化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6289-6301.DOI: 10.11949/0438-1157.20250557

收稿日期:2025-05-21

修回日期:2025-08-02

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

魏进家

作者简介:马紫欢(1997—),女,博士研究生,mazihuan89@163.com

基金资助:

Zihuan MA( ), Xiaoping YANG, Nanjing HAO, Jinjia WEI(

), Xiaoping YANG, Nanjing HAO, Jinjia WEI( )

)

Received:2025-05-21

Revised:2025-08-02

Online:2025-12-31

Published:2026-01-23

Contact:

Jinjia WEI

摘要:

面向高热通量电子器件热管理需求的高效冷却策略,以HFE7100和硅作为工作流体和固体材料,对Z形和楔形歧管微通道(MMC)内过冷流动沸腾过程进行模拟研究,讨论了具有不同楔角配置的楔形MMC对流量分布均匀性、总压降及压降分布均匀性、芯片温度及相体积分数的影响规律。结果表明,楔形MMC能够显著改善流量分布均匀性,其中Taper-200-50将流量分布的标准差最大降低了约50.9%。此外,楔形MMC可显著降低总压降及其波动幅度,有效改善压降分布的均匀性,从而提高流动稳定性。其中Taper-200-50将总压降降低57.3%~60.0%,压降波动标准差降低75.3%~85.1%,压降分布均匀性标准差降低81.2%~84.3%。在换热性能方面,楔形MMC的芯片平均温度与传统Z形差异较小,Taper-150-75和Taper-200-50表现出较优的换热性能,而Taper-250-25的换热效果最差,这表明当楔角过大时可能削弱换热效果。在所考虑的工况范围内,Taper-200-50的性能系数(COP)高达27713,性能评估准则(PEC)高达1.4,展现出优异的热管理潜力。

中图分类号:

马紫欢, 杨小平, 郝南京, 魏进家. 楔形歧管微通道内的过冷流动沸腾模拟研究[J]. 化工学报, 2025, 76(12): 6289-6301.

Zihuan MA, Xiaoping YANG, Nanjing HAO, Jinjia WEI. Simulation study of subcooled flow boiling in wedge-shaped manifold microchannels[J]. CIESC Journal, 2025, 76(12): 6289-6301.

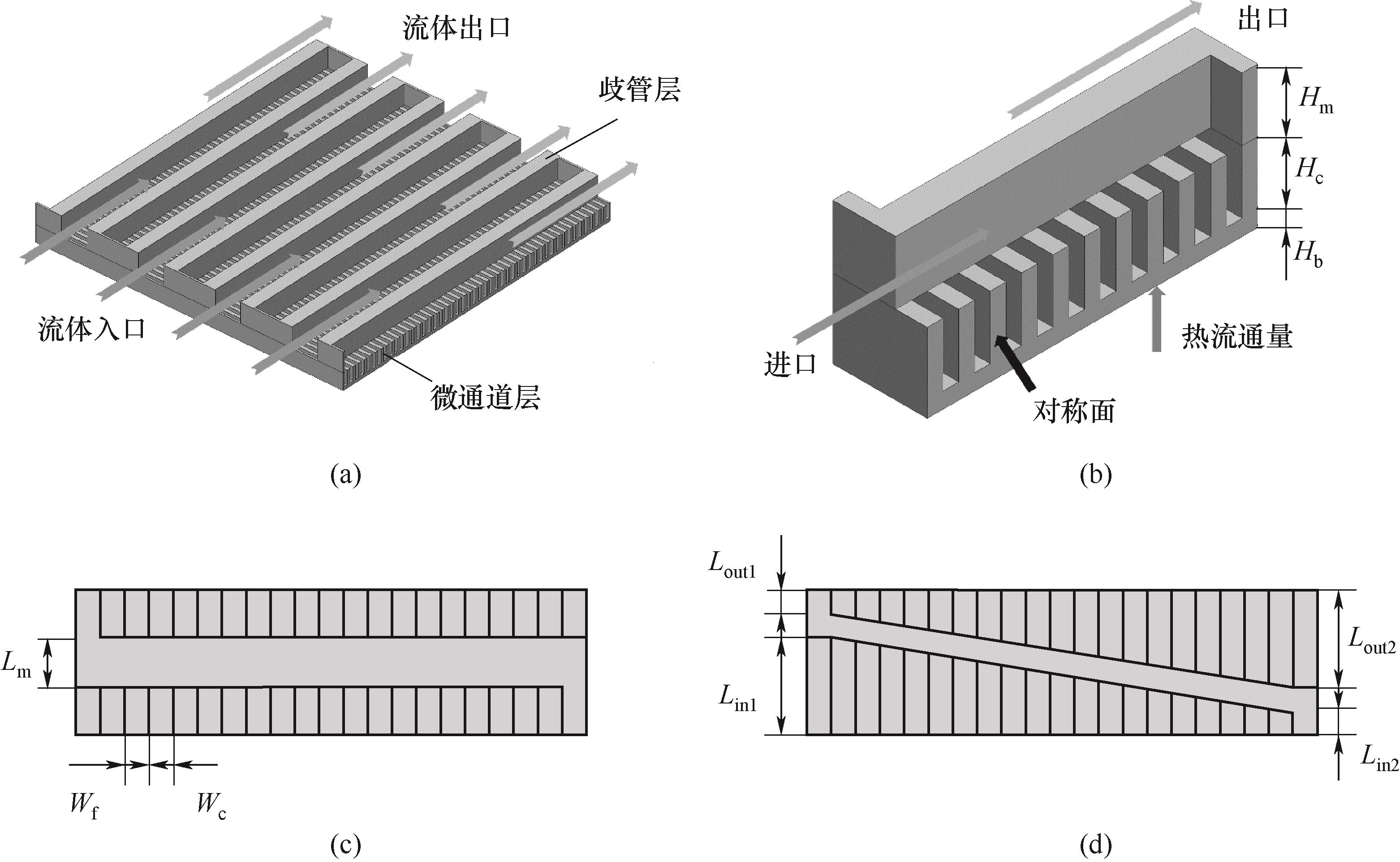

图1 (a)MMC散热器示意图;(b)带有边界条件的Z形MMC计算区域;(c)Z形MMC的俯视图;(d)Taper-200-50的俯视图

Fig.1 (a) Schematic diagram of MMC heat sink; (b) Calculation region of Z-shaped MMC with boundary conditions; (c) Top view of Z-shaped MMC; (d) Top view of Taper-200-50

| MMC配置 | 参数 | 值/μm | MMC配置 | 参数 | 值/μm |

|---|---|---|---|---|---|

| Z形MMC | Lin1, Lout2 | 100 | Taper-200-50 | Lin1, Lout2 | 200 |

| Lin2, Lout1 | 100 | Lin2, Lout1 | 50 | ||

| Lm | 100 | Lm | 50 | ||

| Taper-150-75 | Lin1, Lout2 | 150 | Taper-250-25 | Lin1, Lout2 | 250 |

| Lin2, Lout1 | 75 | Lin2, Lout1 | 25 | ||

| Lm | 75 | Lm | 25 |

表1 MMC散热器的几何参数和尺寸

Table 1 Geometrical parameters and dimensions of the MMC heat sink

| MMC配置 | 参数 | 值/μm | MMC配置 | 参数 | 值/μm |

|---|---|---|---|---|---|

| Z形MMC | Lin1, Lout2 | 100 | Taper-200-50 | Lin1, Lout2 | 200 |

| Lin2, Lout1 | 100 | Lin2, Lout1 | 50 | ||

| Lm | 100 | Lm | 50 | ||

| Taper-150-75 | Lin1, Lout2 | 150 | Taper-250-25 | Lin1, Lout2 | 250 |

| Lin2, Lout1 | 75 | Lin2, Lout1 | 25 | ||

| Lm | 75 | Lm | 25 |

| 参数 | 液相HFE7100 | 气相HFE7100 | Si |

|---|---|---|---|

| 密度ρ/(kg/m3) | 1402 | 11.5 | 2300 |

| 比热容cp /(J/(kg·K)) | 1263 | 870 | 700 |

| 热导率k/(W/(m·K)) | 0.058 | 0.01 | 150 |

| 黏度μ/(Pa·s) | 0.0004 | 1.32×10-5 | — |

| 汽化热hlv/(kJ/kg) | 111.6 | — | — |

| 表面张力σ/(N/m) | 0.00943 | — | — |

| 饱和温度Tsat/K | 339 | — | — |

表2 HFE7100和硅的热物性参数

Table 2 Thermophysical properties of HFE7100 and silicon

| 参数 | 液相HFE7100 | 气相HFE7100 | Si |

|---|---|---|---|

| 密度ρ/(kg/m3) | 1402 | 11.5 | 2300 |

| 比热容cp /(J/(kg·K)) | 1263 | 870 | 700 |

| 热导率k/(W/(m·K)) | 0.058 | 0.01 | 150 |

| 黏度μ/(Pa·s) | 0.0004 | 1.32×10-5 | — |

| 汽化热hlv/(kJ/kg) | 111.6 | — | — |

| 表面张力σ/(N/m) | 0.00943 | — | — |

| 饱和温度Tsat/K | 339 | — | — |

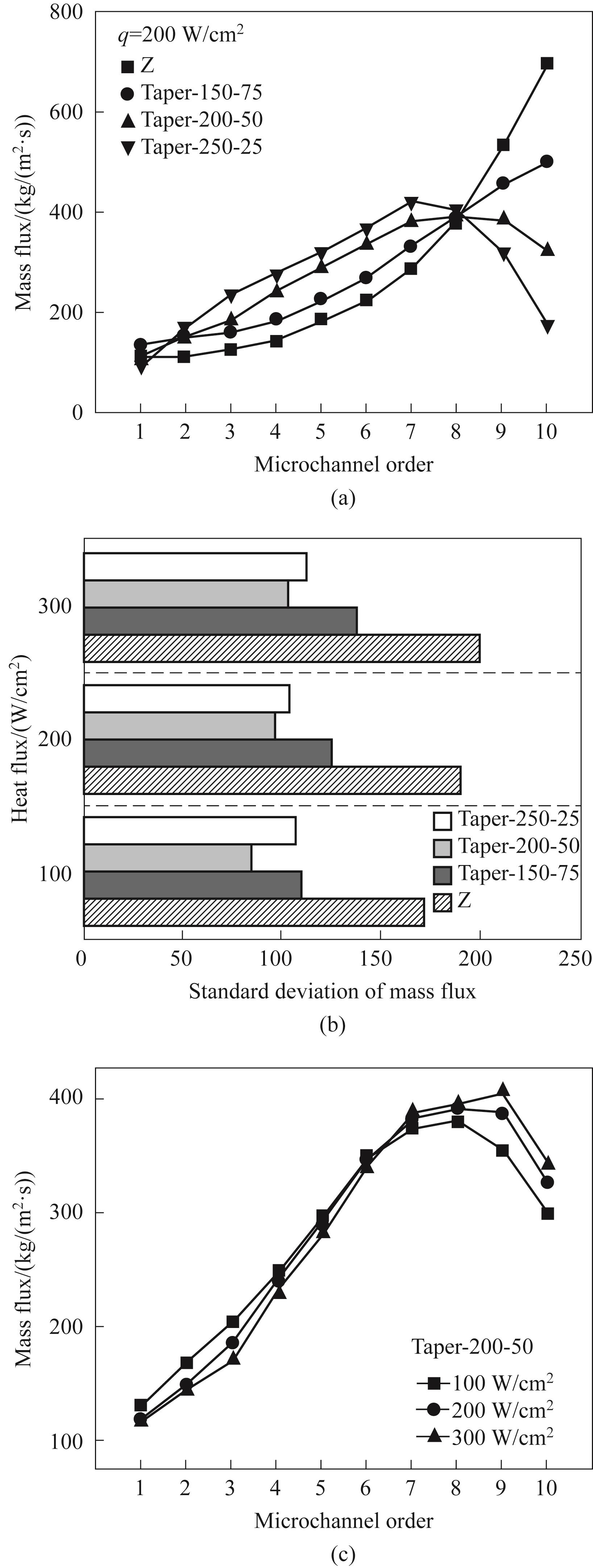

图3 (a)恒定热通量下各MMC微通道的质量流速分布;(b)各工况下微通道质量流速分布的标准差;(c)不同热通量下Taper-200-50每个微通道的质量流速分布

Fig.3 (a) Mass flux distribution in microchannel of the four MMCs under constant heat flux; (b) Standard deviation of mass flux distribution in microchannel at 12 operating conditions; (c) Mass flux distribution in microchannel of Taper-200-50 under different heat fluxes

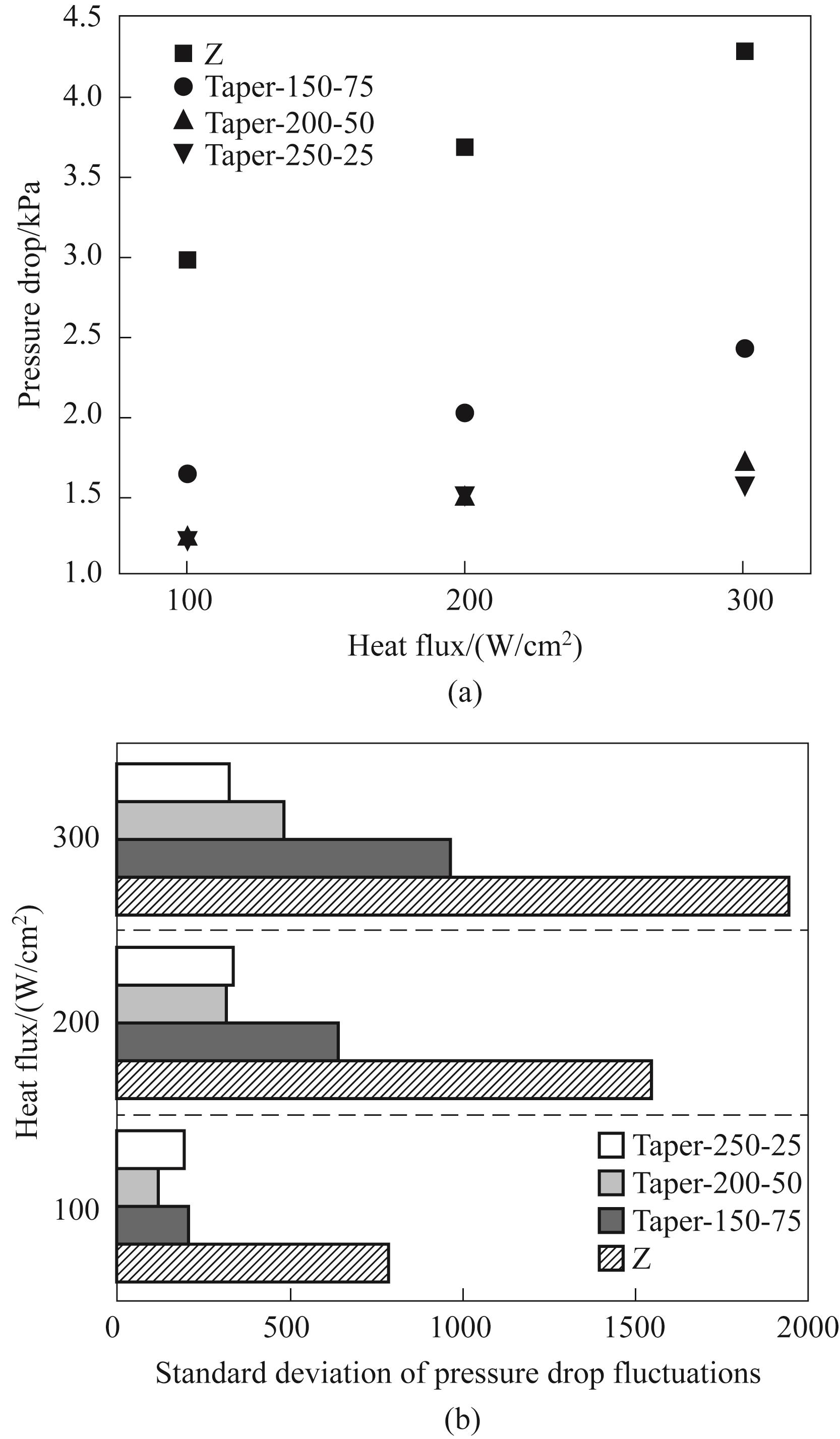

图4 各工况下(a)准稳态时间范围内的总压降和(b)压降波动的标准差

Fig.4 (a) Total pressure drop within the quasi-steady-state period and (b) standard deviation of pressure drop fluctuations under various operating conditions

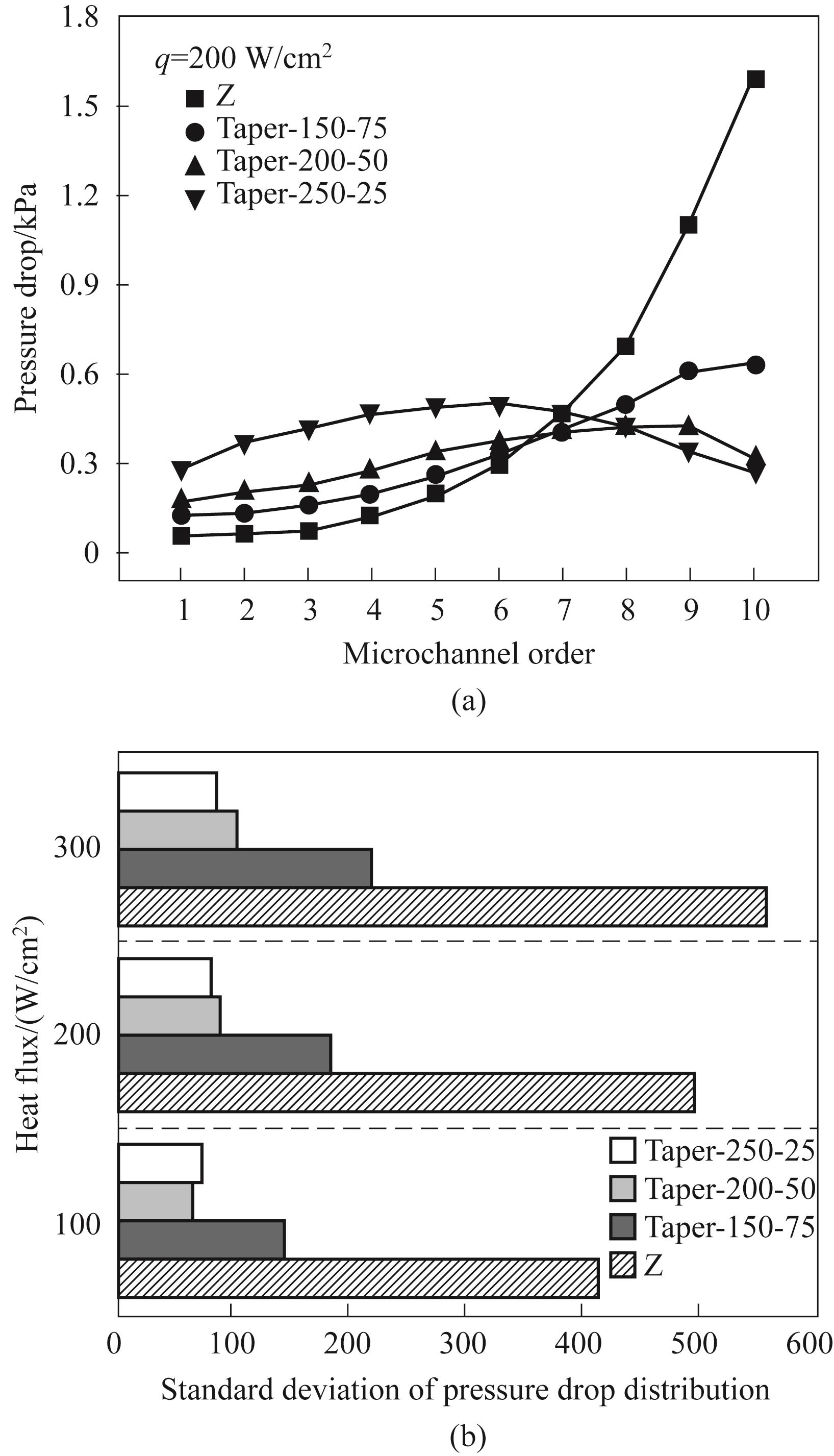

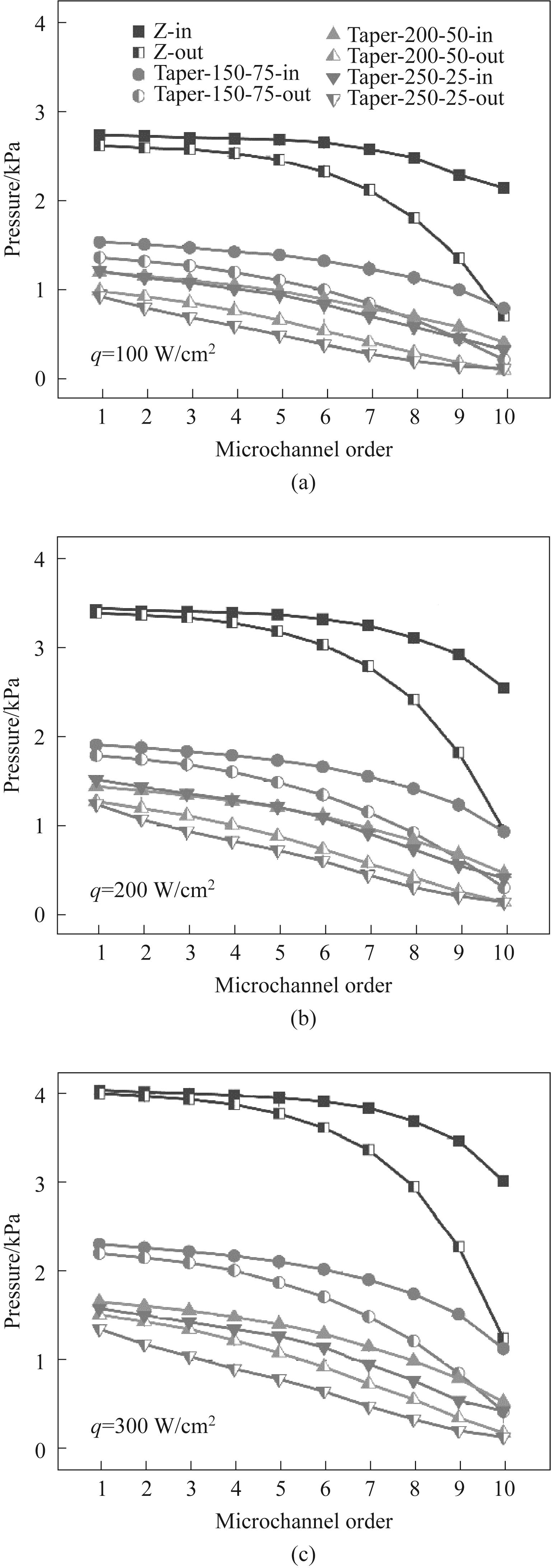

图6 (a)恒定热通量下各MMC每个微通道的压降分布和(b)各工况下微通道的压降分布标准差

Fig.6 (a) Pressure drop distribution in microchannel under constant heat flux for different MMC configurations, and (b) standard deviation of pressure drop distribution in microchannel under various operating conditions

图7 各工况下准稳态时间范围内各微通道的进口和出口压力值

Fig.7 Inlet and outlet pressure values in each microchannel within the quasi-steady-state period for various operating conditions

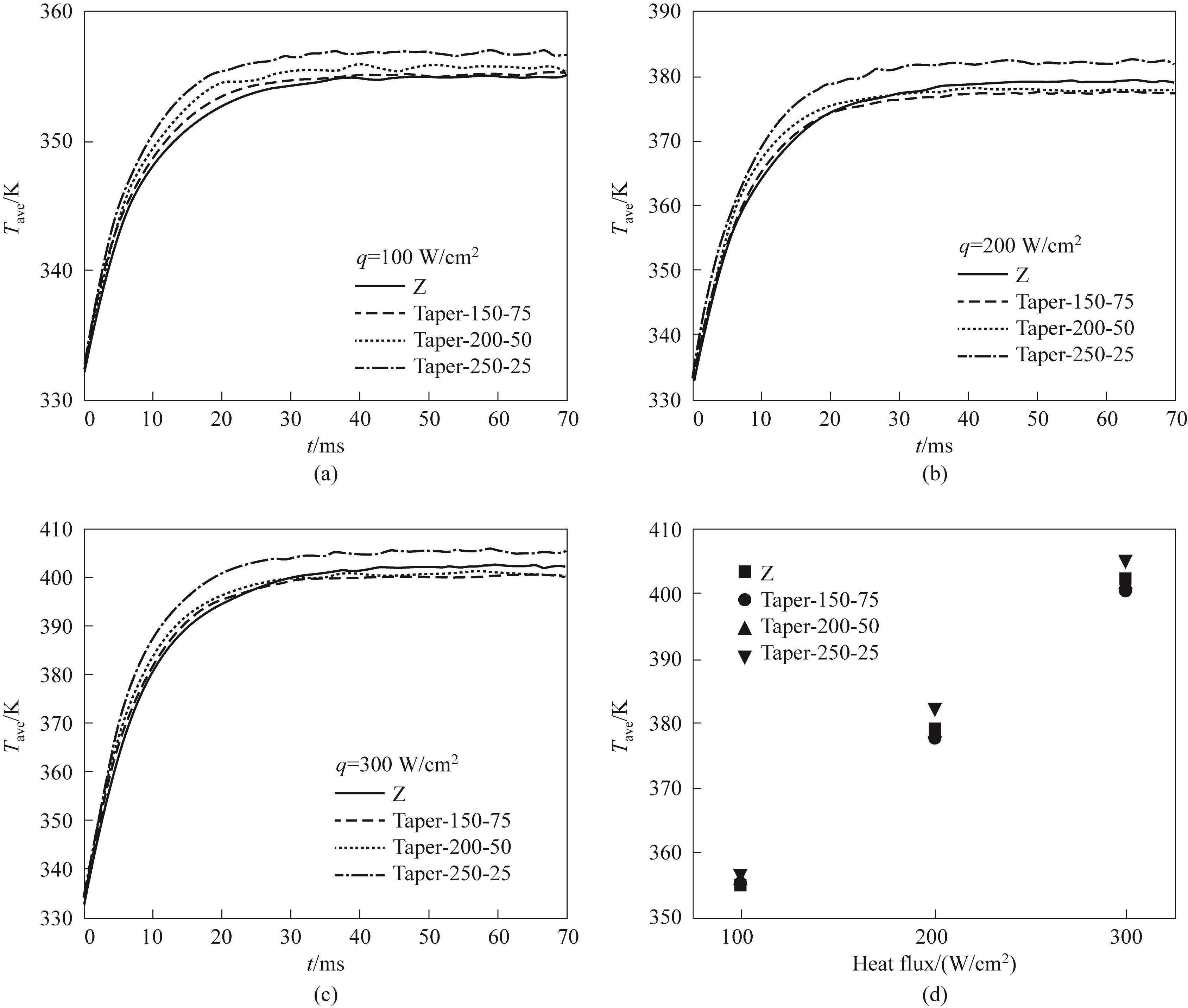

图8 (a)~(c)芯片平均温度随时间的变化趋势和(d)准稳态时间范围内芯片温度的平均值

Fig.8 (a)—(c) The trend of the average chip temperature over time and (d) the average value of chip temperature over the quasi-steady-state period

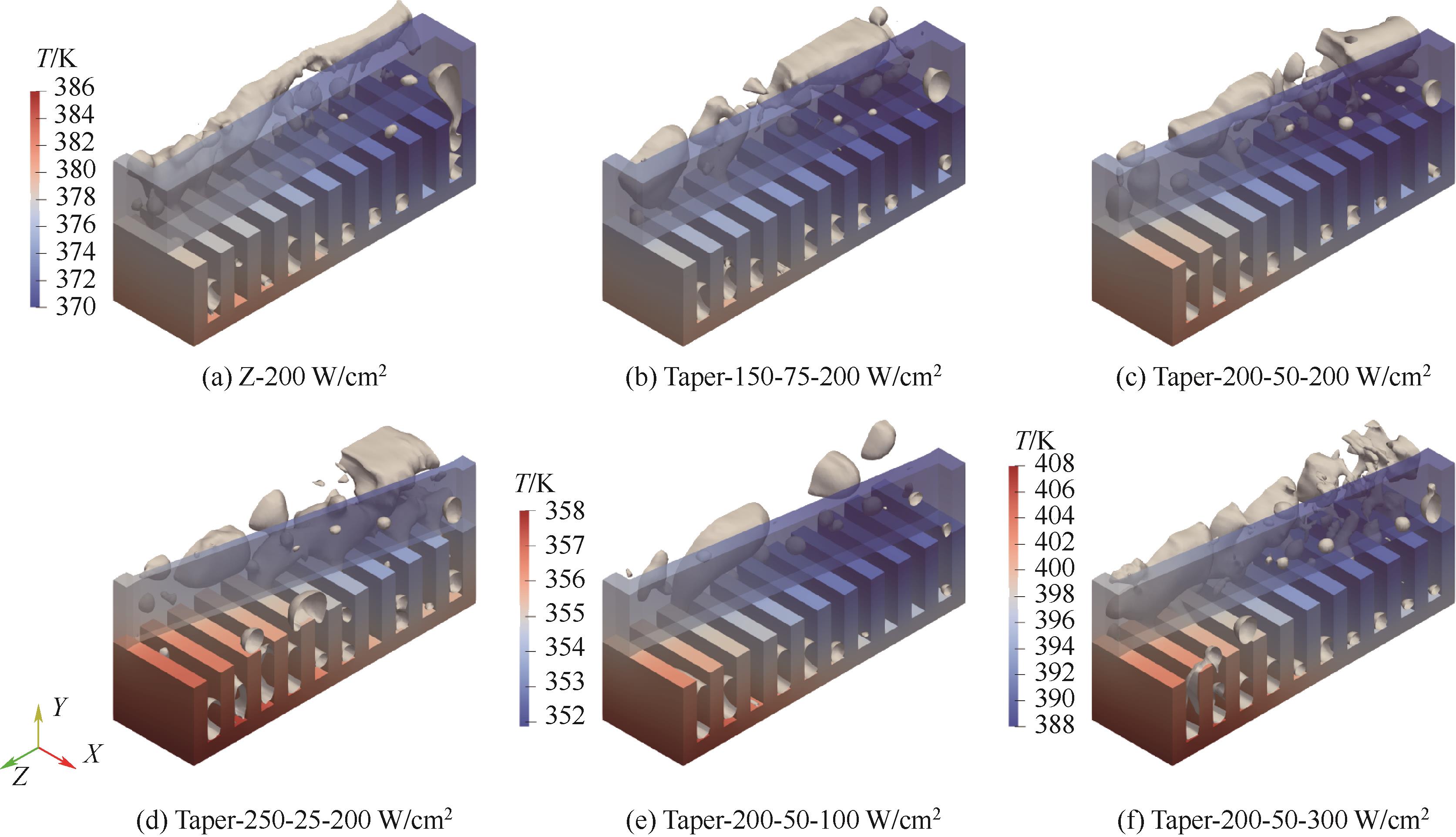

图9 6种工况下固体域的温度云图和流体域的气相体积分数等值线

Fig.9 Temperature contours in the solid domain and contours of vapor volume fraction in the fluid domain for 6 operating conditions

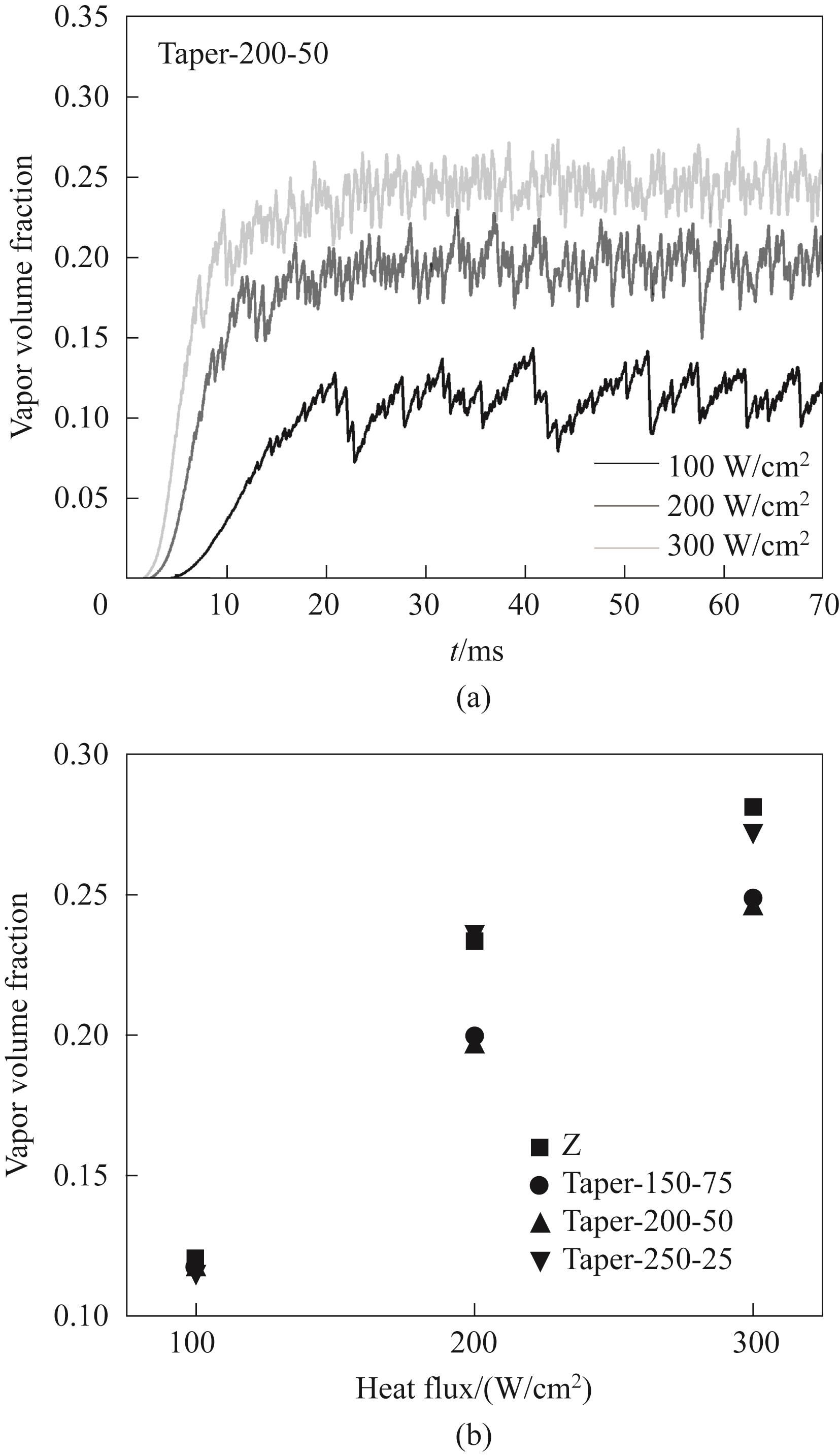

图11 不同热通量下Taper-200-50总气相体积分数随时间的变化趋势(a)和准稳态时间范围内的总气相体积分数平均值(b)

Fig.11 (a) The variation of the total vapor volume fraction in Taper-200-50 with time, and (b) the average value of total vapor volume fraction for quasi-steady-state period at different heat fluxes

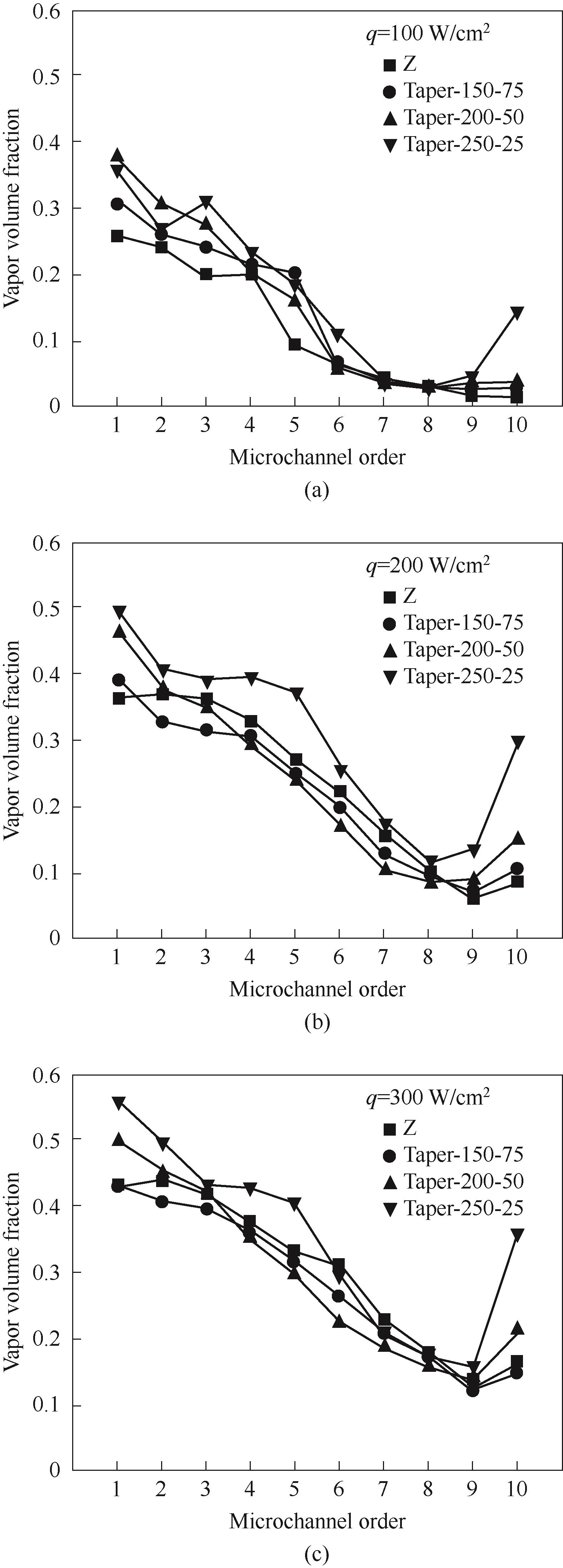

图12 各工况下准稳态时间范围内每个微通道的气相体积分数平均值

Fig.12 Average vapor volume fraction in microchannels within the quasi-steady-state period under various operating conditions

| [1] | van Erp R, Soleimanzadeh R, Nela L, et al. Co-designing electronics with microfluidics for more sustainable cooling[J]. Nature, 2020, 585(7824): 211-216. |

| [2] | Tuckerman D B, Pease R F W. High-performance heat sinking for VLSI[J]. IEEE Electron Device Letters, 1981, 2(5): 126-129. |

| [3] | Yan X, Wu Y, Zhang Z T, et al. Experimental study of flow boiling heat transfer in rectangular ribbed micro-channels with rectangular cavities[J]. International Journal of Heat and Mass Transfer, 2025, 236: 126402. |

| [4] | Raj S, Pathak M, Khan M K. Flow boiling characteristics in different configurations of stepped microchannels[J]. Experimental Thermal and Fluid Science, 2020, 119: 110217. |

| [5] | Hu C Y, Ma Z H, Zhang Y T, et al. Optimizing the performance of microchannel heat sinks: effects of trapezoidal cover plate on flow boiling heat transfer and stability[J]. International Journal of Heat and Mass Transfer, 2025, 244: 126942. |

| [6] | Yin L F, Yang Z L, Zhang K X, et al. Flow boiling heat transfer in multi-stage enhanced open microchannels with micro/nano structures[J]. Applied Thermal Engineering, 2025, 258: 124695. |

| [7] | Yuan B, Zhang Y H, Zhou J, et al. Critical heat flux prediction model for flow boiling on micro-pin-finned surfaces[J]. International Journal of Heat and Mass Transfer, 2020, 154: 119693. |

| [8] | Camarasa J, Crespo A, Vilarrubí M, et al. A review of experimental studies on flow boiling instabilities mitigation through geometrical modifications[J]. International Journal of Heat and Mass Transfer, 2024, 235: 126014. |

| [9] | Yu X J, Xu J L, Liu G H, et al. Phase separation evaporator using pin-fin-porous wall microchannels: comprehensive upgrading of thermal-hydraulic operating performance[J]. International Journal of Heat and Mass Transfer, 2021, 164: 120460. |

| [10] | Li W M, Luo K, Li C, et al. A remarkable CHF of 345 W/cm2 is achieved in a wicked-microchannel using HFE-7100[J]. International Journal of Heat and Mass Transfer, 2022, 187: 122527. |

| [11] | Wang S, Chen H H, Chen C L. Enhanced flow boiling in silicon nanowire-coated manifold microchannels[J]. Applied Thermal Engineering, 2019, 148: 1043-1057. |

| [12] | Chang W, Luo K, Li W M, et al. Enhanced flow boiling of HFE-7100 in silicon microchannels with nanowires coated micro-pinfins[J]. Applied Thermal Engineering, 2022, 216: 119064. |

| [13] | He Z Q, Yan Y F, Zhang Z E. Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: a review[J]. Energy, 2021, 216: 119223. |

| [14] | Harpole G M, Eninger J E. Micro-channel heat exchanger optimization[C]//Proceeding of Seventh IEEE Semiconductor Thermal Measurement and Management Symposium. IEEE, 1991: 59-63. |

| [15] | 刘帆, 张芫通, 陶成, 等. 歧管式射流微通道液冷散热性能[J]. 化工学报, 2024, 75(5): 1777-1786. |

| Liu F, Zhang Y T, Tao C, et al. Performance of manifold microchannel liquid cooling[J]. CIESC Journal, 2024, 75(5): 1777-1786. | |

| [16] | Zhang Y T, Yang X P, Ji X Y, et al. Numerical and experimental study on manifold-distributed jet microchannel with micro-pin-fins[J]. Applied Thermal Engineering, 2025, 258: 124675. |

| [17] | Drummond K P, Back D, Sinanis M D, et al. Characterization of hierarchical manifold microchannel heat sink arrays under simultaneous background and hotspot heating conditions[J]. International Journal of Heat and Mass Transfer, 2018, 126: 1289-1301. |

| [18] | Drummond K P, Back D, Sinanis M D, et al. A hierarchical manifold microchannel heat sink array for high-heat-flux two-phase cooling of electronics[J]. International Journal of Heat and Mass Transfer, 2018, 117: 319-330. |

| [19] | Luo Y, Zhang J Z, Li W. A comparative numerical study on two-phase boiling fluid flow and heat transfer in the microchannel heat sink with different manifold arrangements[J]. International Journal of Heat and Mass Transfer, 2020, 156: 119864. |

| [20] | Lin Y H, Luo Y, Li W, et al. Single-phase and two-phase flow and heat transfer in microchannel heat sink with various manifold arrangements[J]. International Journal of Heat and Mass Transfer, 2021, 171: 121118. |

| [21] | Ma Z H, Zhang Y T, Hu C Y, et al. Simulation of single-phase and subcooled flow boiling in manifold microchannel heat sinks with micro-pin-fin wall[J]. Applied Thermal Engineering, 2025, 271: 126297. |

| [22] | Chen C W, Wang X Y, Yuan B Q, et al. Investigation of flow and heat transfer performance of the manifold microchannel with different manifold arrangements[J]. Case Studies in Thermal Engineering, 2022, 34: 102073. |

| [23] | Tang W Y, Li J Y, Wu Z, et al. A numerical investigation of the thermal-hydraulic performance during subcooled flow boiling in MMCs with different manifolds[J]. Applied Thermal Engineering, 2024, 236: 121820. |

| [24] | 冀昕宇, 张芫通, 杨小平, 等. 楔形歧管微通道流动与沸腾换热[J]. 化工学报, 2024, 75(11): 4196-4204. |

| Ji X Y, Zhang Y T, Yang X P, et al. Flow and boiling heat transfer in wedge-shaped manifold microchannel[J]. CIESC Journal, 2024, 75(11): 4196-4204. | |

| [25] | Ji X Y, Zhang Y T, Yang X P, et al. Efficient flow boiling in wedge-shaped manifold microchannels for high heat flux chips cooling[J]. International Communications in Heat and Mass Transfer, 2025, 164: 108964. |

| [26] | Duryodhan V S, Singh S G, Agrawal A. Liquid flow through converging microchannels and a comparison with diverging microchannels[J]. Journal of Micromechanics and Microengineering, 2014, 24(12): 125002. |

| [27] | Albadawi A, Donoghue D B, Robinson A J, et al. Influence of surface tension implementation in volume of fluid and coupled volume of fluid with level set methods for bubble growth and detachment[J]. International Journal of Multiphase Flow, 2013, 53: 11-28. |

| [28] | Lee W H. A pressure iteration scheme for two-phase flow modeling[J]. Multiphase Transport Fundamentals, Reactor Safety, Applications, 1980, 1: 407-431. |

| [29] | Leong K C, Ho J Y, Wong K K. A critical review of pool and flow boiling heat transfer of dielectric fluids on enhanced surfaces[J]. Applied Thermal Engineering, 2017, 112: 999-1019. |

| [30] | Bai J J, Sun Y L, Huang H Z, et al. An open superhydrophilic microchannel heat sink for thin film boiling with a high coefficient of performance[J]. Renewable and Sustainable Energy Reviews, 2023, 186: 113684. |

| [31] | Boteler L, Jankowski N, McCluskey P, et al. Numerical investigation and sensitivity analysis of manifold microchannel coolers[J]. International Journal of Heat and Mass Transfer, 2012, 55(25/26): 7698-7708. |

| [32] | Tang W, Sun L C, Liu H T, et al. Improvement of flow distribution and heat transfer performance of a self-similarity heat sink with a modification to its structure[J]. Applied Thermal Engineering, 2017, 121: 163-171. |

| [1] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [2] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [3] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [4] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [5] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [6] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [7] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [8] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [9] | 孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296. |

| [10] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [11] | 段炼, 周星睿, 袁文君, 陈飞. 连续相速度脉动对微通道内聚合物液滴生成和形貌的影响规律[J]. 化工学报, 2025, 76(9): 4578-4585. |

| [12] | 杨开源, 陈锡忠. 颗粒破碎的离散元及有限离散元模拟方法比较[J]. 化工学报, 2025, 76(9): 4398-4411. |

| [13] | 贾志勇, 沈宪琨, 蓝晓程, 王铁峰. 气体密度对高压流态化影响的CFD-DEM模拟[J]. 化工学报, 2025, 76(9): 4383-4397. |

| [14] | 王一飞, 李玉星, 欧阳欣, 赵雪峰, 孟岚, 胡其会, 殷布泽, 郭雅琦. 基于裂尖减压特性的CO2管道断裂扩展数值计算[J]. 化工学报, 2025, 76(9): 4683-4693. |

| [15] | 李文龙, 常程, 吴小林, 姬忠礼. 油水聚结过滤材料中的液体分布特性及过程压降演化研究[J]. 化工学报, 2025, 76(9): 4850-4861. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号