化工学报 ›› 2025, Vol. 76 ›› Issue (8): 3976-3989.DOI: 10.11949/0438-1157.20250010

收稿日期:2025-01-03

修回日期:2025-03-14

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

高蓬辉

作者简介:陈科拯(1999—),男,博士研究生,632965834@qq.com

基金资助:

Kezheng CHEN1( ), Penghui GAO1,2(

), Penghui GAO1,2( ), Fuchun YAN1, Bo CHENG1

), Fuchun YAN1, Bo CHENG1

Received:2025-01-03

Revised:2025-03-14

Online:2025-08-25

Published:2025-09-17

Contact:

Penghui GAO

摘要:

为了揭示亲-疏水复合结构表面对冷凝传热的增强作用和冷凝液滴的动态行为的影响,在滴状冷凝(dropwise condensation,DWC)和膜态冷凝(filmwise condensation,FWC)理论的基础上,结合冷凝液滴成核、合并、脱离和滑动清扫效应,建立了亲-疏水复合表面蒸汽冷凝传热特性试验系统和数学模型,分析了不同表面结构尺寸、蒸汽温度和过冷度下,液滴动态行为对冷凝传热特性的影响。复合表面圆形疏水区直径为WDWC,亲水通道间隔为WFWC。结果表明,在不同条件下,冷凝系数随WDWC的增大先提高后减小,有唯一WDWC与WFWC对应,使得冷凝系数达到最高。并且,最佳WDWC仅受WFWC的影响明显,对其他因素的影响不敏感。复合表面加速了液滴的脱离,在接触角110°,过冷度为5℃,饱和蒸汽温度为70℃的工况下,最佳结构尺寸(WDWC=1.5 mm,WFWC=0.5 mm)相比完全疏水表面冷凝系数提高71.4%。

中图分类号:

陈科拯, 高蓬辉, 焉富春, 程博. 考虑液滴动态行为的亲-疏水复合结构表面冷凝特性影响因素分析[J]. 化工学报, 2025, 76(8): 3976-3989.

Kezheng CHEN, Penghui GAO, Fuchun YAN, Bo CHENG. Influencing factors analysis of condensation heat transfer on hydrophilic-hydrophobic composite surfaces considering droplets dynamic behavior[J]. CIESC Journal, 2025, 76(8): 3976-3989.

| 参数 | 亲水区 | 疏水区 |

|---|---|---|

| 左接触角/(°) | 65.3 | 110.4 |

| 右接触角/(°) | 64.4 | 109.8 |

| 平均接触角/(°) | 64.9 | 110.1 |

| 固体黏附功/(mN/m) | 119.82 | 52.97 |

| 固体表面能/(mN/m) | 69.3 | 40.6 |

表1 表面湿润性测试结果

Table 1 Surface wetness test results

| 参数 | 亲水区 | 疏水区 |

|---|---|---|

| 左接触角/(°) | 65.3 | 110.4 |

| 右接触角/(°) | 64.4 | 109.8 |

| 平均接触角/(°) | 64.9 | 110.1 |

| 固体黏附功/(mN/m) | 119.82 | 52.97 |

| 固体表面能/(mN/m) | 69.3 | 40.6 |

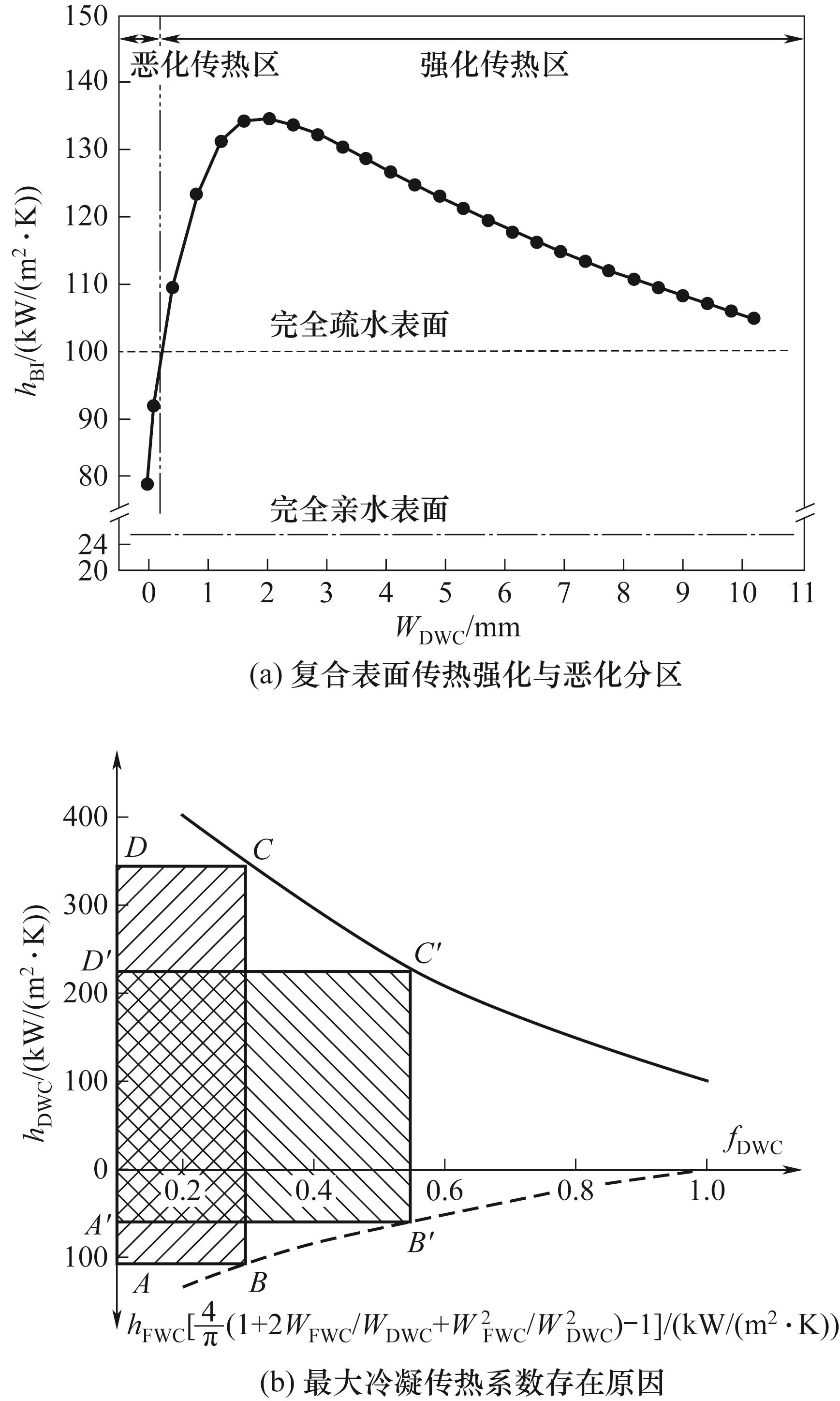

图13 复合结构表面强化传热示意图(WFWC=1.0 mm,Tsat=70℃,ΔT=5℃,θ=110°,θa=120°,θr=105°)

Fig.13 Schematic diagram of enhanced heat transfer of composite structure surface

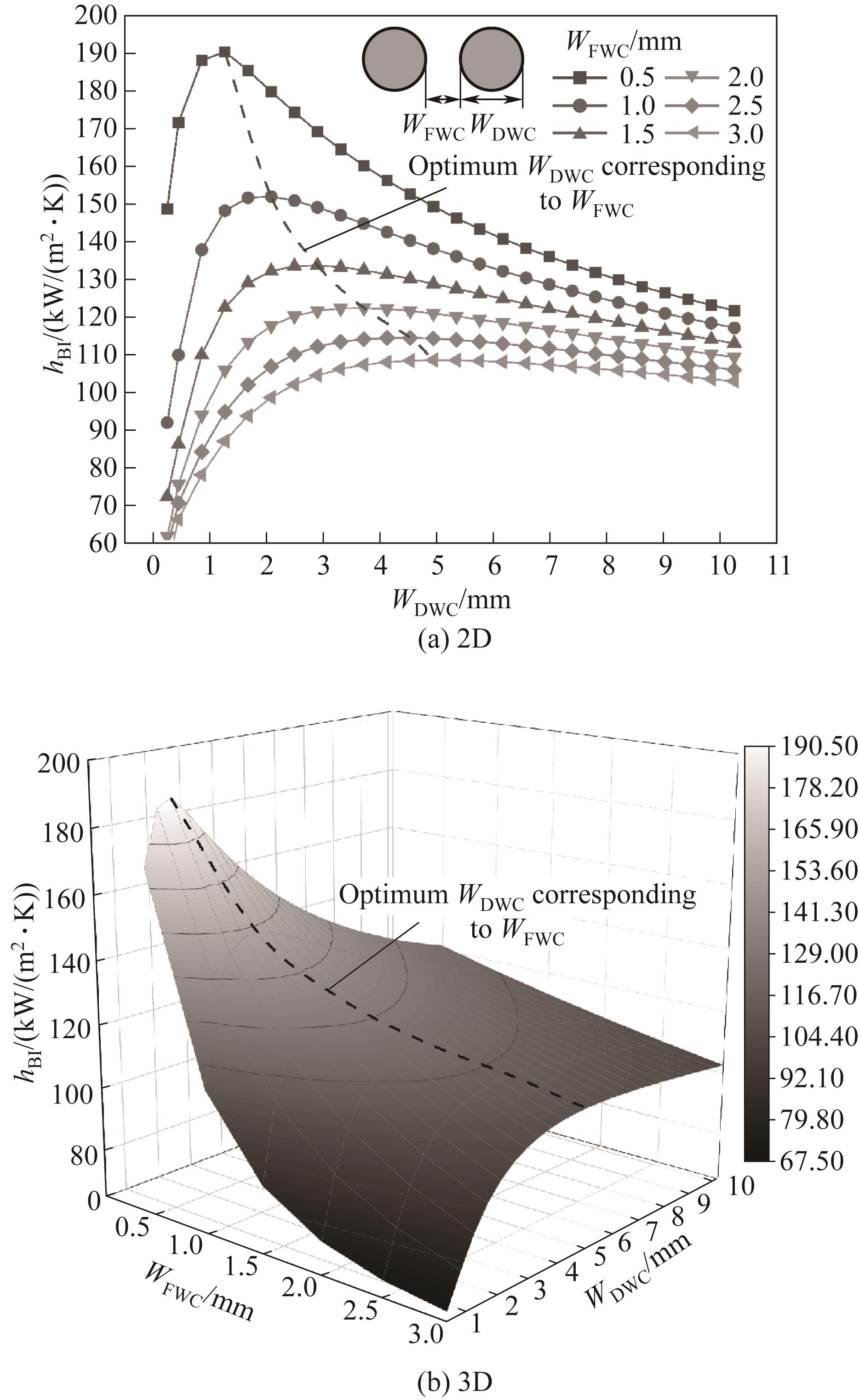

图14 疏水区θ=100°时复合表面结构参数对冷凝传热的影响

Fig.14 Influence of composite structure size on condensation heat transfer at θ=100°(Tsat=70℃,ΔT=5℃,θa=110°,θr=95°,δp=2 nm)

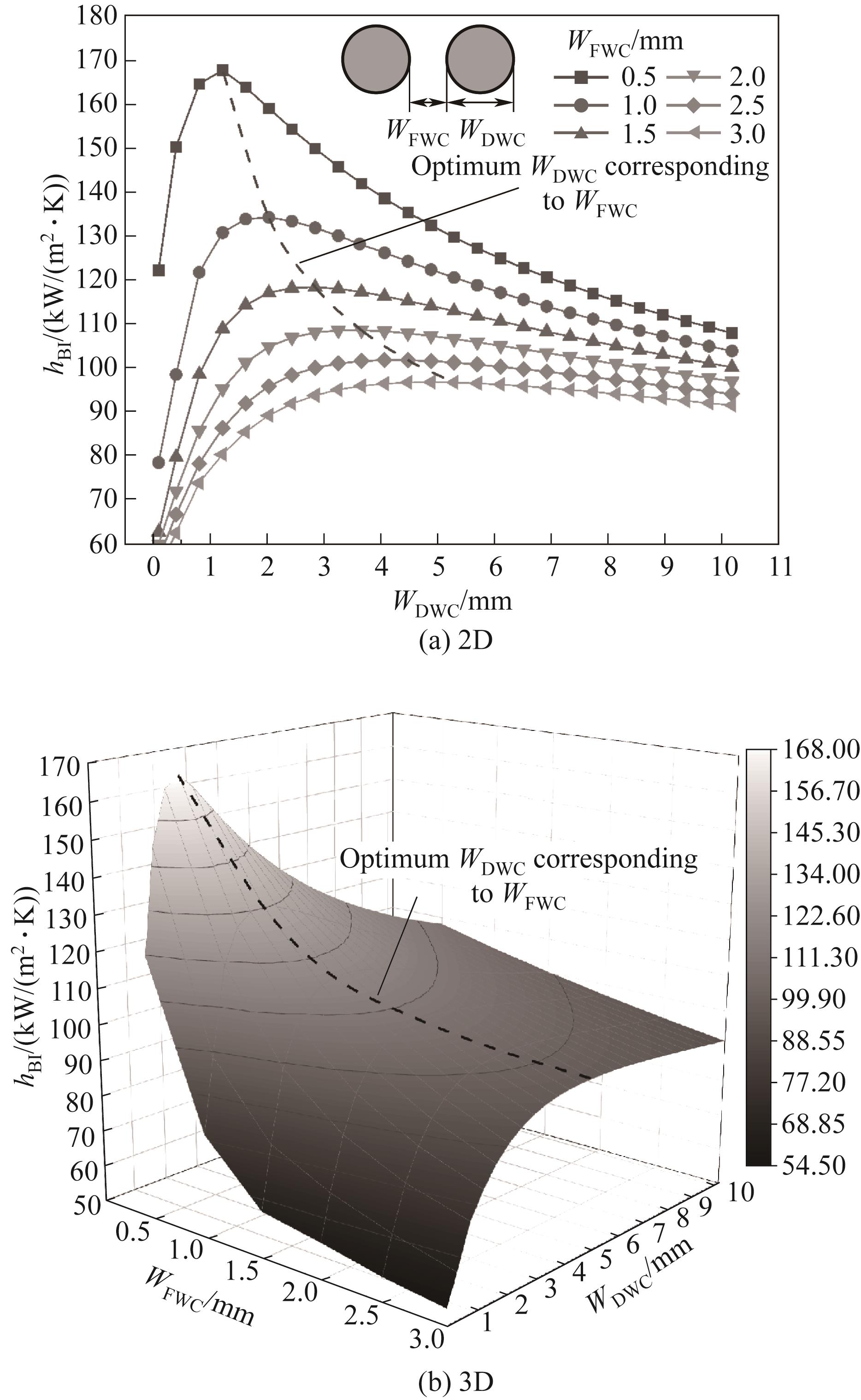

图15 疏水区θ=110°时复合表面结构参数对冷凝传热的影响

Fig.15 Influence of composite structure size on condensation heat transfer at θ=110°(Tsat=70℃,ΔT=5℃,θa=120°,θr=105°,δp=2 nm)

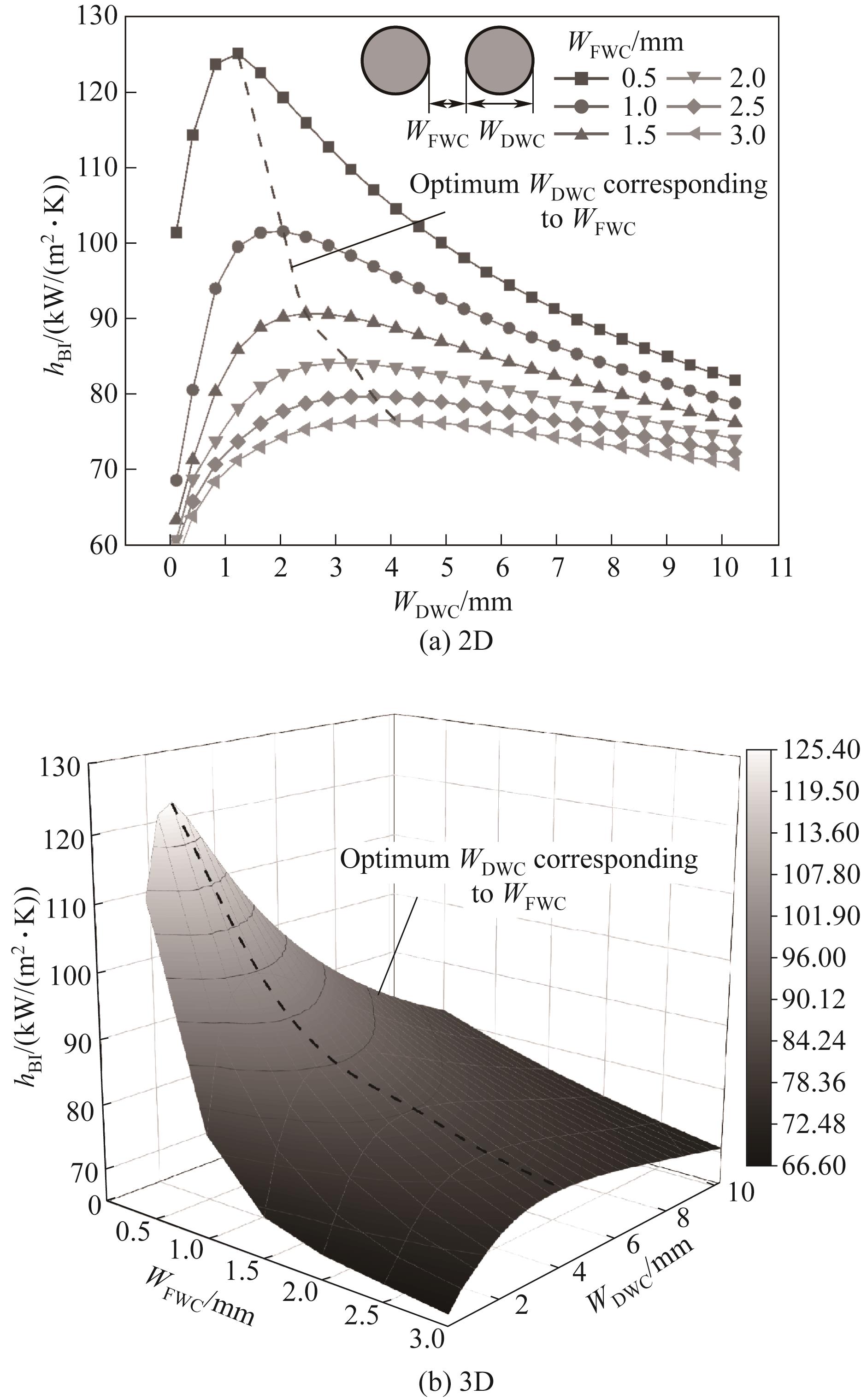

图16 疏水区θ=120°时复合表面结构参数对冷凝传热的影响

Fig.16 Influence of composite structure size on condensation heat transfer at θ=120°(Tsat=70℃,ΔT=5℃,θa=130°,θr=115°,δp=2 nm)

| [1] | Du Z, Liu B, Liu X, et al. Study on high efficiency separation of low condensation lignin and its dissolution mechanism by 1,4-butanediol combined with p-toluene sulfonic acid pretreatment system[J]. Separation and Purification Technology, 2025, 360: 131059. |

| [2] | Beér J M. High efficiency electric power generation: the environmental role[J]. Progress in Energy and Combustion Science, 2007, 33(2): 107-134. |

| [3] | Zhang Y, Shen F, Cao W F, et al. Hydrophilic/hydrophobic Janus membranes with a dual-function surface coating for rapid and robust membrane distillation desalination[J]. Desalination, 2020, 491: 114561. |

| [4] | Kandlikar S G, Lu Z J. Thermal management issues in a PEMFC stack—a brief review of current status[J]. Applied Thermal Engineering, 2009, 29(7): 1276-1280. |

| [5] | Schmidt E, Schurig W, Sellschopp W. Versuche über die kondensation von wasserdampf in film-und tropfenform[J]. Technische Mechanik und Thermodynamik, 1930, 1(2): 53-63. |

| [6] | 甘园园, 纪献兵, 赵昶, 等.超疏水高/低黏附表面的冷凝传热特性[J].表面技术,2022,51(7):288-296, 323. |

| Gan Y Y, Ji X B, Zhao C, et al. Heat transfer characteristics of superhydrophobic high adhesion surface and superhydrophobic low adhesion surface[J]. Surface Technology, 2022, 51(7): 288-296, 323. | |

| [7] | Miljkovic N, Enright R, Wang E N. Modeling and optimization of superhydrophobic condensation[J]. Journal of Heat Transfer, 2013, 135(11): 111004. |

| [8] | Enright R, Miljkovic N, Dou N, et al. Condensation on superhydrophobic copper oxide nanostructures[J]. Journal of Heat Transfer, 2013, 135(9): 091304. |

| [9] | 李科, 贺文介, 王亚雄. 基于LBM方法的超亲水/疏水组合表面的沸腾冷凝特性研究[J]. 热科学与技术, 2021, 20(5): 417-423. |

| Li K, He W J, Wang Y X. Study on boiling bondensation characteristics of superhydrophilic hydrophobic composite surface based on LBM method[J]. Journal of Thermal Science and Technology, 2021, 20(5): 417-423. | |

| [10] | 姜洪鹏, 白敏丽, 高栋栋, 等. 超疏水/亲水性结构表面流动沸腾传热实验研究[J]. 化工学报, 2021, 72(8): 4093-4103. |

| Jiang H P, Bai M L, Gao D D, et al. Experimental study on flow boiling heat transfer on superhydrophobic/hydrophilic structure surface[J]. CIESC Journal, 2021, 72(8): 4093-4103. | |

| [11] | 刘灯辉, 黄志, 冯妍卉, 等. 超亲水-超疏水组合壁面冷凝性能研究[J]. 工程热物理学报, 2021, 42(2):475-480. |

| Liu D H, Huang Z, Feng Y H, et al. Vapor condensation on hybrid superhydrophilic/superhydrophobic surfaces[J]. Journal of Engineering Thermophysics, 2021, 42(2): 475-480. | |

| [12] | Derby M M, Chatterjee A, Peles Y, et al. Flow condensation heat transfer enhancement in a mini-channel with hydrophobic and hydrophilic patterns[J]. International Journal of Heat and Mass Transfer, 2014, 68: 151-160. |

| [13] | Chatterjee A, Derby M M, Peles Y, et al. Condensation heat transfer on patterned surfaces[J]. International Journal of Heat and Mass Transfer, 2013, 66: 889-897. |

| [14] | Chatterjee A, Derby M M, Peles Y, et al. Enhancement of condensation heat transfer with patterned surfaces[J]. International Journal of Heat and Mass Transfer, 2014, 71: 675-681. |

| [15] | Graham C, Griffith P. Drop size distributions and heat transfer in dropwise condensation[J]. International Journal of Heat and Mass Transfer, 1973, 16(2): 337-346. |

| [16] | Chen J C. Surface contact: its significance for multiphase heat transfer: diverse examples[J]. Journal of Heat Transfer, 2003, 125(4): 549-566. |

| [17] | Abu-Orabi M. Modeling of heat transfer in dropwise condensation[J]. International Journal of Heat and Mass Transfer, 1998, 41(1): 81-87. |

| [18] | Fevre E L, Rose J W. A theory of heat transfer by dropwise condensation[C]. Proceedings of 3rd International Heat and Mass Transfer Conference, 1966, 2: 362-375. |

| [19] | Vemuri S, Kim K J. An experimental and theoretical study on the concept of dropwise condensation[J]. International Journal of Heat and Mass Transfer, 2006, 49(3/4): 649-657. |

| [20] | Peng B L, Ma X H, Lan Z, et al. Analysis of condensation heat transfer enhancement with dropwise-filmwise hybrid surface: droplet sizes effect[J]. International Journal of Heat and Mass Transfer, 2014, 77: 785-794. |

| [21] | Peng B L, Ma X H, Lan Z, et al. Experimental investigation on steam condensation heat transfer enhancement with vertically patterned hydrophobic-hydrophilic hybrid surfaces[J]. International Journal of Heat and Mass Transfer, 2015, 83: 27-38. |

| [22] | 彭本利.液滴动态特性调控强化冷凝传热的研究和LB模拟[D]. 大连: 大连理工大学, 2014. |

| Peng B L. Study and LB simulation of condensation heat transfer enhancement by adjusting dynamic characteristics of droplets[D]. Dalian: Dalian University of Technology, 2014. | |

| [23] | Xie J, She Q T, Xu J L, et al. Mixed dropwise-filmwise condensation heat transfer on biphilic surface[J]. International Journal of Heat and Mass Transfer, 2020, 150: 119273. |

| [24] | Mohamed M A, Ahmed S A, Emeara M S, et al. Experimental study for enhancing condensation on large-scale surface using hybrid hydrophilic-hydrophobic patterns[J]. Case Studies in Thermal Engineering, 2023, 45: 102984. |

| [25] | Xie J, Xu J L, Shang W, et al. Mode selection between sliding and rolling for droplet on inclined surface: effect of surface wettability[J]. International Journal of Heat and Mass Transfer, 2018, 122: 45-58. |

| [26] | Qi B J, Wei J J, Zhang L, et al. A fractal dropwise condensation heat transfer model including the effects of contact angle and drop size distribution[J]. International Journal of Heat and Mass Transfer, 2015, 83: 259-272. |

| [27] | 郭亚丽, 王润, 刘瑞, 等.蒸汽滴状冷凝演变和液滴生长方式的研究[J]. 工程热物理学报, 2023, 44(7):1881-1890. |

| Guo Y L, Wang R, Liu R, et al. Study on the evolution of steam dropwise condensation and droplet growth mode[J]. Journal of Engineering Thermophysics, 2023, 44(7): 1881-1890. | |

| [28] | 兰忠, 马学虎, 张宇, 等. 引入液固界面效应的滴状冷凝传热模型[J]. 化工学报, 2005, 56(9): 1626-1632. |

| Lan Z, Ma X H, Zhang Y, et al. Dropwise condensation heat transfer model with liquid-solid surface free energy difference effect[J]. Journal of Chemical Industry and Engineering(China), 2005, 56(9): 1626-1632. | |

| [29] | Lee S, Yoon H K, Kim K J, et al. A dropwise condensation model using a nano-scale, pin structured surface[J]. International Journal of Heat and Mass Transfer, 2013, 60: 664-671. |

| [30] | Vemuri S, Kim K J. An experimental and theoretical study on the concept of dropwise condensation[J]. International Journal of Heat and Mass Transfer, 2006, 49(3/4): 649-657. |

| [1] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [2] | 苏伟, 赵大海, 金旭, 刘忠彦, 李静, 张小松. 吸湿液滴与混合润湿性表面协同抑霜特性研究[J]. 化工学报, 2025, 76(S1): 140-151. |

| [3] | 龚路远, 果正龙, 赵登辉, 郭亚丽, 周健, 韩倩倩, 沈胜强. 不同疏水性表面冷凝传热性能及动力学特征研究[J]. 化工学报, 2025, 76(8): 3932-3943. |

| [4] | 刘璐, 杨莹, 杨浩文, 王太, 王腾, 董新宇, 闫润. 星形亲水区组合表面冷凝液滴脱落特性实验研究[J]. 化工学报, 2025, 76(8): 3905-3914. |

| [5] | 周航, 张斯婧, 刘剑, 张小松. 小通道内非共沸工质流动沸腾换热数值分析[J]. 化工学报, 2025, 76(8): 3864-3872. |

| [6] | 王光磊, 刘晓玲, 徐震, 李琳. 面向压缩空气储能的气-水直接接触换热特性[J]. 化工学报, 2025, 76(4): 1595-1603. |

| [7] | 田浩辰, 马志先, 王之浩. R1234ze(E)水平三维肋管外膜状凝结特性实验研究[J]. 化工学报, 2025, 76(3): 975-984. |

| [8] | 李焱, 郑利军, 张恩勇, 王云飞. 深水海底管道软管内部流体渗透特性模型与试验研究[J]. 化工学报, 2024, 75(S1): 118-125. |

| [9] | 洪奥越, 徐强, 蒋帅之, 李翔宇, 马小俊, 郭烈锦. 蒸汽射流直接接触凝结诱导振动特性研究[J]. 化工学报, 2024, 75(8): 2723-2733. |

| [10] | 赵亮, 张梦妍, 果正龙, 郭亚丽, 龚路远, 沈胜强. 滴状冷凝的液滴分布特性[J]. 化工学报, 2024, 75(12): 4490-4500. |

| [11] | 周尧, 杨小平, 倪一程, 刘继平, 魏进家, 严俊杰. 应用于新型环路热管的两相引射器数值模拟[J]. 化工学报, 2024, 75(1): 268-278. |

| [12] | 苏伟, 马东旭, 金旭, 刘忠彦, 张小松. 表面润湿性对霜层传递特性影响可视化实验研究[J]. 化工学报, 2023, 74(S1): 122-131. |

| [13] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [14] | 时国华, 何林珅, 赵玺灵, 张世钢. 余热回收喷淋塔的烟气颗粒物脱除特性研究[J]. 化工学报, 2023, 74(4): 1735-1745. |

| [15] | 何洋, 高森虎, 吴青云, 张明理, 龙涛, 牛佩, 高景辉, 孟颖琪. 析湿工况下平直开缝翅片传热传质特性的数值研究[J]. 化工学报, 2023, 74(3): 1073-1081. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号