化工学报 ›› 2024, Vol. 75 ›› Issue (4): 1642-1654.DOI: 10.11949/0438-1157.20231418

吕田田( ), 原敏, 王江, 高美珍, 杨佳辉, 徐红, 董晋湘, 石琪(

), 原敏, 王江, 高美珍, 杨佳辉, 徐红, 董晋湘, 石琪( )

)

收稿日期:2024-01-03

修回日期:2024-03-31

出版日期:2024-04-25

发布日期:2024-06-06

通讯作者:

石琪

作者简介:吕田田(1999—),女,硕士研究生,lvtian0609@163.com

基金资助:

Tiantian LYU( ), Min YUAN, Jiang WANG, Meizhen GAO, Jiahui YANG, Hong XU, Jinxiang DONG, Qi SHI(

), Min YUAN, Jiang WANG, Meizhen GAO, Jiahui YANG, Hong XU, Jinxiang DONG, Qi SHI( )

)

Received:2024-01-03

Revised:2024-03-31

Online:2024-04-25

Published:2024-06-06

Contact:

Qi SHI

摘要:

经过生物质酸性催化转化的5-羟甲基糠醛(5-HMF)原液的组成为低浓度水溶液、多组分酸性副产物乙酰丙酸(LA)和甲酸(FA),因此需要设计疏水、耐酸和高选择性的吸附剂来分离5-HMF。以高N的沸石型四氮唑-咪唑骨架材料(ZTIFs)为前体,通过调控碳化和活化条件制备具有耐酸性、疏水性和合适微介孔分布的多孔碳,利用多孔碳和5-HMF的π-π作用可实现含酸水溶液中5-HMF的高效富集分离。以ZTIF-8为前体,通过调控碳化温度和活化碱碳比,制备并筛选三种具有不同N含量和微介孔分布的ZTIF-8基多孔碳;建立ZTIF-8基多孔碳N含量和微介孔分布与5-HMF吸附分离性能的关系;具有低N含量和丰富大微孔小介孔(12~30 Å,1 Å=0.1 nm)的NCZTIF-8700C-800A2是从含酸性副产物水溶液中高效富集分离5-HMF的吸附剂。

中图分类号:

吕田田, 原敏, 王江, 高美珍, 杨佳辉, 徐红, 董晋湘, 石琪. ZTIF基疏水微介孔碳的制备及5-羟甲基糠醛吸附分离性能[J]. 化工学报, 2024, 75(4): 1642-1654.

Tiantian LYU, Min YUAN, Jiang WANG, Meizhen GAO, Jiahui YANG, Hong XU, Jinxiang DONG, Qi SHI. Preparation of ZTIF based hydrophobic micro-mesoporous carbon and their adsorption and separation performance of 5-hydroxymethylfurfural[J]. CIESC Journal, 2024, 75(4): 1642-1654.

| Samples | Bulk N/% | BET/(m²·g-1) | Total pore volume/ (cm³·g-1) | Cumulative pore volume/(cm3·g-1) | ||||

|---|---|---|---|---|---|---|---|---|

| <12 Å | 12~22 Å | 22~30 Å | 12~30 Å | 30~60 Å | ||||

| ZTIF-8 | — | 1570.5 | 0.59 | 0.31 | 0.24 | 0 | 0.24 | 0 |

| NCZTIF-8700C | 21.81 | 853.3 | 0.41 | 0.32 | 0 | 0 | 0 | 0 |

| NCZTIF-8700C-800A0.5 | 12.33 | 1863.5 | 0.86 | 0.51 | 0.29 | 0 | 0.29 | 0 |

| NCZTIF-8700C-800A1 | 6.85 | 3096.0 | 1.96 | 0.50 | 0.72 | 0.63 | 1.35 | 0 |

| NCZTIF-8700C-800A2 | 1.62 | 2701.4 | 2.39 | 0.36 | 0.36 | 0.88 | 1.24 | 0.67 |

| NCZTIF-8700C-800A4 | 1.30 | 2643.5 | 2.83 | 0.29 | 0.43 | 0.32 | 0.75 | 1.43 |

表1 ZTIF-8、NCZTIF-8700C和NCZTIF-8700C-800A z 的孔结构和元素分析

Table 1 Pore structures and elemental analysis of ZTIF-8, NCZTIF-8700C and NCZTIF-8700C-800A z

| Samples | Bulk N/% | BET/(m²·g-1) | Total pore volume/ (cm³·g-1) | Cumulative pore volume/(cm3·g-1) | ||||

|---|---|---|---|---|---|---|---|---|

| <12 Å | 12~22 Å | 22~30 Å | 12~30 Å | 30~60 Å | ||||

| ZTIF-8 | — | 1570.5 | 0.59 | 0.31 | 0.24 | 0 | 0.24 | 0 |

| NCZTIF-8700C | 21.81 | 853.3 | 0.41 | 0.32 | 0 | 0 | 0 | 0 |

| NCZTIF-8700C-800A0.5 | 12.33 | 1863.5 | 0.86 | 0.51 | 0.29 | 0 | 0.29 | 0 |

| NCZTIF-8700C-800A1 | 6.85 | 3096.0 | 1.96 | 0.50 | 0.72 | 0.63 | 1.35 | 0 |

| NCZTIF-8700C-800A2 | 1.62 | 2701.4 | 2.39 | 0.36 | 0.36 | 0.88 | 1.24 | 0.67 |

| NCZTIF-8700C-800A4 | 1.30 | 2643.5 | 2.83 | 0.29 | 0.43 | 0.32 | 0.75 | 1.43 |

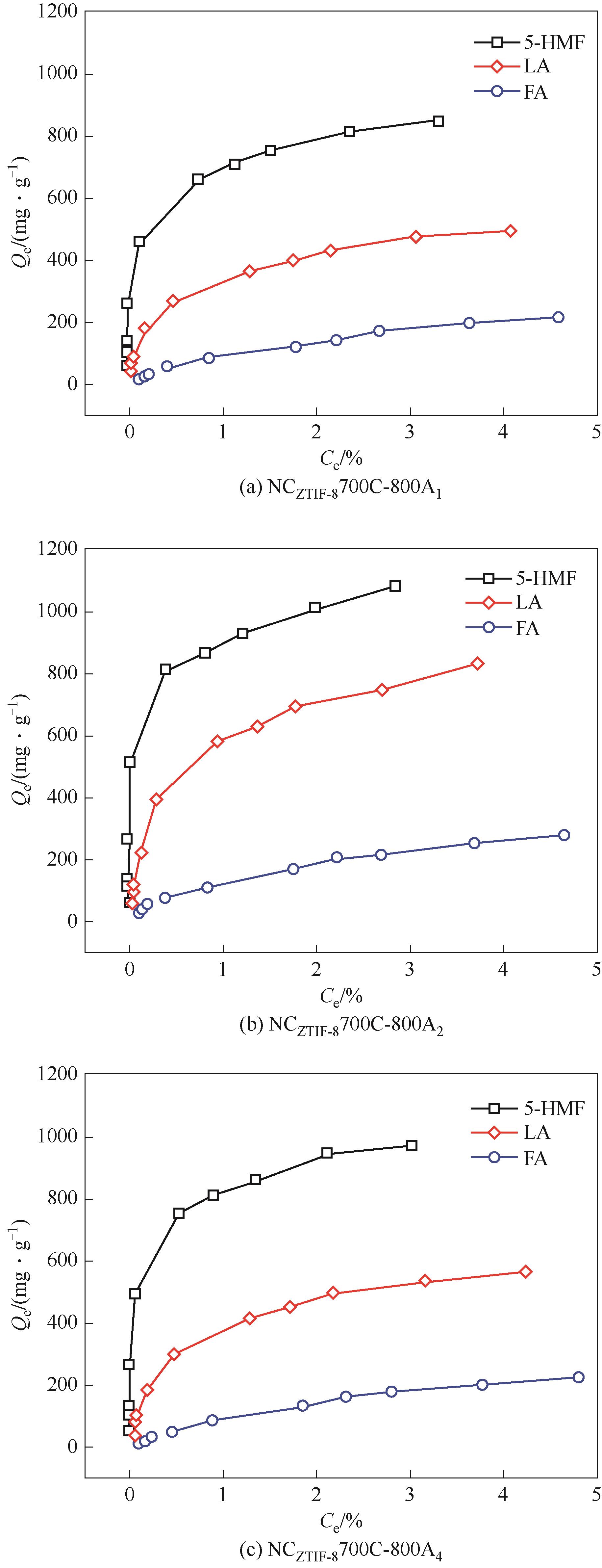

图6 25℃下NCZTIF-8700C-800A z 对单组分5-HMF、LA和FA的静态吸附等温线

Fig.6 Static adsorption isotherms of NCZTIF-8700C-800A z for single-component 5-HMF,LA and FA at 25℃

| Samples | Single-component Qe/(mg·g-1) | Ternary-component Qi,e/(mg·g-1) | Si,j | |||||

|---|---|---|---|---|---|---|---|---|

5-HMF (5.0%) | LA (2.5%) | FA (1.0%) | 5-HMF (5.0%) | LA (2.5%) | FA (1.0%) | 5-HMF/LA | 5-HMF/FA | |

| NCZTIF-8700C-800A1 | 842.0 | 399.7 | 86.1 | 555.8 | 60.8 | 9.5 | 5.0 | 12.3 |

| NCZTIF-8700C-800A2 | 1072.7 | 626.6 | 111.5 | 803.6 | 103.5 | 5.8 | 4.2 | 29.0 |

| NCZTIF-8700C-800A4 | 968.0 | 451.0 | 89.2 | 727.9 | 71.6 | 3.1 | 5.6 | 49.4 |

表2 NCZTIF-8700C-800A z 的静态吸附量和选择性汇总

Table 2 Summary of static adsorption capacity and selectivity of NCZTIF-8700C-800A z

| Samples | Single-component Qe/(mg·g-1) | Ternary-component Qi,e/(mg·g-1) | Si,j | |||||

|---|---|---|---|---|---|---|---|---|

5-HMF (5.0%) | LA (2.5%) | FA (1.0%) | 5-HMF (5.0%) | LA (2.5%) | FA (1.0%) | 5-HMF/LA | 5-HMF/FA | |

| NCZTIF-8700C-800A1 | 842.0 | 399.7 | 86.1 | 555.8 | 60.8 | 9.5 | 5.0 | 12.3 |

| NCZTIF-8700C-800A2 | 1072.7 | 626.6 | 111.5 | 803.6 | 103.5 | 5.8 | 4.2 | 29.0 |

| NCZTIF-8700C-800A4 | 968.0 | 451.0 | 89.2 | 727.9 | 71.6 | 3.1 | 5.6 | 49.4 |

| Samples | Ternary-component Qi,ads/(mg·g-1) | Si,j | |||

|---|---|---|---|---|---|

| 5.0% 5-HMF | 2.5%LA | 1.0%FA | 5-HMF/LA | 5-HMF/FA | |

| NCZTIF-8700C-800A1 | 774.3 | 88.6 | 29.7 | 4.4 | 5.2 |

| NCZTIF-8700C-800A2 | 1092.3 | 109.5 | 15.5 | 5.2 | 14.3 |

| NCZTIF-8700C-800A4 | 1040.3 | 107.1 | 6.8 | 5.1 | 30.4 |

表3 NCZTIF-8700C-800A z 的动态柱吸附量和选择性汇总

Table 3 Summary of dynamic column adsorption capacity and selectivity of NCZTIF-8700C-800A z

| Samples | Ternary-component Qi,ads/(mg·g-1) | Si,j | |||

|---|---|---|---|---|---|

| 5.0% 5-HMF | 2.5%LA | 1.0%FA | 5-HMF/LA | 5-HMF/FA | |

| NCZTIF-8700C-800A1 | 774.3 | 88.6 | 29.7 | 4.4 | 5.2 |

| NCZTIF-8700C-800A2 | 1092.3 | 109.5 | 15.5 | 5.2 | 14.3 |

| NCZTIF-8700C-800A4 | 1040.3 | 107.1 | 6.8 | 5.1 | 30.4 |

| 1 | Gervais E, Shammugam S, Friedrich L, et al. Raw material needs for the large-scale deployment of photovoltaics—effects of innovation-driven roadmaps on material constraints until 2050[J]. Renewable and Sustainable Energy Reviews, 2021, 137: 110589. |

| 2 | Galimova T, Ram M, Bogdanov D, et al. Global demand analysis for carbon dioxide as raw material from key industrial sources and direct air capture to produce renewable electricity-based fuels and chemicals[J]. Journal of Cleaner Production, 2022, 373: 133920. |

| 3 | Martin N, Madrid-López C, Villalba-Méndez G, et al. New techniques for assessing critical raw material aspects in energy and other technologies[J]. Environmental Science & Technology, 2022, 56(23): 17236-17245. |

| 4 | Mujtaba M, Fernandes Fraceto L, Fazeli M, et al. Lignocellulosic biomass from agricultural waste to the circular economy: a review with focus on biofuels, biocomposites and bioplastics[J]. Journal of Cleaner Production, 2023, 402: 136815. |

| 5 | Zhang B, Biswal B K, Zhang J J, et al. Hydrothermal treatment of biomass feedstocks for sustainable production of chemicals, fuels, and materials: progress and perspectives[J]. Chemical Reviews, 2023, 123(11): 7193-7294. |

| 6 | Xu C, Paone E, Rodríguez-Padrón D, et al. Recent catalytic routes for the preparation and the upgrading of biomass derived furfural and 5-hydroxymethylfurfural[J]. Chemical Society Reviews, 2020, 49(13): 4273-4306. |

| 7 | Zhang X G, Wilson K, Lee A F. Heterogeneously catalyzed hydrothermal processing of C5—C6 sugars[J]. Chemical Reviews, 2016, 116(19): 12328-12368. |

| 8 | Slak J, Pomeroy B, Kostyniuk A, et al. A review of bio-refining process intensification in catalytic conversion reactions, separations and purifications of hydroxymethylfurfural (HMF) and furfural[J]. Chemical Engineering Journal, 2022, 429: 132325. |

| 9 | Wang H Y, Zhu C H, Li D, et al. Recent advances in catalytic conversion of biomass to 5-hydroxymethylfurfural and 2, 5-dimethylfuran[J]. Renewable and Sustainable Energy Reviews, 2019, 103: 227-247. |

| 10 | Hu L, Wu Y R, Li M W, et al. Highly selective adsorption of 5-hydroxymethylfurfural from multicomponent mixture by simple pH controlled in batch and fixed-bed column studies: competitive isotherms, kinetic and breakthrough curves simulation[J]. Separation and Purification Technology, 2022, 299: 121756. |

| 11 | Hu L, Wu Z, Jiang Y T, et al. Recent advances in catalytic and autocatalytic production of biomass-derived 5-hydroxymethylfurfural[J]. Renewable and Sustainable Energy Reviews, 2020, 134: 110317. |

| 12 | 石宁, 刘琪英, 王铁军, 等. 葡萄糖催化脱水制取5-羟甲基糠醛研究进展[J]. 化工进展, 2012, 31(4): 792-800. |

| Shi N, Liu Q Y, Wang T J, et al. Preparation of 5-hydroxymethylfurfural from glucose by catalytic dehydration[J]. Chemical Industry and Engineering Progress, 2012, 31(4): 792-800. | |

| 13 | Chen S, Wojcieszak R, Dumeignil F, et al. How catalysts and experimental conditions determine the selective hydroconversion of furfural and 5-hydroxymethylfurfural[J]. Chemical Reviews, 2018, 118(22): 11023-11117. |

| 14 | Sayed M, Warlin N, Hulteberg C, et al. 5-Hydroxymethylfurfural from fructose: an efficient continuous process in a water-dimethyl carbonate biphasic system with high yield product recovery[J]. Green Chemistry, 2020, 22(16): 5402-5413. |

| 15 | Jeong G T, Kim S K. Statistical optimization of levulinic acid and formic acid production from lipid-extracted residue of Chlorella vulgaris [J]. Journal of Environmental Chemical Engineering, 2021, 9(2): 105142. |

| 16 | Enomoto K, Hosoya T, Miyafuji H. High-yield production of 5-hydroxymethylfurfural from D-fructose, D-glucose, and cellulose by its in situ removal from the reaction system[J]. Cellulose, 2018, 25(4): 2249-2257. |

| 17 | Wei Z J, Liu Y X, Thushara D, et al. Entrainer-intensified vacuum reactive distillation process for the separation of 5-hydroxylmethylfurfural from the dehydration of carbohydrates catalyzed by a metal salt-ionic liquid[J]. Green Chemistry, 2012, 14(4): 1220-1226. |

| 18 | Johnson R L, Perras F A, Hanrahan M P, et al. Condensed phase deactivation of solid Brønsted acids in the dehydration of fructose to hydroxymethylfurfural[J]. ACS Catalysis, 2019, 9(12): 11568-11578. |

| 19 | Wang H Y, Cui J J, Zhao Y L, et al. Highly efficient separation of 5-hydroxymethylfurfural from imidazolium-based ionic liquids[J]. Green Chemistry, 2021, 23(1): 405-411. |

| 20 | Román-Leshkov Y, Chheda J N, Dumesic J A. Phase modifiers promote efficient production of hydroxymethylfurfural from fructose[J]. Science, 2006, 312(5782): 1933-1937. |

| 21 | Sun X F, Liu Z H, Xue Z M, et al. Extraction of 5-HMF from the conversion of glucose in ionic liquid [Bmim]Cl by compressed carbon dioxide[J]. Green Chemistry, 2015, 17(5): 2719-2722. |

| 22 | Yang Q, Runge T. Cross-linked polyethylenimine for selective adsorption and effective recovery of lignocellulose-derived organic acids and aldehydes[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(1): 933-943. |

| 23 | Chen X F, Li H L, Ji X R, et al. Preparation, separation and purification of 5-hydroxymethylfurfural from sugarcane molasses by a self-synthesized hyper-cross-linked resin[J]. Separation and Purification Technology, 2023, 315: 123661. |

| 24 | Yabushita M, Li P, Kobayashi H, et al. Complete furanics-sugar separations with metal-organic framework NU-1000[J]. Chemical Communications, 2016, 52(79): 11791-11794. |

| 25 | Yoo W C, Rajabbeigi N, Mallon E E, et al. Elucidating structure-properties relations for the design of highly selective carbon-based HMF sorbents[J]. Microporous and Mesoporous Materials, 2014, 184: 72-82. |

| 26 | 赵宇, 石琪, 董晋湘. ZIFs椭圆形孔窗的精细调控及糠醛/5-羟甲基糠醛吸附分离性能研究[J]. 化工学报, 2021, 72(1): 555-568. |

| Zhao Y, Shi Q, Dong J X. Fine adjustment of elliptical windows of ZIFs and performances of adsorptive separation of furfural/5-hydroxymethylfurfural[J]. CIESC Journal, 2021, 72(1): 555-568. | |

| 27 | Hu L, Zheng J Y, Li Q, et al. Adsorption of 5-hydroxymethylfurfural, levulinic acid, formic acid, and glucose using polymeric resins modified with different functional groups[J]. ACS Omega, 2021, 6(26): 16955-16968. |

| 28 | Hu L, Tao S H, Xian J T, et al. Fabricating amide functional group modified hyper-cross-linked adsorption resin with enhanced adsorption and recognition performance for 5-hydroxymethylfurfural adsorption via simple one-step[J]. Chinese Journal of Chemical Engineering, 2022, 43: 230-239 |

| 29 | Zhang Y B, Luo Q X, Lu M H, et al. Controllable and scalable synthesis of hollow-structured porous aromatic polymer for selective adsorption and separation of HMF from reaction mixture of fructose dehydration [J]. Chemical Engineering Journal, 2019, 358: 467-479. |

| 30 | Jin H, Li Y S, Liu X L, et al. Recovery of HMF from aqueous solution by zeolitic imidazolate frameworks[J]. Chemical Engineering Science, 2015, 124: 170-178. |

| 31 | Swift T D, Bagia C, Nikolakis V, et al. Reactive adsorption for the selective dehydration of sugars to furans: Modeling and experiments [J]. Aiche Journal, 2013, 59(9): 3378-3390. |

| 32 | Dornath P, Fan W. Dehydration of fructose into furans over zeolite catalyst using carbon black as adsorbent[J]. Microporous and Mesoporous Materials, 2014, 191: 10-17. |

| 33 | Li M Y, Wang F, Zhang J. Zeolitic tetrazolate-imidazolate frameworks with SOD topology for room temperature fixation of CO2 to cyclic carbonates[J]. Crystal Growth & Design, 2020, 20(5): 2866-2870. |

| 34 | Yuan M, Liu Z Q, Lv T T, et al. Confinement effect and efficient adsorption of furfural onto ZIF-8-derived microporous carbon [J]. Journal of Chemical Technology and Biotechnology, 2023, 98(5): 1166-1174. |

| 35 | Gao M Z, Wang J, Rong Z H, et al. A combined experimental-computational investigation on water adsorption in various ZIFs with the SOD and RHO topologies[J]. RSC Advances, 2018, 8(69): 39627-39634. |

| 36 | Yuan M, Liu T C, Shi Q, et al. Understanding the KOH activation mechanism of zeolitic imidazolate framework-derived porous carbon and their corresponding furfural/acetic acid adsorption separation performance[J]. Chemical Engineering Journal, 2022, 428: 132016. |

| 37 | Yuan M, Gao M Z, Shi Q, et al. Understanding the characteristics of water adsorption in zeolitic imidazolate framework-derived porous carbon materials[J]. Chemical Engineering Journal, 2020, 379: 122412. |

| [1] | 李添翼, 武玉泰, 王永胜, 顾佳锐, 宋沂恒, 杨丰铖, 郝广平. 轻同位素分离纯化与催化标记研究进展[J]. 化工学报, 2024, 75(4): 1284-1301. |

| [2] | 张子佳, 仇昕月, 孙翔, 罗志斌, 罗海中, 贺高红, 阮雪华. 聚酰亚胺膜材料分子结构设计强化CO2渗透性研究进展[J]. 化工学报, 2024, 75(4): 1137-1152. |

| [3] | 孟园, 倪善, 刘亚锋, 王文杰, 赵越, 朱育丹, 杨良嵘. 功能化多孔氮化碳材料对铀的吸附性能研究[J]. 化工学报, 2024, 75(4): 1616-1629. |

| [4] | 李俊, 赵亮, 高金森, 徐春明. 不同馏分油分级分质加工中萃取技术研究进展[J]. 化工学报, 2024, 75(4): 1065-1080. |

| [5] | 莫滨宇, 张雅馨, 刘国振, 刘公平, 金万勤. 面向一/二价离子分离的金属有机骨架膜研究进展[J]. 化工学报, 2024, 75(4): 1183-1197. |

| [6] | 张凯博, 沈佳新, 李玉霞, 谈朋, 刘晓勤, 孙林兵. Y沸石中Cu(Ⅰ)的可控构筑及其乙烯/乙烷吸附分离性能研究[J]. 化工学报, 2024, 75(4): 1607-1615. |

| [7] | 文一如, 付佳, 刘大欢. 基于机器学习的MOFs材料研究进展:能源气体吸附分离[J]. 化工学报, 2024, 75(4): 1370-1381. |

| [8] | 董霄, 白志山, 杨晓勇, 殷伟, 刘宁普, 于启凡. CHPPO工艺氧化液耦合除杂技术的研究与工业应用[J]. 化工学报, 2024, 75(4): 1630-1641. |

| [9] | 刘莹, 郑芳, 杨启炜, 张治国, 任其龙, 鲍宗必. 二甲苯异构体吸附分离研究进展[J]. 化工学报, 2024, 75(4): 1081-1095. |

| [10] | 张天永, 张晶怡, 姜爽, 李彬, 吕东军, 陈都民, 陈雪. 弱酸性蓝AS染料排放的废盐制碳基吸附剂及利用[J]. 化工学报, 2024, 75(3): 890-899. |

| [11] | 李宁, 朱朋飞, 张立峰, 卢栋臣. 基于非凸与不可分离正则化算法的电容层析成像图像重建[J]. 化工学报, 2024, 75(3): 836-846. |

| [12] | 邢雷, 关帅, 蒋明虎, 赵立新, 蔡萌, 刘海龙, 陈德海. 高气液比井下气液旋流分离器结构设计与性能分析[J]. 化工学报, 2024, 75(3): 900-913. |

| [13] | 王灵洁, 高海龙, 靳继鹏, 王志浩, 李见波. 海水中的污染物对逆电渗析电堆性能的影响[J]. 化工学报, 2024, 75(2): 695-705. |

| [14] | 王宝凤, 王术高, 程芳琴. 固废基硫掺杂多孔炭材料制备及其对CO2吸附性能研究进展[J]. 化工学报, 2024, 75(2): 395-411. |

| [15] | 陶明清, 慕明昊, 程滕, 王博. 喷雾耦合降温强化旋风分离器脱除细颗粒物的研究[J]. 化工学报, 2024, 75(2): 584-592. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号