化工学报 ›› 2022, Vol. 73 ›› Issue (4): 1515-1522.DOI: 10.11949/0438-1157.20211614

收稿日期:2021-11-12

修回日期:2022-02-15

出版日期:2022-04-05

发布日期:2022-04-25

通讯作者:

赵宇

作者简介:张浩(1997—),男,博士研究生,基金资助:

Hao ZHANG( ),Yu ZHAO(

),Yu ZHAO( ),Zhiming XU,Jinhui LI

),Zhiming XU,Jinhui LI

Received:2021-11-12

Revised:2022-02-15

Online:2022-04-05

Published:2022-04-25

Contact:

Yu ZHAO

摘要:

工业循环冷却水中的碳酸钙污垢一直是困扰工业生产者的重要问题,使用快速沉降法(FCP)研究了不同浓度的羧甲基葡聚糖对于碳酸钙污垢的抑制作用。控制溶液中的钙离子浓度为200 mg/L,羧甲基葡聚糖的浓度分别为0.5、1、2和4 mg/L时,对羧甲基葡聚糖的阻垢性能进行分析。结果表明,羧甲基葡聚糖对于减缓碳酸钙的成核过程有明显效果,此外,它也显著降低了碳酸钙成核后晶体的生长速率。当羧甲基葡聚糖的浓度为4 mg/L时,羧甲基葡聚糖对于碳酸钙的成核及晶面生长起到了完全抑制的作用,对于工业应用中碳酸钙的防垢处理,提升换热效率具有借鉴意义。

中图分类号:

张浩, 赵宇, 徐志明, 李晋辉. 羧甲基葡聚糖的快速沉降法阻垢特性研究[J]. 化工学报, 2022, 73(4): 1515-1522.

Hao ZHANG, Yu ZHAO, Zhiming XU, Jinhui LI. Study on scale inhibition characteristics of carboxymethyl dextran by fast controlled precipitation method[J]. CIESC Journal, 2022, 73(4): 1515-1522.

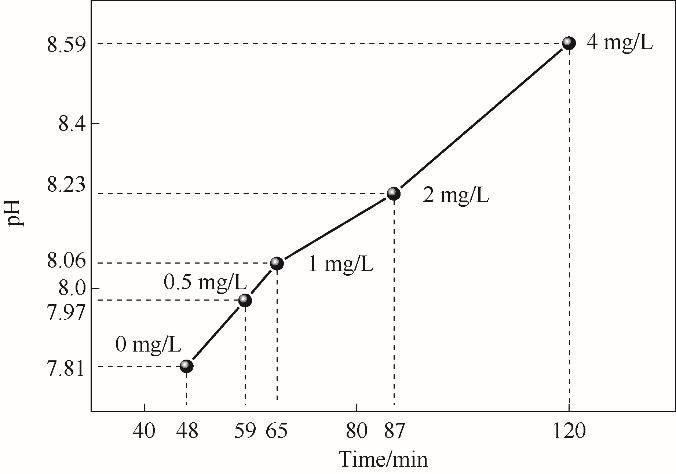

图5 不同浓度的羧甲基葡聚糖对应的pH最高点与时间的关系

Fig.5 Relationship between the highest pH point and time corresponding to different concentrations of carboxymethyl dextran

| C/( mg/L) | pH | 电阻率/(kΩ·cm) |

|---|---|---|

| 0 | 6.53 | 100.12 |

| 0.5 | 6.5 | 100.24 |

| 1 | 6.48 | 100.3 |

| 2 | 6.52 | 100.36 |

| 4 | 6.51 | 100.48 |

表1 不同浓度羧甲基葡聚糖对溶液pH及电阻率的影响

Table 1 Effects of different concentrations of carboxymethyl dextran on pH and resistivity of solution

| C/( mg/L) | pH | 电阻率/(kΩ·cm) |

|---|---|---|

| 0 | 6.53 | 100.12 |

| 0.5 | 6.5 | 100.24 |

| 1 | 6.48 | 100.3 |

| 2 | 6.52 | 100.36 |

| 4 | 6.51 | 100.48 |

| C/(mg/L) | 时间点/min | |

|---|---|---|

| pH | 电阻率 | |

| 0 | 48 | 46 |

| 0.5 | 59 | 60 |

| 1 | 65 | 66 |

| 2 | 87 | 89 |

| 4 | — | — |

表2 pH及电阻率曲线显示的成核结束的时间点

Table 2 The time point of the end of nucleation shown by the pH and resistivity curves

| C/(mg/L) | 时间点/min | |

|---|---|---|

| pH | 电阻率 | |

| 0 | 48 | 46 |

| 0.5 | 59 | 60 |

| 1 | 65 | 66 |

| 2 | 87 | 89 |

| 4 | — | — |

羧甲基葡聚糖的浓度 C/(mg/L) | pH最大值 pHmax | pHmax对应的 时间/min | 阻垢效率 EFCP/% |

|---|---|---|---|

| 0 | 7.81 | 48 | — |

| 0.5 | 7.97 | 59 | 53.09 |

| 1 | 8.06 | 65 | 93.93 |

| 2 | 8.23 | 87 | 98.47 |

| 4 | — | — | 100 |

表3 羧甲基葡聚糖的阻垢效率

Table 3 Scale inhibition efficiency of carboxymethyl dextran

羧甲基葡聚糖的浓度 C/(mg/L) | pH最大值 pHmax | pHmax对应的 时间/min | 阻垢效率 EFCP/% |

|---|---|---|---|

| 0 | 7.81 | 48 | — |

| 0.5 | 7.97 | 59 | 53.09 |

| 1 | 8.06 | 65 | 93.93 |

| 2 | 8.23 | 87 | 98.47 |

| 4 | — | — | 100 |

| 1 | Awais M, Bhuiyan A A. Recent advancements in impedance of fouling resistance and particulate depositions in heat exchangers[J]. International Journal of Heat and Mass Transfer, 2019, 141: 580-603. |

| 2 | Xu Z M, Zhao Y, He J J, et al. Fouling characterization of calcium carbonate on heat transfer surfaces with sodium carboxymethyl cellulose as an inhibitor[J]. International Journal of Thermal Sciences, 2021, 162: 106790. |

| 3 | Wang L C, Li S F, Wang L B, et al. Relationships between the characteristics of CaCO3 fouling and the flow velocity in smooth tube[J]. Experimental Thermal and Fluid Science, 2016, 74: 143-159. |

| 4 | Zhao Y, Xu Z M, Wang B B, et al. Scale inhibition performance of sodium carboxymethyl cellulose on heat transfer surface at various temperatures: experiments and molecular dynamics simulation[J]. International Journal of Heat and Mass Transfer, 2019, 141: 457-463. |

| 5 | Chaussemier M, Pourmohtasham E, Gelus D, et al. State of art of natural inhibitors of calcium carbonate scaling. A review article[J]. Desalination, 2015, 356: 47-55. |

| 6 | Kazi S N, Teng K H, Zakaria M S, et al. Study of mineral fouling mitigation on heat exchanger surface[J]. Desalination, 2015, 367: 248-254. |

| 7 | Xu Z M, Zhao Y, Wang J T, et al. Inhibition of calcium carbonate fouling on heat transfer surface using sodium carboxymethyl cellulose[J]. Applied Thermal Engineering, 2019, 148: 1074-1080. |

| 8 | Kokilaramani S, Al-Ansari M M, Rajasekar A, et al. Microbial influenced corrosion of processing industry by re-circulating waste water and its control measures — a review[J]. Chemosphere, 2021, 265: 129075. |

| 9 | Jafar Mazumder M A. A review of green scale inhibitors: process, types, mechanism and properties[J]. Coatings, 2020, 10(10): 928. |

| 10 | Zhang G C, Ge J J, Sun M Q, et al. Investigation of scale inhibition mechanisms based on the effect of scale inhibitor on calcium carbonate crystal forms[J]. Science in China Series B: Chemistry, 2007, 50(1): 114-120. |

| 11 | 张盼盼, 蒋利辉, 孙军萍, 等. 工业循环冷却水用阻垢缓蚀剂的研究进展[J]. 化学研究, 2018, 29(6): 642-646. |

| Zhang P P, Jiang L H, Sun J P, et al. Research progress of scale and corrosion inhibitor for industrial re-circulating cooling water[J]. Chemical Research, 2018, 29(6): 642-646. | |

| 12 | Zhou Y S, Wang J, Fang Y. Green and high effective scale inhibitor based on ring-opening graft modification of polyaspartic acid[J]. Catalysts, 2021, 11(7): 802. |

| 13 | Boumagoura M, Ghizellaoui S, Rhouati S, et al. Calcium carbonate scaling prevention by a green chemical inhibitor, gallic acid[J]. Water and Environment Journal, 2021, 35(3): 998-1006. |

| 14 | Geng X, Sosa R D, Reynolds M A, et al. Alginate as a green inhibitor of barite nucleation and crystal growth[J]. Molecular Systems Design & Engineering, 2021, 6(7): 508-519. |

| 15 | 张巧玲, 赖川. 阻垢剂作用机理研究进展[J]. 四川文理学院学报, 2020, 30(2): 18-23. |

| Zhang Q L, Lai C. Research progress on the mechanism of scale inhibitors[J]. Sichuan University of Arts and Science Journal, 2020, 30(2): 18-23. | |

| 16 | 任大军, 庄梦娟, 张淑琴, 等. 绿色阻垢剂研究进展[J]. 工业水处理, 2021, 41(12): 41-45. |

| Ren D J, Zhuang M J, Zhang S Q, et al. Research progress of green scale inhibitor[J]. Industrial Water Treatment, 2021, 41(12): 41-45. | |

| 17 | 周瑜, 王芳斌, 刘又年, 等. 羧甲基葡聚糖磁性纳米微球的制备及表征[J]. 化学研究, 2009, 20(2): 5-8. |

| Zhou Y, Wang F B, Liu Y N, et al. Preparation and characterization of carboxymethyldextran-modified magnetic nanoparticles[J]. Chemical Research, 2009, 20(2): 5-8. | |

| 18 | Chahardahcherik M, Ashrafi M, Ghasemi Y, et al. Effect of chemical modification with carboxymethyl dextran on kinetic and structural properties of L-asparaginase[J]. Analytical Biochemistry, 2020, 591: 113537. |

| 19 | 杨文鸽, 李花霞, 薛长湖, 等. 酵母葡聚糖的羧甲基化研究[J]. 食品与发酵工业, 2004, 30(11): 28-30. |

| Yang W G, Li H X, Xue C H, et al. Study on the carboxymethylation of glucan from yeast[J]. Food and Fermentation Industries, 2004, 30(11): 28-30. | |

| 20 | 孙翠玲, 杨文鸽, 李花霞, 等. 羧甲基葡聚糖体外抗肿瘤作用的研究[J]. 中国生化药物杂志, 2006, 26(3): 153-155. |

| Sun C L, Yang W G, Li H X, et al. The anti-cancer effect of carboxymethylglucan in vitro [J]. Chinese Journal of Biochemical Pharmaceutics, 2006, 26(3): 153-155. | |

| 21 | Shin J M, Song S H, Rao N V, et al. A carboxymethyl dextran-based polymeric conjugate as the antigen carrier for cancer immunotherapy[J]. Biomaterials Research, 2018, 22: 21. |

| 22 | Verraest D L, Peters J A, Bekkum H, et al. Carboxymethyl inulin: a new inhibitor for calcium carbonate precipitation[J]. Journal of the American Oil Chemists' Society, 1996, 73(1): 55-62. |

| 23 | Nancollas G H, Kazmierczak T F, Schuttringer E. A controlled composition study of calcium carbonate crystal growth: the influence of scale inhibitors[J]. Corrosion, 1981, 37(2): 76-81. |

| 24 | 陈华林, 冯忠琼, 张枝健, 等. EDTA滴定法测定钙离子浓度的影响因素与优化[J]. 西南民族大学学报(自然科学版), 2020, 46(6): 578-585. |

| Chen H L, Feng Z Q, Zhang Z J, et al. Influence factors and optimization on the EDTA titration of calcium[J]. Journal of Southwest Minzu University (Natural Science Edition), 2020, 46(6): 578-585. | |

| 25 | Lédion J F B, Vienne J. Characterization of the scaling properties of water by fast controlled precipitation test[J]. Journal Europeen d'Hydrologie, 1997, 28(15): 15-35. |

| 26 | Gauthier G, Chao Y J, Horner O, et al. Application of the fast controlled precipitation method to assess the scale-forming ability of raw river waters[J]. Desalination, 2012, 299: 89-95. |

| 27 | Chao Y J, Horner O, Vallée P, et al. In situ probing calcium carbonate formation by combining fast controlled precipitation method and small-angle X-ray scattering[J]. Langmuir, 2014, 30(12): 3303-3309. |

| 28 | Hamdi R, Tlili M M. Conductometric study of calcium carbonate prenucleation stage: underlining the role of CaCO3 ion pairs[J]. Crystal Research and Technology, 2016, 51(1): 99-109. |

| 29 | Peronno D, Cheap-Charpentier H, Horner O, et al. Study of the inhibition effect of two polymers on calcium carbonate formation by fast controlled precipitation method and quartz crystal microbalance[J]. Journal of Water Process Engineering, 2015, 7: 11-20. |

| 30 | Horner O, Cheap-Charpentier H, Cachet X, et al. Antiscalant properties of Herniaria glabra aqueous solution[J]. Desalination, 2017, 409: 157-162. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [4] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [5] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [6] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [7] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [8] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [9] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [10] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [11] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [12] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [13] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [14] | 陈天华, 刘兆轩, 韩群, 张程宾, 李文明. 喷雾冷却换热强化研究进展及影响因素[J]. 化工学报, 2023, 74(8): 3149-3170. |

| [15] | 盛冰纯, 于建国, 林森. 铝基锂吸附剂分离高钠型地下卤水锂资源过程研究[J]. 化工学报, 2023, 74(8): 3375-3385. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号