化工学报 ›› 2023, Vol. 74 ›› Issue (1): 157-169.DOI: 10.11949/0438-1157.20221079

收稿日期:2022-08-01

修回日期:2022-09-23

出版日期:2023-01-05

发布日期:2023-03-20

通讯作者:

卢春喜

作者简介:范怡平(1971—),男,博士,副教授,fanyipin2002@sina.com

基金资助:Received:2022-08-01

Revised:2022-09-23

Online:2023-01-05

Published:2023-03-20

Contact:

Chunxi LU

摘要:

气固分离装备的发展对于实现高温烟气的高效除尘净化具有重要意义。基于单一气固分离机制的除尘装备难以实现精细除尘的目标。将离心分离和移动床分离耦合在同一装备中,实现两种分离机制的协同强化无疑是一种解决方案。在该耦合装备中,旋风壳体和移动床内气相、捕集颗粒、粉尘的运动较之常规单体旋风分离器、移动床均具有一些独特的特性。通过压降-时间响应曲线发现该新型耦合分离装备具有自清洁功能。该装备对黏附性微细粉尘的捕集效率在95%以上;旋风壳体分离了10 μm以上颗粒物,而内置颗粒床捕集到的粉尘粒径在10 μm以下,验证了二者在同一装备中的协同强化。但是,强化自清洁效应和提高捕集效率构成了一对矛盾。研究表明,该新型耦合分离装备仍具有很大的性能提升空间。

中图分类号:

范怡平, 卢春喜. 离心力场-移动床耦合气固分离装备的研究进展[J]. 化工学报, 2023, 74(1): 157-169.

Yiping FAN, Chunxi LU. Research progress on dedust scheme of coupling centrifugal force field with moving bed filtration[J]. CIESC Journal, 2023, 74(1): 157-169.

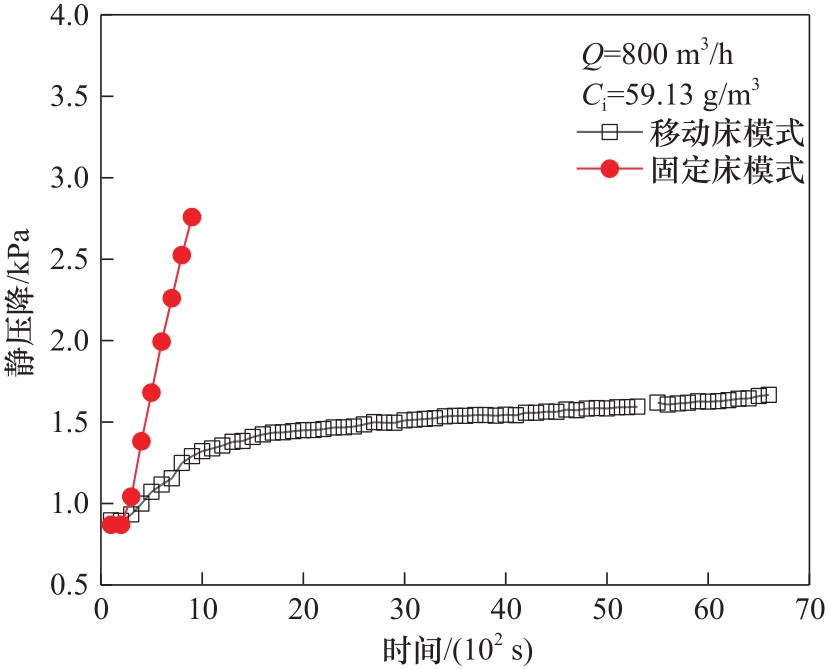

图4 固定床/移动床操作模式下设备压降随操作时间的变化(Geldart C类粉尘)

Fig.4 Static pressure drop at different operating times under fixed bed/moving bed operation(Geldart C dust)

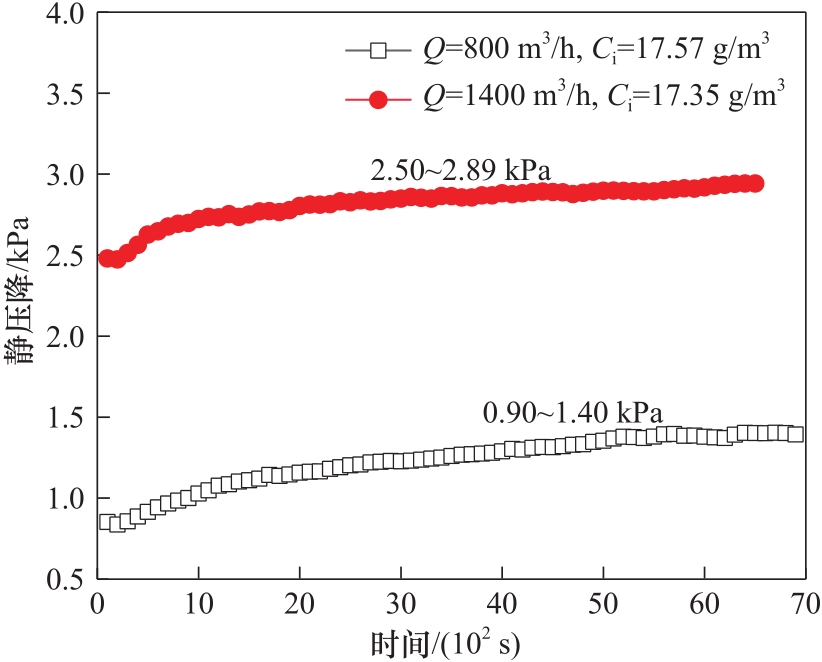

图5 不同入口气量、移动床操作模式下耦合分离装备的压降-时间响应曲线(Geldart C类粉尘)

Fig.5 Pressure drop vs time for moving bed operation mode under different inlet gas flowrate(Geldart C dust)

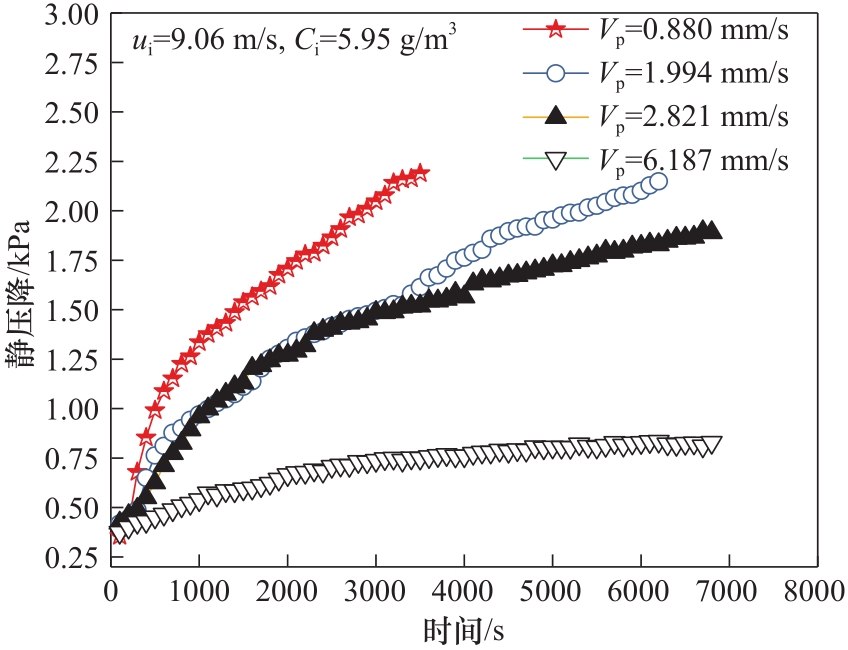

图7 不同捕集颗粒循环速度下满床操作条件下的装备压降(Geldart C类粉尘)

Fig.7 Pressure drop under full-bed operating mode at different collector particle circulation velocities(Geldart C dust)

| 1 | Atimtay A T. Cleaner energy production with integrated gasification combined cycle systems and use of metal oxide sorbents for H2S cleanup from coal gas[J]. Clean Products and Processes, 2001, 2(4): 197-208. |

| 2 | Mojtahedi W, Abbasian J. H2S removal from coal gas at elevated temperature and pressure in fluidized bed with zinc titanate sorbents(Part 1): Cyclic tests[J]. Energy & Fuels, 1995, 9(3): 429-434. |

| 3 | Wiheeb A, Shamsudin I, Ahmad M, et al. Present technologies for hydrogen sulfide removal from gaseous mixtures[J]. Reviews in Chemical Engineering, 2013, 29(6): 449-470. |

| 4 | Rout U K, Voβ A, Singh A, et al. Energy and emissions forecast of China over a long-time horizon[J]. Energy, 2011, 36(1): 1-11. |

| 5 | Pui D Y H, Chen S C, Zuo Z L. PM2.5 in China: measurements, sources, visibility and health effects, and mitigation[J]. Particuology, 2014, 13: 1-26. |

| 6 | Dignon J. NO x and SO x emissions from fossil fuels: a global distribution[J]. Atmospheric Environment. Part A. General Topics, 1992, 26(6): 1157-1163. |

| 7 | Woolcock P J, Brown R C. A review of cleaning technologies for biomass-derived syngas[J]. Biomass and Bioenergy, 2013, 52: 54-84. |

| 8 | 夏兴祥. 高温除尘技术综述[J]. 化工机械, 2000, 27(1):47-52. |

| Xia X X. Review of the high temperature dust removing technology[J]. Chemical Engineering &Machinery, 2000, 27(1): 47-52. | |

| 9 | Seville J P K. Gas Cleaning in Demanding Applications[M]. Dordrecht: Springer Netherlands, 1997: 23-57. |

| 10 | McKenna J D, Turner J H, McKenna J P. Fine Particle (2.5 Microns) Emissions: Regulations, Measurement, and Control[M]. New Jersey: John Wiley & Sons, Inc., 2008: 35-53. |

| 11 | Friedlander S K, Johnstone H F. Deposition of suspended particles from turbulent gas streams[J]. Industrial & Engineering Chemistry, 1957, 49(7): 1151-1156. |

| 12 | Soane D S, Ware J W, Mahoney R P, et al. Systems and methods for removing finely dispersed particulate matter from a fluid stream: US9493367 [P]. 2016-11-15. |

| 13 | Dullien F A L. Theory and practice of a new class of equipment for separation of particulates from gases: the turbulent flow precipitator[J]. Oil & Gas Science and Technology-Rev. IFP, 1999, 54(5): 565-575. |

| 14 | Dou B L, Wang C, Chen H S, et al. Research progress of hot gas filtration, desulphurization and HCl removal in coal-derived fuel gas: a review[J]. Chemical Engineering Research and Design, 2012, 90(11): 1901-1917. |

| 15 | Saxena S C, Henry R F, Podolski W F. Technology status of particulate removal from high-temperature high-pressure combustion gases[J]. Aerosol Science and Technology, 1982, 1(2): 235-257. |

| 16 | Dirgo J, Leith D. Cyclone collection efficiency: comparison of experimental results with theoretical predictions[J]. Aerosol Science and Technology, 1985, 4(4): 401-415. |

| 17 | Weber E, Hübner K, Pape H G, et al. Gas cleaning under extreme conditions of temperature and pressure[J]. Environment International, 1981, 6(1/2/3/4/5/6): 349-360. |

| 18 | Hoffmann A C, Stein L E. Gas Cyclones and Swirl Tubes: Principles, Design and Operation[M]. Heidelberg: Springer-Verlag Berlin, 2008: 120-127. |

| 19 | Reijnen K, Brakel J V. Gas cleaning at high temperatures and high pressures: a review[J]. Powder Technology, 1984, 40(1/2/3): 81-111. |

| 20 | 吴小林, 王红菊, 严超宇, 等. 稳涡杆对旋风分离器旋进涡核的抑制作用[J]. 石油大学学报(自然科学版), 2001, 25(3): 68-70. |

| Wu X L, Wang H J, Yan C Y, et al. Effect of installation of sticks for stabilizing vortex on restraining PVC in a cyclone separator[J]. Journal of the University of Petroleum(Edition of Natural Sciences), 2001, 25(3): 68-70. | |

| 21 | 陈建义, 罗晓兰, 时铭显. PV-E型旋风分离器性能试验研究[J]. 流体机械, 2004, 32(3): 1-4, 43. |

| Chen J Y, Luo X L, Shi M X. Experiment research on performance of model PV-E cyclone separator[J]. Fluid Machinery, 2004, 32(3): 1-4, 43. | |

| 22 | 陈海焱. 涡轮除尘技术[J]. 现代化工, 2003, 23(1): 49-51. |

| Chen H Y. Technique of turbine dusting[J]. Modern Chemical Industry, 2003, 23(1): 49-51. | |

| 23 | 吴晋沪. 移动床高温煤气除尘基础研究[D]. 北京: 中国科学院研究生院(山西煤炭化学研究所), 1998. |

| Wu J H. Study on moving granular bed for high temperature gas cleaning[D]. Beijing: Graduate University of Chinese Academy of Sciences (Shanxi Coal Chemical Research Institute), 1998. | |

| 24 | Sharma S D, Dolan M, Park D, et al. A critical review of syngas cleaning technologies—fundamental limitations and practical problems[J]. Powder Technology, 2008, 180: 115-121. |

| 25 | Smid J, Hsiau S S, Peng C Y, et al. Moving bed filters for hot gas cleanup[J]. Filtration and Separation, 2005, 42(6): 34-37. |

| 26 | Smid J, Hsiau S S, Peng C Y, et al. Granular moving bed filters and adsorbers(GM-BF/A)—patent review: 1970—2000[J]. Advanced Powder Technology, 2005, 16(4): 301-345. |

| 27 | 杨国华, 周江华, 舒海平, 等. 双层滤料颗粒床过滤除尘新方法的研究[J]. 动力工程, 2005, 25(6): 891-894. |

| Yang G H, Zhou J H, Shu H P, et al. A new dual-layered granule bed filter for cleaning-up gas[J]. Power Engineering, 2005, 25(6): 891-894. | |

| 28 | Xiao G, Wang X H, Zhang J P, et al. Granular bed filter: a promising technology for hot gas clean-up[J]. Powder Technology, 2013, 244: 93-99. |

| 29 | Squires A M. Method and apparatus for renewing gas-entry faces of a panel for gas and granular material contacting: US7815717[P]. 2010-10-19. |

| 30 | Doganoglu Y, Thambimuthu K V, Clift R, et al. Removal of fine particulates from gases in fluidized-beds[J]. Transactions of the Institution of Chemical Engineers, 1978, 56: 239-248. |

| 31 | Paretsky L, Theodore L, Pfeffer R, et al. Panel bed filters for simultaneous removal of fly ash and sulfur dioxide(Part Ⅱ): Filtration of dilute aerosols by sand beds[J]. Journal of the Air Pollution Control Association, 1971, 21(4): 204-209. |

| 32 | Zahradnik R L, Anyigbo J, Steinberg R A, et al. Simultaneous removal of fly ash and SO2 from gas streams by a shaft-filter-sorber[J]. Environmental Science and Technology, 1970, 4(8): 663-667. |

| 33 | Kuo J T, Smid J, Hsiau S S, et al. Stagnant zones in granular moving bed filters for flue gas cleanup[J]. Filtration & Separation, 1998, 35(6): 529-534. |

| 34 | Chou C S, Yang T L. Flow patterns and wall stresses in a moving granular filter bed with a curved symmetric louvered wall[J]. Advanced Powder Technology, 2005, 16(5): 451-471. |

| 35 | Chen Y S, Hsiau S S, Smid J, et al. Removal of dust particles from fuel gas using a moving granular bed filter[J]. Fuel, 2016, 182: 174-187. |

| 36 | Hsiau S S, Smid J, Tsai F H, et al. Placement of flow-corrective elements in a moving granular bed with louvered-walls[J]. Chemical Engineering and Processing: Process Intensification, 2004, 43: 1037-1045. |

| 37 | Chou C S, Chen S H. Moving granular filter bed of quartz sand with louvered-walls and flow-corrective inserts[J]. Powder Technology, 2007, 172(1): 41-49. |

| 38 | Chen Y S, Hsiau S S, Lai S C, et al. Filtration of dust particulates with a moving granular bed filter[J]. Journal of Hazardous Materials, 2009, 171(1/2/3): 987-994. |

| 39 | Hsiau S S, Smid J, Tsai S A, et al. Flow of filter granules in moving granular beds with louvers and sublouvers[J]. Chemical Engineering and Processing: Process Intensification, 2008, 47(12): 2084-2097. |

| 40 | Smid J, Hsiau S S, Tsai S A, et al. Study on gravity flow of granules in beds supported by louver-sublouver system[J]. Advanced Powder Technology, 2009, 20(2): 127-138. |

| 41 | Liu B Q, Zhou W N, Tan P L, et al. Dynamic granular bed and its gas-solid separation process[J]. Powder Technology, 2016, 301: 387-395. |

| 42 | Liao C C, Hsiau S S, Yu W J. The influence of driving conditions on flow behavior in sheared granular flows[J]. International Journal of Multiphase Flow, 2012, 46: 22-31. |

| 43 | Smid J, Hsiau S S, Peng C Y, et al. Hot gas cleanup: new designs for moving bed filters[J]. Filtration & Separation, 2005, 42(10): 36-39. |

| 44 | Brown R C, Shi H W, Colver G, et al. Similitude study of a moving bed granular filter[J]. Powder Technology, 2003, 138(2/3): 201-210. |

| 45 | El-Hedok I A, Whitmer L, Brown R C. The influence of granular flow rate on the performance of a moving bed granular filter[J]. Powder Technology, 2011, 214(1): 69-76. |

| 46 | Bai J C, Wu S Y, Lee A S, et al. Filtration of dust in a circulating granular bed filter with conical louver plates (CGBF-CLPs)[J]. Journal of Hazardous Materials, 2007, 142(1/2): 324-331. |

| 47 | Saxena S C, Henry R F, Podolski W F. Particulate removal from high-temperature, high-pressure combustion gases[J]. Progress in Energy and Combustion Science, 1985, 11(3): 193-251. |

| 48 | Dietz P W. Electrostatically enhanced cyclone separators[J]. Powder Technology, 1982, 31(2): 221-226. |

| 49 | Rincón J. Removal of fine particles from gases in a magnetically stabilized fluidized filter[J]. Separation Science and Technology, 1993, 28(6): 1241-1252. |

| 50 | Albert R V, Tien C. Particle collection in magnetically stabilized fluidized filters[J]. AIChE Journal, 1985, 31(2): 288-295. |

| 51 | Yan J P, Chen L Q, Yang L J. Combined effect of acoustic agglomeration and vapor condensation on fine particles removal[J]. Chemical Engineering Journal, 2016, 290: 319-327. |

| 52 | Urciuolo M, Salatino P, Cammarota A, et al. Development of a sound-assisted fluidized bed filter/afterburner for particle-laden gas clean-up[J]. Powder Technology, 2008, 180(1/2): 102-108. |

| 53 | 黄虹宾, 田志鸿, 时铭显. 声波团聚微粒技术的进展与分析[J]. 石油大学学报(自然科学版), 1995, 19(6): 126-131. |

| Huang H B, Tian Z H, Shi M X. Development of agglomeration techniques for fly ash particles on power plant at high temperature[J]. Journal of the University of Petroleum(Edition of Natural Sciences), 1995, 19(6): 126-131. | |

| 54 | 陈万金. 移动式颗粒床除尘器的理论计算[J]. 江苏理工大学学报(自然科学版), 1996, 17(2): 43-49. |

| Chen W J. Theoretical calculation of removable grain bed dust remover[J]. Journal of Jiangsu University of Science and Technology(Natural Science), 1996, 17(2): 43-49. | |

| 55 | 吕保和, 刘春晖. 旋滤组合移动式颗粒床除尘器优化设计建模[J]. 中国安全科学学报, 2006, 16(11): 59-63. |

| Lyu B H, Liu C H. Modeling for the optimum design of cyclone-filtrating removable grain bed dust collector[J]. China Safety Science Journa, 2006, 16(11): 59-63. | |

| 56 | 吕保和. 移动式颗粒床除尘器的设计研究[J]. 中国工程科学, 2007, 9(10): 45-48. |

| Lyu B H. Study on the design of removable grain bed dust remover[J]. Engineering Sciences, 2007, 9(10): 45-48. | |

| 57 | Lu C X, Gao S H, Fan Y P, et al. Separation device: US10758921[P]. 2020-09-01. |

| 58 | 卢春喜, 高思鸿, 范怡平, 等. 分离装置: 208244386U[P]. 2018-12-18. |

| Lu C X, Gao S H, Fan Y P, et al. Separation device: 208244386U[P]. 2018-12-18. | |

| 59 | 卢春喜, 高思鸿, 范怡平, 等. 分离装置: 108392929A[P]. 2018-08-14. |

| Lu C X, Gao S H, Fan Y P, et al. Separation device: 108392929A[P]. 2018-08-14. | |

| 60 | 卢春喜, 高思鸿, 范怡平, 等. 一种气体干法净化旋流吸附耦合设备: 106621583B[P]. 2018-11-20. |

| Lu C X, Gao S H, Fan Y P, et al. Gas dry method purification rotational flow and absorption coupling device: 106621583A[P]. 2018-11-20. | |

| 61 | 卢春喜, 陈伟, 范怡平, 等. 一种催化裂化再生烟气干法脱硫除尘工艺方法: 109351183A[P]. 2019-02-19. |

| Lu C X, Chen W, Fan Y P, et al. Dry desulfurization dust removing technology method for catalytic cracking regenerated flue gas: 109351183A[P]. 2019-02-19. | |

| 62 | Chang M, Fan Y P, Lu C X. The inner/outer self-cleaning phenomenon in the granular bed filter-cyclone coupled separator[J]. Separation and Purification Technology, 2022, 287: 120460. |

| 63 | 高思鸿. 旋流场-颗粒床协同强化气固分离特性的研究[D]. 北京: 中国石油大学(北京), 2020. |

| Gao S H. Separation characteristics of a novel coupled cyclone with built-in circulating granular bed filter (C-CGBF)[D]. Beijing: China University of Petroleum, 2020. | |

| 64 | 高思鸿, 刘堉学, 范怡平, 等. 新型旋流场-颗粒床耦合分离设备静压分布[J]. 化工学报, 2020, 71(2): 516-525. |

| Gao S H, Liu Y X, Fan Y P, et al. Static pressure distribution in coupled cyclone with built-in granular bed filter[J]. CIESC Journal, 2020, 71(2): 516-525. | |

| 65 | 刘堉学, 高思鸿, 范怡平, 等. 旋流分离-颗粒床耦合气固分离装备旋流场静压分布[J]. 过程工程学报, 2020, 20(9): 1008-1015. |

| Liu Y X, Gao S H, Fan Y P, et al. Static pressure distribution in a novel gas-solid separator with coupling centrifugal separation and granular bed filtration[J]. The Chinese Journal of Process Engineering, 2020, 20(9): 1008-1015. | |

| 66 | 高思鸿, 张丹丹, 范怡平, 等. 气体干法净化旋流吸附耦合设备压降特性[J]. 化工学报, 2018, 69(5): 1873-1883. |

| Gao S H, Zhang D D, Fan Y P, et al. Pressure drop characteristics of dry gas purification process in a coupled apparatus of cyclone and granular bed filter/adsorber[J]. CIESC Journal, 2018, 69(5): 1873-1883. | |

| 67 | 龙文宇. 气固错流移动床流动特性[D]. 北京: 中国石油大学(北京), 2014. |

| Long W Y. Hydrodynamic characteristics of cross-flow moving beds[D]. Beijing: China University of Petroleum, 2014. | |

| 68 | Long W Y, Xu J, FanY P, et al. Pinning and cavity in two types of cross-flow moving beds[J]. Powder Technology, 2015, 269: 66-74. |

| 69 | 龙文宇, 徐军, 范怡平, 等. 梯形移动床径向反应器内颗粒的贴壁现象分析[J]. 化工学报, 2014, 65(4): 1179-1185. |

| Long W Y, Xu J, Fan Y P, et al. Phenomenon of pinning in trapezoidal moving beds with cross-flow[J]. CIESC Journal, 2014, 65(4): 1179-1185. | |

| 70 | 卢春喜, 龙文宇, 林泉志. 径向移动床气固流动特性数值模拟[J]. 高校化学工程学报, 2015, 29(1): 49-57. |

| Lu C X, Long W Y, Lin Q Z. Numerical simulation of gas-solid flow characteristics in radial moving bed[J]. Journal of Chemical Engineering of Chinese Universities, 2015, 29(1): 49-57. | |

| 71 | Gao S H, Zhang D D, Fan Y P, et al. A novel gas-solids separator scheme of coupling cyclone with circulating granular bed filter (C-CGBF)[J]. Journal of Hazardous Materials, 2019, 362: 403-411. |

| 72 | 常明, 付金壮, 李永祺, 等. 颗粒床-旋流耦合分离器不同操作模式下的性能分析[J]. 过程工程学报, 2022, 22(5): 631-639. |

| Chang M, Fu J Z, Li Y Q, et al. Performance analysis of the granular bed/cyclone coupled separator under different operation modes[J]. The Chinese Journal of Process Engineering, 2022, 22(5): 631-639. | |

| 73 | 付金壮. 旋风-颗粒床分离器结构优化及耦合特性分析[D]. 北京: 中国石油大学(北京), 2022. |

| Fu J Z. Structural optimization and characteristics analysis on a coupling separator of a cyclone with a built-in granular bed[D]. Beijing: China University of Petroleum, 2022. | |

| 74 | Chang M, Fan Y P, Lu C X. Intrusive sampling of dust deposition in a granular bed filter-cyclone coupled separator[J]. Chemical Engineering Science, 2022, 260: 117824. |

| 75 | Gao S H, Zhang D D, Fan Y P, et al. Separation performance in a novel coupled cyclone with built-in circulating granular bed filter (C-CGBF)[J]. Industrial & Engineering Chemistry Research, 2018, 57:12192-12201. |

| 76 | Chang M, Lu D M, Gao S H, et al. Effects of the swirl space ratio on the performance of a coupling cyclone with a built-in granular bed filter: an experimental examination[J]. Industrial & Engineering Chemistry Research, 2021, 60(1): 571-582. |

| 77 | 李永祺. 旋风-环形百叶窗式颗粒床耦合分离装备性能研究[D]. 北京: 中国石油大学(北京), 2022. |

| Li Y Q. Study on the performance in a coupled cyclone with annular louver granular bed filter[D]. Beijing: China University of Petroleum, 2022. | |

| 78 | 李永祺, 常明, 付金壮, 等. 新型旋流-颗粒床耦合分离设备的三维气相流场分布[J]. 石油炼制与化工, 2022, 53(6): 84-92. |

| Li Y Q, Chang M, Fu J Z, et al. Three-dimensional gas-phase flow field in a coupled cyclone with built-in granular bed filter[J]. Petroleum Processing and Petrochemicals, 2022, 53(6): 84-92. | |

| 79 | Chang M, Fan Y P, Fu J Z, et al. A model for predicting the separation with a built-in granular bed filter[J]. Powder Technology, 2022, 399: 116941. |

| 80 | 付金壮, 常明, 范怡平, 等. 入口粉尘浓度对新型旋流-颗粒床耦合分离器特性的影响[J]. 过程工程学报, 2021, 21(10): 1177-1186. |

| Fu J Z, Chang M, Fan Y P, et al. Influence of inlet dust concentration on characteristics of a new cyclone particle bed coupling separator[J]. The Chinese Journal of Process Engineering, 2021, 21(10): 1177-1186. | |

| 81 | 卢道铭, 范怡平, 卢春喜. 颗粒空气分级技术研究进展[J]. 中国粉体技术, 2020, 26(6): 11-24. |

| Lu D M, Fan Y P, Lu C X. Advances in research on granular air classification[J]. China Powder Science and Technology, 2020, 26(6): 11-24. | |

| 82 | 卢道铭, 唐钊艇, 范怡平, 等. 大差异颗粒分级再生设备的性能研究[J]. 化工学报, 2021, 72(8): 4184-4195. |

| Lu D M, Tang Z T, Fan Y P, et al. Performance of large-difference-particle air classifier[J]. CIESC Journal, 2021, 72(8): 4184-4195. | |

| 83 | 卢春喜, 卢道铭, 范怡平, 等. 颗粒分级装置: 111974682A[P]. 2020-11-24. |

| Lu C X, Lu D M, Fan Y P, et al. Particle classification device: 111974682A[P]. 2020-11-24. | |

| 84 | 卢春喜, 卢道铭, 范怡平, 等. 颗粒分级装置: 212633457U[P]. 2021-03-02. |

| Lu C X, Lu D M, Fan Y P, et al. Particle classification device: 212633457U[P]. 2021-03-02. | |

| 85 | 范怡平, 常明, 卢春喜, 等. 一种大差异颗粒筛分装置: 209646995U[P]. 2019-11-19. |

| Fan Y P, Chang M, Lu C X, et al. Wide-size distribution particle classifier device: 209646995U[P]. 2019-11-19. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [3] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [4] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [5] | 王阳, 戴永强, 曾炜. 2,5-二羟基苯磺酸增强离子水凝胶材料热电性能的研究[J]. 化工学报, 2023, 74(9): 3946-3955. |

| [6] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [7] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [8] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [9] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| [10] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [11] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [12] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [13] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [14] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [15] | 于源, 陈薇薇, 付俊杰, 刘家祥, 焦志伟. 几何相似涡流空气分级机环形区流场变化规律研究及预测[J]. 化工学报, 2023, 74(6): 2363-2373. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号