化工学报 ›› 2021, Vol. 72 ›› Issue (4): 2203-2212.DOI: 10.11949/0438-1157.20201046

谭卓伟1( ),杨留洋2,王振波1,豆肖辉2,张大磊2(

),杨留洋2,王振波1,豆肖辉2,张大磊2( ),张明阳3,金有海1

),张明阳3,金有海1

收稿日期:2020-09-27

修回日期:2020-10-12

出版日期:2021-04-05

发布日期:2021-04-05

通讯作者:

张大磊

作者简介:谭卓伟(1990—),男,博士研究生,基金资助:

TAN Zhuowei1( ),YANG Liuyang2,WANG Zhenbo1,DOU Xiaohui2,ZHANG Dalei2(

),YANG Liuyang2,WANG Zhenbo1,DOU Xiaohui2,ZHANG Dalei2( ),ZHANG Mingyang3,JIN Youhai1

),ZHANG Mingyang3,JIN Youhai1

Received:2020-09-27

Revised:2020-10-12

Online:2021-04-05

Published:2021-04-05

Contact:

ZHANG Dalei

摘要:

天然气管道内表面局部腐蚀缺陷会诱发局部流场突变影响局部腐蚀进程,利用高剪切力的冲刷腐蚀实验装置进行流动状态下的电化学腐蚀在线测试,研究了局部腐蚀深坑对局部腐蚀进程的影响。试样在冲刷腐蚀过程中的界面腐蚀电化学信号通过电化学阻抗谱进行分析,腐蚀产物膜的成分及特征通过扫描电子显微镜(SEM)、能量衍射谱图(EDS)以及X射线衍射(XRD)表征,并结合计算流体力学(CFD)分析了流场参数对腐蚀传质过程的影响。结果表明,表面缺陷会诱导局部位置流场发生变化,增强局部位置的传质作用,缺陷表面腐蚀产物也因此随着流速的变化而呈现不同的微观形态。在较高强度流场下,局部增强的壁面剪切力会剥离部分致密腐蚀产物膜,导致测试表面形成大阴极小阳极的电化学分布,促进局部位置的腐蚀进程,从而加速局部腐蚀发生。

中图分类号:

谭卓伟, 杨留洋, 王振波, 豆肖辉, 张大磊, 张明阳, 金有海. 高剪切力流场下X80管线钢局部腐蚀深坑诱导局部湍流交互机理研究[J]. 化工学报, 2021, 72(4): 2203-2212.

TAN Zhuowei, YANG Liuyang, WANG Zhenbo, DOU Xiaohui, ZHANG Dalei, ZHANG Mingyang, JIN Youhai. Study on interaction mechanism of local turbulent flow induced by local corrosion of X80 pipeline steel in high shear flow field[J]. CIESC Journal, 2021, 72(4): 2203-2212.

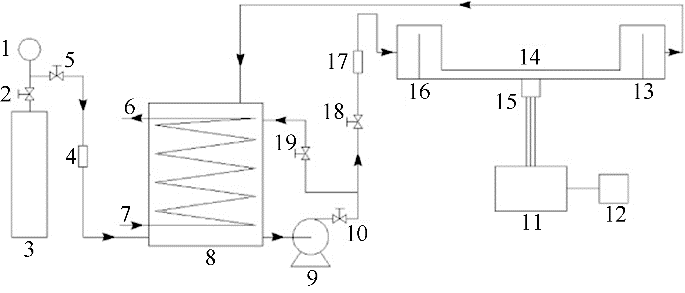

图1 冲刷腐蚀实验装置示意图1—气压表;2—气体主阀;3—气瓶;4—气体流量计;5—气体流量控制阀;6—冷却水出口;7—冷却水进口;8—溶液箱;9—耐腐蚀离心泵;10—溶液主阀;11—电化学工作站;12—数据采集平台;13—溶液缓冲箱;14—测试通道;15—集成电极测试探头;16—溶液均布箱;17—耐腐蚀转子流量计;18—流量控制阀;19—回流阀

Fig.1 Schematic diagram of the experimental set-up

| 成分 | 含量/%(质量) |

|---|---|

| Mn | 1.83 |

| Si | 0.28 |

| C | 0.063 |

| Cr | 0.03 |

| S | 0.0006 |

| P | 0.011 |

| Ni | 0.03 |

| Ti | 0.016 |

| Nb | 0.061 |

| Mo | 0.22 |

| V | 0.059 |

表1 X80管线钢化学成分组成

Table 1 Chemical composition of X80 pipeline steel

| 成分 | 含量/%(质量) |

|---|---|

| Mn | 1.83 |

| Si | 0.28 |

| C | 0.063 |

| Cr | 0.03 |

| S | 0.0006 |

| P | 0.011 |

| Ni | 0.03 |

| Ti | 0.016 |

| Nb | 0.061 |

| Mo | 0.22 |

| V | 0.059 |

v/ (m·s-1) | Rs/(Ω·cm2) | Qdl/(Ω-1·cm-2·s-n) | Rct/(Ω·cm2) | L/(H·cm-2) | RL/(Ω·cm2) | Qf/(Ω-1·cm-2·s-n) | Rf/(Ω·cm2) |

|---|---|---|---|---|---|---|---|

| 3 | 14.75 | 1.8×10-3 | 30.05 | 33.93 | 187.2 | ||

| 5 | 15.42 | 1.4×10-4 | 36.84 | 6.8×10-4 | 15.07 | ||

| 7 | 15.26 | 1.0×10-3 | 19.74 | 29.79 | 47.37 |

表2 拟合电路数据

Table 2 Equivalent circuit fitting of EIS data

v/ (m·s-1) | Rs/(Ω·cm2) | Qdl/(Ω-1·cm-2·s-n) | Rct/(Ω·cm2) | L/(H·cm-2) | RL/(Ω·cm2) | Qf/(Ω-1·cm-2·s-n) | Rf/(Ω·cm2) |

|---|---|---|---|---|---|---|---|

| 3 | 14.75 | 1.8×10-3 | 30.05 | 33.93 | 187.2 | ||

| 5 | 15.42 | 1.4×10-4 | 36.84 | 6.8×10-4 | 15.07 | ||

| 7 | 15.26 | 1.0×10-3 | 19.74 | 29.79 | 47.37 |

| v/(m·s-1) | CK | OK | SiK | MnK | FeK |

|---|---|---|---|---|---|

| 3 | 19.96 | 40.69 | 0.47 | 0.68 | 38.19 |

| 5 | 23.70 | 54.22 | 0.40 | 0.76 | 20.92 |

| 7 | 20.14 | 58.55 | 0.36 | 0.41 | 20.54 |

表3 EDS检测数据

Table 3 Test data of EDS

| v/(m·s-1) | CK | OK | SiK | MnK | FeK |

|---|---|---|---|---|---|

| 3 | 19.96 | 40.69 | 0.47 | 0.68 | 38.19 |

| 5 | 23.70 | 54.22 | 0.40 | 0.76 | 20.92 |

| 7 | 20.14 | 58.55 | 0.36 | 0.41 | 20.54 |

| 1 | Hu Z Y, Duan D L, Hou S H, et al. Preliminary study on corrosion behaviour of carbon steel in oil-water two-phase fluids[J]. Journal of Materials Science & Technology, 2015, 31(12): 1274-1281. |

| 2 | 李连波. 20CrMo抽油杆腐蚀机理研究[D]. 青岛: 中国石油大学, 2008. |

| Li L B. Study on corrosion mechanism of 20CrMo sucker rod[D]. Qingdao: China University of Petroleum (East China), 2008. | |

| 3 | Zeng L, Zhang G A, Guo X P. Erosion-corrosion at different locations of X65 carbon steel elbow[J]. Corrosion Science, 2014, 85: 318-330. |

| 4 | Stack M M, Abdulrahman G H. Mapping erosion-corrosion of carbon steel in oil-water solutions: effects of velocity and applied potential[J]. Wear, 2012, 274/275: 401-413. |

| 5 | 李自力, 程远鹏, 毕海胜, 等. 油气田CO2/H2S共存腐蚀与缓蚀技术研究进展[J]. 化工学报, 2014, 65(2): 406-414. |

| Li Z L, Cheng Y P, Bi H S, et al. Research progress of CO2/H2S corrosion and inhibitor techniques in oil and gas fields[J]. CIESC Journal, 2014, 65(2): 406-414. | |

| 6 | Barmatov E, Hughes T, Nagl M. Efficiency of film-forming corrosion inhibitors in strong hydrochloric acid under laminar and turbulent flow conditions[J]. Corrosion Science, 2015, 92: 85-94. |

| 7 | Zhang G A, Zeng L, Huang H L, et al. A study of flow accelerated corrosion at elbow of carbon steel pipeline by array electrode and computational fluid dynamics simulation[J]. Corrosion Science, 2013, 77: 334-341. |

| 8 | Kim H J, Kim K H. Intuitional experiment and numerical analysis of flow characteristics affected by flow accelerated corrosion in elbow pipe system[J]. Nuclear Engineering and Design, 2016, 301: 183-188. |

| 9 | Wei L, Pang X L, Gao K W. Effect of flow rate on localized corrosion of X70 steel in supercritical CO2 environments[J]. Corrosion Science, 2018, 136: 339-351. |

| 10 | 寇杰, 惠军福. 流动腐蚀研究进展[J]. 油气田地面工程, 2007, 26(10): 4-5. |

| Kou J, Hui J F. Reseach progress of corrosion under flow [J]. Oil-Gasfield Surface Engineering, 2007, 26(10): 4-5. | |

| 11 | Tran T, Brown B, Nesic S. Corrosion of mild steel in an aqueous CO2 environment-basic electrochemical mechanisms revisited[J]. Nace International Corrosion Conference, 2015, 212(14): 5671-5682. |

| 12 | 曹楚南. 腐蚀电化学原理[M]. 3版. 北京: 化学工业出版社, 2008: 268. |

| Cao C N. Principles of electrochemistry of corrosion[M]. 3rd ed. Beijing: Chemical Industry Press, 2008: 268. | |

| 13 | Kahyarian A, Brown B, Nesic S. Electrochemistry of CO2 corrosion of mild steel: effect of CO2 on iron dissolution reaction[J]. Corrosion Science, 2017, 129: 146-151. |

| 14 | Obot I B, Onyeachu I B, Umoren S A. Alternative corrosion inhibitor formulation for carbon steel in CO2-saturated brine solution under high turbulent flow condition for use in oil and gas transportation pipelines[J]. Corrosion Science, 2019, 159: 108140. |

| 15 | Nesic S. Effects of multiphase flow on internal CO2 corrosion of mild steel pipelines[J]. Energy & Fuels, 2012, 26(7): 4098-4111. |

| 16 | Tan Z W, Zhang D L, Yang L Y, et al. Development mechanism of local corrosion pit in X80 pipeline steel under flow conditions[J]. Tribology International, 2020, 146: 106145. |

| 17 | 雍兴跃, 林玉珍, 刘景军, 等. 碳钢在管流体系中的流动腐蚀动力学模型[J]. 化工学报, 2002, 53(7): 680-684. |

| Yong X Y, Lin Y Z, Liu J J, et al. Flow-induced corrosion kinetics model of carbon steel in flow loop system[J]. Journal of Chemical Industry and Engineering (China), 2002, 53(7): 680-684. | |

| 18 | Tan Z W, Yang L Y, Zhang D L, et al. Development mechanism of internal local corrosion of X80 pipeline steel[J]. Journal of Materials Science & Technology, 2020, 49: 186-201. |

| 19 | 何昌春, 徐磊, 陈伟, 等. 常顶系统流动腐蚀机理预测及防控措施优化[J]. 化工学报, 2019, 70(3): 1027-1034. |

| He C C, Xu L, Chen W, et al. Mechanism prediction of flow-induced corrosion and optimization of protection measures in overhead system of atmospheric tower[J]. CIESC Journal, 2019, 70(3): 1027-1034. | |

| 20 | Ezuber H M, Al Shater A. Influence of environmental parameters on the corrosion behavior of 90/10 cupronickel tubes in 3.5% NaCl[J]. Desalination and Water Treatment, 2016, 57(15): 6670-6679. |

| 21 | Eliyan F F, Alfantazi A. Mechanisms of corrosion and electrochemical significance of metallurgy and environment with corrosion of iron and steel in bicarbonate and carbonate solutions—a review[J]. Corrosion, 2014, 70(9): 880-898. |

| 22 | Zhang S H, Hou L F, Wei H, et al. Failure analysis of an oil pipe wall perforated by pitting corrosion[J]. Materials and Corrosion, 2018, 69(8): 1123-1130. |

| 23 | Hamadou L, Kadri A, Benbrahim N. Impedance investigation of thermally formed oxide films on AISI 304L stainless steel[J]. Corrosion Science, 2010, 52(3): 859-864. |

| 24 | 刘旭文, 熊金平, 曹京宜, 等. EIS法研究3种配套涂层体系的腐蚀电化学行为[J]. 化工学报, 2008, 59(3): 659-664. |

| Liu X W, Xiong J P, Cao J Y, et al. Electrochemical corrosion behavior of three coating systems by EIS[J]. Journal of Chemical Industry and Engineering (China), 2008, 59(3): 659-664. | |

| 25 | Zhang G A, Cheng Y F. Electrochemical characterization and computational fluid dynamics simulation of flow-accelerated corrosion of X65 steel in a CO2-saturated oilfield formation water[J]. Corrosion Science, 2010, 52(8): 2716-2724. |

| 26 | Sridhar N, Dunn D S, Anderko A M, et al. Effects of water and gas compositions on the internal corrosion of gas pipelines—modeling and experimental studies[J]. Corrosion, 2001, 57(3): 221-235. |

| 27 | Li Q, Hu H T, Cheng Y F. Corrosion of pipelines in CO2-saturated oil-water emulsion flow studied by electrochemical measurements and computational fluid dynamics modeling[J]. Journal of Petroleum Science and Engineering, 2016, 147: 408-415. |

| 28 | Zhu M, Du C W, Li X G, et al. Effect of AC on stress corrosion cracking behavior and mechanism of X80 pipeline steel in carbonate/bicarbonate solution[J]. Corrosion Science, 2014, 87: 224-232. |

| 29 | Medeiros M J, Pletcher D, Sidorin D. The catalysis of carbon dioxide hydration by acetate ion[J]. Journal of Electroanalytical Chemistry, 2008, 619/620: 83-86. |

| [1] | 于源, 陈薇薇, 付俊杰, 刘家祥, 焦志伟. 几何相似涡流空气分级机环形区流场变化规律研究及预测[J]. 化工学报, 2023, 74(6): 2363-2373. |

| [2] | 张正, 何永平, 孙海东, 张荣子, 孙正平, 陈金兰, 郑一璇, 杜晓, 郝晓刚. 蛇形流场电控离子交换装置用于选择性提锂[J]. 化工学报, 2023, 74(5): 2022-2033. |

| [3] | 李新亚, 邢雷, 蒋明虎, 赵立新. 倒锥注气强化井下油水分离水力旋流器性能研究[J]. 化工学报, 2023, 74(3): 1134-1144. |

| [4] | 范怡平, 卢春喜. 离心力场-移动床耦合气固分离装备的研究进展[J]. 化工学报, 2023, 74(1): 157-169. |

| [5] | 韩昌亮, 辛镜青, 于广滨, 刘俊秀, 许麒澳, 姚安卡, 尹鹏. 微通道内超临界氮气三维热流场实验与数值模拟[J]. 化工学报, 2022, 73(2): 653-662. |

| [6] | 彭明, 夏强峰, 蒋理想, 张瑞元, 郭凌燚, 陈黎, 陶文铨. 流道布置对风冷燃料电池性能影响的研究[J]. 化工学报, 2022, 73(10): 4625-4637. |

| [7] | 任盼锋, 海润泽, 李奇, 李文彬, 余国琮. 流化床液固两相传质过程的模拟研究进展[J]. 化工学报, 2022, 73(1): 1-17. |

| [8] | 张海, 徐英, 张涛, 孙涔崴, 魏传顺, 戴志向. 丝网传感器的气液两相流可视化测量特性研究[J]. 化工学报, 2021, 72(9): 4573-4583. |

| [9] | 李文金, 周勇军, 袁名岳, 何华, 孙建平. 几种框式桨搅拌槽内流动特性的比较研究[J]. 化工学报, 2021, 72(4): 1998-2005. |

| [10] | 刘志刚,董开明,吕明明,季璨,江亚柯. 基于微观粒子图像测速法的微肋阵通道内流场特性研究[J]. 化工学报, 2021, 72(10): 5094-5101. |

| [11] | 周鑫, 邱鸣慧, 罗平. 陶瓷膜接触器化学吸收氮氧化物的传质过程与阻力分析[J]. 化工学报, 2020, 71(8): 3652-3660. |

| [12] | 赵强, 郭航, 叶芳, 马重芳. 质子交换膜燃料电池流场板研究进展[J]. 化工学报, 2020, 71(5): 1943-1963. |

| [13] | 杨锋苓, 张翠勋, 苏腾龙. 柔性Rushton搅拌桨的功耗与流场特性研究[J]. 化工学报, 2020, 71(2): 614-625. |

| [14] | 孙立强, 王迪, 宋健斐, 王江云, 魏耀东. 旋风分离器有无灰斗对气相流场动态特性的影响[J]. 化工学报, 2019, 70(6): 2202-2210. |

| [15] | 尤东江, 魏建云, 李雪菁, 娄景媛. 基于框架设计的液流电池流场优化模拟研究[J]. 化工学报, 2019, 70(11): 4437-4448. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号