化工学报 ›› 2024, Vol. 75 ›› Issue (2): 584-592.DOI: 10.11949/0438-1157.20231175

收稿日期:2023-11-14

修回日期:2024-02-07

出版日期:2024-02-25

发布日期:2024-04-10

通讯作者:

程滕,王博

作者简介:陶明清(1999—),男,硕士研究生,taomq21@lzu.edu.cn

基金资助:

Mingqing TAO( ), Minghao MU, Teng CHENG(

), Minghao MU, Teng CHENG( ), Bo WANG(

), Bo WANG( )

)

Received:2023-11-14

Revised:2024-02-07

Online:2024-02-25

Published:2024-04-10

Contact:

Teng CHENG, Bo WANG

摘要:

通过在冷凝换热器前耦合喷雾的方式,将雾化团聚和水汽相变团聚结合以提高旋风分离器对细颗粒物的脱除效果,用于湿式除尘器后近饱和高湿烟气的深度处理。通过开展实验室试验和某金属冶炼厂烟气旁路试验,考察了该技术对颗粒物的脱除特性。实验室研究结果表明,典型工况下喷雾耦合降温能够显著增强旋风分离器对颗粒物的脱除,比单独喷雾或降温具有更好的增强效果。提高喷雾量和换热器温降,细颗粒物脱除效率先升高后趋于稳定,在温降6℃、喷雾量0.046 L/m3时达到最优脱除效果。烟气温度越高,湿度越接近饱和,细颗粒物脱除效率越高。工业烟气旁路试验表明,该系统适用于湿式除尘后的近饱和高湿烟气,且对波动工况的适应性强,当入口颗粒物浓度不超过2000 mg/m3时,出口颗粒物浓度可保持在20 mg/m3以内,平均脱除效率超过99.2%。

中图分类号:

陶明清, 慕明昊, 程滕, 王博. 喷雾耦合降温强化旋风分离器脱除细颗粒物的研究[J]. 化工学报, 2024, 75(2): 584-592.

Mingqing TAO, Minghao MU, Teng CHENG, Bo WANG. Research on spray coupled cooling to enhance the removal of fine particles by cyclone separator[J]. CIESC Journal, 2024, 75(2): 584-592.

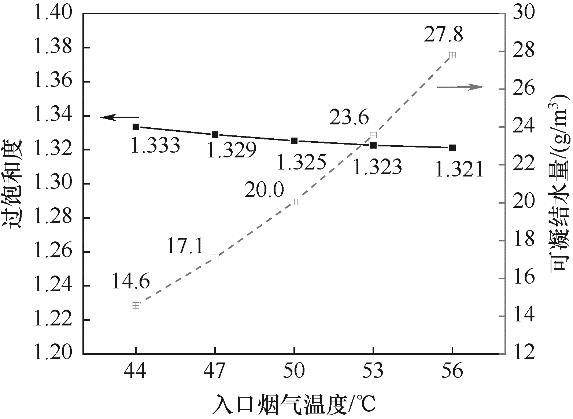

图9 不同入口烟气温度下换热器内理论过饱和度及可凝结水量

Fig.9 Theoretical supersaturation and condensable vapor amount in heat exchangers at different inlet flue gas temperatures

| 工艺阶段 | 入口颗粒物浓度/ (mg/m³) | 出口颗粒物浓度/(mg/m³) | 脱除效率/% | 工艺阶段 | 入口颗粒物浓度/ (mg/m³) | 出口颗粒物浓度/(mg/m³) | 脱除效率/% |

|---|---|---|---|---|---|---|---|

| 化料 | 1408.63 | 9.95 | 99.29 | 吹炼/精炼 | 1467.61 | 9.32 | 99.36 |

| 1558.62 | 7.62 | 99.51 | 947.95 | 7.95 | 99.16 | ||

| 2266.67 | 22.22 | 99.02 | 1339.80 | 12.17 | 99.09 | ||

| 1900.00 | 15.38 | 99.19 | 890.42 | 8.18 | 99.08 | ||

| 2193.10 | 25.62 | 98.83 | 1451.88 | 14.29 | 99.02 | ||

| 1868.76 | 8.84 | 99.53 | 1272.59 | 8.22 | 99.35 | ||

| 1649.43 | 6.88 | 99.58 | 1590.34 | 10.82 | 99.32 | ||

| 1676.96 | 8.00 | 99.52 | 1454.13 | 12.61 | 99.13 | ||

| 1014.73 | 7.79 | 99.23 | 1507.92 | 10.71 | 99.29 | ||

| 1208.59 | 14.73 | 98.78 | 1637.71 | 6.18 | 99.62 | ||

| 1077.55 | 9.02 | 99.16 | 973.44 | 13.62 | 98.60 | ||

| 1306.47 | 9.26 | 99.29 | 1523.49 | 12.01 | 99.21 | ||

| 1669.59 | 14.78 | 99.11 | 944.43 | 6.51 | 99.31 | ||

| 1076.78 | 12.81 | 98.81 | 1278.47 | 11.45 | 99.10 | ||

| 1700.62 | 7.32 | 99.57 | 1239.11 | 6.14 | 99.50 | ||

| 1899.58 | 6.14 | 99.68 | 815.37 | 8.40 | 98.97 | ||

表1 喷雾耦合降温强化旋风分离系统运行监测数据

Table 1 Operation monitoring data of spray-coupled cooling enhanced cyclone separation system

| 工艺阶段 | 入口颗粒物浓度/ (mg/m³) | 出口颗粒物浓度/(mg/m³) | 脱除效率/% | 工艺阶段 | 入口颗粒物浓度/ (mg/m³) | 出口颗粒物浓度/(mg/m³) | 脱除效率/% |

|---|---|---|---|---|---|---|---|

| 化料 | 1408.63 | 9.95 | 99.29 | 吹炼/精炼 | 1467.61 | 9.32 | 99.36 |

| 1558.62 | 7.62 | 99.51 | 947.95 | 7.95 | 99.16 | ||

| 2266.67 | 22.22 | 99.02 | 1339.80 | 12.17 | 99.09 | ||

| 1900.00 | 15.38 | 99.19 | 890.42 | 8.18 | 99.08 | ||

| 2193.10 | 25.62 | 98.83 | 1451.88 | 14.29 | 99.02 | ||

| 1868.76 | 8.84 | 99.53 | 1272.59 | 8.22 | 99.35 | ||

| 1649.43 | 6.88 | 99.58 | 1590.34 | 10.82 | 99.32 | ||

| 1676.96 | 8.00 | 99.52 | 1454.13 | 12.61 | 99.13 | ||

| 1014.73 | 7.79 | 99.23 | 1507.92 | 10.71 | 99.29 | ||

| 1208.59 | 14.73 | 98.78 | 1637.71 | 6.18 | 99.62 | ||

| 1077.55 | 9.02 | 99.16 | 973.44 | 13.62 | 98.60 | ||

| 1306.47 | 9.26 | 99.29 | 1523.49 | 12.01 | 99.21 | ||

| 1669.59 | 14.78 | 99.11 | 944.43 | 6.51 | 99.31 | ||

| 1076.78 | 12.81 | 98.81 | 1278.47 | 11.45 | 99.10 | ||

| 1700.62 | 7.32 | 99.57 | 1239.11 | 6.14 | 99.50 | ||

| 1899.58 | 6.14 | 99.68 | 815.37 | 8.40 | 98.97 | ||

| 1 | 王莉娜, 杨燕萍, 杨丽丽, 等. 兰州市秋季PM2.5污染特征及来源解析研究[J]. 绿色科技, 2020(14): 80-83, 96. |

| Wang L N, Yang Y P, Yang L L, et al. Study on the characteristics and source apportionment of PM2.5 autumn pollution in Lanzhou[J]. Journal of Green Science and Technology, 2020(14): 80-83, 96. | |

| 2 | Seinfeld J H. Atmospheric Chemistry and Physics of Air Pollution[M]. New York: Wiley, 1986 |

| 3 | 任战. 武汉市环境细颗粒物短期暴露与呼吸系统和心血管系统疾病住院风险研究[D]. 武汉: 武汉大学, 2021. |

| Ren Z. Short-term effect of ambient fine particulate (PM2.5) on hospital admissions for respiratory and cardiovascular diseases in Wuhan[D].Wuhan: Wuhan University, 2021. | |

| 4 | Groma V, Alföldy B, Börcsök E, et al. Sources and health effects of fine and ultrafine aerosol particles in an urban environment[J]. Atmospheric Pollution Research, 2022, 13(2): 101302. |

| 5 | Teng C Z, Li J. Performance of reduction on particle emission by combining the charged water drop atomization and electric field in wet electrostatic precipitator[J]. Process Safety and Environmental Protection, 2021, 155: 543-554. |

| 6 | 李秀芬, 冯伟杰, 康奕菁, 等. 气动乳化除尘脱硫+湿式静电除尘器组合处理器净化污泥焙烧烟气的应用[J]. 当代化工研究, 2021(22): 126-128. |

| Li X F, Feng W J, Kang Y J, et al. Application of pneumatic emulsion dust removal and desulfurization + wet electrostatic precipitator combined processor to purify sludge roasting flue gas[J]. Modern Chemical Research, 2021(22): 126-128. | |

| 7 | 卓俭进. 铜冶炼废气超低排放治理[J]. 黄金, 2021, 42(7): 86-88. |

| Zhuo J J. Ultra-low emission treatment of copper smelting flue gas[J]. Gold, 2021, 42(7): 86-88. | |

| 8 | Chen L J, Ma H, Sun Z J, et al. Effect of inlet periodic velocity on the performance of standard cyclone separators[J]. Powder Technology, 2022, 402: 117347. |

| 9 | Karagoz I, Avci A, Surmen A, et al. Design and performance evaluation of a new cyclone separator[J]. Journal of Aerosol Science, 2013, 59: 57-64. |

| 10 | Song C M, Pei B B, Jiang M T, et al. Numerical analysis of forces exerted on particles in cyclone separators[J]. Powder Technology, 2016, 294: 437-448. |

| 11 | Wang B, Liu H Y, Zhou C L, et al. Enhancing the collection efficiency of a gas cyclone with atomization and electrostatic charging[J]. Powder Technology, 2020, 364: 562-571. |

| 12 | Yang S L, Wang S, Luo K, et al. Numerical investigation of the cluster property and flux distribution in three-dimensional full-loop circulating fluidized bed with multiple parallel cyclones[J]. Powder Technology, 2019, 342: 253-266. |

| 13 | Guo Y Q, Zhang J Y, Zhao Y C, et al. Chemical agglomeration of fine particles in coal combustion flue gas: experimental evaluation[J]. Fuel, 2017, 203: 557-569. |

| 14 | Zhang X Y, Gan Z W, Li Y Z. Collection of particles on cold surfaces: a review[J]. Industrial & Engineering Chemistry Research, 2020, 59(38): 16493-16506. |

| 15 | Heidenreich S, Schabel S, Sachweh B, et al. Submicron particle separation in cyclones based on droplet growth by heterogeneous condensation[J]. Journal of Aerosol Science, 1995, 26: S873-S874. |

| 16 | Fu P B, Jiang X, Ma L, et al. Enhancement of PM2.5 cyclone separation by droplet capture and particle sorting[J]. Environmental Science & Technology, 2018, 52(20): 11652-11659. |

| 17 | Cheng Z L, Jiang L, Cai Y W, et al. Removal model of fine particles from the flue gas of the coal-fired power plant in a water-sparged aerocyclone[J]. The Canadian Journal of Chemical Engineering, 2019, 97(12): 3148-3155. |

| 18 | Wu H, Yang L J, Yan J P, et al. Improving the removal of fine particles by heterogeneous condensation during WFGD processes[J]. Fuel Processing Technology, 2016, 145: 116-122. |

| 19 | Tan H Z, Wang Y B, Cao R J, et al. Development of wet phase transition agglomerator for multi-pollutant synergistic removal[J]. Applied Thermal Engineering, 2018, 130: 1208-1214. |

| 20 | Krames J, Büttner H. The cyclone scrubber—a high efficiency wet separator[J]. Chemical Engineering & Technology, 1994, 17(2): 73-80. |

| 21 | Yu Y, Xu C W, Fu C. Effects of coal-fired flue gas composition on condensational growth by water vapor for fine SiO2 particles[J]. Process Safety and Environmental Protection, 2021, 158(2): 34-41. |

| 22 | Ray M B, Hoffmann A C, Postma R S. Performance of different analytical methods in evaluating grade efficiency of centrifugal separators[J]. Journal of Aerosol Science, 2000, 31(5): 563-581. |

| 23 | 周璐璐, 张军, 徐俊超, 等. 典型煤灰成分细颗粒物在过饱和水汽环境中的长大特性[J]. 燃料化学学报, 2015, 43(6): 754-760. |

| Zhou L L, Zhang J, Xu J C, et al. Growth of fine particulates of typical coal ash components in supersaturated water environment[J]. Journal of Fuel Chemistry and Technology, 2015, 43(6): 754-760. | |

| 24 | Cao R J, Tan H Z, Xiong Y Y, et al. Improving the removal of particles and trace elements from coal-fired power plants by combining a wet phase transition agglomerator with wet electrostatic precipitator[J]. Journal of Cleaner Production, 2017, 161: 1459-1465. |

| 25 | Chen C C, Tao C J, Shu H J. Heterogeneous nucleation of n-butanol vapor on submicrometer charged and neutral particles of lactose and monosodium glutamate[J]. Journal of Colloid and Interface Science, 2000, 224(1): 11-22. |

| 26 | Gan Z W, Li Y Z, Zhang X Y, et al. Mechanism of stefan flow in the collection of particles on evaporating/condensing surfaces: a review[J]. Industrial & Engineering Chemistry Research, 2021, 60(13): 4766-4776. |

| 27 | Wang B, Yu A B. Computational investigation of the mechanisms of particle separation and “fish-hook” phenomenon in hydrocyclones[J]. AIChE Journal, 2010, 56(7): 1703-1715. |

| 28 | Podgórski A, Bałazy A, Gradoń L. Application of nanofibers to improve the filtration efficiency of the most penetrating aerosol particles in fibrous filters[J]. Chemical Engineering Science, 2006, 61(20): 6804-6815. |

| 29 | Fletcher N H. Size effect in heterogeneous nucleation[J]. The Journal of Chemical Physics, 1958, 29(3): 572-576. |

| 30 | Wang X, Zhang L, Moran M D. Uncertainty assessment of current size-resolved parameterizations for below-cloud particle scavenging by rain[J]. Atmospheric Chemistry and Physics, 2010, 10(12): 5685-5705. |

| 31 | Park S H, Jung C H, Jung K R, et al. Wet scrubbing of polydisperse aerosols by freely falling droplets[J]. Journal of Aerosol Science, 2005, 36(12): 1444-1458. |

| [1] | 李晓阳, 李东, 陶明磊, 周致富, 张灵怡, 苏力争, 张天宁, 李智, 陈斌. 多喷嘴喷雾冷却表面传热特性实验研究[J]. 化工学报, 2024, 75(1): 231-241. |

| [2] | 陈天华, 刘兆轩, 韩群, 张程宾, 李文明. 喷雾冷却换热强化研究进展及影响因素[J]. 化工学报, 2023, 74(8): 3149-3170. |

| [3] | 张浩, 徐惠斌, 高健, 刘帝宏, 周泽华. Geldart-D类湿颗粒倾斜落料行为及其强化[J]. 化工学报, 2023, 74(4): 1519-1527. |

| [4] | 任金胜, 刘克润, 焦志伟, 刘家祥, 于源. 涡流空气分级机近导叶处团聚体解团机理研究[J]. 化工学报, 2023, 74(4): 1528-1538. |

| [5] | 范怡平, 卢春喜. 离心力场-移动床耦合气固分离装备的研究进展[J]. 化工学报, 2023, 74(1): 157-169. |

| [6] | 姚翰林, 辛忠. 液相沉淀反应在管式微通道反应器中的流动行为研究[J]. 化工学报, 2022, 73(8): 3518-3528. |

| [7] | 宋健斐, 孙立强, 解明, 魏耀东. 旋风分离器内气相旋转流不稳定性的实验研究[J]. 化工学报, 2022, 73(7): 2858-2864. |

| [8] | 李俊, 黎仕华, 孙志高, 宋士博. 超声对无沸腾区浸液式喷雾冷却的影响研究[J]. 化工学报, 2022, 73(4): 1566-1574. |

| [9] | 熊桂龙, 谢静雯, 杨林军. 粗糙度对水汽在细颗粒表面异质核化影响的数值模拟[J]. 化工学报, 2021, 72(8): 4304-4313. |

| [10] | 周昊,伍其威,程方正. 火焰喷雾合成法制备La0.8Sr0.2Mn1-xCuxO3催化氧化CO性能研究[J]. 化工学报, 2021, 72(10): 5159-5171. |

| [11] | 王斌, 沈聪, 王佳音, 杨景轩, 郝晓刚. 旋风分离器内细颗粒浓度分布及运动分析[J]. 化工学报, 2020, 71(S2): 201-209. |

| [12] | 施智雄, 潘科玮, 平力, 杨斌. 喷嘴雾化参数轨迹图像法测量实验研究[J]. 化工学报, 2020, 71(8): 3527-3534. |

| [13] | 余廷芳, 高巨, 熊桂龙, 李水清, 姚强. 基于分子运动学的水汽在细颗粒表面异质核化的数值模拟[J]. 化工学报, 2020, 71(7): 3071-3079. |

| [14] | 周年勇, 徐慕豪, 冯浩, 段锋, 王庆荣, 陈海飞, 郭强. 闭式喷雾冷却的瞬态传热过程研究[J]. 化工学报, 2020, 71(3): 1018-1025. |

| [15] | 孙宗康, 张笑丹, 杨林军, 陈帅, 吴新. 化学与湍流团聚耦合促进燃煤细颗粒物团聚与脱除[J]. 化工学报, 2020, 71(3): 1317-1325. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号