化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2327-2336.DOI: 10.11949/0438-1157.20241223

宁丹东1( ), 李建惠1, 陈杨1,2, 李晋平1,2, 李立博1,2(

), 李建惠1, 陈杨1,2, 李晋平1,2, 李立博1,2( )

)

收稿日期:2024-10-31

修回日期:2025-02-11

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

李立博

作者简介:宁丹东(1996—),男,硕士研究生,ningdandongtyut@163.com

基金资助:

Dandong NING1( ), Jianhui LI1, Yang CHEN1,2, Jinping LI1,2, Libo LI1,2(

), Jianhui LI1, Yang CHEN1,2, Jinping LI1,2, Libo LI1,2( )

)

Received:2024-10-31

Revised:2025-02-11

Online:2025-05-25

Published:2025-06-13

Contact:

Libo LI

摘要:

近年来,金属有机骨架材料(MOF)因其比表面积大、孔尺寸高度可调及功能多样等特点,在气体吸附与分离、催化、传感等领域展现出广阔的应用前景。然而,大多数MOF材料仍局限于实验室的小规模合成,MOF宏量制备面临着许多挑战,包括合成条件严苛、产量低以及后处理困难等,限制了其广泛应用的可能性。在众多MOF材料中,MIL-101(Cr)因其卓越的热稳定性、化学稳定性以及超高的孔隙率和比表面积而备受研究者青睐。MIL-101(Cr)可以通过简单的水热合成法,使用成本较低的对苯二甲酸和铬盐进行合成,展现出优异的工业应用潜力。然而,传统水热合成过程中,MIL-101(Cr)颗粒因粒径较小导致沉降困难,需要多次过滤洗涤,这些因素限制了其生产效率。为了解决这一问题,引入了絮凝剂并通过调控絮凝剂的种类和用量,缩短了过滤时间,提高了生产效率。重要的是,加入絮凝剂后MIL-101(Cr)热稳定性得以保持,BET比表面积达到3211 m2/g,二氧化碳吸附量达到40 cm3/g,性能得到了良好的保持。

中图分类号:

宁丹东, 李建惠, 陈杨, 李晋平, 李立博. MIL-101(Cr)批量化生产中的絮凝工艺研究[J]. 化工学报, 2025, 76(5): 2327-2336.

Dandong NING, Jianhui LI, Yang CHEN, Jinping LI, Libo LI. Study on flocculation techniques in the large-scale production of MIL-101(Cr)[J]. CIESC Journal, 2025, 76(5): 2327-2336.

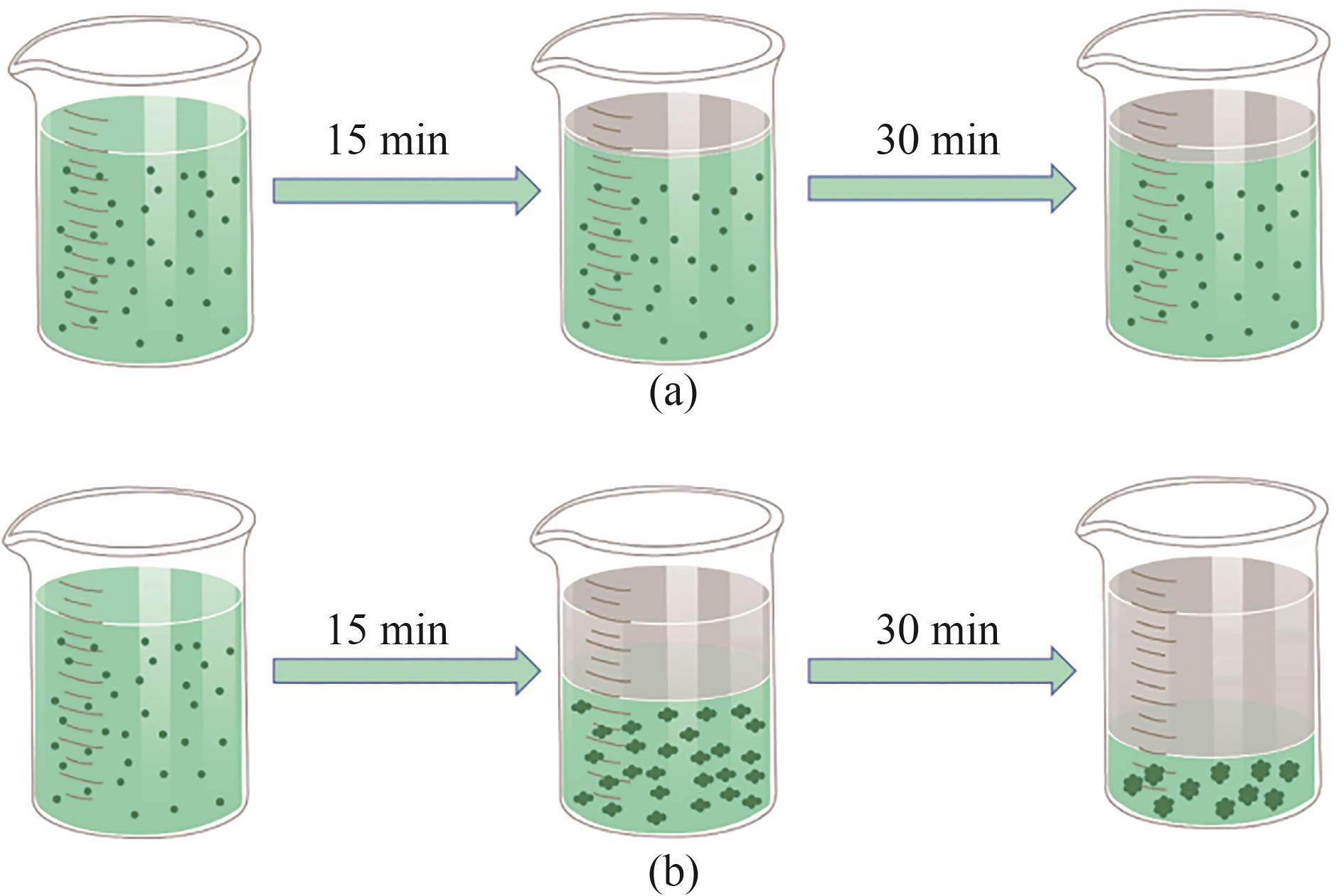

图1 MIL-101(Cr)混合液未添加(a)和添加(b)絮凝剂辅助沉降示意图

Fig.1 Schematic diagram of the sedimentation process of MIL-101(Cr) suspension without (a) and with (b) the addition of flocculants

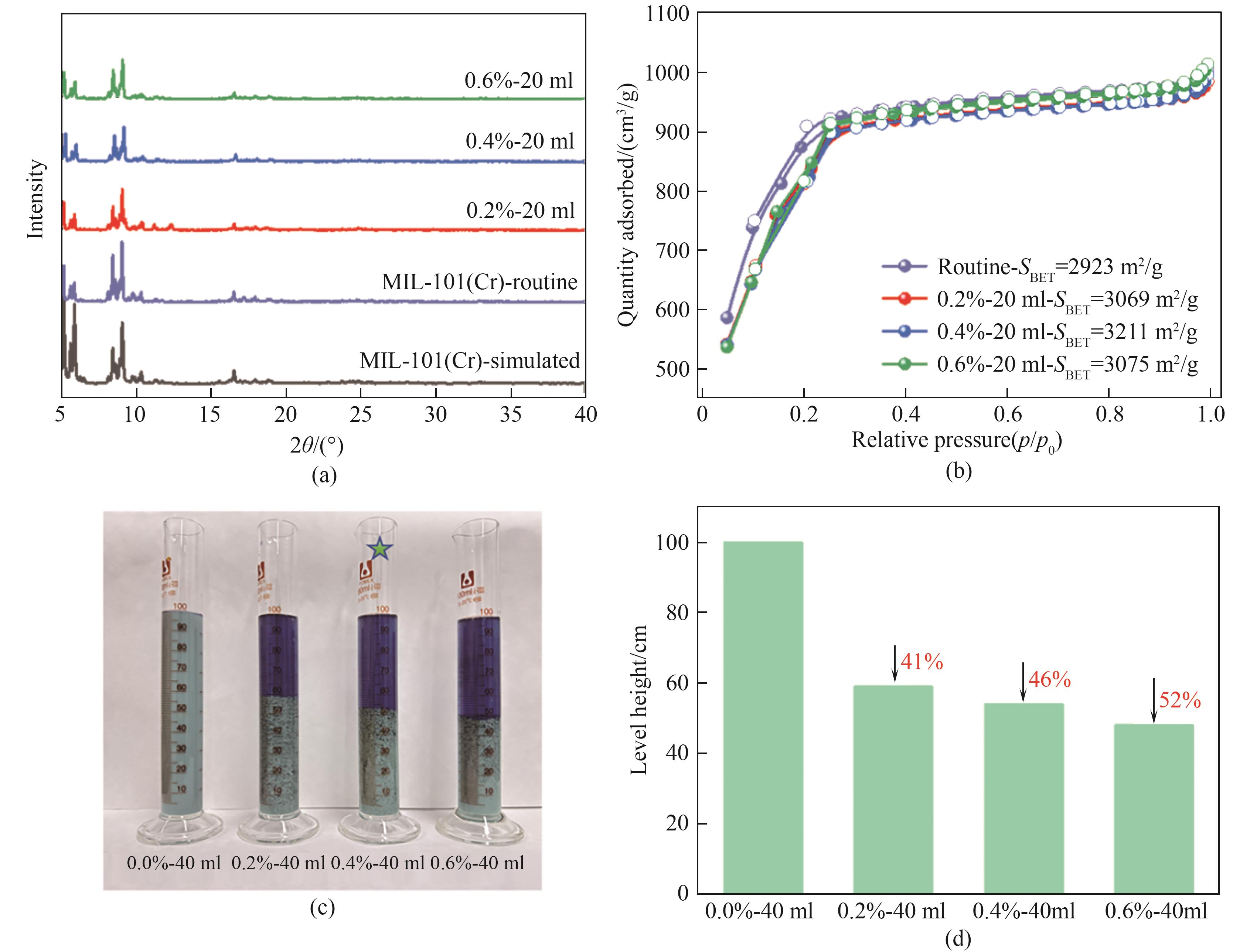

图2 (a)添加不同种类絮凝剂处理得到的MIL-101(Cr)样品的PXRD谱图;(b)添加不同种类絮凝剂处理得到的MIL-101(Cr)样品在77 K下的N2吸附等温线;(c)、(d)不同种类絮凝剂沉降30 min后效果图

Fig.2 (a) PXRD patterns of MIL-101 (Cr) samples obtained by adding different kinds of flocculants; (b) N2 sorption isotherms at 77 K for MIL-101(Cr) samples obtained by adding different kinds of flocculants; (c), (d) Effects of different types of flocculants after 30 minutes of sedimentation

| Volume mixtures/L | Tadd/h | Twithout/h | Tadd/Twithout | Madd/g | Mwithout/g | Madd/Mwithout |

|---|---|---|---|---|---|---|

| 1 | 0.2 | 2 | 0.10 | 36 | 21 | 1.71 |

| 3 | 0.7 | 8 | 0.09 | 107 | 61 | 1.75 |

| 5 | 1.3 | 15 | 0.08 | 180 | 99 | 1.82 |

表1 不同体积混合液过滤效率对比参数

Table 1 Parameters for comparing filtration efficiencies of different volume mixtures

| Volume mixtures/L | Tadd/h | Twithout/h | Tadd/Twithout | Madd/g | Mwithout/g | Madd/Mwithout |

|---|---|---|---|---|---|---|

| 1 | 0.2 | 2 | 0.10 | 36 | 21 | 1.71 |

| 3 | 0.7 | 8 | 0.09 | 107 | 61 | 1.75 |

| 5 | 1.3 | 15 | 0.08 | 180 | 99 | 1.82 |

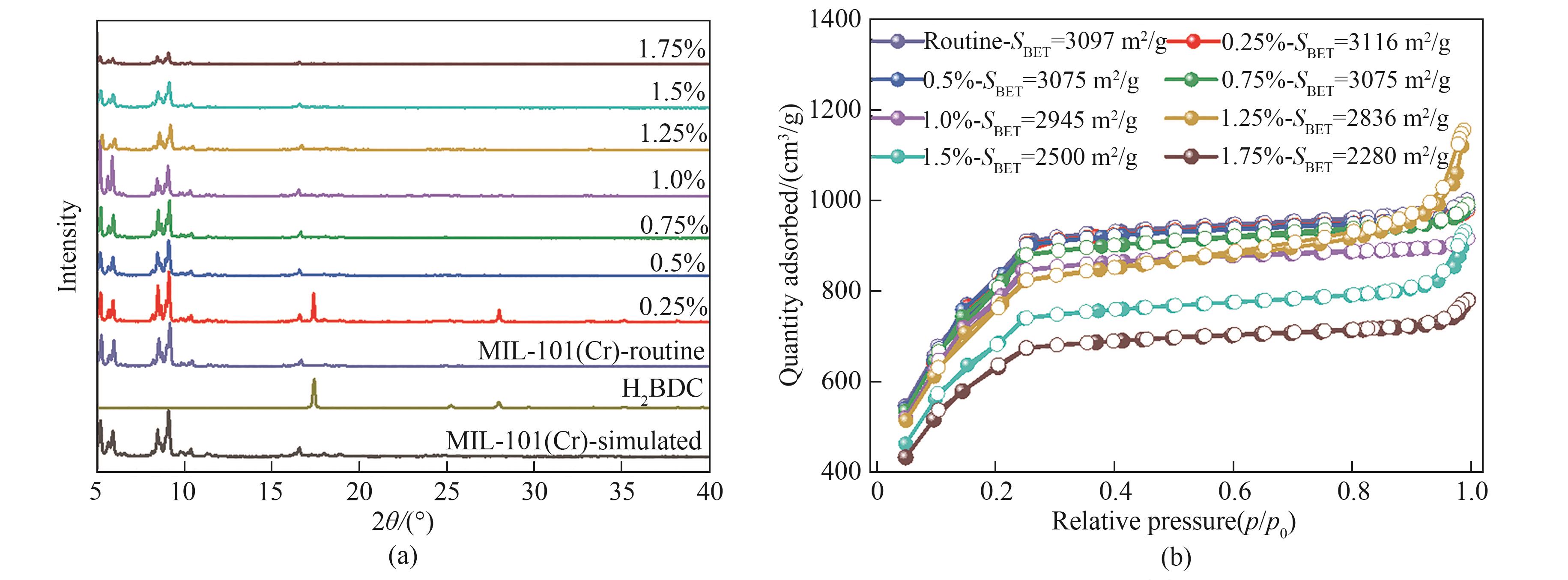

图3 (a)不同浓度的絮凝剂处理得到的MIL-101(Cr)样品的PXRD谱图;(b)不同浓度的絮凝剂处理得到的MIL-101(Cr)样品在77 K下的N2吸附等温线;(c)、(d)不同浓度絮凝剂30 min后沉降效果图

Fig.3 (a) PXRD patterns of MIL-101(Cr) samples treated with different concentrations of flocculants; (b) N2 sorption isotherms at 77 K for MIL-101(Cr) samples treated with different concentrations of flocculants; (c), (d) Effects of different types of flocculants after 30 min of sedimentation

图4 (a)添加不同浓度的氨水处理得到的MIL-101(Cr)样品的PXRD谱图;(b)添加不同浓度氨水处理得到的MIL-101(Cr)样品在77 K下的N2吸附等温线

Fig.4 (a) PXRD patterns of MIL-101(Cr) samples obtained by adding different concentrations of ammonia; (b) N2 sorption isotherms at 77 K for MIL-101(Cr) samples obtained by adding different concentrations of ammonia

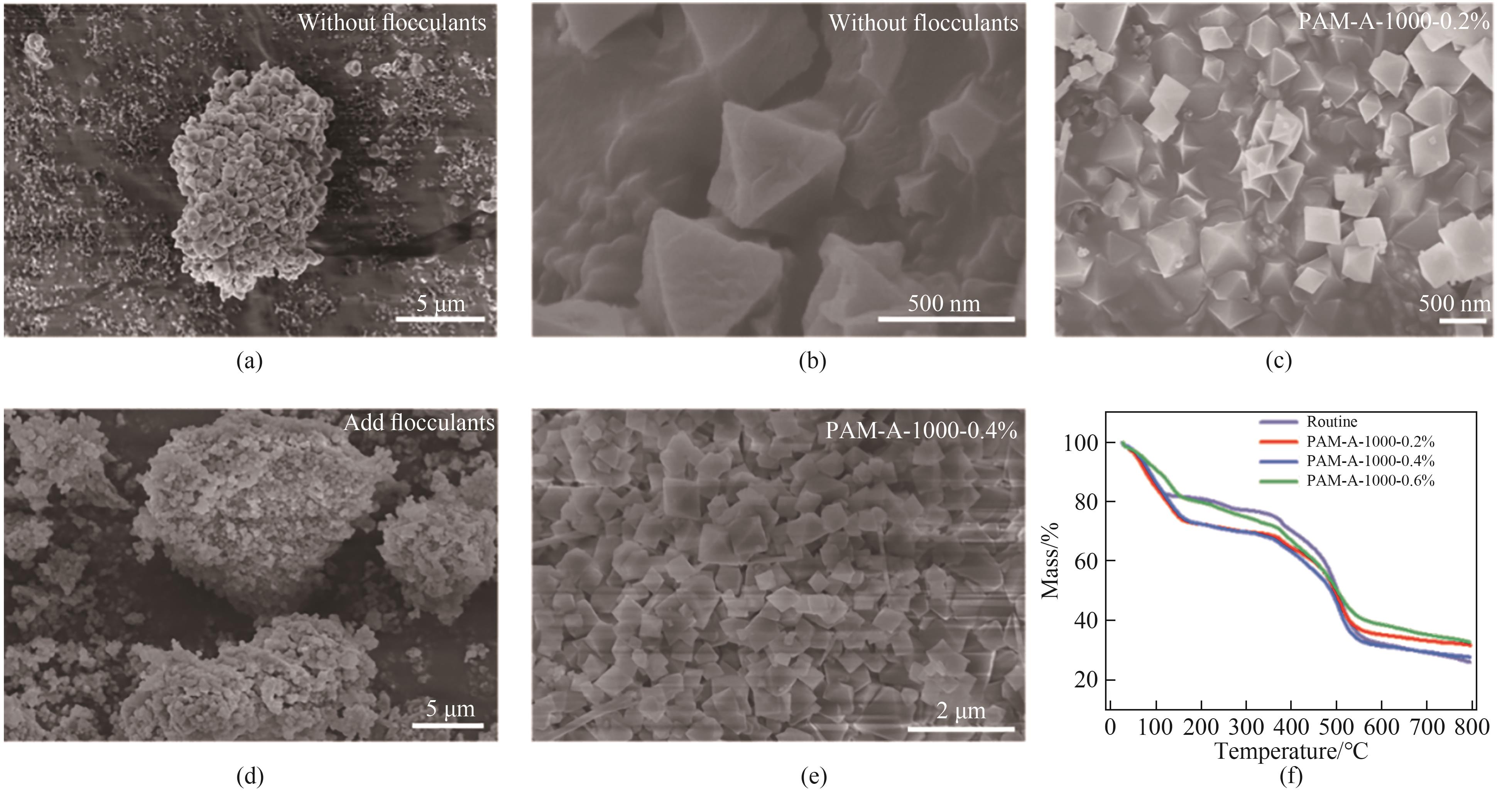

图5 (a)、(b)未加絮凝剂的SEM图;(c)~(e)加入絮凝剂的SEM图;(f)原始MIL-101(Cr)与加入絮凝剂后的MIL-101(Cr)的TGA曲线

Fig.5 (a), (b) SEM images of sample without flocculant; (c)—(e) SEM images of sample with the addition of flocculant; (f) TGA curves of pristine MIL-101(Cr) and MIL-101(Cr) obtained by adding flocculants

图6 (a)不同浓度絮凝剂处理得到的MIL-101(Cr)样品在298 K和1 bar(1 bar=0.1 MPa)下的CO2吸附等温线图;(b)在25℃和1 bar下,加入絮凝剂与未加絮凝剂处理的MIL-101(Cr)样品CO2/N2(15/85,体积比)混合气穿透曲线;(c)加入絮凝剂穿透循环性能测试图;(d)未加入絮凝剂穿透循环性能测试图

Fig.6 (a) CO2 adsorption isotherms of MIL-101(Cr) samples treated with different concentrations of flocculants at 298 K and 1 bar; (b) The breakthrough curves of CO₂/N₂ (15/85, volume) mixed gas for MIL-101(Cr) samples treated with and without the addition of flocculant at 25 °C and 1 bar; (c) Test chart of breakthrough cycling performance with the addition of flocculant; (d) Test chart of breakthrough cycling performance without the addition of flocculant

| 1 | Li H L, Eddaoudi M, O’Keeffe M, et al. Design and synthesis of an exceptionally stable and highly porous metal-organic framework[J]. Nature, 1999, 402: 276-279. |

| 2 | 李建惠, 兰天昊, 陈杨, 等. MOF复合材料在气体吸附分离中的研究进展[J]. 化工学报, 2021, 72(1): 167-179. |

| Li J H, Lan T H, Chen Y, et al. Research progress of MOF-based composites for gas adsorption and separation[J]. CIESC Journal, 2021, 72(1): 167-179. | |

| 3 | Li L B, Lin R B, Krishna R, et al. Ethane/ethylene separation in a metal-organic framework with iron-peroxo sites[J]. Science, 2018, 362(6413): 443-446. |

| 4 | Surblé S, Millange F, Serre C, et al. Synthesis of MIL-102, a chromium carboxylate metal-organic framework, with gas sorption analysis[J]. Journal of the American Chemical Society, 2006, 128(46): 14889-14896. |

| 5 | Yulia F, Zulys A, Ruliandini R. Metal-organic framework based chromium terephthalate (MIL-101 Cr) growth for carbon dioxide capture: a review[J]. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 2019, 57(2): 158-174. |

| 6 | Derrien G, Hassoun J, Panero S, et al. Nanostructured Sn-C composite as an advanced anode material in high-performance lithium-ion batteries[J]. Advanced Materials, 2007, 19(17): 2336-2340. |

| 7 | Li J R, Ma Y G, McCarthy M C, et al. Carbon dioxide capture-related gas adsorption and separation in metal-organic frameworks[J]. Coordination Chemistry Reviews, 2011, 255(15/16): 1791-1823. |

| 8 | Amin J, Kaye M, Skidmore S, et al. HIV and hepatitis C coinfection within the CAESAR study[J]. HIV Medicine, 2004, 5(3): 174-179. |

| 9 | Qiu L G, Li Z Q, Wu Y, et al. Facile synthesis of nanocrystals of a microporous metal-organic framework by an ultrasonic method and selective sensing of organoamines[J]. Chemical Communications, 2008(31): 3642-3644. |

| 10 | Yaghi O M, Li G M, Li H L. Selective binding and removal of guests in a microporous metal-organic framework[J]. Nature, 1995, 378: 703-706. |

| 11 | 张万珍, 占传威, 时双琴, 等. 微波法制备MOFs的研究进展[J]. 应用化工, 2022, 51(5): 1485-1489. |

| Zhang W Z, Zhan C W, Shi S Q, et al. Research progress on preparation of MOFs by microwave method[J]. Applied Chemical Industry, 2022, 51(5):1485-1489. | |

| 12 | Duan Y L, Guo Z G, Zhang J F, et al. Construction of bimetallic phosphide Fe x Co1- x P nanostructured array as a bifunctional electrocatalyst for overall water splitting[J]. Applied Physics A, 2024, 130(10): 673. |

| 13 | Bar A K, Mostafa G, Mukherjee P S. A Pd6 molecular cage via multicomponent self-assembly incorporating both neutral and anionic linkers[J]. Inorganic Chemistry, 2010, 49(17): 7647-7649. |

| 14 | Rubio-Martinez M, Avci-Camur C, Thornton A W, et al. New synthetic routes towards MOF production at scale[J]. Chemical Society Reviews, 2017, 46(11): 3453-3480. |

| 15 | Głowniak S, Szczęśniak B, Choma J, et al. Mechanochemistry: toward green synthesis of metal-organic frameworks[J]. Materials Today, 2021, 46: 109-124. |

| 16 | Kim J, Lee Y R, Ahn W S. Dry-gel conversion synthesis of Cr-MIL-101 aided by grinding: high surface area and high yield synthesis with minimum purification[J]. Chemical Communications, 2013, 49(69): 7647-7649. |

| 17 | Lin J B, Nguyen T T T, Vaidhyanathan R, et al. A scalable metal-organic framework as a durable physisorbent for carbon dioxide capture[J]. Science, 2021, 374(6574): 1464-1469. |

| 18 | Teo W L, Zhou W Q, Qian C, et al. Industrializing metal-organic frameworks: scalable synthetic means and their transformation into functional materials[J]. Materials Today, 2021, 47: 170-186. |

| 19 | Kumar S, Jain S, Nehra M, et al. Green synthesis of metal-organic frameworks: a state-of-the-art review of potential environmental and medical applications[J]. Coordination Chemistry Reviews, 2020, 420: 213407. |

| 20 | Pobłocki K, Drzeżdżon J, Gawdzik B, et al. Latest trends in the large-scale production of MOFs in accordance with the principles of green chemistry[J]. Green Chemistry, 2022, 24(24): 9402-9427. |

| 21 | Nagappan S, Duraivel M, Elayappan V, et al. Metal-organic frameworks-based cathode materials for energy storage applications: a review[J]. Energy Technology, 2023, 11(3): 2201200. |

| 22 | Férey G, Mellot-Draznieks C, Serre C, et al. A chromium terephthalate-based solid with unusually large pore volumes and surface area[J]. Science, 2005, 309(5743): 2040-2042. |

| 23 | Zou M M, Dong M, Zhao T. Advances in metal-organic frameworks MIL-101(Cr)[J]. International Journal of Molecular Sciences, 2022, 23(16): 9396. |

| 24 | Kavun V, van der Veen M A, Repo E. Selective recovery and separation of rare earth elements by organophosphorus modified MIL-101(Cr)[J]. Microporous and Mesoporous Materials, 2021, 312: 110747. |

| 25 | Rajati H, Navarchian A H, Rodrigue D, et al. Effect of immobilizing ionic liquid on amine-functionalized MIL-101(Cr) incorporated in Matrimid membranes for CO2/CH4 separation[J]. Chemical Engineering and Processing - Process Intensification, 2021, 168: 108590. |

| 26 | Wang Y D, Jia M T, Wu X, et al. PEG modified column MIL-101(Cr)/PVA cryogel as a sorbent in stir bar solid phase extraction for determination of non-steroidal anti-inflammatory drugs in water samples[J]. Microchemical Journal, 2019, 146: 214-219. |

| 27 | Wang F C, Zhang X, Wang Q Q, et al. Preparation of MS/MIL-101(Cr) composite material and its properties of atmospheric water collection[J]. Journal of Solid State Chemistry, 2021, 304: 122572. |

| 28 | Yang J F, Zhao Q, Li J P, et al. Synthesis of metal-organic framework MIL-101 in TMAOH-Cr(NO3)3-H2BDC-H2O and its hydrogen-storage behavior[J]. Microporous and Mesoporous Materials, 2010, 130(1/2/3): 174-179. |

| 29 | Zhao T, Li S H, Shen L, et al. The sized controlled synthesis of MIL-101(Cr) with enhanced CO2 adsorption property[J]. Inorganic Chemistry Communications, 2018, 96: 47-51. |

| 30 | Zhao T, Jeremias F, Boldog I, et al. High-yield, fluoride-free and large-scale synthesis of MIL-101(Cr)[J]. Dalton Transactions, 2015, 44(38): 16791-16801. |

| 31 | Zhao H Z, Li Q W, Wang Z Y, et al. Synthesis of MIL-101(Cr) and its water adsorption performance[J]. Microporous and Mesoporous Materials, 2020, 297: 110044. |

| 32 | Keshta B E, Yu H J, Wang L, et al. Cost-effective synthesis of MIL-101(Cr) from recyclable wastes and composite with polyaniline as an ion-to-electron transducer for potentiometric Pb2+ sensing[J]. Chemical Engineering Journal, 2024, 485: 150049. |

| 33 | Leng K Y, Sun Y Y, Li X L, et al. Rapid synthesis of metal-organic frameworks MIL-101(Cr) without the addition of solvent and hydrofluoric acid[J]. Crystal Growth & Design, 2016, 16(3): 1168-1171. |

| 34 | Bromberg L, Diao Y, Wu H M, et al. Chromium(Ⅲ) terephthalate metal organic framework (MIL-101): HF-free synthesis, structure, polyoxometalate composites, and catalytic properties[J]. Chemistry of Materials, 2012, 24(9): 1664-1675. |

| 35 | Liu Z N, Shi X L, Wei B L, et al. Preparation of MIL-53(Cr) and MIL-101(Cr)/reduced graphene oxide/polyaniline composites for Cr(Ⅵ) adsorption[J]. Journal of Porous Materials, 2025, 32(1): 353-364. |

| 36 | Teymouri N, Khoshnavazi R, Molaei S, et al. Keggin trimetallo-POM@MIL-101(Cr), synthesis, characterization and catalytic applications[J]. Catalysis Letters, 2025, 155(2): 61. |

| 37 | 安昊天, 韩章烨, 陆慕瑶, 等. 推进MOF产业化应用: 宏量制备与成型[J]. 化工学报, 2025, 76(5): 2011-2025. |

| An H T, Han Z Y, Lu M Y, et al. Promoting industrial application of MOF: scale-up preparation and shaping[J]. CIESC Journal, 2025, 76(5): 2011-2025. | |

| 38 | 孙丽媛, 张亚飞, 巩雁军. 微孔-微孔复合分子筛的结构特征及应用[J]. 物理化学学报, 2016, 32(5): 1105-1122. |

| Sun L Y, Zhang Y F, Gong Y J. Structural features and application of micro-microporous composite zeolites[J]. Acta Physico-Chimica Sinica, 2016, 32(5): 1105-1122. | |

| 39 | Hong L W, Zang J Z, Li B, et al. Research progress on the synthesis of nanosized and hierarchical beta zeolites[J]. Inorganics, 2023, 11(5): 214. |

| 40 | Seman N, Tarmizi Z I, Ali R R, et al. Preparation method of titanium dioxide nanoparticles and its application: an update[J]. IOP Conference Series: Earth and Environmental Science, 2022, 1091(1): 10. |

| 41 | 张密林, 丁立国, 景晓燕, 等. 纳米二氧化硅的制备、改性与应用研究进展[J]. 应用科技, 2004, 31(6): 64-66. |

| Zhang M L, Ding L G, Jing X Y, et al. Preparation, modification and application of nanoscale SiO2 [J]. Applied Science and Technology, 2004, 31(6): 64-66. | |

| 42 | 蔡靖, 林聪. 纳米材料与无机絮凝剂的复配絮凝实验研究[J]. 化工技术与开发, 2010, 39(2): 40-42. |

| Cai J, Lin C. Flocculation experiment of nano-material complicated with inorganic flocculants[J]. Technology & Development of Chemical Industry, 2010, 39(2): 40-42. | |

| 43 | Li Y L, Xu Z T, Wang W X. Effective flocculation of harmful algae Microcystis aeruginosa by nanoscale metal-organic framework NH2-MIL-101(Cr)[J]. Chemical Engineering Journal, 2022, 433: 134584. |

| 44 | Shao Y M, Fan X F, Wang S S, et al. Insights into adsorption and diffusion of CO2, CH4 and their mixture in MIL-101(Cr) via molecular simulation[J]. Chemical Engineering Journal, 2024, 480: 148215. |

| [1] | 张冰, 李建惠, 马欣蓉, 陈杨, 李晋平, 李立博. 蒸气相辅助法制备MOF基材料的研究进展[J]. 化工学报, 2025, 76(5): 2026-2041. |

| [2] | 李远华, 凌思棋, 封科军, 冯颖, 郭于菁, 谢世桓. 基于cMOFs的固定化脂肪酶微反应器的构筑及其扁桃酸催化应用[J]. 化工学报, 2025, 76(3): 1170-1179. |

| [3] | 潘娜, 田昌, 怀兰坤, 刘玉玉, 张芬芬, 高晓梅, 刘伟, 闫良国, 赵艳侠. 聚合铝钛基絮凝剂的合成与应用[J]. 化工学报, 2024, 75(3): 1009-1018. |

| [4] | 张浩, 赵宇, 徐志明, 李晋辉. 羧甲基葡聚糖的快速沉降法阻垢特性研究[J]. 化工学报, 2022, 73(4): 1515-1522. |

| [5] | 王毅, 熊启钊, 陈杨, 杨江峰, 李立博, 李晋平. 锆基金属有机骨架材料用于氨吸附性能的研究[J]. 化工学报, 2022, 73(4): 1772-1780. |

| [6] | 王莹, 郑柏树, 王刘盛, 汪冠宇, 曾文江, 汪朝旭, 阳庆元. 锆基金属-有机骨架材料分离放射性气体Rn的计算筛选研究[J]. 化工学报, 2021, 72(5): 2688-2696. |

| [7] | 李建惠, 兰天昊, 陈杨, 杨江峰, 李立博, 李晋平. MOF复合材料在气体吸附分离中的研究进展[J]. 化工学报, 2021, 72(1): 167-179. |

| [8] | 刘普旭, 贺朝辉, 李立博, 李晋平. 高稳定双金属MOF材料用于低浓度乙烷的高效分离[J]. 化工学报, 2020, 71(9): 4211-4218. |

| [9] | 韩强, 程振飞, 刘纪昌, 汪成, 欧苏慧, 汪瑜懿, 简雨培, 杨小娟, 王紫竹, 杨璐彬. 羧酸改性HKUST-1提高甲烷吸附容量[J]. 化工学报, 2018, 69(11): 4902-4909. |

| [10] | 李立欣, 刘婉萌, 马放. 复合型微生物絮凝剂研究进展[J]. 化工学报, 2018, 69(10): 4139-4147. |

| [11] | 魏金枝, 张少平, 王雪亮, 孙晓君, 张凤鸣. 巯基修饰Cu-MOFs材料的制备及其汞吸附性能[J]. 化工学报, 2017, 68(5): 2186-2194. |

| [12] | 苏叶, 鲍宗必, 张治国, 邢华斌, 杨启炜, 苏宝根, 杨亦文, 任其龙. L酸/B酸可调的磺酸功能化MIL-101(Cr)材料催化葡萄糖脱水 制备5-羟甲基糠醛[J]. 化工学报, 2016, 67(7): 2799-2807. |

| [13] | 张所瀛, 刘红, 刘朋飞, 吴培培, 杨祝红, 阳庆元, 陆小华. 金属有机骨架材料在CO2/CH4吸附分离中的研究进展[J]. 化工学报, 2014, 65(5): 1563-1570. |

| [14] | 杨祝红, 吴培培, 张所瀛, 刘红, 刘朋飞, 阳庆元, 陆小华. 不同氨基修饰条件对NH2-MIL-53(Al)CO2吸附性能的影响[J]. 化工学报, 2014, 65(5): 1928-1934. |

| [15] | 苑宏英1,2,王小佩 1,2,王亭 1,2,牛四芳1,2,祁丽 1,2. 不同絮凝剂对剩余污泥水解和脱水特性的影响[J]. 化工进展, 2014, 33(10): 2790-2794. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号