化工学报 ›› 2020, Vol. 71 ›› Issue (2): 614-625.DOI: 10.11949/0438-1157.20190960

收稿日期:2019-08-21

修回日期:2019-09-27

出版日期:2020-02-05

发布日期:2020-02-05

通讯作者:

杨锋苓

作者简介:杨锋苓(1979—),男,博士,副教授, 基金资助:

Fengling YANG1,2,3( ),Cuixun ZHANG4,Tenglong SU1

),Cuixun ZHANG4,Tenglong SU1

Received:2019-08-21

Revised:2019-09-27

Online:2020-02-05

Published:2020-02-05

Contact:

Fengling YANG

摘要:

基于传统的Rushton桨,开发了一种柔性叶片Rushton搅拌桨。采用数值模拟方法研究了柔性桨的功耗及层流和湍流流场特性,并分别采用扭矩测量法和粒子图像测速法进行了实验验证。结果表明,对于实验规模的搅拌容器,当介质黏度与甘油接近时,可用橡胶作为柔性桨叶制作材料。Reynolds数≤100时,柔性桨的功耗大于刚性桨;Reynolds数大于该值后,柔性桨的功耗小于刚性桨。柔性桨叶对被搅拌流体具有自适应特性,流固耦合作用下产生的变形增加了流体的径向流动能力。搅拌低黏度流体时,柔性桨能提升近桨区流体的速度,增加桨叶远端流体的循环流动能力;搅拌高黏度流体时,近桨区和桨叶远端流体的速度均大于刚性桨。就尾涡而言,柔性桨产生的涡量较小,耗能少。

中图分类号:

杨锋苓, 张翠勋, 苏腾龙. 柔性Rushton搅拌桨的功耗与流场特性研究[J]. 化工学报, 2020, 71(2): 614-625.

Fengling YANG, Cuixun ZHANG, Tenglong SU. Power and flow characteristics of flexible-blade Rushton impeller[J]. CIESC Journal, 2020, 71(2): 614-625.

柔性桨叶 材料 | 物性参数 | ||

|---|---|---|---|

| 弹性模量 E/MPa | 泊松比 | 密度 ρ/(kg·m -3) | |

| 超高分子量聚乙烯 | 1~1.25×10 5 | 0.3 | 935~945 |

| 硬聚氯乙烯 | 3.14~3.92×10 3 | 0.319 | 1350~1400 |

| 橡胶 | 7.8 | 0.47 | 900~1000 |

| 硅橡胶 | 2.1 | 0.48 | 1200 |

表1 柔性桨叶材料物性参数

Table 1 Parameters of flexible blade materials

柔性桨叶 材料 | 物性参数 | ||

|---|---|---|---|

| 弹性模量 E/MPa | 泊松比 | 密度 ρ/(kg·m -3) | |

| 超高分子量聚乙烯 | 1~1.25×10 5 | 0.3 | 935~945 |

| 硬聚氯乙烯 | 3.14~3.92×10 3 | 0.319 | 1350~1400 |

| 橡胶 | 7.8 | 0.47 | 900~1000 |

| 硅橡胶 | 2.1 | 0.48 | 1200 |

| Reynolds数 | 转速 N/ (r·s -1) | 密度 ρ/ (kg·m -3) | 动力黏度 μ/(Pa·s) | 搅拌介质 |

|---|---|---|---|---|

| 10 | 0.5 | 1263.3 | 1.412 | 甘油 |

| 40 | 2 | 1263.3 | 1.412 | 甘油 |

| 100 | 5 | 1263.3 | 1.412 | 甘油 |

| 254 | 2 | 1236.79 | 0.219 | 90%甘油水溶液 |

| 906 | 2 | 1210.28 | 0.060 | 80%甘油水溶液 |

| 2367 | 2 | 1183.77 | 0.023 | 70%甘油水溶液 |

| 4735 | 4 | 1183.77 | 0.023 | 70%甘油水溶液 |

| 11196 | 0.5 | 998.2 | 0.001 | 水 |

| 44784 | 2 | 998.2 | 0.001 | 水 |

| 111961 | 5 | 998.2 | 0.001 | 水 |

表2 转矩测量工况

Table 2 Measurement conditions of torque

| Reynolds数 | 转速 N/ (r·s -1) | 密度 ρ/ (kg·m -3) | 动力黏度 μ/(Pa·s) | 搅拌介质 |

|---|---|---|---|---|

| 10 | 0.5 | 1263.3 | 1.412 | 甘油 |

| 40 | 2 | 1263.3 | 1.412 | 甘油 |

| 100 | 5 | 1263.3 | 1.412 | 甘油 |

| 254 | 2 | 1236.79 | 0.219 | 90%甘油水溶液 |

| 906 | 2 | 1210.28 | 0.060 | 80%甘油水溶液 |

| 2367 | 2 | 1183.77 | 0.023 | 70%甘油水溶液 |

| 4735 | 4 | 1183.77 | 0.023 | 70%甘油水溶液 |

| 11196 | 0.5 | 998.2 | 0.001 | 水 |

| 44784 | 2 | 998.2 | 0.001 | 水 |

| 111961 | 5 | 998.2 | 0.001 | 水 |

| Reynolds数 | 功率准数 N P | |||

|---|---|---|---|---|

刚性桨 (模拟) | 刚性桨 (实验) | 柔性桨 (模拟) | 柔性桨 (实验) | |

| 10 | 5.779 | 6.241 | 6.198 | 6.570 |

| 40 | 2.921 | 3.184 | 3.350 | 3.618 |

| 100 | 2.545 | 2.723 | 2.569 | 2.749 |

| 254 | 2.339 | 2.573 | 2.213 | 2.412 |

| 906 | 2.035 | 2.198 | 1.794 | 1.973 |

| 2367 | 1.755 | 1.913 | 1.452 | 1.597 |

| 4735 | 1.500 | 1.604 | 1.253 | 1.353 |

| 11196 | 1.445 | 1.560 | 1.237 | 1.324 |

| 44784 | 1.291 | 1.408 | 1.170 | 1.240 |

| 111961 | 1.204 | 1.325 | 1.190 | 1.297 |

表3 功率准数的数值模拟及实验测量值

Table 3 Power number obtained by numerical simulations and experimental measurements

| Reynolds数 | 功率准数 N P | |||

|---|---|---|---|---|

刚性桨 (模拟) | 刚性桨 (实验) | 柔性桨 (模拟) | 柔性桨 (实验) | |

| 10 | 5.779 | 6.241 | 6.198 | 6.570 |

| 40 | 2.921 | 3.184 | 3.350 | 3.618 |

| 100 | 2.545 | 2.723 | 2.569 | 2.749 |

| 254 | 2.339 | 2.573 | 2.213 | 2.412 |

| 906 | 2.035 | 2.198 | 1.794 | 1.973 |

| 2367 | 1.755 | 1.913 | 1.452 | 1.597 |

| 4735 | 1.500 | 1.604 | 1.253 | 1.353 |

| 11196 | 1.445 | 1.560 | 1.237 | 1.324 |

| 44784 | 1.291 | 1.408 | 1.170 | 1.240 |

| 111961 | 1.204 | 1.325 | 1.190 | 1.297 |

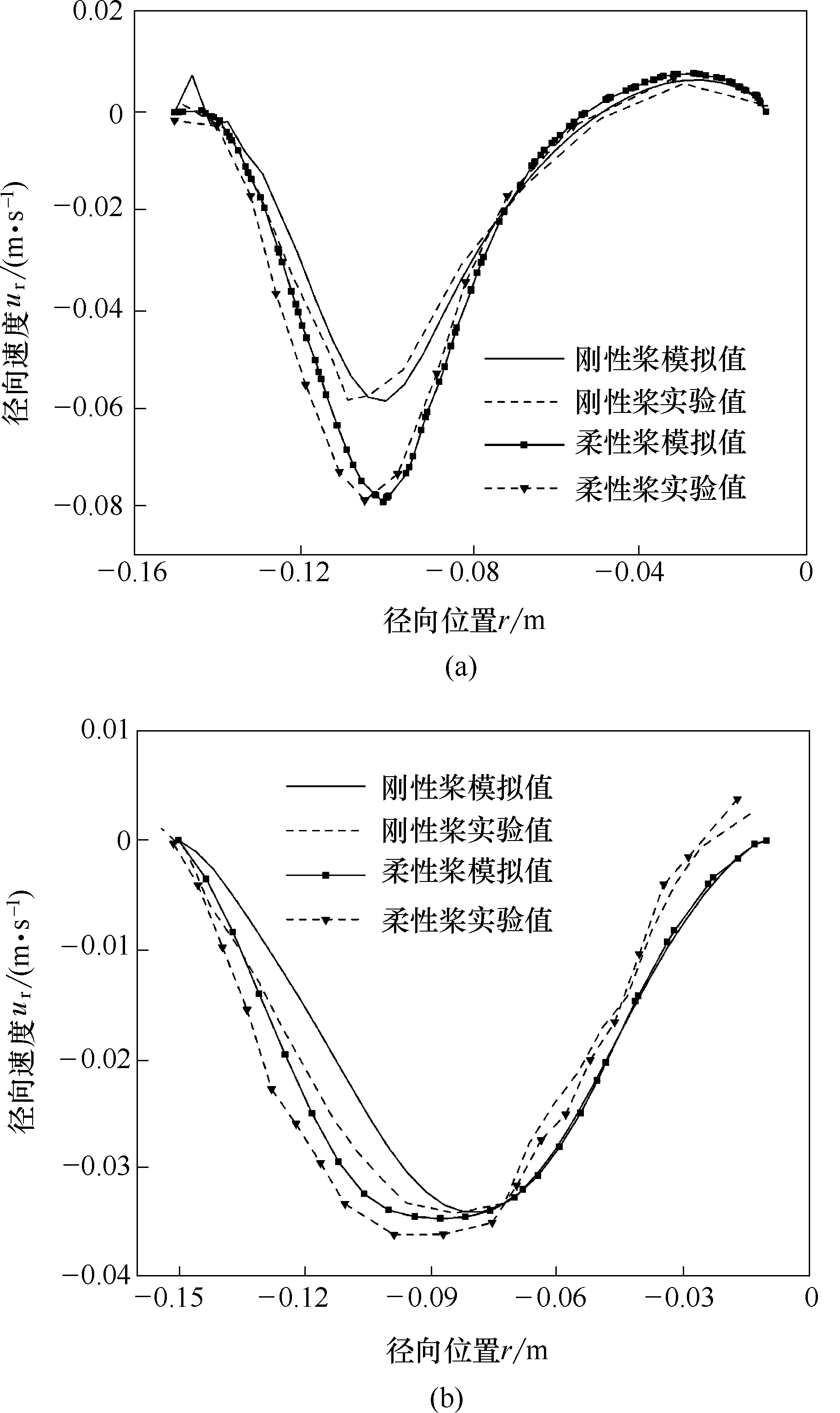

图12 轴向高度 z=150 mm处介质分别为水(a)和甘油(b)时径向速度分布的PIV实验结果

Fig.12 PIV experimentally measured radial velocity distributions for water(a) and glycerin(b) at z=150 mm

| 1 | 朱俊, 周政霖, 刘作华, 等. 刚柔组合搅拌桨强化流体混合的流固耦合行为[J]. 化工学报, 2015, 66( 10): 3849- 3856. |

| Zhu J, Zhou Z L, Liu Z H, et al. Fluid-structure interaction in liquid mixing intensified by flexible-rigid impeller[J]. CIESC Journal, 2015, 66( 10): 3849- 3856. | |

| 2 | Liu Z H, He H X, Zhu J, et al. Energy saving and noise reduction of flow mixing performance intensified by rigid-flexible combination impeller[J]. Asia-Pac. J. Chem. Eng., 2015, 10( 5): 700- 708. |

| 3 | Stefanie B, Dirk W. CFD analysis of inter-phase mass transfer and energy dissipation in a milliliter-scale stirred-tank reactor for filamentous microorganisms[J]. Chem. Eng. Res. Des., 2014, 92( 2): 240- 248. |

| 4 | Claudio C, Giuseppina M, Tapio W, et al. Analysis of solid concentration distribution in dense solid-liquid stirred tanks by electrical resistance tomography[J]. Chem. Eng. Sci., 2014, 119( 8): 53- 64. |

| 5 | Nester R G. High-speed flexible-blade stirrer and stirrer seal for high-vacuum use[J]. Rev. Sci. Instrum., 1956, 27( 12): 1080- 1081. |

| 6 | Young R N, Ga A. Method and apparatus for aeration using flexible blade impeller: US5993158[P]. 1999-11-30. |

| 7 | Bullock L S, Schober S D, Hansen T L. Flexible agitator fins: D477697[P]. 2003-07-22. |

| 8 | Driss Z, Karray S, Kchaou H, et al. Computer simulations of fluid-structure interaction generated by a flat-blade paddle in a vessel tank[J]. Int. Rev. Mech. Eng., 2007, 1( 6): 608- 617. |

| 9 | Karray S, Driss Z, Kchaou H, et al. Numerical simulation of fluid-structure interaction in a stirred vessel equipped with an anchor impeller[J]. J. Mech. Sci. Technol., 2011, 25( 7): 1749- 1760. |

| 10 | Karray S, Driss Z, Kchaou H, et al. Hydromechanics characterization of the turbulent flow generated by anchor impellers[J]. Eng. Appl. Comput. Fluid Mech., 2011, 5( 3): 315- 328. |

| 11 | Karray S, Driss Z, Kaffel A, et al. Fluid-structure interaction in a stirred vessel equipped with a Rushton turbine[J]. Int. J. Mech. Appl., 2012, 2( 6): 129- 139. |

| 12 | Berger T, Fischer M, Strohmeier K. Fluid-structure interaction of stirrers in mixing vessels[J]. J . Pressure Vessel Technol., 2003, 125( 4): 440- 445. |

| 13 | Berger T, Strohmeier K. Numerical simulation of stirrer oscillations in consideration of fluid-structure-interaction and flexible restraint systems[C]. In: ASME 2003 Pressure Vessels and Piping Conference, 2003, 460: 29- 34. |

| 14 | 刘作华, 杨鲜艳, 谢昭明, 等. 柔性桨与自浮颗粒协同强化高黏度流体混沌混合[J]. 化工学报, 2013, 64( 8): 2794- 2800. |

| Liu Z H, Yang X Y, Xie Z M, et al. Chaotic mixing performance of high-viscosity fluid synergistically intensified by flexible impeller and floating particles[J]. CIESC Journal, 2013, 64( 8): 2794- 2800. | |

| 15 | 刘作华, 曾启琴, 王运东, 等. 柔性桨强化高黏度流体混合的能效分析[J]. 化工学报, 2013, 64( 10): 3620- 3625. |

| Liu Z H, Zen Q Q, Wang Y D, et al. Energy efficiency analysis for high-viscosity fluid mixing enhanced by flexible impeller[J]. CIESC Journal, 2013, 64( 10): 3620- 3625. | |

| 16 | 刘作华, 曾启琴, 杨鲜艳, 等. 刚柔组合搅拌桨与刚性桨调控流场结构的对比[J]. 化工学报, 2014, 65( 6): 2078- 2084. |

| Liu Z H, Zen Q Q, Yang X Y, et al. Flow field structure with rigid-flexible impeller and rigid impeller[J]. 2014, 65( 6): 2078- 2084. | |

| 17 | 刘仁龙, 李爽, 刘作华, 等. 穿流-柔性组合桨强化搅拌槽中流体混沌混合特性[J]. 化工学报, 2015, 66( 12): 4736- 4742. |

| Liu R L, Li S, Liu Z H, et al. Chaotic mixing enhanced by punched-flexible impeller in stirred vessel[J]. CIESC Journal, 2015, 66( 12): 4736- 4742. | |

| 18 | 刘作华, 许恢琴, 谷德银, 等. 单层钢丝柔性桨强化搅拌槽中流体混沌混合行为[J]. 化工学报, 2017, 68( 12): 4592- 4599. |

| Liu Z H, Xu H Q, Gu D Y, et al. Chaotic mixing performance enhanced by single-wire flexible impeller in stirred vessel[J]. CIESC Journal, 2017, 68( 12): 4592- 4599. | |

| 19 | 熊黠, 刘作华, 谷德银, 等. 刚柔组合桨强化粉煤灰酸浸搅拌槽内固液混沌混合[J]. 化工学报, 2019, 70( 5): 1693- 1701. |

| Xiong X, Liu Z H, Gu D Y, et al. Chaotic mixing process of fly ash in acid leaching tank intensified by rigid-flexible impeller[J]. CIESC Journal, 2019, 70( 5): 1693- 1701. | |

| 20 | 赵婉丽. 柔性桨叶搅拌槽内流固耦合特性的研究[D]. 北京: 北京化工大学, 2017. |

| Zhao W L. Study of fluid-structure interaction characteristics of flexible blade in a stirred tank[D]. Beijing: Beijing University of Chemical Technology, 2017. | |

| 21 | 徐博航. 易形变桨叶搅拌槽内流场特性研究[D]. 北京: 北京化工大学, 2018. |

| Xu B H. Flow field characteristics in a stirred vessel with flexible blades[D]. Beijing: Beijing University of Chemical Technology, 2018. | |

| 22 | Ghobadi N, Ogino C, Ogawa T, et al. Using a flexible shaft agitator to enhance the rheology of a complex fungal fermentation culture[J]. Bioprocess. Biosyst. Eng., 2016, 39( 11): 1793- 1801. |

| 23 | Ogawa T, Yamamoto M. Frictionless clean reactor “SWINGSTIR”[OL]. . |

| 24 | Staheli C C, Knudsen B M, Williams T G, et al. Fluid mixing system with flexible drive line and foldable impeller: 0117142[P]. 2015-04-30. |

| 25 | Rannade V V, Perrard M, Xureb C, et al. Influence of gas flow rate on the structure of trailing vortices of a Rushton turbine[J]. Chem. Eng. Res. Des., 2001, 79( 8): 957- 964. |

| 26 | Ng K, Fentiman N J, Lee K C, et al. Assessment of sliding mesh CFD predictions and LDA measurements of the flow in a tank stirred by a Rushton impeller[J]. Chem. Eng. Res. Des., 1998, 76( 6): 737- 747. |

| 27 | Derksen J J, Doelman M S, van den Akker H E A. Three-dimensional LDA measurements in the impeller region of a turbulently stirred tank[J]. Exp. Fluids, 1999, 27( 6): 522- 532. |

| 28 | Yianneskis M, Popiolek Z, Withelaw J H. An experimental study of the steady and unsteady flow characteristics of stirred reactors[J]. J. Fluid Mech., 1987, 175: 537- 555. |

| 29 | Yianneskis M, Whitelaw J H. On the structure of the trailing vortices around Rushton turbine blades[J]. Chem. Eng. Res. Des., 1993, 71: 543- 550. |

| 30 | Escudié R, Bouyer D, Liné A. Characterization of trailing vortices generated by a Rushton turbine[J]. AIChE Journal, 2004, 50( 1): 75- 86. |

| [1] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [2] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [3] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [4] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [5] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| [6] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 何晓崐, 刘锐, 薛园, 左然. MOCVD生长AlN单晶薄膜的气相和表面化学反应综述[J]. 化工学报, 2023, 74(7): 2800-2813. |

| [9] | 牛超, 沈胜强, 杨艳, 潘泊年, 李熠桥. 甲烷BOG喷射器流动过程计算与性能分析[J]. 化工学报, 2023, 74(7): 2858-2868. |

| [10] | 于源, 陈薇薇, 付俊杰, 刘家祥, 焦志伟. 几何相似涡流空气分级机环形区流场变化规律研究及预测[J]. 化工学报, 2023, 74(6): 2363-2373. |

| [11] | 刘道银, 陈柄岐, 张祖扬, 吴琰. 颗粒聚团结构对曳力特性影响的数值模拟[J]. 化工学报, 2023, 74(6): 2351-2362. |

| [12] | 李晨曦, 刘永峰, 张璐, 刘海峰, 宋金瓯, 何旭. O2/CO2氛围下正庚烷的燃烧机理研究[J]. 化工学报, 2023, 74(5): 2157-2169. |

| [13] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [14] | 李正涛, 袁志杰, 贺高红, 姜晓滨. 疏水界面上的NaCl液滴蒸发过程内环流调控机制研究[J]. 化工学报, 2023, 74(5): 1904-1913. |

| [15] | 张正, 何永平, 孙海东, 张荣子, 孙正平, 陈金兰, 郑一璇, 杜晓, 郝晓刚. 蛇形流场电控离子交换装置用于选择性提锂[J]. 化工学报, 2023, 74(5): 2022-2033. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号