化工学报 ›› 2025, Vol. 76 ›› Issue (6): 2549-2558.DOI: 10.11949/0438-1157.20241115

李琳1( ), 王明媚1, 宋二伟1, 王雯雯1, 张耀昌2, 王二强1(

), 王明媚1, 宋二伟1, 王雯雯1, 张耀昌2, 王二强1( )

)

收稿日期:2024-10-08

修回日期:2024-12-16

出版日期:2025-06-25

发布日期:2025-07-09

通讯作者:

王二强

作者简介:李琳(1998—),女,硕士研究生,lilin22@mails.ucas.ac.cn

基金资助:

Lin LI1( ), Mingmei WANG1, Erwei SONG1, Wenwen WANG1, Yaochang ZHANG2, Erqiang WANG1(

), Mingmei WANG1, Erwei SONG1, Wenwen WANG1, Yaochang ZHANG2, Erqiang WANG1( )

)

Received:2024-10-08

Revised:2024-12-16

Online:2025-06-25

Published:2025-07-09

Contact:

Erqiang WANG

摘要:

针对C5馏分中常见的异戊二烯-正戊烷共沸体系,提出了一种借助智能优化算法评估萃取精馏工艺,并从热力学原理进行设计的方法。首先,基于残余曲线图进行概念设计,并利用改进的遗传算法对工艺参数进行闭环全局优化,以经济性、能源效率及萃取段分离效率(萃取精馏所特有)为评价指标来进行综合优化。接着,结合TOPSIS方法从Pareto前沿解中筛选出最佳设计方案,并基于热力学原理对优化结果进行分析。研究结果表明,最佳方案在分离效率、经济性和能量利用率上均表现优异;通过减少萃取剂用量、适当增加塔板数和优化回流比,可有效提高分离效率并降低成本。研究结果为工业上异戊二烯与正戊烷的高效分离提供了理论依据和设计指导。

中图分类号:

李琳, 王明媚, 宋二伟, 王雯雯, 张耀昌, 王二强. 异戊二烯-正戊烷分离工艺的热力学分析及优化[J]. 化工学报, 2025, 76(6): 2549-2558.

Lin LI, Mingmei WANG, Erwei SONG, Wenwen WANG, Yaochang ZHANG, Erqiang WANG. Thermodynamic analysis and optimization of isoprene/n-pentane separation process[J]. CIESC Journal, 2025, 76(6): 2549-2558.

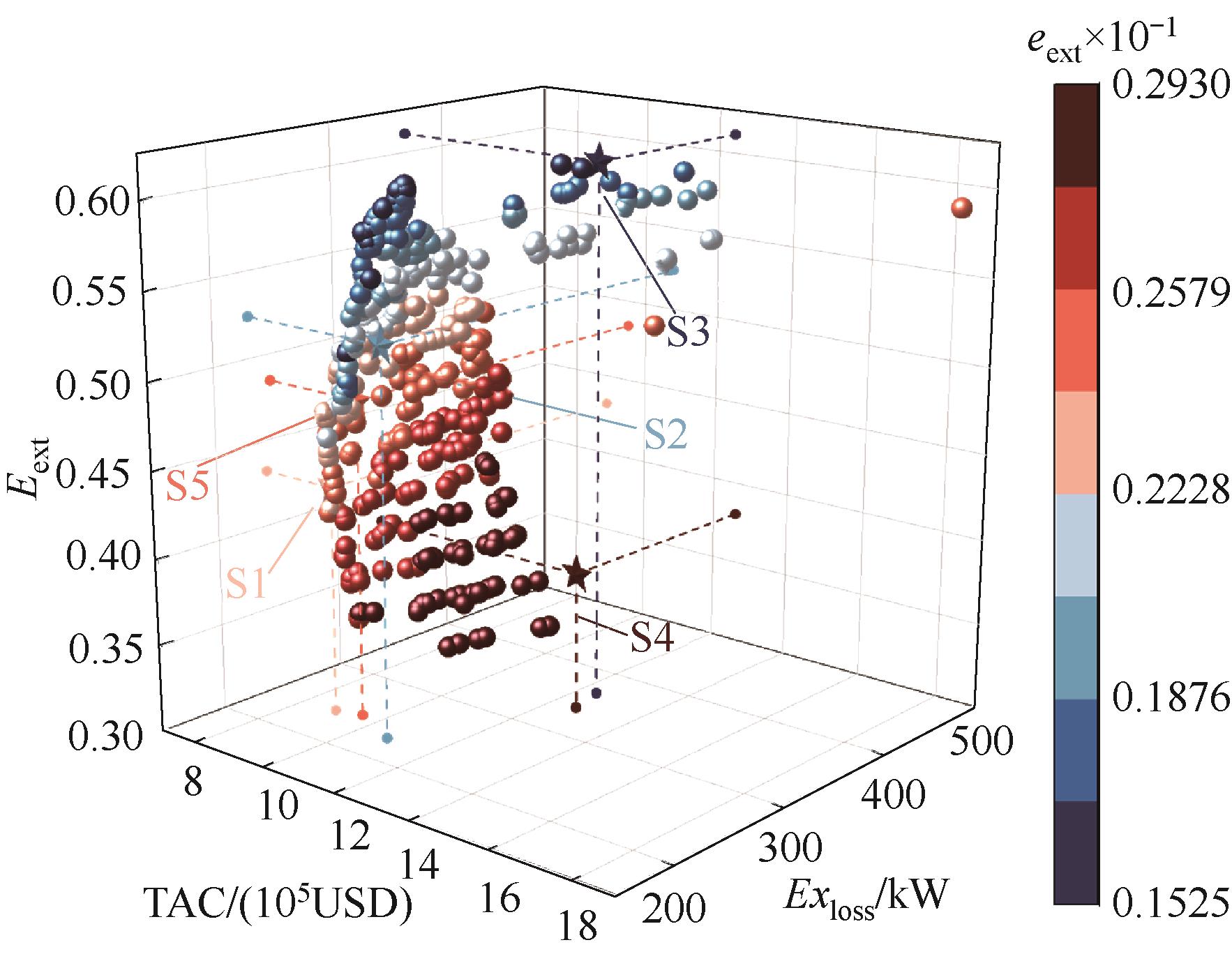

图6 用于IP/n-Pen/DMF体系分离的萃取精馏工艺的多目标优化结果

Fig.6 Multi-objective optimization result for the extraction distillation process used in the separation of the IP/n-Pen/DMF system

| Item | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| NEDC | 77 | 127 | 116 | 78 | 90 |

| NE | 8 | 7 | 9 | 9 | 12 |

| NF, EDC | 27 | 35 | 50 | 23 | 33 |

| DEDC/(kmol/h) | 14.97 | 15.00 | 14.98 | 15.01 | 15.00 |

| FE/(kmol/h) | 130.52 | 87.26 | 86.11 | 216.68 | 112.94 |

| REDC | 9.422 | 10.53 | 14.95 | 14.31 | 11.01 |

| NSRC | 19 | 49 | 24 | 52 | 27 |

| NF, SRC | 7 | 10 | 8 | 30 | 7 |

| DSRC/(kmol/h) | 60.04 | 60.05 | 60.05 | 60.04 | 60.05 |

| RSRC | 0.202 | 0.204 | 1.225 | 0.274 | 0.226 |

| TOC/(105 USD) | 5.52 | 5.26 | 7.34 | 8.13 | 5.72 |

| TCC/(105 USD) | 3.60 | 5.92 | 5.23 | 5.09 | 4.05 |

| TAC/(105 USD) | 9.12 | 11.19 | 12.57 | 13.22 | 9.77 |

| Exloss/kW | 240.71 | 228.62 | 366.20 | 339.55 | 245.63 |

| Eext | 0.432 | 0.524 | 0.611 | 0.381 | 0.484 |

| eext✕10-1 | 0.240 | 0.194 | 0.153 | 0.293 | 0.242 |

表1 异戊二烯-正戊烷分离的萃取精馏5组优化方案的设计参数

Table 1 Design parameters of five optimized schemes for the extractive distillation of isoprene/n-pentane separation

| Item | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| NEDC | 77 | 127 | 116 | 78 | 90 |

| NE | 8 | 7 | 9 | 9 | 12 |

| NF, EDC | 27 | 35 | 50 | 23 | 33 |

| DEDC/(kmol/h) | 14.97 | 15.00 | 14.98 | 15.01 | 15.00 |

| FE/(kmol/h) | 130.52 | 87.26 | 86.11 | 216.68 | 112.94 |

| REDC | 9.422 | 10.53 | 14.95 | 14.31 | 11.01 |

| NSRC | 19 | 49 | 24 | 52 | 27 |

| NF, SRC | 7 | 10 | 8 | 30 | 7 |

| DSRC/(kmol/h) | 60.04 | 60.05 | 60.05 | 60.04 | 60.05 |

| RSRC | 0.202 | 0.204 | 1.225 | 0.274 | 0.226 |

| TOC/(105 USD) | 5.52 | 5.26 | 7.34 | 8.13 | 5.72 |

| TCC/(105 USD) | 3.60 | 5.92 | 5.23 | 5.09 | 4.05 |

| TAC/(105 USD) | 9.12 | 11.19 | 12.57 | 13.22 | 9.77 |

| Exloss/kW | 240.71 | 228.62 | 366.20 | 339.55 | 245.63 |

| Eext | 0.432 | 0.524 | 0.611 | 0.381 | 0.484 |

| eext✕10-1 | 0.240 | 0.194 | 0.153 | 0.293 | 0.242 |

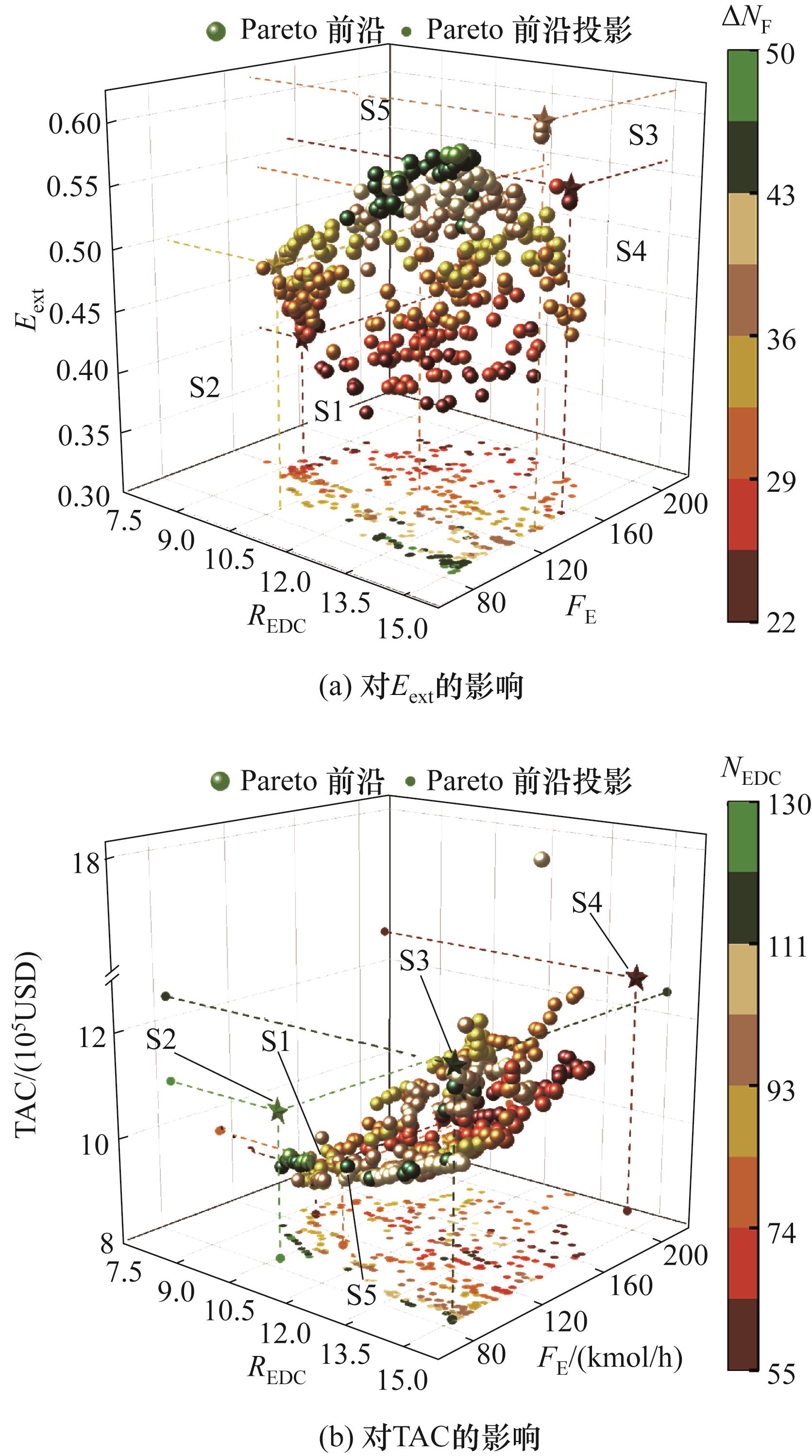

图7 EDC塔的关键设计参数REDC和Eext对目标函数Eext和TAC的影响

Fig.7 The influence of key design parameters FE and REDC of the EDC column on the objective functions Eext and TAC

| [1] | Alabdullah M A, Gomez A R, Vittenet J, et al. A viewpoint on the refinery of the future: catalyst and process challenges[J]. ACS Catalysis, 2020, 10(15): 8131-8140. |

| [2] | 田保亮, 唐国旗, 张齐, 等. 从裂解碳五分离聚合级异戊二烯的一段萃取工艺[J]. 化工进展, 2009, 28(4): 714-720. |

| Tian B L, Tang G Q, Zhang Q, et al. One-stage extraction technology of separating polymer-grade isoprene from cracked C5 fraction[J]. Chemical Industry and Engineering Progress, 2009, 28(4): 714-720. | |

| [3] | 方键. 碳五馏分分离方法及其下游产品开发方向研究进展[J]. 现代化工, 2012, 32(4): 39-42. |

| Fang J. Research progress for the separation method of C5 fraction and development direction of its downstream products[J]. Modern Chemical Industry, 2012, 32(4): 39-42. | |

| [4] | 过良, 李东风, 王金福. 国内裂解碳五馏分分离技术的研究进展[J]. 石油化工, 2015, 44(2): 252-260. |

| Guo L, Li D F, Wang J F. Progresses in the separation of steam cracking C5 fraction at home[J]. Petrochemical Technology, 2015, 44(2): 252-260. | |

| [5] | 沙裕, 葛春方. 碳五分离先进工艺的开发研究[J]. 炼油技术与工程, 2010, 40(7): 5-8. |

| Sha Y, Ge C F. Research & development of advanced C5 separation process[J]. Petroleum Refinery Engineering, 2010, 40(7): 5-8. | |

| [6] | 杨傲. 多元多共沸体系精馏分离系统的设计、优化和控制研究[D]. 重庆: 重庆大学, 2021. |

| Yang A. Study on design, optimization and control of distillation separation system of multicomponent azeotropic system[D]. Chongqing: Chongqing University, 2021. | |

| [7] | 孙诗瑞, 杨傲, 石涛, 等. 特殊精馏热耦合强化技术研究进展[J]. 化工学报, 2020, 71(10): 4575-4589. |

| Sun S R, Yang A, Shi T, et al. Research advances in thermally coupled intensification technology for special distillation[J]. CIESC Journal, 2020, 71(10): 4575-4589. | |

| [8] | 石涛. 共沸混合物的特殊精馏强化设计和控制研究[D]. 重庆: 重庆大学, 2020. |

| Shi T. The Study of process intensification and control for separating azeotropic mixture by special distillation[D]. Chongqing: Chongqing University, 2020. | |

| [9] | 李晔. 常规及夹带剂辅助变压精馏分离二元共沸物的设计与控制[D]. 天津: 天津大学, 2019. |

| Li Y. Design and control of separation of binary azeotrope by conventional and entrainer-assisted pressure swing distillation[D]. Tianjin: Tianjin University, 2019. | |

| [10] | Gerbaud V, Rodriguez-Donis I, Hegely L, et al. Review of extractive distillation. Process design, operation, optimization and control[J]. Chemical Engineering Research and Design, 2019, 141: 229-271. |

| [11] | 李东风, 马立国. 裂解碳五馏分分离技术的研究进展[J]. 石油化工, 2007, 36(8): 755-762. |

| Li D F, Ma L G. Progress in research for separation of steam cracking C5 fraction[J]. Petrochemical Technology, 2007, 36(8): 755-762. | |

| [12] | 马立国. 二甲基甲酰胺法碳五馏分分离萃取精馏塔的模拟[J]. 石油化工, 2014, 43(6): 675-680. |

| Ma L G. Process simulation for separation of C5 fraction by extractive distillation with N,N-dimethylformamide[J]. Petrochemical Technology, 2014, 43(6): 675-680. | |

| [13] | 武庭宇, 王超, 秦余涛, 等. 乙酸乙酯/乙醇/水体系预分离萃取精馏工艺研究[J]. 化工学报, 2023, 74(11): 4578-4586. |

| Wu T Y, Wang C, Qin Y T, et al. Study of extractive distillation processes with preconcentration for separating ethyl acetate/ethanol/water azeotropic mixture[J]. CIESC Journal, 2023, 74(11): 4578-4586. | |

| [14] | Cerda-Flores S C, Rojas-Punzo A A, Nápoles-Rivera F. Applications of multi-objective optimization to industrial processes: a literature review[J]. Processes, 2022, 10(1): 133. |

| [15] | 黄仁宇. 基于初值优选的模拟数据驱动型复杂精馏塔操作优化[D]. 广州: 华南理工大学, 2019. |

| Huang R Y. Operation optimization of complex distillation column driven by analog data based on initial value optimization[D]. Guangzhou: South China University of Technology, 2019. | |

| [16] | Qiu P, Huang B, Dai Z H, et al. Data-driven analysis and optimization of externally heat-integrated distillation columns (EHIDiC)[J]. Energy, 2019, 189: 116177. |

| [17] | 黄鹏飞. 离线数据驱动的进化优化研究[D]. 西安: 西安电子科技大学, 2021. |

| Huang P F. Research on off-line data-driven evolutionary optimization[D]. Xi'an: Xidian University, 2021. | |

| [18] | Li Z Y, Huang X, Wang L C, et al. Sustainable and efficient separation of ternary multi-azeotropic mixture butanone/ethanol/water based on the intensified reactive extractive distillation: process design, multi-objective optimization, and multi-criteria decision-making[J]. Separation and Purification Technology, 2025, 355: 129694. |

| [19] | Yang A, Kong Z Y, Sun S R, et al. Design and multiobjective optimization of a novel double extractive dividing wall column with a side reboiler scheme for the recovery of ethyl acetate and methanol from wastewater[J]. Industrial & Engineering Chemistry Research, 2023, 62(44): 18591-18602. |

| [20] | Lei Y, Guo Z Q, Du L, et al. Replacing DMF with ionic liquid in isoprene/n-pentane separation in C5 plants: solvent design, process optimization, and industrial-scale assessment[J]. Fuel, 2024, 357: 130006. |

| [21] | 孙兰义. 化工过程模拟实训: Aspen Plus教程[M]. 2版. 北京: 化学工业出版社, 2017: 36-37. |

| Sun L Y. Chemical Process Simulation Training: Aspen Plus Tutorial[M]. 2nd ed. Beijing: Chemical Industry Press, 2017: 36-37. | |

| [22] | Howat C S, Swift G W. Vapor: liquid phase equilibria for the isoprene: n-pentane binary system from 300 to 330 K[J]. Fluid Phase Equilibria, 1985, 21(1/2): 113-134. |

| [23] | Kedrina N N, Semenov L V, Gaile A A, et al. Thermodynamic functions of mixing of the C5 and C6 hydrocarbons with N,N-dimethylformamide[J]. Russ. J. Phys. Chem, 1983, 57: 1776-1778. |

| [24] | Kiva V N, Serafimov L A. Batch distillation of ternary mixtures at constant reflux ratio ( Ⅱ ) : Analysis of the dynamic system of the distillate and the splitting into regions of distillation[J]. Russ. J. Phys. Chem, 1973, 47(3): 634-637. |

| [25] | Kiva V N, Hilmen E K, Skogestad S. Azeotropic phase equilibrium diagrams: a survey[J]. Chemical Engineering Science, 2003, 58(10): 1903-1953. |

| [26] | Rodriguez-Donis I, Gerbaud V, Joulia X. Thermodynamic insights on the feasibility of homogeneous batch extractive distillation(1): Azeotropic mixtures with a heavy entrainer[J]. Industrial & Engineering Chemistry Research, 2009, 48(7): 3544-3559. |

| [27] | Rodríguez-Donis I, Gerbaud V, Joulia X. Thermodynamic insights on the feasibility of homogeneous batch extractive distillation(2): Low-relative-volatility binary mixtures with a heavy entrainer[J]. Industrial & Engineering Chemistry Research, 2009, 48(7): 3560-3572. |

| [28] | Shen W F, Benyounes H, Gerbaud V. Extension of thermodynamic insights on batch extractive distillation to continuous operation(1): Azeotropic mixtures with a heavy entrainer[J]. Industrial & Engineering Chemistry Research, 2013, 52(12): 4606-4622. |

| [29] | Rodríguez-Donis I, Gerbaud V, Joulia X. Thermodynamic insight on extractive distillation with entrainer forming new azeotropes[J]. Distillation & Absorption 2010, 2010, 9: 431-436. |

| [30] | Yoshiaki W. Utilization of C5 stream and its prospects[J]. Chem. Econ. Eng. Rev., 1974, 6(8): 36-41. |

| [31] | 谷静连. 热力学探究在变压精馏和萃取精馏过程中的应用研究[D]. 重庆: 重庆大学, 2019. |

| Gu J L. Study on the application of thermodynamic inquiry in pressure swing distillation and extractive distillation[D]. Chongqing: Chongqing University, 2019. | |

| [32] | 道格拉斯. 化工过程的概念设计[M]. 蒋楚生, 译. 北京: 化学工业出版社, 1994: 347-349. |

| Douglas J M. Conceptual Design of Chemical Processes[M]. Jiang C S, trans. Beijing: Chemical Industry Press, 1994: 347-349. | |

| [33] | Suphanit B, Bischert A, Narataruksa P. Exergy loss analysis of heat transfer across the wall of the dividing-wall distillation column[J]. Energy, 2007, 32(11): 2121-2134. |

| [34] | You X Q, Rodriguez-Donis I, Gerbaud V. Improved design and efficiency of the extractive distillation process for acetone-methanol with water[J]. Industrial & Engineering Chemistry Research, 2015, 54(1): 491-501. |

| [35] | Deb K, Pratap A, Agarwal S, et al. A fast and elitist multiobjective genetic algorithm: NSGA-Ⅱ[J]. IEEE Transactions on Evolutionary Computation, 2002, 6(2): 182-197. |

| [36] | Deb K, Agrawal R B. Simulated binary crossover for continuous search space[J]. Complex Systems, 1994, 9: 1-34. |

| [37] | Behzadian M, Khanmohammadi Otaghsara S, Yazdani M, al et, et al. A state-of the-art survey of TOPSIS applications[J]. Expert Systems with Applications, 2012, 39(17): 13051-13069. |

| [38] | Zhang H R, Jiao Y Y, Zhao Q, et al. Sustainable separation of ternary azeotropic mixtures based on enhanced extractive distillation/pervaporation structure and multi-objective optimization[J]. Separation and Purification Technology, 2022, 298: 121685. |

| [1] | 臧子晴, 李修真, 谈莹莹, 刘晓庆. 分凝器对两级分离自复叠制冷循环特性影响研究[J]. 化工学报, 2025, 76(S1): 17-25. |

| [2] | 李银龙, 刘国强, 晏刚. 分馏与闪蒸分离耦合自复叠制冷循环性能分析[J]. 化工学报, 2025, 76(S1): 26-35. |

| [3] | 朱腾飞, 刘晔. 低GWP制冷剂在新能源汽车空调应用性能分析[J]. 化工学报, 2025, 76(S1): 343-350. |

| [4] | 吴迪, 胡斌, 姜佳彤. R1233zd(E)高温热泵实验研究与应用分析[J]. 化工学报, 2025, 76(S1): 377-383. |

| [5] | 苏伟, 赵大海, 金旭, 刘忠彦, 李静, 张小松. 吸湿液滴与混合润湿性表面协同抑霜特性研究[J]. 化工学报, 2025, 76(S1): 140-151. |

| [6] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [7] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [8] | 韩光泽, 张佩璇. 静电场作用下液体凝固点变化的热力学机理[J]. 化工学报, 2025, 76(6): 2544-2548. |

| [9] | 江锦波, 陈竹鑫, 肖洋溢, 彭新, 陈源, 于辰, 孟祥铠, 彭旭东. 运行工况对超临界CO2干气密封端面热力学过程及稳态性能影响研究[J]. 化工学报, 2025, 76(6): 2913-2928. |

| [10] | 翟祥瑞, 张伟, 张倩倩, 曲玖哲, 杨绪飞, 邓雅军, 宇波. 基于外场扰动的固液相变储能主动强化换热技术[J]. 化工学报, 2025, 76(4): 1432-1446. |

| [11] | 刘淑丽, 周文豪, 张少良, 沈永亮. 太阳能直接吸收相变集-蓄热器的放热特性研究[J]. 化工学报, 2025, 76(4): 1722-1730. |

| [12] | 戴文智, 沈雄健, 宋晓博, 杨新乐. 生物质双级蒸发双回热有机朗肯循环系统环境分析[J]. 化工学报, 2025, 76(3): 1230-1242. |

| [13] | 卢昕悦, 陈锐莹, 姜夏雪, 梁海瑞, 高歌, 叶正芳. 耦合LNG冷能的液态空气储能系统和液态CO2储能系统对比分析[J]. 化工学报, 2024, 75(9): 3297-3309. |

| [14] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| [15] | 李新泽, 张双星, 杨洪海, 杜文静. 基于电池冷却用新型脉动热管性能的实验研究[J]. 化工学报, 2024, 75(6): 2222-2232. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号