化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6163-6178.DOI: 10.11949/0438-1157.20250274

• 综述与专论 • 上一篇

胡敏睿1( ), 杨占兵1(

), 杨占兵1( ), 李帅2,3, 殷朝辉2,3(

), 李帅2,3, 殷朝辉2,3( )

)

收稿日期:2025-03-20

修回日期:2025-05-09

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

杨占兵,殷朝辉

作者简介:胡敏睿,(2000—),男,硕士研究生,hmr893188163@163.com

基金资助:

Minrui HU1( ), Zhanbing YANG1(

), Zhanbing YANG1( ), Shuai LI2,3, Zhaohui YIN2,3(

), Shuai LI2,3, Zhaohui YIN2,3( )

)

Received:2025-03-20

Revised:2025-05-09

Online:2025-12-31

Published:2026-01-23

Contact:

Zhanbing YANG, Zhaohui YIN

摘要:

三维有序大孔(three-dimensional ordered macropores,3DOM)催化剂因其独特的孔道结构、高比表面积和优异的传质性能,在气体催化吸附领域展现出巨大潜力。然而,3DOM催化剂的制备工艺复杂,面临孔径分布不均匀、合成耗时长、产率低等问题,且孔道的均匀性和稳定性易受到合成条件的影响,导致催化性能不稳定。因此,低成本、高效率的制备工艺,以及可调控的材料孔径、表面化学性质及活性组分,使其适用于特定气体的催化吸附是3DOM催化剂当前的研究重点。综述了胶晶模板法制备3DOM催化剂的工艺优化策略,分析了不同活性组分对VOCs、CO、NO x 、H2S及CO2等气体的催化吸附机制,并探讨了多级孔结构对反应动力学的促进作用。最后,展望了3DOM催化剂在工业气体净化与碳中和领域的应用前景。

中图分类号:

胡敏睿, 杨占兵, 李帅, 殷朝辉. 三维孔道结构催化剂的制备及其在气体纯化领域的研究进展[J]. 化工学报, 2025, 76(12): 6163-6178.

Minrui HU, Zhanbing YANG, Shuai LI, Zhaohui YIN. Preparation of catalysts with three-dimensional pore structure and its research progress in gas purification field[J]. CIESC Journal, 2025, 76(12): 6163-6178.

| 自组装方式 | 孔径分布 | 合成 周期 | 成本 | 产率 | 模板质量 | 文献 |

|---|---|---|---|---|---|---|

| 重力沉积 | 较宽(多孔缺陷) | 7~30 d | 低 | 低 | 中 | |

| 加速沉积 | 中等均匀 | <5 h | 中等 | 中等 | 低 | |

| 垂直沉积 | 高均匀性 | 1~24 h | 中等 | 高 | 高 | |

| 电泳沉积 | 高度可控 | 0.5~2 h | 高 | 低 | 高 | |

| 蒸发自组装 | 均匀 | 12~24 h | 低 | 高 | 低 | |

| 静电辅助逐层组装 | 高度均匀 | 1~2.5 h | 中等 | 中等 | 高 | |

| 直写自组装 | 高度可控 | <1 h | 高 | 低 | 高 |

表1 胶体微球组装方式的优缺点

Table 1 Advantages and disadvantages of colloidal microsphere assembly methods

| 自组装方式 | 孔径分布 | 合成 周期 | 成本 | 产率 | 模板质量 | 文献 |

|---|---|---|---|---|---|---|

| 重力沉积 | 较宽(多孔缺陷) | 7~30 d | 低 | 低 | 中 | |

| 加速沉积 | 中等均匀 | <5 h | 中等 | 中等 | 低 | |

| 垂直沉积 | 高均匀性 | 1~24 h | 中等 | 高 | 高 | |

| 电泳沉积 | 高度可控 | 0.5~2 h | 高 | 低 | 高 | |

| 蒸发自组装 | 均匀 | 12~24 h | 低 | 高 | 低 | |

| 静电辅助逐层组装 | 高度均匀 | 1~2.5 h | 中等 | 中等 | 高 | |

| 直写自组装 | 高度可控 | <1 h | 高 | 低 | 高 |

| 填充方法 | 优点 | 缺点 | 文献 |

|---|---|---|---|

| 溶胶-凝胶法 | 操作简单,纯度高 | 机械强度低 | |

| 电沉积法 | 高结晶度,高质量 | 工艺复杂 | |

| 原子层沉积法 | 结构稳定 | 操作复杂 | |

| 化学气相沉积法 | 填充均匀,效率高 | 操作复杂 |

表2 不同模板填充方法的优缺点

Table 2 Advantages and disadvantages of different template filling methods

| 填充方法 | 优点 | 缺点 | 文献 |

|---|---|---|---|

| 溶胶-凝胶法 | 操作简单,纯度高 | 机械强度低 | |

| 电沉积法 | 高结晶度,高质量 | 工艺复杂 | |

| 原子层沉积法 | 结构稳定 | 操作复杂 | |

| 化学气相沉积法 | 填充均匀,效率高 | 操作复杂 |

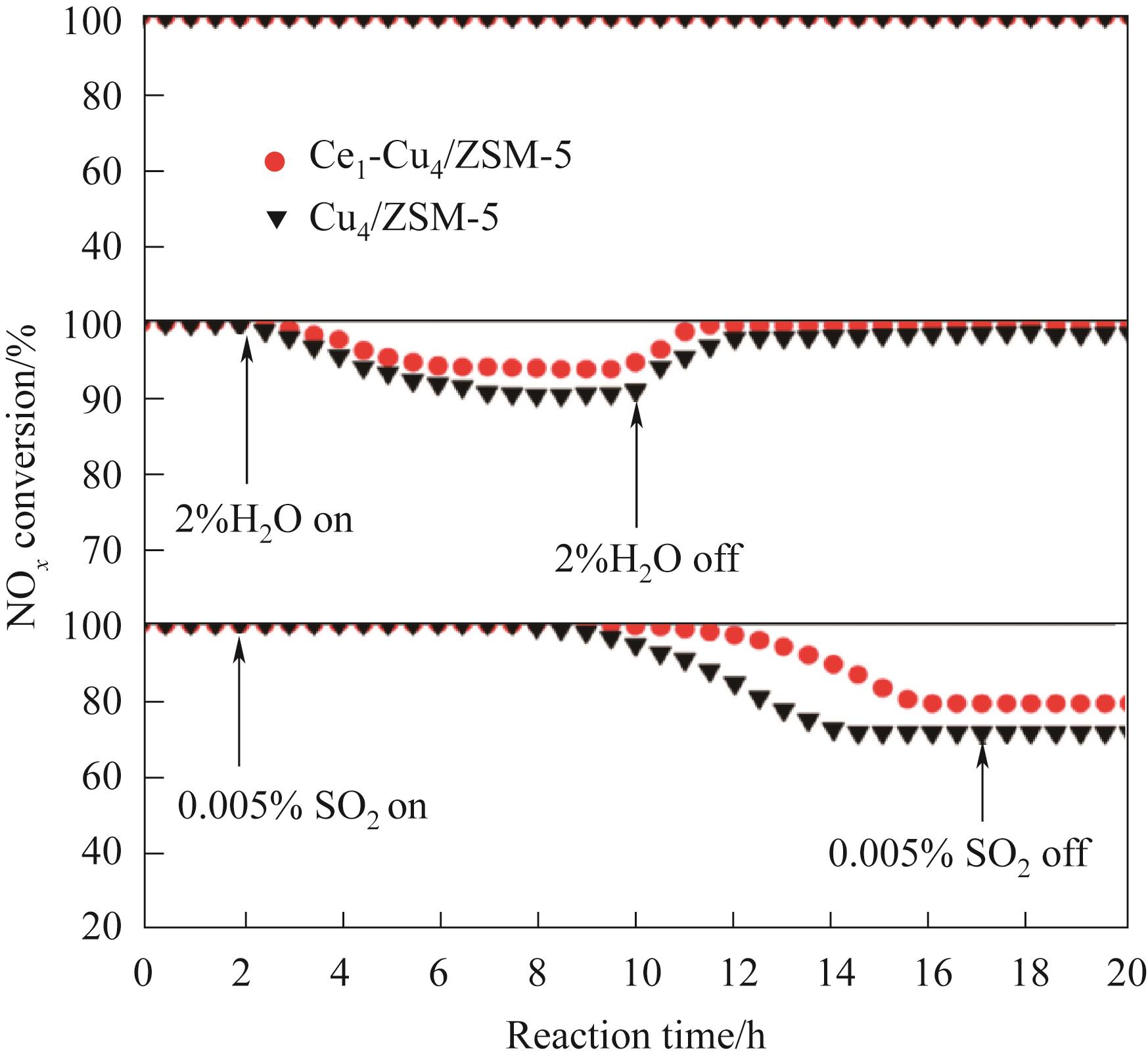

图10 SO2和H2O气体对不同催化剂SCR反应催化活性的影响(反应条件:0.2 g催化剂,0.05% NO,0.05% NH3,200℃,GHSV= 55000 h-1)[97]

Fig.10 Effect of SO2 and H2O gases on the catalytic activity of SCR reactions with different catalysts[97]

| [1] | Zhu G X, Zhu W, Lou Y, et al. Encapsulate α-MnO2 nanofiber within graphene layer to tune surface electronic structure for efficient ozone decomposition[J]. Nature Communications, 2021, 12(1): 4152. |

| [2] | Zhang H H, Wang Z W, Wei L, et al. Recent progress on VOC pollution control via the catalytic method[J]. Chinese Journal of Catalysis, 2024, 61: 71-96. |

| [3] | 黄江华, 陶亨聪, 陈增良, 等. 光催化去除烟气NO x 和VOCs的研究进展[J]. 能源环境保护, 2024, 38(4): 144-154. |

| Huang J H, Tao H C, Chen Z L, et al. Advances in photocatalytic removal of NO x and VOCs from flue gas[J]. Energy Environmental Protection, 2024, 38(4): 144-154. | |

| [4] | Liu Y Z, Guo R T, Duan C P, et al. Removal of gaseous pollutants by using 3DOM-based catalysts: a review[J]. Chemosphere, 2021, 262: 127886. |

| [5] | Stein A. Achieving functionality and multifunctionality through bulk and interfacial structuring of colloidal-crystal-templated materials[J]. Langmuir, 2023, 39(8): 2890-2910. |

| [6] | Guo S B, Yu B, Gao F Y, et al. Research status and development trend of three-dimensional colloidal crystals[J]. Journal of Industrial and Engineering Chemistry, 2021, 96: 34-58. |

| [7] | Guo R T, Hu X, Chen X, et al. Recent progress of three-dimensionally ordered macroporous (3DOM) materials in photocatalytic applications: a review[J]. Small, 2023, 19(15): 2207767. |

| [8] | Hu Y Q, Ding S P, Tan C C, et al. Three-dimensionally ordered macroporous (3DOM) structure promoted the activity and H2O poisoning resistance of CeMn/3DOM-TiO2 catalyst in NH3-SCR[J]. Journal of Rare Earths, 2024, 42(3): 523-533. |

| [9] | 符璇, 张天娇, 马秀彪, 等. 三维有序大孔铈锰复合氧化物催化氧化VOCs[J]. 油气田环境保护, 2022, 32(6): 41-46. |

| Fu X, Zhang T J, Ma X B, et al. Three-dimensional ordered macropores cerium-manganese composite oxides catalyze the oxidation of VOCs[J]. Environmental Protection of Oil & Gas Fields, 2022, 32(6): 41-46. | |

| [10] | Li M, Zhang H, Zhong W, et al. Preparation and chromatographic properties of ordered macroporous polymer monoliths by colloidal crystal templating method[J]. Polymer Bulletin, 2025, 82(1): 69-85. |

| [11] | Fang J F, Xuan Y M, Li Q. Preparation of three-dimensionally ordered macroporous perovskite materials[J]. Chinese Science Bulletin, 2011, 56(20): 2156-2161. |

| [12] | Wen F S, Liu W L. Three-dimensional ordered macroporous materials for photocatalysis: design and applications[J]. Journal of Materials Chemistry A, 2021, 9(34): 18129-18147. |

| [13] | Ali U, Karim K J B A, Buang N A. A review of the properties and applications of poly (methyl methacrylate) (PMMA)[J]. Polymer Reviews, 2015, 55(4): 678-705. |

| [14] | Wang P P, Meng Z H. Progress in polystyrene microspheres[J]. IOP Conference Series: Materials Science and Engineering, 2019, 563(2): 022001. |

| [15] | Stöber W, Fink A, Bohn E. Controlled growth of monodisperse silica spheres in the micron size range[J]. Journal of Colloid and Interface Science, 1968, 26(1): 62-69. |

| [16] | Chaudhary V, Sharma S. Suspension polymerization technique: parameters affecting polymer properties and application in oxidation reactions[J]. Journal of Polymer Research, 2019, 26(5): 102. |

| [17] | 陆思宇. 基于聚苯乙烯的微球研制及检测应用[D]. 北京: 军事科学院, 2023. |

| Lu S Y. Development and detection application of microspheres based on polystyrene[D]. Beijing: Academy of Military Sciences, 2023. | |

| [18] | Chen L Y, Li Y P. Machine learning-guided strategies for reaction conditions design and optimization[J]. Beilstein Journal of Organic Chemistry, 2024, 20: 2476-2492. |

| [19] | Ouyang W Z, Sun Z W, Zhong J, et al. Polymorph selection in the crystallization of hard-core Yukawa system[J]. Science China Chemistry, 2016, 59(3): 316-323. |

| [20] | Zhu J X, Li M, Rogers R, et al. Crystallization of hard-sphere colloids in microgravity[J]. Nature, 1997, 387: 883-885. |

| [21] | 张昭辰, 常森, 李昕, 等. 三维有序胶晶模板的合成及在3DOM-SiO2碘吸附剂中的应用[J]. 化工技术与开发, 2024, 53(4): 18-21, 67. |

| Zhang Z C, Chang S, Li X, et al. Synthesis of three-dimensional ordered colloidal crystal template and its application in 3DOM-SiO2 iodine adsorbent[J]. Technology & Development of Chemical Industry, 2024, 53(4): 18-21, 67. | |

| [22] | Chen X, Sun Z Q, Chen Z M, et al. Alternative preparation and morphologies of self-assembled colloidal crystals via combining capillarity and vertical deposition between two desired substrates[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2008, 315(1/2/3): 89-97. |

| [23] | 李壮, 须秋洁, 刘国金, 等. 基于胶体微球自组装光子晶体的结构生色[J]. 材料研究学报, 2021, 35(3): 175-183. |

| Li Z, Xu Q J, Liu G J, et al. Structural coloration of photonic crystals based on self-assembly of colloid microspheres[J]. Chinese Journal of Materials Research, 2021, 35(3): 175-183. | |

| [24] | Jiang Q S, Li C, Shi S G, et al. Assembling ultra-thick and crack-free colloidal crystals via an isothermal heating evaporation induced self-assembly method[J]. Journal of Non-Crystalline Solids, 2012, 358(12/13): 1611-1616. |

| [25] | Askar K, Leo S Y, Xu C, et al. Rapid electrostatics-assisted layer-by-layer assembly of near-infrared-active colloidal photonic crystals[J]. Journal of Colloid and Interface Science, 2016, 482: 89-94. |

| [26] | Fonseca J, Meng L X, Imaz I, et al. Self-assembly of colloidal metal-organic framework (MOF) particles[J]. Chemical Society Reviews, 2023, 52(7): 2528-2543. |

| [27] | Guillot K A, Brahana P J, Al Harraq A, et al. Selective vapor condensation for the synthesis and assembly of spherical colloids with a precise rough patch[J]. JACS Au, 2024, 4(3): 1107-1117. |

| [28] | Liu G J, Zhou L, Wu Y J, et al. Optical properties of three-dimensional P(St-MAA) photonic crystals on polyester fabrics[J]. Optical Materials, 2015, 42: 72-79. |

| [29] | Ravnik M, Alexander G P, Yeomans J M, et al. Three-dimensional colloidal crystals in liquid crystalline blue phases[J]. Proceedings of the National Academy of Sciences of the United States of America, 2011, 108(13): 5188-5192. |

| [30] | Louh R F, Huang Y J, Tsai Y C, et al. Fabrication and characterization of 3-D photonic crystals of various microspheres by electrophoretic self-assembly[J]. Key Engineering Materials, 2015, 654: 106-113. |

| [31] | Yan H T, Colloidal photonic crystal self-assembled onto the side of an optical fiber: fabrication and characterization[J]. Optical Engineering, 2010, 49(6): 063401. |

| [32] | Huang K M, Ho C L, Chang H J, et al. Fabrication of inverted zinc oxide photonic crystal using sol-gel solution by spin coating method[J]. Nanoscale Research Letters, 2013, 8(1): 306. |

| [33] | You X Q, Pikul J H, King W P, et al. Zinc oxide inverse opal enzymatic biosensor[J]. Applied Physics Letters, 2013, 102(25): 253103. |

| [34] | Liu Y R, Hsueh Y C, Perng T P. Fabrication of TiN inverse opal structure and Pt nanoparticles by atomic layer deposition for proton exchange membrane fuel cell[J]. International Journal of Hydrogen Energy, 2017, 42(15): 10175-10183. |

| [35] | Jiang Y J, Zheng P J, Li D, et al. Enzyme-containing silica inverse opals prepared by using water-soluble colloidal crystal templates: characterization and application[J]. Biochemical Engineering Journal, 2016, 112: 123-129. |

| [36] | Bruna A d D, Martins L C, Paulino T M A, et al. Uniform composition of sol-gel synthetic aluminosilicate precursor as a key factor for the production of geopolymers[J]. Journal of Materials in Civil Engineering, 2023, 35(8): 04023265. |

| [37] | Huang K, Cai Z Y. Synthesis and characterization of three-dimensional ordered macroporous Si-Al compound oxide by sol-gel process[J]. Journal of Sol-Gel Science and Technology, 2018, 87(2): 264-268. |

| [38] | Shim Y H, Lee K E, Shin T J, et al. Tailored colloidal stability and rheological properties of graphene oxide liquid crystals with polymer-induced depletion attractions[J]. ACS Nano, 2018, 12(11): 11399-11406. |

| [39] | Chen X Q, Li Z S, Ye J H, et al. Forced impregnation approach to fabrication of large-area, three-dimensionally ordered macroporous metal oxides[J]. Chemistry of Materials, 2010, 22(12): 3583-3585. |

| [40] | Gu F B, Cui Y Z, Han D M, et al. Atomically dispersed Pt(Ⅱ) on WO3 for highly selective sensing and catalytic oxidation of triethylamine[J]. Applied Catalysis B: Environmental, 2019, 256: 117809. |

| [41] | Wang J X, Zhang W C, Zheng Z L, et al. Enhanced thermal decomposition properties of ammonium perchlorate through addition of 3DOM core-shell Fe2O3/Co3O4 composite[J]. Journal of Alloys and Compounds, 2017, 724: 720-727. |

| [42] | Hatton B, Mishchenko L, Davis S, et al. Assembly of large-area, highly ordered, crack-free inverse opal films[J]. Proceedings of the National Academy of Sciences of the United States of America, 2010, 107(23): 10354-10359. |

| [43] | Míguez H, Meseguer F, López C, et al. Synthesis and photonic bandgap characterization of polymer inverse opals[J]. Advanced Materials, 2001, 13(6): 393-396. |

| [44] | Thakkar R, Bandyopadhyay R. Preparation, characterization, and post-synthetic modification of layered MCM-22 zeolite precursor[J]. Journal of Chemical Sciences, 2017, 129(11): 1671-1676. |

| [45] | Wang Y G, Yuan X H, Liu X H, et al. Mesoporous single-crystal Cr2O3: synthesis, characterization, and its activity in toluene removal[J]. Solid State Sciences, 2008, 10(9): 1117-1123. |

| [46] | Wang X L, Guo Y C, Nan X R, et al. Preparation of inverse opal adsorbent by water-soluble colloidal crystal template to obtain ultrahigh adsorption capacity for salicylic acid removal from aqueous solution[J]. Journal of Hazardous Materials, 2019, 371: 362-369. |

| [47] | Sun Y Q, Feng B, Lian Q, et al. Ordered hierarchical porous structure of PtSn/3DOMM-Al2O3 catalyst for promoting propane non-oxidative dehydrogenation[J]. Nanomaterials, 2023, 13(4): 728. |

| [48] | 陈学兵, 陈刚, 栗嘉琪, 等. 双模板法制备大孔/介孔HPW/SiO2催化剂及其氧化脱硫性能研究[J]. 现代化工, 2023, 43(7): 95-98. |

| ChenX B, Chen G, Li J Q, et al. Preparation of macroporous/mesoporous HPW/SiO2 catalyst by double template method and study on its oxidative desulfurization performance[J]. Modern Chemical Industry, 2023, 43(7): 95-98. | |

| [49] | Davletbaeva I M, Sazonov O O. Macromolecular architecture in the synthesis of micro- and mesoporous polymers[J]. Polymers, 2024, 16(23): 3267. |

| [50] | Wang Y, Arandiyan H, Scott J, et al. Recent advances in ordered meso/macroporous metal oxides for heterogeneous catalysis: a review[J]. Journal of Materials Chemistry A, 2017, 5(19): 8825-8846. |

| [51] | Li L, Huang X D, Zhang J Q, et al. Multi-layer three-dimensionally ordered bismuth trioxide/titanium dioxide nanocomposite: synthesis and enhanced photocatalytic activity[J]. Journal of Colloid and Interface Science, 2015, 443: 13-22. |

| [52] | Wei F C, Zhang T T, Fu J W, et al. Mesoporous polymers: soft-template self-assembly synthesis and applications[J]. Science China Chemistry, 2024, 67(5): 1442-1464. |

| [53] | 刘玮, 蒋丽佳, 戎梅竹. 多孔碳材料的制备及应用进展[J]. 化工新型材料, 2024, 52(8): 8-14. |

| Liu W, Jiang L J, Rong M Z. Preparation and application progress of porous carbon materials[J]. New Chemical Materials, 2024, 52(8): 8-14. | |

| [54] | Sun M H, Huang S Z, Chen L H, et al. Applications of hierarchically structured porous materials from energy storage and conversion, catalysis, photocatalysis, adsorption, separation, and sensing to biomedicine[J]. Chemical Society Reviews, 2016, 45(12): 3479-3563. |

| [55] | Xiong J, Wu Q Q, Mei X L, et al. Fabrication of spinel-type Pd x Co3- x O4 binary active sites on 3D ordered meso-macroporous Ce-Zr-O2 with enhanced activity for catalytic soot oxidation[J]. ACS Catalysis, 2018, 8(9): 7915-7930. |

| [56] | Yang H G, Deng J G, Liu Y X, et al. Preparation and catalytic performance of Ag, Au, Pd or Pt nanoparticles supported on 3DOM CeO2-Al2O3 for toluene oxidation[J]. Journal of Molecular Catalysis A: Chemical, 2016, 414: 9-18. |

| [57] | Deng X H, Chen K, Tüysüz H. Protocol for the nanocasting method: preparation of ordered mesoporous metal oxides[J]. Chemistry of Materials, 2017, 29(1): 40-52. |

| [58] | Sun T T, Shan N N, Xu L B, et al. General synthesis of 3D ordered macro-/mesoporous materials by templating mesoporous silica confined in opals[J]. Chemistry of Materials, 2018, 30(5): 1617-1624. |

| [59] | Wang J J, Li Q, Knoll W, et al. Preparation of multilayered trimodal colloid crystals and binary inverse opals[J]. Journal of the American Chemical Society, 2006, 128(49): 15606-15607. |

| [60] | Hermia J, Vigneron S. Catalytic incineration for odour abatement and VOC destruction[J]. Catalysis Today, 1993, 17(1/2): 349-358. |

| [61] | Kamal M S, Razzak S A, Hossain M M. Catalytic oxidation of volatile organic compounds (VOCs)—A review[J]. Atmospheric Environment, 2016, 140: 117-134. |

| [62] | Ordóñez S, Bello L, Sastre H, et al. Kinetics of the deep oxidation of benzene, toluene, n-hexane and their binary mixtures over a platinum on γ-alumina catalyst[J]. Applied Catalysis B: Environmental, 2002, 38(2): 139-149. |

| [63] | Zhang J, Jin Y, Li C Y, et al. Creation of three-dimensionally ordered macroporous Au/CeO2 catalysts with controlled pore sizes and their enhanced catalytic performance for formaldehyde oxidation[J]. Applied Catalysis B: Environmental, 2009, 91(1/2): 11-20. |

| [64] | Everaert K, Baeyens J. Catalytic combustion of volatile organic compounds[J]. Journal of Hazardous Materials, 2004, 109(1/2/3): 113-139. |

| [65] | Wang Q Y, Li Y X, Serrano-Lotina A, et al. Operando investigation of toluene oxidation over 1D Pt@CeO2 derived from Pt cluster-containing MOF[J]. Journal of the American Chemical Society, 2021, 143(1): 196-205. |

| [66] | Behar S, Gómez-Mendoza N A, Gómez-García M Á, et al. Study and modelling of kinetics of the oxidation of VOC catalyzed by nanosized Cu-Mn spinels prepared via an alginate route[J]. Applied Catalysis A: General, 2015, 504: 203-210. |

| [67] | Zabihi M, Khorasheh F, Shayegan J. Studies on the catalyst preparation methods and kinetic behavior of supported cobalt catalysts for the complete oxidation of cyclohexane[J]. Reaction Kinetics, Mechanisms and Catalysis, 2015, 114(2): 611-628. |

| [68] | Wang P F, Ma X L, Hao X G, et al. Oxygen vacancy defect engineering to promote catalytic activity toward the oxidation of VOCs: a critical review[J]. Catalysis Reviews, 2024, 66(2): 586-639. |

| [69] | Zheng Y E, Li K Z, Wang H, et al. Structure dependence and reaction mechanism of CO oxidation: a model study on macroporous CeO2 and CeO2- ZrO2 catalysts[J]. Journal of Catalysis, 2016, 344: 365-377. |

| [70] | Ou H H, Jin Y, Chong B, et al. Hydroxyl-bonded co single atom site on boroncarbonitride surface realizes nonsacrificial H2O2 synthesis in the near-infrared region[J]. Advanced Materials, 2024, 36(30): 2404851. |

| [71] | Ma Q, Zhang X L, Li J, et al. Transition metal catalysts for atmospheric heavy metal removal: a review of current innovations and advances[J]. Molecules, 2023, 28(22): 7620. |

| [72] | Bastos S S T, Carabineiro S A C, J J M Ó, et al. Total oxidation of ethyl acetate, ethanol and toluene catalyzed by exotemplated manganese and cerium oxides loaded with gold[J]. Catalysis Today, 2012, 180(1): 148-154. |

| [73] | Xie S H, Dai H X, Deng J G, et al. Preparation and high catalytic performance of Au/3DOM Mn2O3 for the oxidation of carbon monoxide and toluene[J]. Journal of Hazardous Materials, 2014, 279: 392-401. |

| [74] | Xie S H, Deng J G, Liu Y X, et al. Excellent catalytic performance, thermal stability, and water resistance of 3DOM Mn2O3-supported Au-Pd alloy nanoparticles for the complete oxidation of toluene[J]. Applied Catalysis A: General, 2015, 507: 82-90. |

| [75] | Xu P, Zhang X, Zhao X T, et al. Preparation, characterization, and catalytic performance of PdPt/3DOM LaMnAl11O19 for the combustion of methane[J]. Applied Catalysis A: General, 2018, 562: 284-293. |

| [76] | Zheng Y F, Xu W N, Yang J N, et al. Catalytic oxidation of VOCs and CO on cobalt-based materials: strategies and mechanisms for improving activity and stability[J]. Chemical Engineering Journal, 2024, 484: 149296. |

| [77] | Liu B C, Liu Y, Li C Y, et al. Three-dimensionally ordered macroporous Au/CeO2-Co3O4 catalysts with nanoporous walls for enhanced catalytic oxidation of formaldehyde[J]. Applied Catalysis B: Environmental, 2012, 127: 47-58. |

| [78] | Liu Y Y, Peyravi A, Dong X B, et al. Effect of microstructure in mesoporous adsorbents on the adsorption of low concentrations of VOCs: an experimental and simulation study[J]. Journal of Hazardous Materials, 2023, 458: 131934. |

| [79] | Li X Q, Zhang L, Yang Z Q, et al. Adsorption materials for volatile organic compounds (VOCs) and the key factors for VOCs adsorption process: a review[J]. Separation and Purification Technology, 2020, 235: 116213. |

| [80] | Liu B C, Li C Y, Zhang Y F, et al. Investigation of catalytic mechanism of formaldehyde oxidation over three-dimensionally ordered macroporous Au/CeO2 catalyst[J]. Applied Catalysis B: Environmental, 2012, 111: 467-475. |

| [81] | 彭林森, 李凝, 蒋武, 等. 掺杂离子种类对三维有序大孔La0.9Ni0.7Mn0.3O3+ δ 催化性能的影响[J]. 广东石油化工学院学报, 2024, 34(4): 39-45. |

| Peng L S, Li N, Jiang W, et al. Synthesis and characterization of 3DOM La0.9Ni0.7M0.3O3+ δ perovskite oxide catalysts[J]. Journal of Guangdong University of Petrochemical Technology, 2024, 34(4): 39-45. | |

| [82] | Liu D, Hu F Y, Yan Y, et al. Promotion of oxygen vacancies and metal-support interaction over 3DOM Au/ CeO2 catalyst for CO oxidation[J]. Applied Surface Science, 2023, 629: 157438. |

| [83] | Yu S H, Jiang N X, Zou W X, et al. A general and inherent strategy to improve the water tolerance of low temperature NH3-SCR catalysts via trace SiO2 deposition[J]. Catalysis Communications, 2016, 84: 75-79. |

| [84] | Wu H, Li J L, Gao M J, et al. Deactivation mechanisms and strategies to mitigate deactivation of iron-based catalysts in NH3-SCR for NO x reduction: a comprehensive review[J]. Separation and Purification Technology, 2025, 358: 130268. |

| [85] | Gao F Y, Tang X L, Sani Z, et al. Spinel-structured Mn-Ni nanosheets for NH3-SCR of NO with good H2O and SO2 resistance at low temperature[J]. Catalysis Science & Technology, 2020, 10(22): 7486-7501. |

| [86] | Gong X J, Teng W K, Liu W, et al. A sucker-reactor polyoxometalate assembled superstructures for efficient photocatalytic nitrogen fixation[J]. Advanced Materials, 2025, 37(3): 2412924. |

| [87] | Fang D, Hou S S, Ye Y L, et al. Insight into highly efficient FeO x catalysts for the selective catalytic reduction of NO x by NH3: experimental and DFT study[J]. Applied Surface Science, 2022, 599: 153998. |

| [88] | Sun D K, Liu Q Y, Liu Z Y, et al. An in situ DRIFTS study on SCR of NO with NH3 over V2O5/AC surface[J]. Catalysis Letters, 2009, 132(1): 122-126. |

| [89] | Jiang B Q, Deng B Y, Zhang Z Q, et al. Effect of Zr addition on the low-temperature SCR activity and SO2 tolerance of Fe-Mn/Ti catalysts[J]. The Journal of Physical Chemistry C, 2014, 118(27): 14866-14875. |

| [90] | Ettireddy P R, Ettireddy N, Boningari T, et al. Investigation of the selective catalytic reduction of nitric oxide with ammonia over Mn/ TiO2 catalysts through transient isotopic labeling and in situ FT-IR studies[J]. Journal of Catalysis, 2012, 292: 53-63. |

| [91] | Wang J P, Yan Z, Liu L L, et al. In situ DRIFTS investigation on the SCR of NO with NH3 over V2O5 catalyst supported by activated semi-coke[J]. Applied Surface Science, 2014, 313: 660-669. |

| [92] | Li G B, Shen K, Wang L, et al. Synergistic degradation mechanism of chlorobenzene and NH3 over the multi-active center catalyst: the role of NO2, Brønsted acidic site, oxygen vacancy[J]. Applied Catalysis B: Environmental, 2021, 286: 119865. |

| [93] | Yang J, Li Z F, Cui J X, et al. Fabrication of wide temperature lanthanum and cerium doped Cu/TNU-9 catalyst with excellent NH3-SCR performance and outstanding SO2+H2O tolerance[J]. Journal of Rare Earths, 2023, 41(8): 1195-1202. |

| [94] | Chen L, Ren S, Liu L, et al. Catalytic performance over Mn-Ce catalysts for NH3-SCR of NO at low temperature: different zeolite supports[J]. Journal of Environmental Chemical Engineering, 2022, 10(2): 107167. |

| [95] | Zhu L, Zeng Y Q, Zhang S L, et al. Effects of synthesis methods on catalytic activities of CoO x -TiO2 for low-temperature NH3-SCR of NO[J]. Journal of Environmental Sciences, 2017, 54: 277-287. |

| [96] | Guo X, Ding Z Y, Kang N, et al. Ce enhanced low-temperature performance of Mn modified Cu-beta zeolite catalyst for NH3-SCR[J]. Fuel, 2024, 361: 130694. |

| [97] | Lai S S, Meng D M, Zhan W C, et al. The promotional role of Ce in Cu/ZSM-5 and in situ surface reaction for selective catalytic reduction of NO x with NH3 [J]. RSC Advances, 2015, 5(110): 90235-90244. |

| [98] | Tan C, Shen K, Zhou Y, et al. Poisoning mechanism study of metal ions on a three-dimensional ordered macroporous structure Ce0.2Mn0.2/3DOM-TiO2 catalyst for low-temperature SCR of NO with NH3 [J]. Industrial & Engineering Chemistry Research, 2024, 63(15): 6534-6545. |

| [99] | Madhav D, Wang J, Keloth R, et al. A review of proton exchange membrane degradation pathways, mechanisms, and mitigation strategies in a fuel cell[J]. Energies, 2024, 17(5): 998. |

| [100] | Xue M, Chitrakar R, Sakane K, et al. Screening of adsorbents for removal of H2S at room temperature[J]. Green Chemistry, 2003, 5(5): 529-534. |

| [101] | Yazdanbakhsh F, Bläsing M, Sawada J A, et al. Copper exchanged nanotitanate for high temperature H2S adsorption[J]. Industrial & Engineering Chemistry Research, 2014, 53(29): 11734-11739. |

| [102] | Bouzaza A, Laplanche A, Marsteau S. Adsorption-oxidation of hydrogen sulfide on activated carbon fibers: effect of the composition and the relative humidity of the gas phase[J]. Chemosphere, 2004, 54(4): 481-488. |

| [103] | Meeyoo V, Lee J H, Trimm D L, et al. Hydrogen sulphide emission control by combined adsorption and catalytic combustion[J]. Catalysis Today, 1998, 44(1/2/3/4): 67-72. |

| [104] | Yang C, Wang Y S, Fan H L, et al. Bifunctional ZnO-MgO/activated carbon adsorbents boost H2S room temperature adsorption and catalytic oxidation[J]. Applied Catalysis B: Environmental, 2020, 266: 118674. |

| [105] | Shi Z, Dong F, Tang Z C, et al. Design Sr, Mn-doped 3DOM LaCoO3 perovskite catalysts with excellent SO2 resistance for benzene catalytic combustion[J]. Chemical Engineering Journal, 2023, 473: 145476. |

| [106] | Wang J, Wang L J, Fan H L, et al. Highly porous copper oxide sorbent for H2S capture at ambient temperature[J]. Fuel, 2017, 209: 329-338. |

| [107] | Xu M, Zhang Q Y, Wei S P, et al. Engineering heteronuclear dual-metal active sites in ordered macroporous architectures for enhanced C2H4 production from CO2 photoreduction[J]. Angewandte Chemie International Edition, 2025, 64(23): e202506072. |

| [108] | Martín-Martínez J M, Torregrosa-Maciá R, Mittelmeijer-Hazeleger M C, et al. Mechanisms of adsorption of CO2 in the micropores of activated anthracite[J]. Fuel, 1995, 74(1): 111-114. |

| [109] | Zhao C, Jin Y, Yuan J K, et al. Tailoring activation intermediates of CO2 initiates C—N coupling for highly selective urea electrosynthesis[J]. Journal of the American Chemical Society, 2025, 147(10): 8871-8880. |

| [110] | Zhao J, Zhang P, Yuan T, et al. Modulation of *CH x O adsorption to facilitate electrocatalytic reduction of CO2 to CH4 over Cu-based catalysts[J]. Journal of the American Chemical Society, 2023, 12: 6622-6627. |

| [111] | Vorokhta M, Morávková J, Daniela Ř, et al. CO2 capture using three-dimensionally ordered micromesoporous carbon[J]. Journal of CO2 Utilization, 2019, 31: 124-134. |

| [112] | Vorokhta M, Nováková J, Dopita M, et al. Activated three-dimensionally ordered micro mesoporous carbons for CO2 capture[J]. Materials Today Sustainability, 2023, 24: 100509. |

| [113] | He H K, Zhong M J, Konkolewicz D, et al. Colloidal crystals: three-dimensionally ordered macroporous polymeric materials by colloidal crystal templating for reversible CO2 capture[J]. Advanced Functional Materials, 2013, 23(37): 4719. |

| [114] | Choi S, Drese J H, Eisenberger P M, et al. Application of amine-tethered solid sorbents for direct CO2 capture from the ambient air[J]. Environmental Science & Technology, 2011, 45(6): 2420-2427. |

| [1] | 苏伟, 赵大海, 金旭, 刘忠彦, 李静, 张小松. 吸湿液滴与混合润湿性表面协同抑霜特性研究[J]. 化工学报, 2025, 76(S1): 140-151. |

| [2] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [3] | 裴星亮, 叶翠平, 裴赢丽, 李文英. 碱改性MIL-53(Cr)选择性吸附分离二甲苯异构体[J]. 化工学报, 2025, 76(S1): 258-267. |

| [4] | 吴梓航, 徐震原, 游锦方, 潘权稳, 王如竹. 基于吸附式储冷技术的深井钻探设备冷却系统[J]. 化工学报, 2025, 76(S1): 309-317. |

| [5] | 黄国瑞, 赵耀, 谢明熹, 陈尔健, 代彦军. 一种新型数据中心余热回收系统实验与分析[J]. 化工学报, 2025, 76(S1): 409-417. |

| [6] | 任现超, 谷雅秀, 段少斌, 贾文竹, 李汉林. 翅片式椭圆套管蒸发式冷凝器传热传质性能实验研究[J]. 化工学报, 2025, 76(S1): 75-83. |

| [7] | 赵维, 邢文乐, 韩朝旭, 袁兴中, 蒋龙波. g-C3N4基非金属异质结光催化降解水中有机污染物的研究进展[J]. 化工学报, 2025, 76(9): 4752-4769. |

| [8] | 张茹, 朱传强, 张栋, 黄政, 肖雨果, 李明, 李长明. 采用高分子非催化还原脱硝的垃圾焚烧工艺伴生固废含氮污染物特征研究[J]. 化工学报, 2025, 76(9): 4944-4959. |

| [9] | 钱慧慧, 王文婕, 陈文尧, 周兴贵, 张晶, 段学志. 聚丙烯定向转化制芳烃:金属-分子筛协同催化机制[J]. 化工学报, 2025, 76(9): 4838-4849. |

| [10] | 佟丽丽, 陈英, 艾敏华, 舒玉美, 张香文, 邹吉军, 潘伦. ZnO/WO3异质结光催化环烯烃[2+2]环加成制备高能量密度燃料[J]. 化工学报, 2025, 76(9): 4882-4892. |

| [11] | 陈科拯, 高蓬辉, 焉富春, 程博. 考虑液滴动态行为的亲-疏水复合结构表面冷凝特性影响因素分析[J]. 化工学报, 2025, 76(8): 3976-3989. |

| [12] | 周航, 张斯婧, 刘剑, 张小松. 小通道内非共沸工质流动沸腾换热数值分析[J]. 化工学报, 2025, 76(8): 3864-3872. |

| [13] | 巢欣旖, 陈文尧, 张晶, 钱刚, 周兴贵, 段学志. 甲醇和乙酸甲酯一步法制丙酸甲酯催化剂的可控制备与性能调控[J]. 化工学报, 2025, 76(8): 4030-4041. |

| [14] | 杨敏, 段新伟, 吴俊宏, 米杰, 王建成, 武蒙蒙. Sm2O3/γ-Al2O3催化剂的COS催化水解性能及失活机制[J]. 化工学报, 2025, 76(8): 4061-4070. |

| [15] | 周媚, 曾浩桀, 蒋火炎, 蒲婷, 曾星星, 刘宝玉. 二次晶化法改性合成MTW分子筛及其在苯和环己烯烷基化反应中的催化性能[J]. 化工学报, 2025, 76(8): 4071-4080. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号