• •

收稿日期:2025-10-21

修回日期:2025-12-09

出版日期:2025-12-10

通讯作者:

张桥

作者简介:段文婷(1998—),女,博士研究生,dwt1998@stu.xjtu.edu.cn

基金资助:Received:2025-10-21

Revised:2025-12-09

Online:2025-12-10

Contact:

Qiao ZHANG

摘要:

煤基冷热电联供可显著提升化工企业的能量利用效率。传统单供系统中高温烟气未按温度区间合理分级利用,缺乏基于热力学原理的联供优化方法。提出了煤基冷热电一体联供系统,对高温烟气进行温区划分,并在各温区设置不同的冷、热、电生产路径,以建立超结构。此外,以系统总㶲效率为目标函数,建立了多温区级联取热混合整数非线性规划数学模型。由某企业实际案例分析结果表明,当高温烟气的取热温区为1400-100 °C时,煤基冷热电一体联供系统的最高总㶲效率为69.01 %。相比于传统的单温区供热系统和供电系统,系统的总㶲效率分别提高了5.62 %、1.92 %。煤基冷热电联供比传统单供方式可显著提高系统能效。

中图分类号:

段文婷, 张桥. 煤基冷热电联供优化方法[J]. 化工学报, DOI: 10.11949/0438-1157.20251173.

Wenting DUAN, Qiao ZHANG. Optimization method of coal-based cooling, heating and power co-generation[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251173.

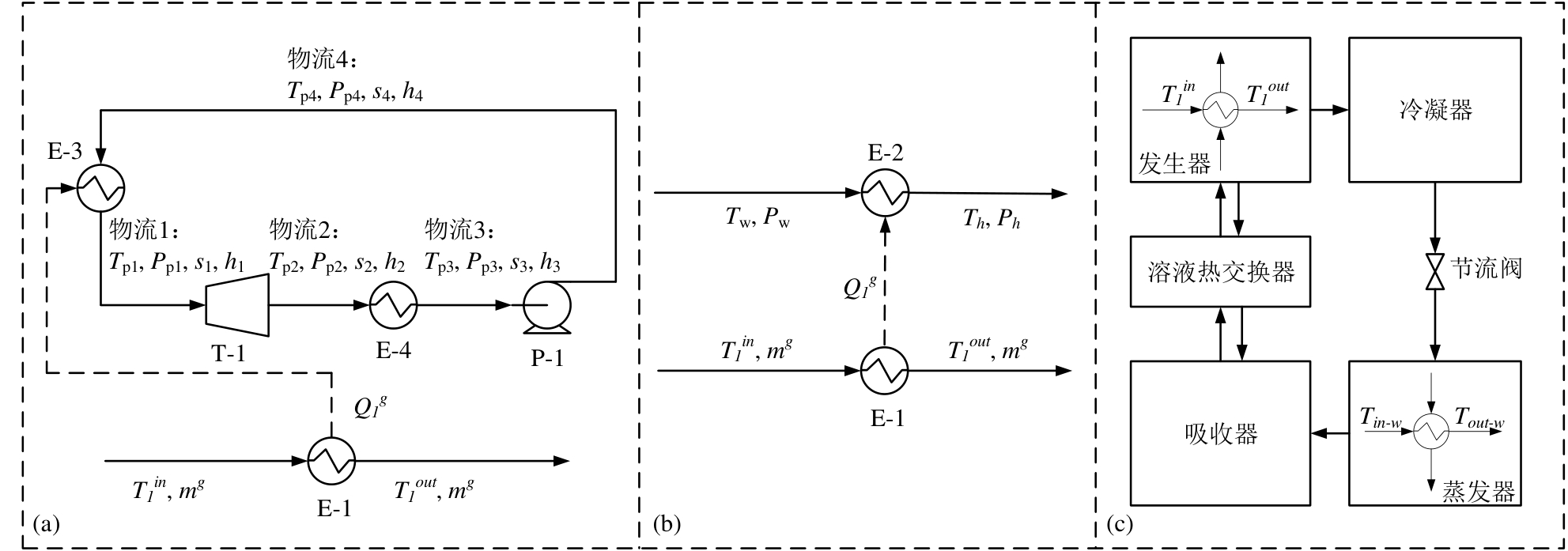

图2 不同生产路径示意框图:(a)产电系统;(b)产蒸汽系统;(c)吸收式制冷系统

Fig.2 Schematic diagrams of different production pathways: (a)Power generation system; (b)Steam generation system; (c)Absorption refrigeration system

| 工质 | 化学式 | 临界温度/ ℃ | 临界压力/ MPa | 沸点/ ℃ |

|---|---|---|---|---|

| R600 | C4H10 | 153.2 | 3.79 | -0.5 |

表1 工质物性信息及其他参数

Table 1 Working medium physical property information and other parameters

| 工质 | 化学式 | 临界温度/ ℃ | 临界压力/ MPa | 沸点/ ℃ |

|---|---|---|---|---|

| R600 | C4H10 | 153.2 | 3.79 | -0.5 |

| 生产路径 | 组件 | 模块 | 生产路径 | 组件 | 模块 |

|---|---|---|---|---|---|

| 产电系统 | 蒸发器 | HeatX | 吸收式制冷系统 | 发生器 | HeatX+Flash2 |

| 冷凝器 | HeatX | 冷凝器 | Heater | ||

| 汽轮机/膨胀机 | Turbine | 蒸发器 | HeatX | ||

| 泵 | Pump | 吸收器 | Heater+Mixer | ||

| 产蒸汽系统 | 换热器 | HeatX | 溶液热交换器 | Heater | |

| 泵 | Pump | ||||

| 节流阀 | Valve |

表2 不同生产路径的模块选择

Table 2 Models selected in different production pathways

| 生产路径 | 组件 | 模块 | 生产路径 | 组件 | 模块 |

|---|---|---|---|---|---|

| 产电系统 | 蒸发器 | HeatX | 吸收式制冷系统 | 发生器 | HeatX+Flash2 |

| 冷凝器 | HeatX | 冷凝器 | Heater | ||

| 汽轮机/膨胀机 | Turbine | 蒸发器 | HeatX | ||

| 泵 | Pump | 吸收器 | Heater+Mixer | ||

| 产蒸汽系统 | 换热器 | HeatX | 溶液热交换器 | Heater | |

| 泵 | Pump | ||||

| 节流阀 | Valve |

| 产电系统 | 产蒸汽系统 | 吸收式制冷系统 | ||||

|---|---|---|---|---|---|---|

| 超超临界发电系统 | ORC系统 | 产高压蒸汽系统 | 产低压蒸汽系统 | |||

| 工质流体进口温度/ ℃ | 157 | 34 | 100 | 100 | 12 | |

| 工质流体出口温度/ ℃ | 603 | 137 | 306 | 171 | 7 | |

| 出口压力/ MPa | 25 | 3 | 9.2 | 0.7 | / | |

| 汽化潜热/ kJ·kg-1 | / | 145.7 | 1360.25 | 2052.70 | / | |

| 比热容/kJ·(kg·K)-1 | 6.3 | 3.2 | 4.6 | 4.3 | 4.2 | |

| 物流1 | 质量焓/ kJ·kg-1 | -12481.01 | -2049.24 | / | / | / |

| 质量熵/ kJ·(kg·K)-1 | -3.05 | -6.34 | / | / | / | |

| 物流2 | 质量焓/ kJ·kg-1 | -13199.78 | -2115.65 | / | / | / |

| 质量熵/ kJ·(kg·K)-1 | -2.53 | -6.26 | / | / | / | |

| 物流3 | 质量焓/ kJ·kg-1 | -15339.92 | -2526.66 | / | / | / |

| 质量熵/ kJ·(kg·K)-1 | -7.56 | -7.60 | / | / | / | |

| 物流4 | 质量焓/ kJ·kg-1 | -15302.87 | -2519.76 | / | / | / |

| 质量熵/ kJ·(kg·K)-1 | -7.54 | -7.59 | / | / | / | |

| 汽轮机T-1的㶲效率 | 0.83 | 0.74 | / | / | / | |

| 泵P-1的㶲效率 | 0.80 | 0.67 | / | / | / | |

| COP | / | / | / | / | 0.75 | |

表3 不同生产路径的相关参数

Table 3 Relevant parameters of different production pathways

| 产电系统 | 产蒸汽系统 | 吸收式制冷系统 | ||||

|---|---|---|---|---|---|---|

| 超超临界发电系统 | ORC系统 | 产高压蒸汽系统 | 产低压蒸汽系统 | |||

| 工质流体进口温度/ ℃ | 157 | 34 | 100 | 100 | 12 | |

| 工质流体出口温度/ ℃ | 603 | 137 | 306 | 171 | 7 | |

| 出口压力/ MPa | 25 | 3 | 9.2 | 0.7 | / | |

| 汽化潜热/ kJ·kg-1 | / | 145.7 | 1360.25 | 2052.70 | / | |

| 比热容/kJ·(kg·K)-1 | 6.3 | 3.2 | 4.6 | 4.3 | 4.2 | |

| 物流1 | 质量焓/ kJ·kg-1 | -12481.01 | -2049.24 | / | / | / |

| 质量熵/ kJ·(kg·K)-1 | -3.05 | -6.34 | / | / | / | |

| 物流2 | 质量焓/ kJ·kg-1 | -13199.78 | -2115.65 | / | / | / |

| 质量熵/ kJ·(kg·K)-1 | -2.53 | -6.26 | / | / | / | |

| 物流3 | 质量焓/ kJ·kg-1 | -15339.92 | -2526.66 | / | / | / |

| 质量熵/ kJ·(kg·K)-1 | -7.56 | -7.60 | / | / | / | |

| 物流4 | 质量焓/ kJ·kg-1 | -15302.87 | -2519.76 | / | / | / |

| 质量熵/ kJ·(kg·K)-1 | -7.54 | -7.59 | / | / | / | |

| 汽轮机T-1的㶲效率 | 0.83 | 0.74 | / | / | / | |

| 泵P-1的㶲效率 | 0.80 | 0.67 | / | / | / | |

| COP | / | / | / | / | 0.75 | |

| [1] | Li Y H, Wang P X, Peng B, et al. Operation strategy and matching of supply and demand of CCHP system with various building types[J]. Journal of Thermal Science, 2024, 33(6): 2203-2220. |

| [2] | Xu Q L, Wang S, Luo K, et al. Process modelling and optimization of a 250 MW IGCC system: Model setup, validation, and preliminary predictions[J]. Energy, 2023, 272: 127040. |

| [3] | Yan X R, He J L, Guo D, et al. Continuous DeNO x technology for improved flexibility and reliability of 1000 MW coal-fired power plants: engineering design, optimization, and environmental benefits[J]. Processes, 2024, 12(1): 56. |

| [4] | Bartela L, Gladysz P, Andreades C, et al. Techno-economic assessment of coal-fired power unit decarbonization retrofit with KP-FHR small modular reactors[J]. Energies, 2021, 14(9): 2557. |

| [5] | Chen C, Zhou Z Q, Bollas G M. Dynamic modeling, simulation and optimization of a subcritical steam power plant. Part I: Plant model and regulatory control[J]. Energy Conversion and Management, 2017, 145: 324-334. |

| [6] | Rocha D H D, Siqueira D S, Silva R J. Exergoenvironmental analysis for evaluating coal-fired power plants technologies[J]. Energy, 2021, 233: 121169. |

| [7] | Zhao Y L, Liu M, Wang C Y, et al. Exergy analysis of the regulating measures of operational flexibility in supercritical coal-fired power plants during transient processes[J]. Applied Energy, 2019, 253: 113487. |

| [8] | Zhou J, Duan F, Wang Y, et al. Dynamic assessment of 1000 MW ultra-supercritical coal-fired power flexibility retrofitting through lean- and rich-fuel integrated gas turbine[J]. Energy, 2024, 305: 132064. |

| [9] | 鄢烈祥, 胡晟华, 麻德贤. 锅炉蒸汽系统多操作周期的优化调度[J]. 化工学报, 2003, 54(12): 1708-1712. |

| Yan L X, Hu S H, Ma D X. Optimal multi-period operational planning for boiler steam systems[J]. CIESC Journal, 2003, 54(12): 1708-1712. | |

| [10] | 陈红, 韩雅芳, 唐志伟. 蒸汽锅炉零排污节能改造及经济分析[J]. 化工进展, 2012, 31(S1): 510-514. |

| Chen H, Han Y F, Tang Z W. Modification and economic analysis of zero emission in steam boiler for energy saving[J]. Chemical Industry and Engineering Progress, 2012, 31(S1): 510-514. | |

| [11] | Ohijeagbon I O, Waheed M A, Jekayinfa S O. Methodology for the physical and chemical exergetic analysis of steam boilers[J]. Energy, 2013, 53: 153-164. |

| [12] | 刘畅, 孙力, 贺高红, 等. 基于不确定蒸汽需求和设备故障的锅炉系统随机规划设计[J]. 化工学报, 2014, 65(9): 3512-3518. |

| Liu C, Sun L, He G H, et al. Boiler system design based on stochastic programming under uncertain steam demand and equipment failure[J]. CIESC Journal, 2014, 65(9): 3512-3518. | |

| [13] | 王晨升, 冯霄. 吸收式制冷循环的能级分析[J]. 计算机与应用化学, 2016, 33(1): 10-16. |

| Wang C S, Feng X. Energy level analysis of an absorption refrigeration cycle[J]. Computers and Applied Chemistry, 2016, 33(1): 10-16. | |

| [14] | Kadam S T, Kyriakides A S, Khan M S, et al. Thermo-economic and environmental assessment of hybrid vapor compression-absorption refrigeration systems for district cooling[J]. Energy, 2022, 243: 122991. |

| [15] | Li W J, Yang Y, Zhang Q, et al. Absorption-compression hybrid refrigeration analysis and application for energy conservation of cryogenic separation in propane dehydrogenation[J]. Computers & Chemical Engineering, 2023, 177: 108336. |

| [16] | Benalcazar P. Sizing and optimizing the operation of thermal energy storage units in combined heat and power plants: An integrated modeling approach[J]. Energy Conversion and Management, 2021, 242: 114255. |

| [17] | 夏大伟, 张少锋, 李玲, 等. 热电联产系统集成蒸汽喷射器性能分析[J]. 热力发电, 2024, 53(11): 147-154. |

| Xia D W, Zhang S F, Li L, et al. Performance analysis of integrated steam injectors in cogeneration systems[J]. Thermal Power Generation, 2024, 53(11): 147-154. | |

| [18] | Sun R Q, Liu M, Chen X, et al. Thermodynamic optimization on supercritical carbon dioxide Brayton cycles to achieve combined heat and power generation[J]. Energy Conversion and Management, 2022, 251: 114929. |

| [19] | Liu R T, Liu M M, Xu C, et al. Thermodynamic study of a novel combined heat and power system integrated with solar energy[J]. Applied Thermal Engineering, 2023, 234: 121192. |

| [20] | Ren S Y, Feng X, Wang Y F. Emergy evaluation of the integrated gasification combined cycle power generation systems with a carbon capture system[J]. Renewable and Sustainable Energy Reviews, 2021, 147: 111208. |

| [21] | 杨干, 翟晓强, 郑春元, 等. 国内冷热电联供系统现状和发展趋势[J]. 化工学报, 2015, 66(S2): 1-9. |

| Yang G, Zhai X Q, Zheng C Y, et al. Current situation and development tendency of CCHP systems in China[J]. CIESC Journal, 2015, 66(S2): 1-9. | |

| [22] | Cui Q, Ma P P, Huang L, et al. Effect of device models on the multiobjective optimal operation of CCHP microgrids considering shiftable loads[J]. Applied Energy, 2020, 275: 115369. |

| [23] | 张亚飞, 王婧, 曹艺怀, 等. 基于双效吸收式冷热水机的冷热电联产系统3E研究[J]. 热能动力工程, 2025, 40(2): 58-66. |

| Zhang Y F, Wang J, Cao Y H, et al. Research on 3E of CCHP system based on double-effect absorption heat pump/chiller[J]. Journal of Engineering for Thermal Energy and Power, 2025, 40(2): 58-66. | |

| [24] | Li F, Sun B, Zhang C H, et al. Operation optimization for combined cooling, heating, and power system with condensation heat recovery[J]. Applied Energy, 2018, 230: 305-316. |

| [25] | Li Y H, Bian X Y, Peng B, et al. Research on interconnected operation characteristics of combined cooling heating and power system based on load difference[J]. Case Studies in Thermal Engineering, 2025, 73: 106509. |

| [26] | Zhao X M, Guo J X, He M G. Multi-objective optimization and improvement of multi-energy combined cooling, heating and power system based on system simplification[J]. Renewable Energy, 2023, 217: 119195. |

| [27] | Wei M L, Yuan W X, Fu L, et al. Summer performance analysis of coal-based CCHP with new configurations comparing with separate system[J]. Energy, 2018, 143: 104-113. |

| [28] | Zhang T T, Tan Y F, Bai L. Numerical simulation of a new district cooling system in cogeneration plants[J]. Energy Procedia, 2012, 14: 855-860. |

| [29] | Zhang J L, Hu Z P. Economic-emission dispatch problem in a biomass-coal co-firing CCHP system based on natural gas deep peak-shaving and carbon capture technologies[J]. Computers & Industrial Engineering, 2025, 203: 110953. |

| [30] | Liao G L, Liu L J, Zhang F, et al. A novel combined cooling-heating and power (CCHP) system integrated organic Rankine cycle for waste heat recovery of bottom slag in coal-fired plants[J]. Energy Conversion and Management, 2019, 186: 380-392. |

| [31] | Li R N, Afzali S F, Mahalec V. Environmental impacts of optimal designs of community energy systems under different CO2 footprints of electric grids[J]. Computers & Chemical Engineering, 2023, 178: 108389. |

| [1] | 臧子晴, 李修真, 谈莹莹, 刘晓庆. 分凝器对两级分离自复叠制冷循环特性影响研究[J]. 化工学报, 2025, 76(S1): 17-25. |

| [2] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [3] | 郭纪超, 徐肖肖, 孙云龙. 基于植物工厂中的CO2浓度气流模拟及优化研究[J]. 化工学报, 2025, 76(S1): 237-245. |

| [4] | 李银龙, 刘国强, 晏刚. 分馏与闪蒸分离耦合自复叠制冷循环性能分析[J]. 化工学报, 2025, 76(S1): 26-35. |

| [5] | 石一帆, 柯钢, 陈浩, 黄孝胜, 叶芳, 李成娇, 郭航. 大型高低温环境实验室温度控制仿真[J]. 化工学报, 2025, 76(S1): 268-280. |

| [6] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [7] | 马爱华, 赵帅, 王林, 常明慧. 太阳能吸收制冷循环动态特性仿真方法研究[J]. 化工学报, 2025, 76(S1): 318-325. |

| [8] | 朱腾飞, 刘晔. 低GWP制冷剂在新能源汽车空调应用性能分析[J]. 化工学报, 2025, 76(S1): 343-350. |

| [9] | 吴成云, 孙浩然. 民用飞机空调系统性能仿真与燃油代偿损失研究[J]. 化工学报, 2025, 76(S1): 351-359. |

| [10] | 李卫, 陈浩, 柯钢, 黄孝胜, 李成娇, 郭航, 叶芳. 高原环境适应性试验室模拟平台新风系统仿真[J]. 化工学报, 2025, 76(S1): 360-369. |

| [11] | 吴迪, 胡斌, 姜佳彤. R1233zd(E)高温热泵实验研究与应用分析[J]. 化工学报, 2025, 76(S1): 377-383. |

| [12] | 何婷, 张开, 林文胜, 陈利琼, 陈家富. 沼气超临界压力低温脱碳-液化耦合流程研究[J]. 化工学报, 2025, 76(S1): 418-425. |

| [13] | 刘豪, 王林, 丁昊, 耿嘉怡. R1150+R1234ze(E)二元体系223.15~253.15 K汽液相平衡研究[J]. 化工学报, 2025, 76(S1): 1-8. |

| [14] | 沙鑫权, 胡然, 丁磊, 蒋珍华, 吴亦农. 空间用单机两级有阀线性压缩机研制及测试[J]. 化工学报, 2025, 76(S1): 114-122. |

| [15] | 苏伟, 赵大海, 金旭, 刘忠彦, 李静, 张小松. 吸湿液滴与混合润湿性表面协同抑霜特性研究[J]. 化工学报, 2025, 76(S1): 140-151. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号