化工学报 ›› 2025, Vol. 76 ›› Issue (8): 3805-3821.DOI: 10.11949/0438-1157.20250289

范夏雨1( ), 孙建辰1, 李可莹1, 姚馨雅2, 商辉1(

), 孙建辰1, 李可莹1, 姚馨雅2, 商辉1( )

)

收稿日期:2025-03-24

修回日期:2025-04-06

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

商辉

作者简介:范夏雨(1998—),女,博士研究生,fanxiayu2022@163.com

基金资助:

Xiayu FAN1( ), Jianchen SUN1, Keying LI1, Xinya YAO2, Hui SHANG1(

), Jianchen SUN1, Keying LI1, Xinya YAO2, Hui SHANG1( )

)

Received:2025-03-24

Revised:2025-04-06

Online:2025-08-25

Published:2025-09-17

Contact:

Hui SHANG

摘要:

在全球气候变化加剧与能源结构转型的双重挑战下,发展高效清洁的氢能储运技术已成为实现碳中和目标的关键路径。液态有机氢载体(LOHCs)储氢技术因其高安全性、可利用现有基础设施等优势成为氢能储运领域的研究热点,但其产业化受制于脱氢动力学缓慢、催化剂依赖性强等问题。近年来机器学习(ML)在新材料设计、反应优化以及数据驱动建模中的突破为LOHCs技术注入了新动能。本文聚焦于ML在LOHCs分子设计与筛选、催化剂设计和反应条件优化等方面的最新研究,提出了目前研究的短板,并展望了未来发展方向。

中图分类号:

范夏雨, 孙建辰, 李可莹, 姚馨雅, 商辉. 机器学习驱动液态有机储氢技术的系统优化[J]. 化工学报, 2025, 76(8): 3805-3821.

Xiayu FAN, Jianchen SUN, Keying LI, Xinya YAO, Hui SHANG. Machine learning drives system optimization of liquid organic hydrogen storage technology[J]. CIESC Journal, 2025, 76(8): 3805-3821.

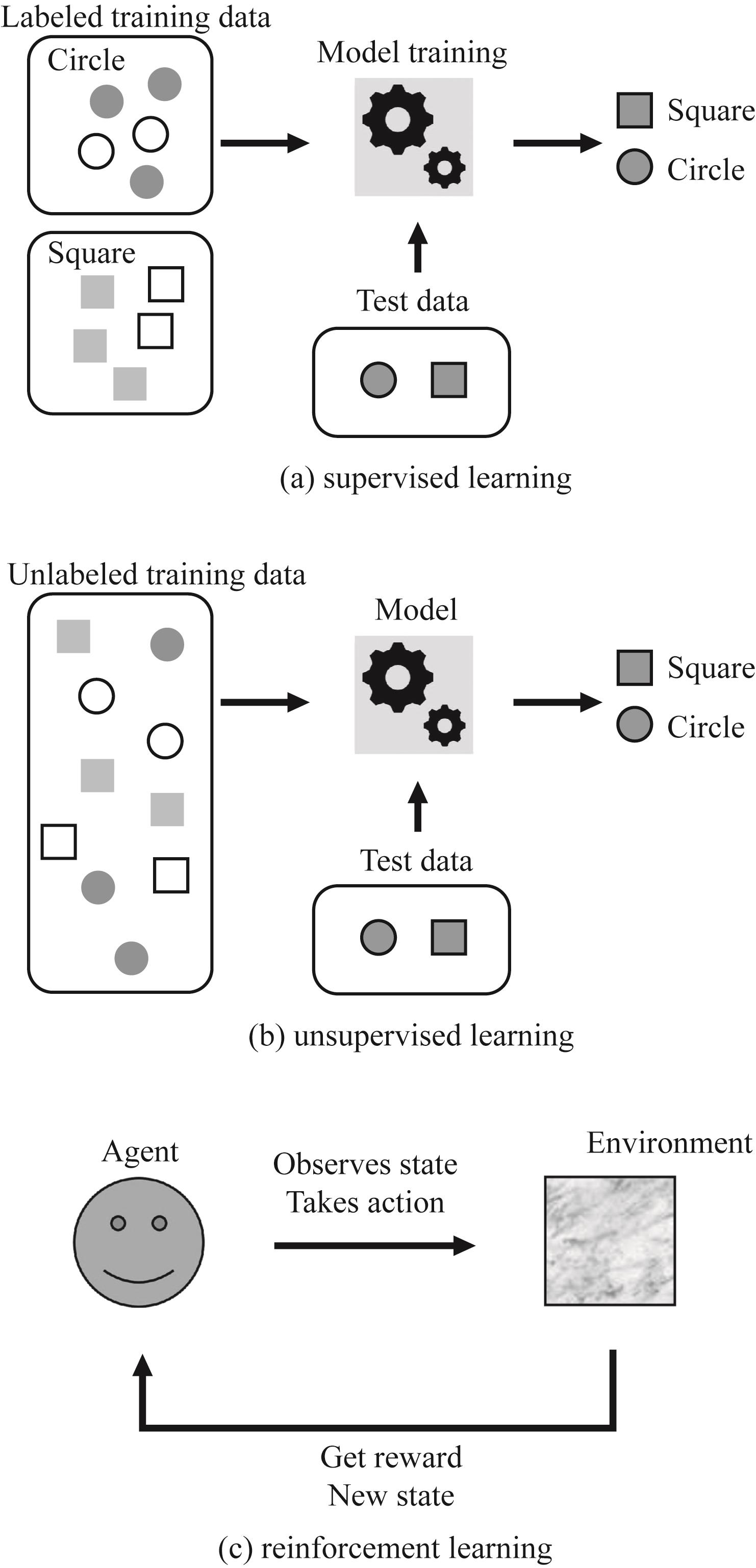

图4 监督学习(a)、无监督学习(b)和强化学习(c)图示[29]

Fig.4 Graphical representations of supervised learning (a), unsupervised learning (b) and reinforcement learning (c)[29]

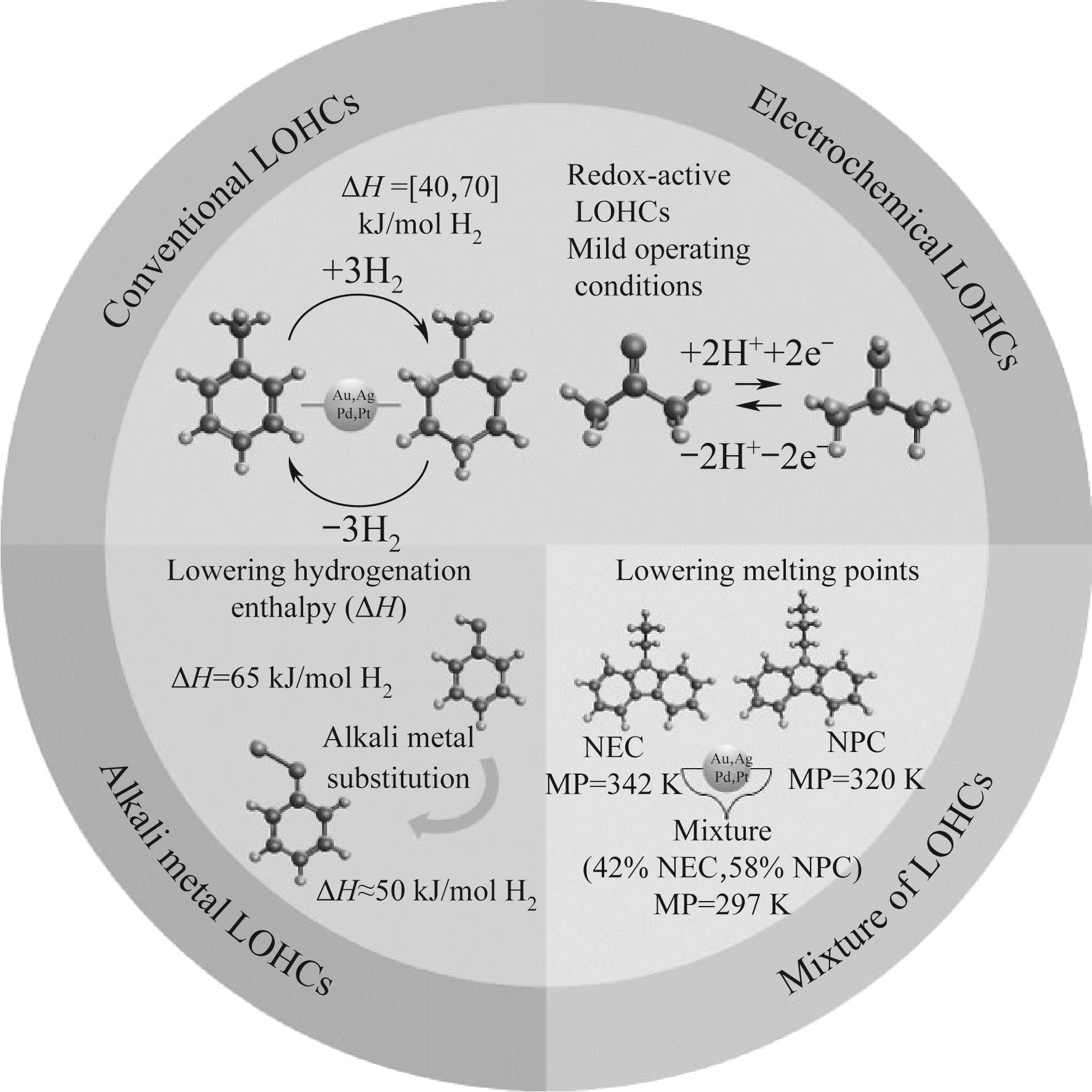

图7 4类液态LOHCs分子:常规、电化学、碱金属和LOHCs混合物(MP代表熔点,ΔH是脱氢焓)[44]

Fig.7 Four categories of LOHCs molecules: conventional, electrochemical, alkali metal and mixtures of LOHCs(MP stands for melting point, ΔH is dehydrogenation enthalpy)[44]

| 储氢体系 | 目标值 | 特征值 | 最优ML模型 | 精度 |

|---|---|---|---|---|

| 甲酸[ | 甲酸在M@g-C3N4上的吸附能 | M—N键长、电荷转移量、M-g-C3N4内聚能、金属原子d带中心、电负性、电子亲和力、第一电离能、共价半径、荣格半径、d轨道电子数和原子序数等 | GBR模型 | 训练集R2=1,RMSE=0.00 eV;测试集R2=0.92,RMSE=0.07 eV |

| 甲醇 | 筛选催化剂[ | 原子序数、原子量、电负性、电离能、电子亲和能、原子半径、离子半径、氧化态、电子构型、价电子数、金属性、非金属性、电导率、热导率、硬度、熔点、沸点、密度、磁性等 | PMC-IGM模型 | 准确率61%,兰德指数97% |

| Cu/ZnO/Al₂O₃的铜表面积[ | Cu/Zn、Al%、老化时间、老化温度、pH、沉淀剂、煅烧时间、煅烧温度等 | RF分类模型 | 训练集准确率90.0%,测试集准确率94.7% | |

| MCH[ | 脱氢中间体的吸附能 | 配位数、内聚能、电负性以及所有不饱和碳与其最近的金属原子之间的平均键长(d̅C—Pt/M) | GPR模型 | 训练集MAE=0.05 eV,验证集MAE=0.13 eV,测试集MAE=0.12 eV |

| 12H-NECZ[ | 反应的Gibbs自由能 | 各种二维和三维描述符,包括OpenBabel 描述符、库仑矩阵、Bag of bonds、Fractional buried volumes等 | 深度神经网络 | — |

表1 ML助力催化剂设计案例综合

Table 1 Comprehensive cases of ML assisting catalyst design

| 储氢体系 | 目标值 | 特征值 | 最优ML模型 | 精度 |

|---|---|---|---|---|

| 甲酸[ | 甲酸在M@g-C3N4上的吸附能 | M—N键长、电荷转移量、M-g-C3N4内聚能、金属原子d带中心、电负性、电子亲和力、第一电离能、共价半径、荣格半径、d轨道电子数和原子序数等 | GBR模型 | 训练集R2=1,RMSE=0.00 eV;测试集R2=0.92,RMSE=0.07 eV |

| 甲醇 | 筛选催化剂[ | 原子序数、原子量、电负性、电离能、电子亲和能、原子半径、离子半径、氧化态、电子构型、价电子数、金属性、非金属性、电导率、热导率、硬度、熔点、沸点、密度、磁性等 | PMC-IGM模型 | 准确率61%,兰德指数97% |

| Cu/ZnO/Al₂O₃的铜表面积[ | Cu/Zn、Al%、老化时间、老化温度、pH、沉淀剂、煅烧时间、煅烧温度等 | RF分类模型 | 训练集准确率90.0%,测试集准确率94.7% | |

| MCH[ | 脱氢中间体的吸附能 | 配位数、内聚能、电负性以及所有不饱和碳与其最近的金属原子之间的平均键长(d̅C—Pt/M) | GPR模型 | 训练集MAE=0.05 eV,验证集MAE=0.13 eV,测试集MAE=0.12 eV |

| 12H-NECZ[ | 反应的Gibbs自由能 | 各种二维和三维描述符,包括OpenBabel 描述符、库仑矩阵、Bag of bonds、Fractional buried volumes等 | 深度神经网络 | — |

| 储氢体系 | 目标值 | 特征值 | 最优ML模型 | 精度 |

|---|---|---|---|---|

| 甲醇 | 产氢速率[ | 反应条件(GHSV、温度、S/C、O2/C、催化剂质量等)、元素以及元素描述符 | DTR模型 | R2=0.99762 MSE=2.8150×10-7 MAE=4.6309×10-5 |

| 技术性能:氢气产率 | 反应器数量、操作温度、氢气渗透率、膜面积、吹扫气流量、S/C 反应器成本、压缩机成本、人工成本、反应物成本、天然气成本、电力成本 | DTR | RMSE=0.00132 | |

| 环境性能:二氧化碳排放率 | SVR、DTR、GPR | 均能较好地拟合数据 | ||

| 经济性能:单位氢气生产成本[ | GPR | |||

| CH3OH转化率和H2产率[ | 进料气体温度、S/C和Reynolds数等 | 基于反向传播网络的神经网络(NN)模型 | H₂产率和CH₃OH转化率的预测误差分别为0.206%和1.004% | |

| 甲酸[ | 甲酸转化率 | 温度、时间、甲酸浓度、催化剂尺寸、催化剂质量、甲酸钠浓度和溶液体积等 | ET模型 | RMSE=3.16,R2=0.97,MAE=0.75 |

| DBT/H18-DBT | DBT储氢能力预测 | 各种反应参数(如底物、催化剂、试剂、添加剂、溶剂、浓度、温度以及反应器类型等) | ① HSP-SVM模型[ ② HSPS-WFML模型[ ③ HSPSML模型[ | ① HV方法准确率97.0% ② 总体准确率96.40%,误分类率3.60% ③ BR和SCG准确率均为98.70% |

| H18-DBT脱氢反应[ | 温度、压力、催化剂用量、搅拌速率和反应物浓度等 | HPPSML模型 | 整体准确率89.80% |

表2 ML助力反应条件优化案例综合

Table 2 Comprehensive cases of ML assisting reaction condition optimization

| 储氢体系 | 目标值 | 特征值 | 最优ML模型 | 精度 |

|---|---|---|---|---|

| 甲醇 | 产氢速率[ | 反应条件(GHSV、温度、S/C、O2/C、催化剂质量等)、元素以及元素描述符 | DTR模型 | R2=0.99762 MSE=2.8150×10-7 MAE=4.6309×10-5 |

| 技术性能:氢气产率 | 反应器数量、操作温度、氢气渗透率、膜面积、吹扫气流量、S/C 反应器成本、压缩机成本、人工成本、反应物成本、天然气成本、电力成本 | DTR | RMSE=0.00132 | |

| 环境性能:二氧化碳排放率 | SVR、DTR、GPR | 均能较好地拟合数据 | ||

| 经济性能:单位氢气生产成本[ | GPR | |||

| CH3OH转化率和H2产率[ | 进料气体温度、S/C和Reynolds数等 | 基于反向传播网络的神经网络(NN)模型 | H₂产率和CH₃OH转化率的预测误差分别为0.206%和1.004% | |

| 甲酸[ | 甲酸转化率 | 温度、时间、甲酸浓度、催化剂尺寸、催化剂质量、甲酸钠浓度和溶液体积等 | ET模型 | RMSE=3.16,R2=0.97,MAE=0.75 |

| DBT/H18-DBT | DBT储氢能力预测 | 各种反应参数(如底物、催化剂、试剂、添加剂、溶剂、浓度、温度以及反应器类型等) | ① HSP-SVM模型[ ② HSPS-WFML模型[ ③ HSPSML模型[ | ① HV方法准确率97.0% ② 总体准确率96.40%,误分类率3.60% ③ BR和SCG准确率均为98.70% |

| H18-DBT脱氢反应[ | 温度、压力、催化剂用量、搅拌速率和反应物浓度等 | HPPSML模型 | 整体准确率89.80% |

| [1] | Olhoff A, Bataille C. Emissions Gap Report 2024: No more hot air … please! With a massive gap between rhetoric and reality, countries draft new climate commitments[R]. Nairobi: United Nations Environment Programme, 2024. |

| [2] | Kearney A T. 2024 statistical review of world energy[R]. London: Energy Institute, 2024. |

| [3] | Sun J C, Shang H, Miao C, et al. Microwave enhanced hydrogen production from liquid organic hydrogen carriers: a review[J]. Chemical Engineering and Processing - Process Intensification, 2023, 190: 109432. |

| [4] | 舟丹. 氢能将成为我国深度脱碳的关键选择[J]. 中外能源, 2025, 30(1): 37. |

| Zhou D. Hydrogen energy will become the key choice for deep decarbonization in China[J]. Sino-Global Energy, 2025, 30(1): 37. | |

| [5] | 张丝钰, 张宁, 卢静, 等. 绿氢示范项目模式分析与发展展望[J]. 南方能源建设, 2023, 10(3): 89-96. |

| Zhang S Y, Zhang N, Lu J, et al. Analysis and development outlook on the typical modes of green hydrogen projects[J]. Southern Energy Construction, 2023, 10(3): 89-96. | |

| [6] | Hren R, Vujanović A, Van Fan Y, et al. Hydrogen production, storage and transport for renewable energy and chemicals: an environmental footprint assessment[J]. Renewable and Sustainable Energy Reviews, 2023, 173: 113113. |

| [7] | Muhammed N S, Gbadamosi A O, Epelle E I, et al. Hydrogen production, transportation, utilization, and storage: recent advances towards sustainable energy[J]. Journal of Energy Storage, 2023, 73: 109207. |

| [8] | 刘若璐, 汤海波, 罗凤盈, 等. 液态有机储氢技术应用与展望[J]. 现代化工, 2025, 45(2): 47-51, 56. |

| Liu R L, Tang H B, Luo F Y, et al. Application and prospect of liquid organics hydrogen storage technology[J]. Modern Chemical Industry, 2025, 45(2): 47-51, 56. | |

| [9] | Chu C Y, Wu K, Luo B B, et al. Hydrogen storage by liquid organic hydrogen carriers: catalyst, renewable carrier, and technology — a review[J]. Carbon Resources Conversion, 2023, 6(4): 334-351. |

| [10] | Munyentwali A, Tan K C, He T. Advancements in the development of liquid organic hydrogen carrier systems and their applications in the hydrogen economy[J]. Progress in Natural Science: Materials International, 2024, 34(5): 825-839. |

| [11] | Gemechu D N, Mohammed A M, Redi M, et al. First principles-based approaches for catalytic activity on the dehydrogenation of liquid organic hydrogen carriers: a review[J]. International Journal of Hydrogen Energy, 2023, 48(85): 33186-33206. |

| [12] | Ugwu L I, Morgan Y, Ibrahim H. Application of density functional theory and machine learning in heterogenous-based catalytic reactions for hydrogen production[J]. International Journal of Hydrogen Energy, 2022, 47(4): 2245-2267. |

| [13] | Cao Y J, Wang B J, Fan M H, et al. DFT calculations and machine learning for the study of ethane dehydrogenation on the heteroatom-doped graphene supported Pt SACs[J]. Chemical Engineering Science, 2025, 305: 121169. |

| [14] | Ding Y, Shang H, Yang C Z, et al. Identifying efficient and inexpensive hydrodesulfurization catalysts through machine learning-assisted analysis of metal-sulfur bonds in transition metal sulfides[J]. Chemical Engineering Science, 2024, 298: 120337. |

| [15] | Verma A, Wilson N, Joshi K. Solid state hydrogen storage: decoding the path through machine learning[J]. International Journal of Hydrogen Energy, 2024, 50: 1518-1528. |

| [16] | Salehi K, Rahmani M, Atashrouz S. Machine learning assisted predictions for hydrogen storage in metal-organic frameworks[J]. International Journal of Hydrogen Energy, 2023, 48(85): 33260-33275. |

| [17] | Jia Z P, Lu S, Song P, et al. Machine learning accelerates design of bilayer-modified graphene hydrogen storage materials[J]. Separation and Purification Technology, 2025, 352: 128229. |

| [18] | Abdul Jameel A G, Al-Muslem A, Ahmad N, et al. Predicting enthalpy of combustion using machine learning[J]. Processes, 2022, 10(11): 2384. |

| [19] | Lu Z L, Wang J W, Wu Y F, et al. Prediction and theoretical investigation of dehydrogenation enthalpy of V-Ti-Cr-Fe alloy using machine learning and density functional theory[J]. International Journal of Hydrogen Energy, 2024, 50: 379-389. |

| [20] | Ali A, Khan M A, Choi H. Supervised machine learning-based prediction of hydrogen storage classes utilizing dibenzyltoluene as an organic carrier[J]. Molecules, 2024, 29(6): 1280. |

| [21] | Zhang X, Zheng Q R, He H Z. Machine-learning-based prediction of hydrogen adsorption capacity at varied temperatures and pressures for MOFs adsorbents[J]. Journal of the Taiwan Institute of Chemical Engineers, 2022, 138: 104479. |

| [22] | Peng C C, Liu X Y, Long R, et al. Performance optimization of adsorption hydrogen storage system via computation fluid dynamics and machine learning[J]. Chemical Engineering Research and Design, 2024, 207: 100-109. |

| [23] | Lu Z L, Wang J W, Wu Y F, et al. Predicting hydrogen storage capacity of V-Ti-Cr-Fe alloy via ensemble machine learning[J]. International Journal of Hydrogen Energy, 2022, 47(81): 34583-34593. |

| [24] | Huang P R, Cai D, Lin H Z, et al. Materials genome engineering-based hydrogen storage materialsdatabase and its applications[J]. Scientia Sinica Chimica, 2022, 52(10): 1863-1870. |

| [25] | Allal Z, Noura H N, Salman O, et al. A review on machine learning applications in hydrogen energy systems[J]. International Journal of Thermofluids, 2025, 26: 101119. |

| [26] | 吴铮, 李全安, 陈晓亚, 等. 机器学习在镁合金应用中的研究进展[J]. 工程科学学报, 2024, 46(10): 1797-1811. |

| Wu Z, Li Q A, Chen X Y, et al. Applications of machine learning on magnesium alloys[J]. Chinese Journal of Engineering, 2024, 46(10): 1797-1811. | |

| [27] | 文一如, 付佳, 刘大欢. 基于机器学习的MOFs材料研究进展: 能源气体吸附分离[J]. 化工学报, 2024, 75(4): 1370-1381. |

| Wen Y R, Fu J, Liu D H. Advances in machine learning-based materials research for MOFs: energy gas adsorption separation[J]. CIESC Journal, 2024, 75(4): 1370-1381. | |

| [28] | Zhou P P, Zhou Q W, Xiao X Z, et al. Machine learning in solid-state hydrogen storage materials: challenges and perspectives[J]. Advanced Materials, 2025, 37(6): 2413430. |

| [29] | Gombolay G Y, Gopalan N, Bernasconi A, et al. Review of machine learning and artificial intelligence (ML/AI) for the pediatric neurologist[J]. Pediatric Neurology, 2023, 141: 42-51. |

| [30] | Yang Z, Gao W. Applications of machine learning in alloy catalysts: rational selection and future development of descriptors[J]. Advanced Science, 2022, 9(12): 2106043. |

| [31] | Moosaei H, Ganaie M A, Hladík M, et al. Inverse free reduced universum twin support vector machine for imbalanced data classification[J]. Neural Networks, 2023, 157: 125-135. |

| [32] | Gao W, Xu F, Zhou Z H. Towards convergence rate analysis of random forests for classification[J]. Artificial Intelligence, 2022, 313: 103788. |

| [33] | Dong M H, Ma R, Sun G C, et al. Size distribution of pores and their geometric analysis in red mud-based autoclaved aerated concrete (AAC) using regression neural network and elastic mechanics[J]. Construction and Building Materials, 2022, 359: 129420. |

| [34] | Liu W, Zou P, Jiang D G, et al. Zoning of reservoir water temperature field based on K-means clustering algorithm[J]. Journal of Hydrology: Regional Studies, 2022, 44: 101239. |

| [35] | Chen H R, Li J H, Gao J B, et al. Maximally correlated principal component analysis based on deep parameterization learning[J]. ACM Transactions on Knowledge Discovery from Data, 2019, 13(4): 1-17. |

| [36] | 杨凯博, 钟铭恩, 谭佳威, 等. 基于半监督学习的多场景火灾小规模稀薄烟雾检测[J]. 浙江大学学报(工学版), 2025, 59(3): 546-556, 565. |

| Yang K B, Zhong M E, Tan J W, et al. Small-scale sparse smoke detection in multiple fire scenarios based on semi-supervised learning[J]. Journal of Zhejiang University (Engineering Science), 2025, 59(3): 546-556, 565. | |

| [37] | 马幼捷, 刘熠铭, 周雪松, 等. 微网储能侧DC-DC变换器的强化学习自抗扰控制策略[J]. 太阳能学报, 2025, 46(3): 63-72. |

| Ma Y J, Liu Y M, Zhou X S, et al. Reinforcement learning active disturbance rejection control strategy for microgrid energy storage side DC-DC converter[J]. Acta Energiae Solaris Sinica, 2025, 46(3): 63-72. | |

| [38] | Pedregosa F, Varoquaux G, Gramfort A, et al. Scikit-Learn: machine learning in python[J]. Journal of Machine Learning Research, 2011, 12: 2825-2830. |

| [39] | Abadi M, Agarwal A, Barham P, et al. TensorFlow: large-scale machine learning on heterogeneous distributed systems[J]. arXiv, 2016: 1603.04467. |

| [40] | Fang J H, Xie M, He X Q, et al. Machine learning accelerates the materials discovery[J]. Materials Today Communications, 2022, 33: 104900. |

| [41] | D'Ambra F, Gébel G. Literature review: state-of-the-art hydrogen storage technologies and liquid organic hydrogen carrier (LOHC) development[J]. Science and Technology for Energy Transition, 2023, 78: 32. |

| [42] | Han L, Pei Q J, Tan K C, et al. Photothermal catalytic dehydrogenation of methylcyclohexane at ambient temperature for hydrogen storage[J]. International Journal of Hydrogen Energy, 2025, 102: 163-170. |

| [43] | 李文达, 王凤丽, 赵俊哲, 等. Pt/NiAl层状双金属氢氧化物载体催化剂上十氢萘产氢性能[J]. 石油化工, 2025, 54(2): 151-160. |

| Li W D, Wang F L, Zhao J Z, et al. Hydrogen production performance of decalin over Pt/NiAl layered double hydroxide-based supported catalyst[J]. Petrochemical Technology, 2025, 54(2): 151-160. | |

| [44] | Harb H, Elliott S N, Ward L, et al. Accurate dehydrogenation enthalpies dataset for liquid organic hydrogen carriers[J]. Scientific Data, 2025, 12(1): 171. |

| [45] | Paragian K, Li B W, Massino M, et al. A computational workflow to discover novel liquid organic hydrogen carriers and their dehydrogenation routes[J]. Molecular Systems Design & Engineering, 2020, 5(10): 1658-1670. |

| [46] | 刘焕. 甲酸脱氢催化剂的研究进展[J]. 四川化工, 2024, 27(5): 26-30. |

| Liu H. Research progress of formic acid dehydrogenation catalysts[J]. Sichuan Chemical Industry, 2024, 27(5): 26-30. | |

| [47] | Li H M, Gui Y, Zhang J H, et al. Simultaneous alkali/air activation for hierarchical pore development in biochar and its use as catalyst carrier for formic acid dehydrogenation[J]. Biomass and Bioenergy, 2025, 193: 107549. |

| [48] | Berfin Ekin Ü, Coşkuner Filiz B, Açıkalın K, et al. Boron-based hydrogen storage materials for highly selective hydrogenation to liquid organic hydrogen carriers synthesis focus on formic acid[J]. International Journal of Hydrogen Energy, 2024: 12.237. |

| [49] | Gao X, Yang Y Y, Yang S, et al. Production of CO-free H2 through aqueous formic acid dehydrogenation over the α-Mo2C/NC catalyst[J]. Chemical Engineering Journal, 2024, 500: 156933. |

| [50] | Zhao X M, Wang L, Pei Y. Single metal atom catalyst supported on g-C3N4 for formic acid dehydrogenation: a combining density functional theory and machine learning study[J]. The Journal of Physical Chemistry C, 2021, 125(41): 22513-22521. |

| [51] | Lu H, Zhong Y, Jie Y, et al. DFT study on the mechanism of methanol dehydrogenation over Ru x P y surfaces[J]. Physical Chemistry Chemical Physics, 2024, 26(42): 26900-26910. |

| [52] | Thirumalesh B S, Asapu D R. State of the art of methanol reforming for hydrogen generation[J]. ChemBioEng Reviews, 2024, 11(3): 543-554. |

| [53] | 廖逸飞, 商辉, 杨捷, 等. 甲醇液相重整制氢研究进展[J]. 现代化工, 2024, 44(1): 78-82. |

| Liao Y F, Shang H, Yang J, et al. Advances on hydrogen production through liquid phase methanol reforming[J]. Modern Chemical Industry, 2024, 44(1): 78-82. | |

| [54] | Liu Y J, Liang Z W, Huang J Z, et al. Screening of steam-reforming catalysts using unsupervised machine learning[J]. Catalysis Science & Technology, 2023, 13(21): 6281-6290. |

| [55] | Saffary S, Rafiee M, Varnoosfaderani M S, et al. Smart paradigm to predict copper surface area of Cu/ZnO/Al2O3 catalyst based on synthesis parameters[J]. Chemical Engineering Research and Design, 2023, 191: 604-616. |

| [56] | Lin C H, Lee B C S, Anjum U, et al. Harnessing physics-inspired machine learning to design nanocluster catalysts for dehydrogenating liquid organic hydrogen carriers[J]. Applied Catalysis B: Environment and Energy, 2025, 371: 125192. |

| [57] | Dong C Y, Gao Z R, Li Y L, et al. Fully exposed palladium cluster catalysts enable hydrogen production from nitrogen heterocycles[J]. Nature Catalysis, 2022, 5: 485-493. |

| [58] | Zhou W H, Li X X, Chen C, et al. Sn modified carbon support PdCo bimetallic oxide for boosting low-temperature dehydrogenation of dodecahydro-N-ethylcarbazole[J]. Fuel, 2025, 382: 133718. |

| [59] | Permude P, Tang C G, Ahmad A, et al. Effective catalysts for typical liquid organic hydrogen carrier N-ethylcarbazole[J]. International Journal of Hydrogen Energy, 2025, 98: 1492-1509. |

| [60] | Vishwakarma G, Hachmann J. Liquid organic hydrogen carriers: high-throughput screening of homogeneous catalysts[J]. ChemRxiv, 2023: s8pkf. |

| [61] | Liang Z W, Huang J Z, Zhong B Q, et al. Unveiling feature importance in methanol reforming systems through the machine learning[J]. Industrial & Engineering Chemistry Research, 2024, 63(32): 14104-14114. |

| [62] | Byun M, Lee H, Choe C, et al. Machine learning based predictive model for methanol steam reforming with technical, environmental, and economic perspectives[J]. Chemical Engineering Journal, 2021, 426: 131639. |

| [63] | Chen W H, Chen Z Y, Hsu S Y, et al. Reactor design of methanol steam reforming by evolutionary computation and hydrogen production maximization by machine learning[J]. International Journal of Energy Research, 2022, 46(14): 20685-20703. |

| [64] | Tazikeh S, Davoudi A, Zendehboudi S, et al. Predicting hydrogen production from formic acid dehydrogenation using smart connectionist models[J]. International Journal of Hydrogen Energy, 2025, 109: 574-590. |

| [65] | Xu M K, Gao R J, Shi C X, et al. Study on the dehydrogenation of perhydro-dibenzyltoluene catalyzed by Pt/Al2O3 in a fixed bed reactor[J]. Chemical Engineering Science, 2024, 287: 119754. |

| [66] | Ali A, G U K, Lee H J. Parametric study of the hydrogenation of dibenzyltoluene and its dehydrogenation performance as a liquid organic hydrogen carrier[J]. Journal of Mechanical Science and Technology, 2020, 34(7): 3069-3077. |

| [67] | Ali A, Kumar G U, Lee H J. Investigation of hydrogenation of dibenzyltoluene as liquid organic hydrogen carrier[J]. Materials Today: Proceedings, 2021, 45: 1123-1127. |

| [68] | Ali A, Rohini A K, Lee H J. Dehydrogenation of perhydro-dibenzyltoluene for hydrogen production in a microchannel reactor[J]. International Journal of Hydrogen Energy, 2022, 47(48): 20905-20914. |

| [69] | Ali A, Khan M A, Choi H. Hydrogen storage prediction in dibenzyltoluene as liquid organic hydrogen carrier empowered with weighted federated machine learning[J]. Mathematics, 2022, 10(20): 3846. |

| [70] | Ali A, Khan M A, Abbas N, et al. Prediction of hydrogen storage in dibenzyltoluene empowered with machine learning[J]. Journal of Energy Storage, 2022, 55: 105844. |

| [71] | Ali A, Khan M A, Choi H. Prediction of hydrogen generation from perhydro-dibenzyltoluene empowered with machine learning[J]. International Journal of Hydrogen Energy, 2024, 51: 171-178. |

| [1] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [2] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [3] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [4] | 冯彪, 张昭, 李思琪, 王秉睿, 吴红颖, 史淼, 王丹, 马素霞. 适配环保制冷剂R290的阻燃剂性能研究[J]. 化工学报, 2025, 76(S1): 462-468. |

| [5] | 周奕彤, 周明熙, 刘若晨, 叶爽, 黄伟光. 光伏与电网协同驱动氢基直接还原铁炼钢的技术经济分析[J]. 化工学报, 2025, 76(8): 4318-4330. |

| [6] | 杨宁, 李皓男, LIN Xiao, GEORGIADOU Stella, LIN Wen-Feng. 从塑料废弃物到能源催化剂:塑料衍生碳@CoMoO4复合材料在电解水析氢反应中的应用[J]. 化工学报, 2025, 76(8): 4081-4094. |

| [7] | 陈治宏, 吴佳伟, 楼小玲, 贠军贤. 化学品生物制造过程机器学习的研究进展[J]. 化工学报, 2025, 76(8): 3789-3804. |

| [8] | 李科, 谢昊琳, 文键. 耦合多重蒸气冷却屏的液氢储罐绝热性能的多目标遗传算法优化[J]. 化工学报, 2025, 76(8): 4217-4227. |

| [9] | 高正, 汪辉, 屈治国. 数据驱动辅助高通量筛选阴离子柱撑金属有机框架储氢[J]. 化工学报, 2025, 76(8): 4259-4272. |

| [10] | 王御风, 罗小雪, 范鸿亮, 吴白婧, 李存璞, 魏子栋. 耦合电解水制氢的绿色有机电合成——电极界面调控策略综述[J]. 化工学报, 2025, 76(8): 3753-3771. |

| [11] | 吴小龙, 黄晓璜, 肖媛, 单灵海, 叶家慧, 崔国民. 一种预留节点策略应用于换热网络优化[J]. 化工学报, 2025, 76(7): 3388-3402. |

| [12] | 杨鹏, 尤万里, 凌忠钱, 曾宪阳, 李允超, 林佳一, 王丽建, 袁定琨. 紧凑式三室RTO系统处理乙酸乙酯废气性能的实验研究[J]. 化工学报, 2025, 76(7): 3585-3595. |

| [13] | 陈佳祥, 周伟, 张学伟, 王丽杰, 黄玉明, 于洋, 孙苗婷, 李宛静, 袁骏舒, 张宏博, 孟晓晓, 高继慧, 赵广播. 脉冲电压下二维PEMWE模型的制氢特性仿真研究[J]. 化工学报, 2025, 76(7): 3521-3530. |

| [14] | 陈宇航, 陈金国, 陈炜毅, 王康, 郑昊, 韩昌亮. 沉浸式气化器烟气分布器布气性能与多目标参数优化[J]. 化工学报, 2025, 76(7): 3274-3285. |

| [15] | 王涛, 李光明, 胡秋霞, 徐静. 基于时序演变粒子群算法的双色注射产品翘曲工艺优化[J]. 化工学报, 2025, 76(7): 3403-3415. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号