524-2543. | |

| [6] | 于泽淼, 乔庆东, 肖伟. 锂离子电池隔膜制备工艺及检测方法研究进展[J]. 化工新型材料, 2025, 53(7): 87-91. |

| Yu Z M, Qiao Q D, Xiao W. Research progress on preparation process and detection methods of lithium-ion battery separators[J]. New Chemical Materials, 2025, 53(7): 87-91. | |

| [7] | 王振华, 彭代冲, 孙克宁. 锂离子电池隔膜材料研究进展[J]. 化工学报, 2018, 69(1): 282-294. |

| Wang Z H, Peng D C, Sun K N. Research progress of separator materials for lithium ion batteries[J]. CIESC Journal, 2018, 69(1): 282-294. | |

| [8] | 瞿艳, 陈娟, 王诚文, 等. 涂胶隔膜在软包圆柱锂离子电池中的性能研究[J]. 电池工业, 2021, 25(4): 194-197. |

| Qu Y, Chen J, Wang C W, et al. Effect of adhesive-separators on the performance of soft-pack cylindrical lithium-ion battery[J]. Chinese Battery Industry, 2021, 25(4): 194-197. | |

| [9] | 刘一铮, 石斌, 冉岭, 等. 热电池电解质与隔膜材料研究进展[J]. 化工学报, 2021, 72(7): 3524-3537. |

| Liu Y Z, Shi B, Ran L, et al. Research progress of molten salt electrolyte and separator materials for thermal batteries[J]. CIESC Journal, 2021, 72(7): 3524-3537. | |

| [10] | 马平川, 刘杲珺, 高飞飞, 等. 溶剂型多层复合隔膜的制备及其性能研究[J]. 工程塑料应用, 2023, 51(1): 28-33. |

| Ma P C, Liu G J, Gao F F, et al. Preparation and properties of composite separator of multilayer structure for lithium battery[J]. Engineering Plastics Application, 2023, 51(1): 28-33. | |

| [11] | Chishti A N, Iqbal S, Ali M, et al. Modification of polypropylene separator with multifunctional layers to achieve highly stable sodium metal anode[J]. Journal of Energy Chemistry, 2025, 101: 223-232. |

| [12] | Rahman M M, Mateti S, Cai Q R, et al. High temperature and high rate lithium-ion batteries with boron nitride nanotubes coated polypropylene separators[J]. Energy Storage Materials, 2019, 19: 352-359. |

| [13] | Chen L, Lin X H, Dang W Q, et al. Tantalum oxide nanosheets/polypropylene composite separator constructing lithium-ion channels for stable lithium metal batteries[J]. Advanced Composites and Hybrid Materials, 2022, 6(1): 12. |

| [14] | Choi S, Hassan S Z, Roh Y, et al. Comprehensive crosslinking strategy using fluorinated azide to enhance the thermal stability of ceramic-coated separators for Li-ion batteries[J]. Chemical Engineering Journal, 2024, 498: 155238. |

| [15] | Cho Y, Lee E, Lee K S, et al. Preparation of three-dimensionally interconnected sulfur-deficient MoS2/nitrogen-doped carbon composite via salt template method for separator modification in lithium–Sulfur batteries[J]. Chemical Engineering Journal, 2024, 489: 151337. |

| [16] | Li J, Huang Y D, Zhang S, et al. Decoration of silica nanoparticles on polypropylene separator for lithium–sulfur batteries[J]. ACS Applied Materials & Interfaces, 2017, 9(8): 7499-7504. |

| [17] | Huang Y J, Chen Y Q, Xu Q, et al. TiO2-Ti3C2T x MXene@CNTs hybrids modified polypropylene separator for high-performance lithium-sulfur battery[J]. Journal of Energy Storage, 2025, 113: 115645. |

| [18] | Wang J T, Zhai P F, Zhao T K, et al. Laminar MXene-Nafion-modified separator with highly inhibited shuttle effect for long-life lithium–sulfur batteries[J]. Electrochimica Acta, 2019, 320: 134558. |

| [19] | Ma Z Y, Qi Z Q, Song G H, et al. α-MnO2/RuO2 heterostructure-modified polypropylene separator for high-performance lithium–sulfur battery[J]. Advanced Functional Materials, 2024, 34(39): 2403101. |

| [20] | 王理, 陈志伟. 钴酸锂软包电池高温循环膨胀改善研究[J]. 广东化工, 2021, 48(12): 24-25. |

| Wang L, Chen Z W. Swelling improvement research of cycle life at high temperature for lithiμm cobalt oxide soft-package batteries[J]. Guangdong Chemical Industry, 2021, 48(12): 24-25. | |

| [21] | 刘中奎, 陈峰. 涂胶隔膜对锂离子电池性能的影响[J]. 电池, 2024, 54(2): 213-216. |

| Liu Z K, Chen F. Effect of adhesive-coated separator on performance of Li-ion battery[J]. Battery Bimonthly, 2024, 54(2): 213-216. | |

| [22] | 庹新林, 何濂远. 芳纶纳米纤维/聚丙烯复合锂离子电池隔膜的制备[C]//中国化学会2017全国高分子学术论文报告会论文集. 成都, 2017: 15-16. |

| [23] | 张恒, 甄琪, 崔国士, 等. 动力锂离子电池隔膜材料的研究进展[J]. 绝缘材料, 2018, 51(11): 14-20. |

| Zhang H, Zhen Q, Cui G S, et al. Research progress of lithium-ion battery separator[J]. Insulating Materials, 2018, 51(11): 14-20. | |

| [24] | 刘远哲, 姜波, 张明祖, 等. 醋酸纤维素/甲基丙烯酸甲酯交联隔膜的制备与性能[J]. 高分子材料科学与工程, 2021, 37(12): 121-127. |

| Liu Y Z, Jiang B, Zhang M Z, et al. Preparation and properties of cellulose acetate/methyl methacrylate cross-linked separator[J]. Polymer Materials Science & Engineering, 2021, 37(12): 121-127. | |

| [25] | 赵欢欢, 董煜, 葛烨倩. PVDF/PMMA/PVDF层合纳米纤维隔膜的结构与性能[J]. 中国纤检, 2021(7): 124-127. |

| Zhao H H, Dong Y, Ge Y Q. Development of PVDF/PMMA/PVDF laminated nanofiber-based separator[J]. China Fiber Inspection, 2021(7): 124-127. | |

| [26] | Fan Z X, Chen X Y, Shi J J, et al. Functionalized separators boosting electrochemical performances for lithium batteries[J]. Nano-Micro Letters, 2025, 17(1): 128. |

| [27] | Liu X X, Xin X, Shen L, et al. Poly(methyl methacrylate)-based gel polymer electrolyte for high-performance solid state LiO2 battery with enhanced cycling stability[J]. ACS Applied Energy Materials, 2021, 4(4): 3975-3982. |

| [28] | Yang B, Yang Y D, Xu X, et al. Hierarchical microstructure and performance of PVDF/PMMA/SiO2lithium battery separator fabricated by thermally-induced phase separation (TIPS)[J]. Journal of Materials Science, 2022, 57(24): 11274-11288. |

| [29] | Cao S L, He X, Chen M L, et al. A CF4 plasma functionalized polypropylene separator for dendrite-free lithium metal anodes[J]. Journal of Materials Chemistry A, 2023, 11(14): 7545-7555. |

| [30] | Wang W, Li Z H, Huang H B, et al. Facile design of novel nanocellulose-based gel polymer electrolyte for lithium-ion batteries application[J]. Chemical Engineering Journal, 2022, 445: 136568. |

| [31] | Lu C H, Jiang H B, Cheng X R, et al. High-performance fibre battery with polymer gel electrolyte[J]. Nature, 2024, 629(8010): 86-91. |

| [32] | Jeon D H. Wettability in electrodes and its impact on the performance of lithium-ion batteries[J]. Energy Storage Materials, 2019, 18: 139-147. |

| [33] | Schulz N, Hausbrand R, Dimesso L, et al. XPS-surface analysis of SEI layers on Li-ion cathodes: part I. investigation of initial surface chemistry[J]. Journal of the Electrochemical Society, 2018, 165(5): A819-A832. |

| [34] | Da H R, Pan S S, Li J, et al. Greatly recovered electrochemical performances of regenerated graphite anode enabled by an artificial PMMA solid electrolyte interphase layer[J]. Energy Storage Materials, 2023, 56: 457-467. |

| [35] | Da H R, Li J, Shi J T, et al. Enhancing the depressed initial Coulombic efficiency of regenerated graphite anodes via the surface modification of a TiNb2O7 nanolayer[J]. Carbon, 2022, 193: 157-170. |

| [36] | Zhao L N, Bi S Y, Li J Y, et al. Prussian blue analogues for advanced non-aqueous sodium ion batteries: Redox mechanisms, key challenges and modification strategies[J]. Energy Storage Materials, 2025, 78: 104256. |

| [1] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [2] | 石一帆, 柯钢, 陈浩, 黄孝胜, 叶芳, 李成娇, 郭航. 大型高低温环境实验室温度控制仿真[J]. 化工学报, 2025, 76(S1): 268-280. |

| [3] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [4] | 何婷, 张开, 林文胜, 陈利琼, 陈家富. 沼气超临界压力低温脱碳-液化耦合流程研究[J]. 化工学报, 2025, 76(S1): 418-425. |

| [5] | 沙鑫权, 胡然, 丁磊, 蒋珍华, 吴亦农. 空间用单机两级有阀线性压缩机研制及测试[J]. 化工学报, 2025, 76(S1): 114-122. |

| [6] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [7] | 蒋智洪, 雷骞, 朱引军, 雷志刚, 陈洪林. 三聚甲醛体系物性模型和提浓工艺研究[J]. 化工学报, 2025, 76(9): 4872-4881. |

| [8] | 黄正宗, 刘科成, 李泽方, 曾平生, 刘永富, 闫红杰, 刘柳. 锌精馏炉砖砌式换热室数值模拟与场协同优化[J]. 化工学报, 2025, 76(9): 4425-4439. |

| [9] | 王三一, 黄文来. 电化学合成氨流程建模与优化[J]. 化工学报, 2025, 76(9): 4474-4486. |

| [10] | 李雪雯, 王治红, 高阳, 吴明鸥, 马文皓, 谭仁敏. 基于热泵技术的醇胺法脱硫再生系统多目标优化研究[J]. 化工学报, 2025, 76(9): 4563-4577. |

| [11] | 娄岚浩, 杨立鹏, 杨晓光. 锂离子电池电化学机理模型参数辨识研究综述[J]. 化工学报, 2025, 76(9): 4369-4382. |

| [12] | 曹潇风, 张华海, 王江云, 王利民. 锥形气体层流元件结构设计及流动特性研究[J]. 化工学报, 2025, 76(9): 4440-4448. |

| [13] | 周轶磊, 李智, 彭鑫. 基于代理模型的连续重整反应过程自优化控制结构设计[J]. 化工学报, 2025, 76(9): 4499-4511. |

| [14] | 刘璐, 王文玥, 王腾, 王太, 董新宇, 汤建成, 王少恒. 基于双混合工质深冷的氢液化工艺优化与分析[J]. 化工学报, 2025, 76(9): 4933-4943. |

| [15] | 赵婧, 董书辰, 李高洋, 黄友科, 石浩森, 缪舒文, 谭辰妍, 朱唐琦, 李永帅, 潘慧, 凌昊. 基于电化学模型的电池性能模拟与优化[J]. 化工学报, 2025, 76(9): 4922-4932. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号