化工学报 ›› 2025, Vol. 76 ›› Issue (10): 5067-5075.DOI: 10.11949/0438-1157.20250369

李勋新1( ), 徐惠斌1,2(

), 徐惠斌1,2( ), 马驰1, 王威宇1, 彭飞子1

), 马驰1, 王威宇1, 彭飞子1

收稿日期:2025-04-09

修回日期:2025-05-05

出版日期:2025-10-25

发布日期:2025-11-25

通讯作者:

徐惠斌

作者简介:李勋新(1996—),男,硕士研究生,m18860873892@163.com

基金资助:

Xunxin LI1( ), Huibin XU1,2(

), Huibin XU1,2( ), Chi MA1, Weiyu WANG1, Feizi PENG1

), Chi MA1, Weiyu WANG1, Feizi PENG1

Received:2025-04-09

Revised:2025-05-05

Online:2025-10-25

Published:2025-11-25

Contact:

Huibin XU

摘要:

外热式回转窑因其具有加热均匀、温度控制精准、节能环保等优点,在锂电池负极人造石墨制备关键环节石油焦碳化工艺中具有良好的应用前景。对石油焦碳化过程中回转窑壁床换热性能规律的认识不足,制约了该类回转窑的精准设计及节能低碳运行。利用电加热回转窑实验系统,研究了操作参数对石油焦、石英砂颗粒壁床传热系数的影响。结果表明:随着填充率的增加,石英砂和石油焦颗粒的壁床传热系数出现不同程度的下降;提高转速可以使石英砂颗粒壁床传热系数得到显著提升,但对石油焦颗粒强化传热作用有限,主要原因在于石英砂颗粒呈滚动运动,而石油焦颗粒呈滑动运动;滑动运动的壁床传热系数远低于滚动运动,炉体内壁设置肋带可以使石油焦颗粒床发生规律混合,从而强化传热70%~180%。

中图分类号:

李勋新, 徐惠斌, 马驰, 王威宇, 彭飞子. 外热式回转窑颗粒运动传热实验研究[J]. 化工学报, 2025, 76(10): 5067-5075.

Xunxin LI, Huibin XU, Chi MA, Weiyu WANG, Feizi PENG. Experimental study of particle motion and heat transfer in externally heated rotary kiln[J]. CIESC Journal, 2025, 76(10): 5067-5075.

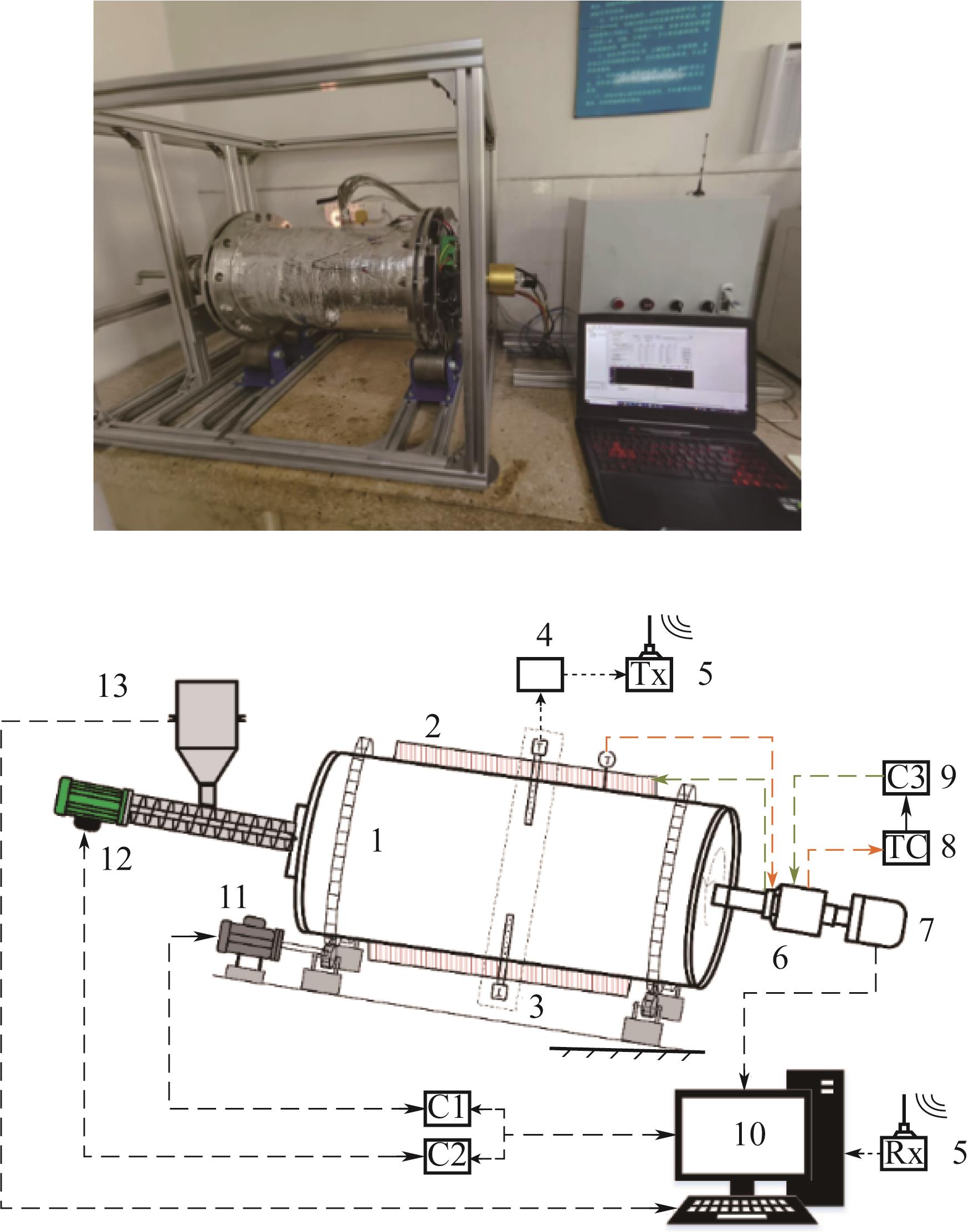

图1 电加热回转窑实验系统1—不锈钢炉体;2—加热电缆;3—温度测量板;4—数据采集卡;5—Lora无线传输模块(发送模块和接收模块);6—导电滑环;7—角度编码器;8—温控仪;9—加热电缆控制器;10—计算机;11—减速电机;12—螺旋给料器;13—称重传感器)

Fig.1 Experimental system of electrically heated rotary kiln1—stainless steel cylinder; 2—heating cable; 3—temperature measurement board; 4—data acquisition card; 5—Lora wireless transmission module(transmitter module and receiver module); 6—conductive slip ring; 7—angle encoder; 8—temperature controller; 9—heating cable controller; 10—computer; 11—reducer motor; 12—screw feeder; 13—mass sensor

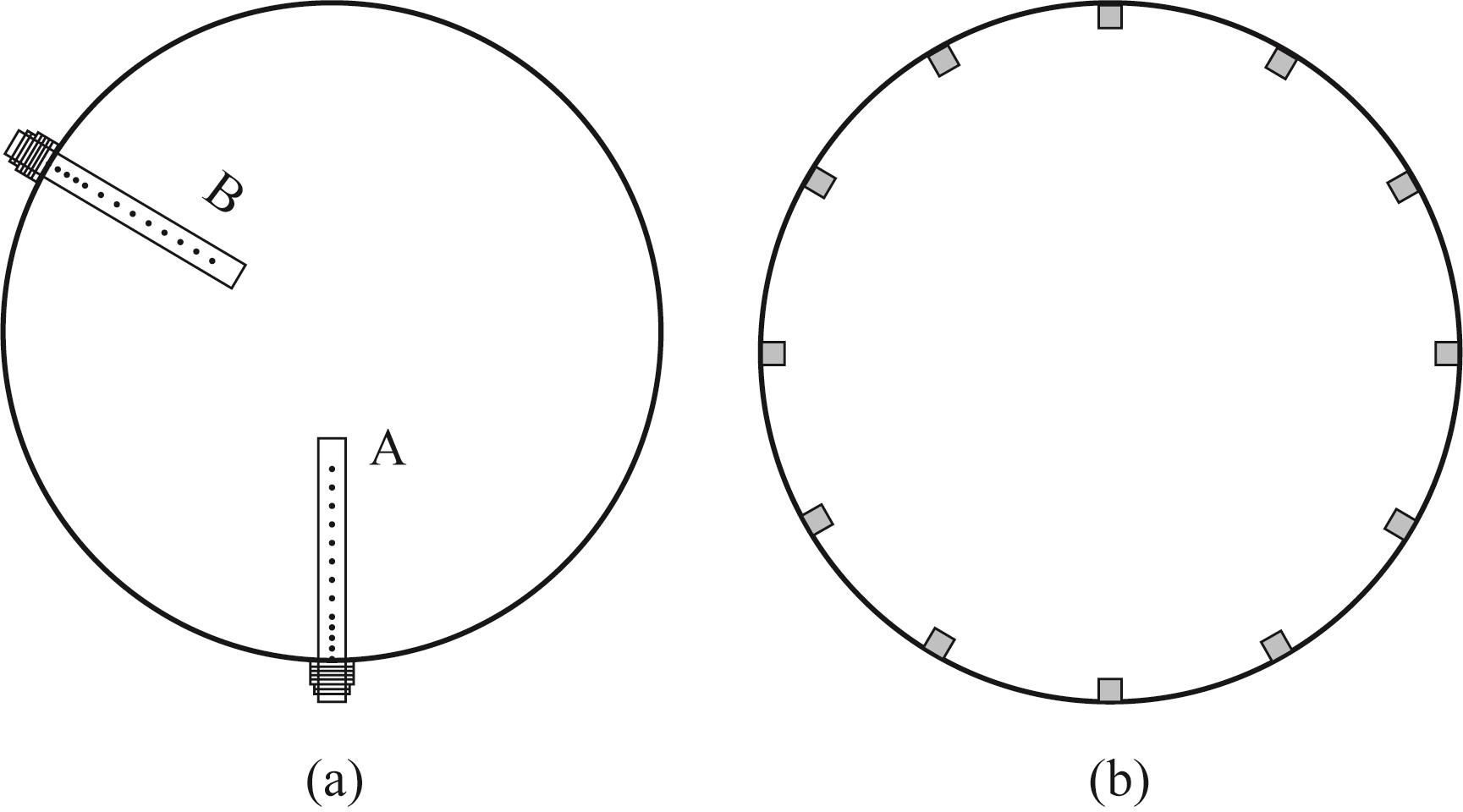

图2 (a) 炉内测温薄板布置示意图;(b) 12条不锈钢肋带布置示意图

Fig.2 (a) Schematic layout of temperature measuring plate in the furnace; (b) Schematic layout of 12 stainless steel strips

| 物性及工况参数 | 石英砂 | 石油焦 |

|---|---|---|

| 颗粒粒径D10/μm | 269 | 2.8 |

| 颗粒粒径D50/μm | 400 | 6.1 |

| 颗粒粒径D90/μm | 584 | 13.1 |

| 20℃物料堆积密度ρs/(kg/m3) | 1369 | 535 |

| 转速n/(r/min) | 1,2,3,4 | 1,2,3,4 |

| 填充率F/% | 5,10,15,20 | 5,10,15,20 |

表1 物料物性及实验工况参数

Table 1 Material properties and experimental working condition parameters

| 物性及工况参数 | 石英砂 | 石油焦 |

|---|---|---|

| 颗粒粒径D10/μm | 269 | 2.8 |

| 颗粒粒径D50/μm | 400 | 6.1 |

| 颗粒粒径D90/μm | 584 | 13.1 |

| 20℃物料堆积密度ρs/(kg/m3) | 1369 | 535 |

| 转速n/(r/min) | 1,2,3,4 | 1,2,3,4 |

| 填充率F/% | 5,10,15,20 | 5,10,15,20 |

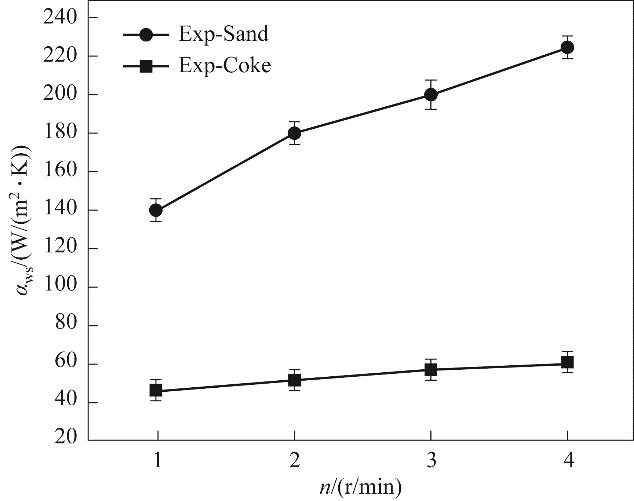

图6 转速对石英砂和石油焦壁床传热系数的影响(F=5%,Ts,m=40℃)

Fig.6 Effect of rotational speed on wall-bed heat transfer coefficient of quartz sand and petroleum coke (F=5%,Ts,m=40℃)

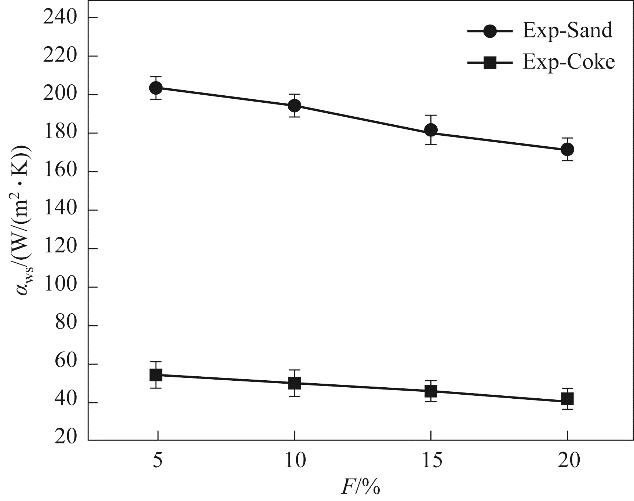

图7 填充率对石英砂和石油焦壁床传热系数的影响(n=3 r/min,Ts,m=40℃)

Fig.7 Effect of filling rate on wall-bed heat transfer coefficient of quartz sand and petroleum coke(n=3 r/min,Ts,m=40℃)

| 文献 | 经验关系式 |

|---|---|

| [ | |

| [ | |

| [ | |

| [ | |

| [ |

表2 壁床换热关系式

Table 2 Wall-bed heat transfer relational model

| 文献 | 经验关系式 |

|---|---|

| [ | |

| [ | |

| [ | |

| [ | |

| [ |

| [1] | Zhang Y T, Ji G Z, Chen C S, et al. Liquid oils produced from pyrolysis of plastic wastes with heat carrier in rotary kiln[J]. Fuel Processing Technology, 2020, 206: 106455. |

| [2] | Bahhou A, Taha Y, Hakkou R, et al. Evaluating rotary and static calcination processes for montmorillonite marl: pozzolanic properties, compressive strength, and cementitious paste characteristics[J]. Applied Clay Science, 2024, 258: 107501. |

| [3] | Wang K C, Xu S P. Preparation of high specific surface area activated carbon from petroleum coke by KOH activation in a rotary kiln[J]. Processes, 2024, 12(2): 241. |

| [4] | Heo J, Baek S, Kurniawan K, et al. Optimizing rotary kiln operations for molybdenite concentrate oxidation roasting to produce molybdic trioxide[J]. Chemical Engineering Journal Advances, 2024, 20: 100642. |

| [5] | Gu C H, Yuan Z L, Sun S S, et al. Simulation investigation of drying characteristics of wet filamentous biomass particles in a rotary kiln[J]. Fuel Processing Technology, 2018, 178: 344-352. |

| [6] | 王广伟, 刘嘉雯, 李仁国, 等. 回转窑处理固体废弃物的研究进展[J]. 中国冶金, 2023, 33(10): 1-7, 16. |

| Wang G W, Liu J W, Li R G, et al. Research progress of solid waste treatment in rotary kilns[J]. China Metallurgy, 2023, 33(10): 1-7, 16. | |

| [7] | 杨远平, 黄云, 宋民航, 等. 回转窑低阶煤热解提质工艺及应用技术研究进展[J]. 中国电机工程学报, 2025, 45(6): 2251-2264. |

| Yang Y P, Huang Y, Song M H, et al. Research progress on upgrading technologies and applications of low-rank coal pyrolysis in a rotary kiln[J]. Proceedings of the CSEE, 2025, 45(6): 2251-2264. | |

| [8] | Jian Q S, Gu H L, Wang K G, et al. Numerical study of particle behaviours and heat transfer in a complex rotary kiln[J]. Particuology, 2024, 92: 81-94. |

| [9] | 胡义华. 新能源电池正极材料前驱体: 单晶四氧化三锰制备方法研究[J]. 当代化工研究, 2022(21): 174-176. |

| Hu Y H. New energy battery cathode material precursor: study on the preparation method of single crystal manganese tetroxide[J]. Modern Chemical Research, 2022(21): 174-176. | |

| [10] | 杜进桥, 田杰, 李艳. 废旧磷酸铁锂正极片的低温热解工艺研究[J]. 电源技术, 2022, 46(7): 743-747. |

| Du J Q, Tian J, Li Y. Study on roasting process at low temperature of waste LiFePO4 cathode material[J]. Chinese Journal of Power Sources, 2022, 46(7): 743-747. | |

| [11] | Herz F, Mitov I, Specht E, et al. Influence of operational parameters and material properties on the contact heat transfer in rotary kilns[J]. International Journal of Heat and Mass Transfer, 2012, 55(25/26): 7941-7948. |

| [12] | Herz F, Mitov I, Specht E, et al. Influence of the motion behavior on the contact heat transfer between the covered wall and solid bed in rotary kilns[J]. Experimental Heat Transfer, 2015, 28(2): 174-188. |

| [13] | Moumin G, Tescari S, Sattler C. Impact of bed motion on the wall-to-bed heat transfer for powders in a rotary kiln and effect of built-ins[J]. International Journal of Heat and Mass Transfer, 2021, 177: 121473. |

| [14] | Njeng A S B, Vitu S, Clausse M, et al. Wall-to-solid heat transfer coefficient in flighted rotary kilns: experimental determination and modeling[J]. Experimental Thermal and Fluid Science, 2018, 91: 197-213. |

| [15] | Schlünder E U. Heat transfer to packed and stirred beds from the surface of immersed bodies[J]. Chemical Engineering and Processing: Process Intensification, 1984, 18(1): 31-53. |

| [16] | Mellmann J. The transverse motion of solids in rotating cylinders: forms of motion and transition behavior[J]. Powder Technology, 2001, 118(3): 251-270. |

| [17] | Ardalani E, Borghard W G, Glasser B J, et al. Heat transfer of cohesive particles in a rotary drum: effect of material properties and processing conditions[J]. Powder Technology, 2024, 447: 120215. |

| [18] | Chou S H, Hsiau S S, Liu S Y. Experimental study of heat transfer and transport properties of granular material in indirectly heated rotary drums[J]. International Journal of Heat and Mass Transfer, 2025, 238: 126485. |

| [19] | Yin H C, Zhang M, Liu H. Numerical simulation of three-dimensional unsteady granular flows in rotary kiln[J]. Powder Technology, 2014, 253: 138-145. |

| [20] | Bisulandu B R M, Huchet F. Rotary kiln process: an overview of physical mechanisms, models and applications[J]. Applied Thermal Engineering, 2023, 221: 119637. |

| [21] | Wu W N, Liu X Y, Hu Z, et al. Measurement of the local material depth in a directly-heated pilot rotary kiln based on temperature fields[J]. Powder Technology, 2018, 330: 12-18. |

| [22] | Nafsun A I, Herz F. Experiments on the temperature distribution in the solid bed of rotary drums[J]. Applied Thermal Engineering, 2016, 103: 1039-1047. |

| [23] | Sullivan W N, Sabersky R H. Heat transfer to flowing granular media[J]. International Journal of Heat and Mass Transfer, 1975, 18(1): 97-107. |

| [24] | Li S Q, Ma L B, Wan W, et al. A mathematical model of heat transfer in a rotary kiln thermo-reactor[J]. Chemical Engineering & Technology, 2005, 28(12): 1480-1489. |

| [25] | Wachters L. The calcining of sodium bicarbonate in a rotary kiln[C]//Proceedings of 3rd European Symposium Chemical Reaction Engineering. 1964. |

| [26] | Wes G W J, Drinkenburg A A H, Stemerding S. Heat transfer in a horizontal rotary drum reactor[J]. Powder Technology, 1976, 13(2): 185-192. |

| [27] | Tscheng S H, Watkinson A P. Convective heat transfer in a rotary kiln[J]. The Canadian Journal of Chemical Engineering, 1979, 57(4): 433-443. |

| [28] | Xu G G, Zhang Y, Yang X G, et al. Effect of drum structure on particle mixing behavior based on DEM method[J]. Particuology, 2023, 74: 74-91. |

| [29] | Seidenbecher J, Herz F, Specht E, et al. Contact heat transfer analysis in flighted rotary drums[J]. Thermal Science and Engineering Progress, 2024, 47: 102265. |

| [30] | Nafsun A I, Herz F, Specht E, et al. Heat transfer experiments in a rotary drum for a variety of granular materials[J]. Experimental Heat Transfer, 2016, 29(4): 520-535. |

| [31] | Nafsun A I, Herz F. The effect of solid bed dispersity on the contact heat transfer in rotary drums[C]//12th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics. 2016. |

| [32] | Zhang Z, Liu Y L, Zhao X Q, et al. Mixing and heat transfer of granular materials in an externally heated rotary kiln[J]. Chemical Engineering & Technology, 2019, 42(5): 987-995. |

| [33] | Nafsun A I, Herz F, Specht E, et al. Thermal bed mixing in rotary drums for different operational parameters[J]. Chemical Engineering Science, 2017, 160: 346-353. |

| [34] | Seidenbecher J, Herz F, Meitzner C, et al. Experimental analysis of the flight design effect on the temperature distribution in rotary kilns[J]. Chemical Engineering Science, 2021, 240: 116652. |

| [1] | 袁琳慧, 王瑜. 单服务器浸没射流式液冷系统散热性能[J]. 化工学报, 2025, 76(S1): 160-169. |

| [2] | 臧子晴, 李修真, 谈莹莹, 刘晓庆. 分凝器对两级分离自复叠制冷循环特性影响研究[J]. 化工学报, 2025, 76(S1): 17-25. |

| [3] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [4] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [5] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [6] | 李银龙, 刘国强, 晏刚. 分馏与闪蒸分离耦合自复叠制冷循环性能分析[J]. 化工学报, 2025, 76(S1): 26-35. |

| [7] | 孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296. |

| [8] | 刘豪, 王林, 丁昊, 耿嘉怡. R1150+R1234ze(E)二元体系223.15~253.15 K汽液相平衡研究[J]. 化工学报, 2025, 76(S1): 1-8. |

| [9] | 吴馨, 龚建英, 李祥宇, 王宇涛, 杨小龙, 蒋震. 超声波激励疏水表面液滴运动的实验研究[J]. 化工学报, 2025, 76(S1): 133-139. |

| [10] | 杨语晴, 李银龙, 晏刚. 采用低GWP制冷剂的级联加热自复叠高温热泵循环热力学分析[J]. 化工学报, 2025, 76(S1): 43-53. |

| [11] | 冯彪, 张昭, 李思琪, 王秉睿, 吴红颖, 史淼, 王丹, 马素霞. 适配环保制冷剂R290的阻燃剂性能研究[J]. 化工学报, 2025, 76(S1): 462-468. |

| [12] | 任现超, 谷雅秀, 段少斌, 贾文竹, 李汉林. 翅片式椭圆套管蒸发式冷凝器传热传质性能实验研究[J]. 化工学报, 2025, 76(S1): 75-83. |

| [13] | 丁昊, 王林, 刘豪. R290/R245fa汽液相平衡混合规则对比研究[J]. 化工学报, 2025, 76(S1): 9-16. |

| [14] | 郭旭, 贾继宁, 姚克俭. 基于优化CNN-BiLSTM神经网络的间歇精馏过程建模[J]. 化工学报, 2025, 76(9): 4613-4629. |

| [15] | 胡金琦, 闵春华, 李小龙, 范元鸿, 王坤. 振动叶片耦合柔性板强化流体混沌混合与传热研究[J]. 化工学报, 2025, 76(9): 4824-4837. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号