化工学报 ›› 2023, Vol. 74 ›› Issue (3): 1134-1144.DOI: 10.11949/0438-1157.20221516

李新亚1,2( ), 邢雷1,2, 蒋明虎1,2(

), 邢雷1,2, 蒋明虎1,2( ), 赵立新1,2

), 赵立新1,2

收稿日期:2022-11-22

修回日期:2022-12-26

出版日期:2023-03-05

发布日期:2023-04-19

通讯作者:

蒋明虎

作者简介:李新亚(1996—),男,博士研究生, 18435368494@163.com

基金资助:

Xinya LI1,2( ), Lei XING1,2, Minghu JIANG1,2(

), Lei XING1,2, Minghu JIANG1,2( ), Lixin ZHAO1,2

), Lixin ZHAO1,2

Received:2022-11-22

Revised:2022-12-26

Online:2023-03-05

Published:2023-04-19

Contact:

Minghu JIANG

摘要:

为了进一步提高井下油水分离水力旋流器的分离性能,提出一种倒锥注气式井下油水分离水力旋流器结构,开展倒锥注气对油水分离性能影响研究。利用数值模拟和实验研究相结合的方法,对不同注气量、含油浓度、分流比、入口流量等操作参数下的流场分布特性和油水分离效率进行分析。结果表明,随着注气量的增加,分离效率呈现先升高后降低的趋势,当注气量为2.034 m3/d时,分离效率达到最大值98.52%;当水力旋流器的入口含油浓度为0.75%、分流比为40%、入口流量为5.4 m³/h时,可获得水力旋流器的最佳分离效率为99.51%,较注气前提高了1.11%。针对注气后的井下油水分离水力旋流器开展室内分离性能实验研究,数值模拟和实验结果呈现相同的变化趋势,验证了倒锥注气强化分离性能的可行性及数值模拟结果的准确性。

中图分类号:

李新亚, 邢雷, 蒋明虎, 赵立新. 倒锥注气强化井下油水分离水力旋流器性能研究[J]. 化工学报, 2023, 74(3): 1134-1144.

Xinya LI, Lei XING, Minghu JIANG, Lixin ZHAO. Research on performance of downhole oil-water separation hydrocyclone enhanced by inverted cone gas injection[J]. CIESC Journal, 2023, 74(3): 1134-1144.

| 主要结构 | 参数尺寸/mm |

|---|---|

| 旋流器总长L | 461 |

| 入口腔长度L1 | 50 |

| 螺旋流道长度L2 | 57 |

| 柱段旋流腔长度L3 | 65 |

| 倒锥锥段长度L4 | 150 |

| 底流管长度L5 | 50 |

| 溢流口直径d | 8 |

| 柱段旋流腔直径D | 50 |

| 柱段倒锥直径D1 | 15 |

| 底流管直径D2 | 25 |

表1 井下油水分离水力旋流器结构参数

Table 1 Structural parameters of downhole oil-water separation hydrocyclone

| 主要结构 | 参数尺寸/mm |

|---|---|

| 旋流器总长L | 461 |

| 入口腔长度L1 | 50 |

| 螺旋流道长度L2 | 57 |

| 柱段旋流腔长度L3 | 65 |

| 倒锥锥段长度L4 | 150 |

| 底流管长度L5 | 50 |

| 溢流口直径d | 8 |

| 柱段旋流腔直径D | 50 |

| 柱段倒锥直径D1 | 15 |

| 底流管直径D2 | 25 |

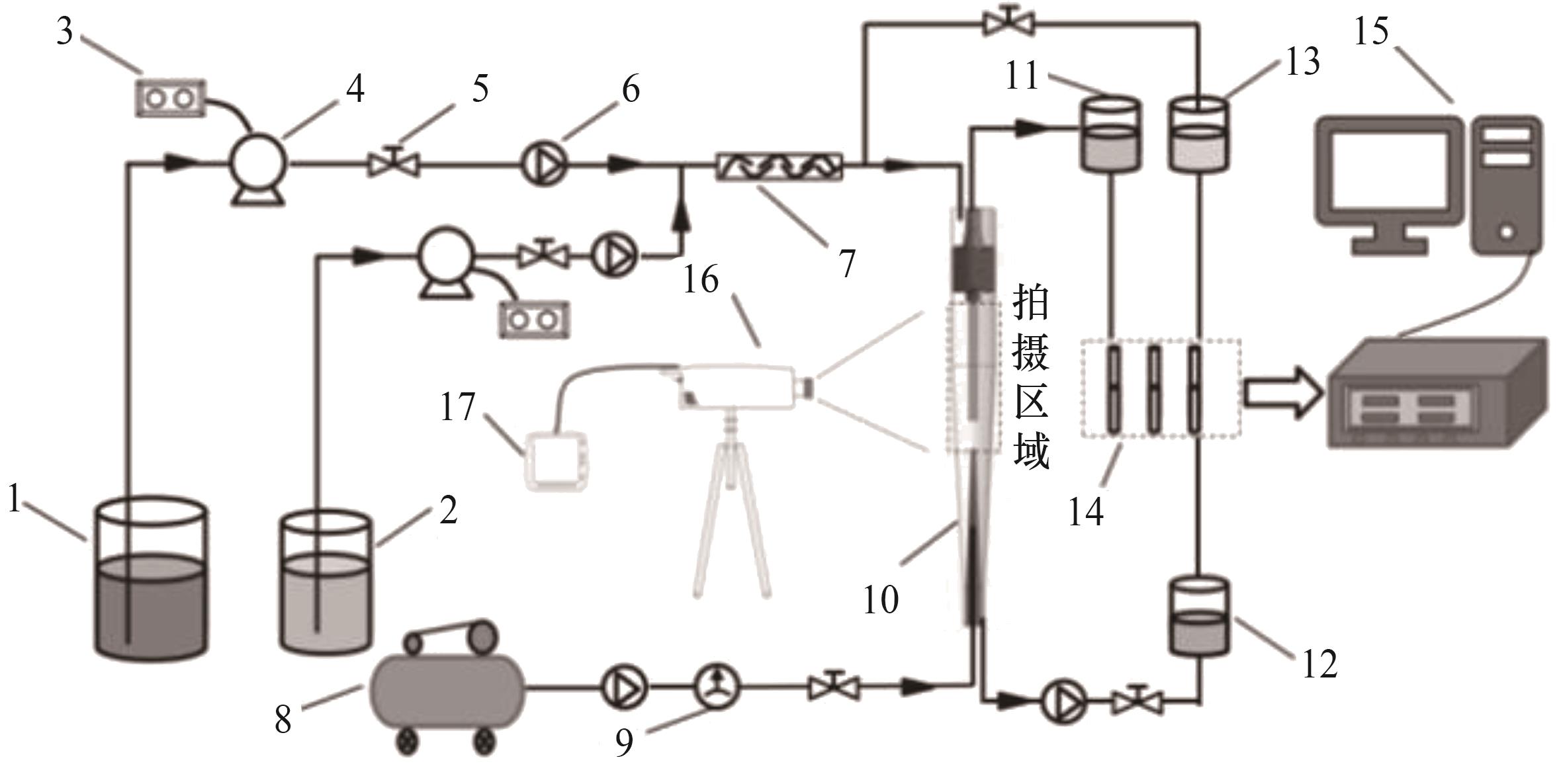

图5 实验工艺流程1—储水罐;2—储油罐;3—变频控制器;4—泵;5—开关阀;6—流量计;7—静态混合器;8—空气压缩机;9—压力表;10—水力旋流器;11—溢流采样烧杯;12—底流采样烧杯;13—入流采样烧杯;14—比色皿;15—红外分光测油仪;16—高速摄像机;17—高速摄像控制器

Fig.5 Experimental technological process

| 1 | 杨茂青. 重介质旋流器选煤技术在我国的创新发展与应用[J]. 选煤技术, 2022, 50(3): 7-13. |

| Yang M Q. Innovative development and application of China’s heavy medium cyclone coal washing[J]. Coal Preparation Technology, 2022, 50(3): 7-13. | |

| 2 | Zhang C, Cui B Y, Wei D Z, et al. Predicting the optimum range of feed flow rate in a hydrocyclone using the method combined flow pattern and equation model[J]. Powder Technology, 2017, 319: 279-288. |

| 3 | Lv W J, Dang Z H, He Y, et al. UU-type parallel mini-hydrocyclone group for oil-water separation in methanol-to-olefin industrial wastewater[J]. Chemical Engineering and Processing, 2020, 149: 1-11. |

| 4 | 刘培坤, 牛志勇, 杨兴华, 等. 微型旋流器对超细颗粒的分离性能[J]. 中国粉体技术, 2016, 22(6): 1-6. |

| Liu P K, Niu Z Y, Yang X H, et al. Separation performance contrastive study of micro hydrocyclone for ultrafine particles[J]. China Powder Science and Technology, 2016, 22(6): 1-6. | |

| 5 | 隋元伟, 贾广如, 许高洁, 等. 水力旋流器研究现状及其在煤化工废水处理中的应用前景[J]. 过程工程学报, 2019, 19(2): 235-245. |

| Sui Y W, Jia G R, Xu G J, et al. Research status of hydrocyclone and its application prospect in wastewater treatment of coal chemical industry[J]. The Chinese Journal of Process Engineering, 2019, 19(2): 235-245. | |

| 6 | 袁惠新, 吴敏浩, 付双成, 等. 微型旋流器溢流口结构参数对SCR废催化剂分离性能的影响[J]. 机械设计与制造, 2020, 8(8): 159-162. |

| Yuan H X, Wu M H, Fu S C, et al. Effect of design parameters of a micro hydrocyclone on the separation performance of waste SCR catalyst[J]. Machinery Design and Manufacture, 2020, 8(8): 159-162. | |

| 7 | 党君祥, 李刚, 钟圣俊. 超细粉体在微型旋风分离器中的分级性能研究[J]. 中国粉体技术, 2006(4): 23-26. |

| Dang J X, Li G, Zhong S J. Study on classification capability of mini-cyclones for super-fine powder[J]. China Powder Science and Technology, 2006(4): 23-26. | |

| 8 | 朱剑伟, 华欲飞, 张彩猛, 等. 应用微型旋流器分离豌豆浆液中的淀粉[J]. 食品与机械, 2019, 35(6): 104-107. |

| Zhu J W, Hua Y F, Zhang C M, et al. Separation of pea slurry by hydrocyclone[J]. Flood and Machinery, 2019, 35(6): 104-107. | |

| 9 | Maira S S, Fateme M, Christopher M, et al. Particle movement and fluid behavior visualization using an optically transparent 3D-printed micro-hydrocyclone[J]. Biomicrofluidics, 2020, 14(6): 1-12. |

| 10 | Liu L, Zhao L X, Xu Y, et al. Innovative design and study of oil-water coupling separator magnetic hydrocyclone[J]. Separation and Purification Technology, 2019, 213: 389-400. |

| 11 | 邢雷, 李金煜, 赵立新, 等. 基于响应面法的井下旋流分离器结构优化[J]. 中国机械工程, 2021, 32(15): 1818-1826. |

| Xing L, Li J Y, Zhao L X, et al. Structural optimization of downhole hydrocyclone based on response surface methodology[J]. China Mechanical Engineering, 2021, 32(15): 1818-1826. | |

| 12 | 赵传伟, 李增亮, 邓良驹, 等. 井下双级串联式油水分离器工作特性研究[J]. 机械工程学报, 2014, 50(18): 177-185. |

| Zhao C W, Li Z L, Deng L J, et al. Research on operating characteristic of downhole dual-stage tandem oil-water separator[J]. Journal of Mechanical Engineering, 2014, 50(18): 177-185. | |

| 13 | 徐晓峰, 史仕荧. 轴流式井下旋流油水分离器压降比性能研究[J]. 中国矿业, 2015, 24(8): 144-147. |

| Xu X F, Shi S Y. Study on the performance of pressure drop ratio about a new type of down-hole axial oil-water separation cyclone[J]. China Mining Magazine, 2015, 24(8): 144-147. | |

| 14 | Zhan M, Cheng X, Yang W, et al. Numerical investigation on the swirler parameters for an axial liquid-liquid hydrocyclone[J]. IOP Conference Series: Earth and Environmental Science, 2021, 675(1): 012210. |

| 15 | Zeng X, Zhao L, Zhao W, et al. Experimental study on a novel axial separator for oil-water separation[J]. Industrial and Engineering Chemistry Research, 2020, 59(48): 21177-21186. |

| 16 | Mofarrah M, Chen P, Liu Z, et al. Performance comparison between micro and electro micro cyclone[J]. Journal of Electrostatics, 2019, 101(C): 1-5. |

| 17 | Zhang J P, Zha Z T, Che P, et al. Theoretical study on submicron particle escape reduced by magnetic confinement effect in low inlet speed electrostatic cyclone precipitators[J]. Powder Technology, 2018, 339: 89-103. |

| 18 | 邢雷, 蒋明虎, 赵立新, 等. 水力聚结器结构参数优选[J]. 机械科学与技术, 2021, 40(4): 527-533. |

| Xing L, Jiang M H, Zhao L X, et al. Structural parameters optimization of hydraulic coalescer[J]. Mechanical Science and Technology for Aerospace Engineering, 2021, 40(4): 527-533. | |

| 19 | 赵健华, 杨威, 胡大鹏. 注气对油水分离水力旋流器流场影响模拟分析[J]. 化工机械, 2014, 41(3): 345-349. |

| Zhao J H, Yang W, Hu D P. Simulation analysis of gas injection influence on flow field in oil-water hydrocyclone[J]. Chemical Machinery, 2014, 41(3): 345-349. | |

| 20 | 赵立新, 朱宝军, 李枫, 等. 气携式液液水力旋流器分离性能影响因素[J]. 化学工程, 2007, 35(2): 34-37. |

| Zhao L X, Zhu B J, Li F, et al. Influent factors study on the separation performance of the air-injected liquid-liquid hydrocyclones[J]. Chemical Engineering(China), 2007, 35(2): 34-37. | |

| 21 | 李枫, 刘海龙, 邢雷, 等. 进气量对气举式同向出流旋流器性能的影响研究[J]. 石油机械, 2021, 49(8): 100-106, 141. |

| Li F, Liu H L, Xing L, et al. Study on the effect of air inlet flow rate on the separation performance of gas-lift co-directional outflow hydrocyclone[J]. Petroleum Machinery, 2021, 49(8): 100-106, 141. | |

| 22 | Zhu G F, Liow J L, Neely A. Computational study of the flow characteristics and separation efficiency in a mini-hydrocyclone[J]. Chemical Engineering Research and Design, 2012, 90(12): 2135-2147. |

| 23 | Mehdi A, Mohsen A, Ali M. A CFD study of the effect of cyclone size on its performance parameters[J]. Journal of Hazardous Materials, 2010, 182: 835-841. |

| 24 | Kaya F, Karagoz I. Performance analysis of numerical schemes in highly swirling turbulent flows in cyclones[J]. Current Science, 2008, 94(10): 1273-1278. |

| 25 | 王瑞, 高曙明, 吴海燕. 六面体网格生成和优化研究进展[J]. 计算机辅助设计与图形学学报, 2020, 32(5): 693-708. |

| Wang R, Gao S M, Wu H Y. Progress in hexahedral mesh generation and optimization[J]. Journal of Computer-Aided Design and Computer Graphics, 2020, 32(5): 693-708. | |

| 26 | 赵立新, 李枫. 离心分离技术[M]. 哈尔滨: 东北林业大学出版社, 2000. |

| Zhao L X, Li F. Centrifugal Separation Technology[M]. Harbin: Northeast Forestry University Press, 2000. | |

| 27 | 程家胜, 舒珺, 袁友为, 等. 轴流式水力旋流器的设计与数值模拟计算[J]. 化工机械, 2020, 47(3): 327-331. |

| Cheng J S, Shu J, Yuan Y W, et al. Design and simulation calculation of axial flow hydrocyclones[J]. Chemical Machinery, 2020, 47(3): 327-331. | |

| 28 | Fang X, Wang D R, Zhong L, et al. Adaptability analysis of operating parameters of hydrate hydrocyclone separator based on a CFD simulation[J]. Separation Science and Technology, 2021, 57(6): 979-989. |

| 29 | 赵立新, 代佳鑫, 郭现臣. 叶片式水力旋流器操作参数优选[J]. 流体机械, 2013, 41(10): 7-9. |

| Zhao L X, Dai J X, Guo X C. Optimization study on a vane-type hydrocyclone[J]. Fluid Machinery, 2013, 41(10): 7-9. | |

| 30 | 舒朝晖, 杨拓, 周宇, 等. 除油旋流器操作参数对分离效率影响的数值模拟[J]. 石油化工设备, 2015, 44(5): 1-6. |

| Shu Z H, Yang T, Zhou Y, et al. Numerical simulation for the effect of operational parameters on separation efficiency in de-oiling hydrocyclones[J]. Petro-Chemical Equipment, 2015, 44(5): 1-6. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [7] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [8] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [9] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [10] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [11] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [12] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [13] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [14] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [15] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号