化工学报 ›› 2025, Vol. 76 ›› Issue (10): 5390-5401.DOI: 10.11949/0438-1157.20250367

翟庆伟1( ), 林锦辉2, 李彦锋3, 韩东旭3(

), 林锦辉2, 李彦锋3, 韩东旭3( ), 吴小华3, 王鹏3, 陈宇杰3, 宇波4

), 吴小华3, 王鹏3, 陈宇杰3, 宇波4

收稿日期:2025-04-09

修回日期:2025-05-21

出版日期:2025-10-25

发布日期:2025-11-25

通讯作者:

韩东旭

作者简介:翟庆伟(1993—),男,博士研究生,zhaiqingwei6@163.com

基金资助:

Qingwei ZHAI1( ), Jinhui LIN2, Yanfeng LI3, Dongxu HAN3(

), Jinhui LIN2, Yanfeng LI3, Dongxu HAN3( ), Xiaohua WU3, Peng WANG3, Yujie CHEN3, Bo YU4

), Xiaohua WU3, Peng WANG3, Yujie CHEN3, Bo YU4

Received:2025-04-09

Revised:2025-05-21

Online:2025-10-25

Published:2025-11-25

Contact:

Dongxu HAN

摘要:

为满足70 MPa氢燃料电池汽车加注的需求,液氢加氢站多采用增压汽化工艺,但该工艺对液氢泵要求较高。为推动核心设备国产化,提出了结合45 MPa液氢泵与热压缩的泵-热协同增压系统,以降低液氢泵出口压力,提高系统可行性及国产泵的适配性。基于泵-热协同增压液氢加氢站系统,构建了热力学和㶲分析模型。通过对核心组件、加注过程及全系统的研究,分析了液氢泵、压力容器、换热器和压力控制阀等部件在不同工况下的㶲损及㶲效率。结果表明:液氢泵的㶲效率随着出口温度和压力的增加而降低,45 MPa液氢泵的㶲效率优于90 MPa液氢泵;初始温度和压力对压力容器在泵-热增压过程中的㶲效率影响显著;通过优化调整部件及其进出口参数,系统部件的㶲效率均可保持在0.74以上。通过㶲分析揭示了新型液氢加氢站系统的能量利用情况,为系统优化和性能提升提供了依据。

中图分类号:

翟庆伟, 林锦辉, 李彦锋, 韩东旭, 吴小华, 王鹏, 陈宇杰, 宇波. 新型泵-热协同增压液氢加氢站系统㶲分析[J]. 化工学报, 2025, 76(10): 5390-5401.

Qingwei ZHAI, Jinhui LIN, Yanfeng LI, Dongxu HAN, Xiaohua WU, Peng WANG, Yujie CHEN, Bo YU. Exergy analysis of novel pump-thermal synergistic pressurization liquid hydrogen refueling station system[J]. CIESC Journal, 2025, 76(10): 5390-5401.

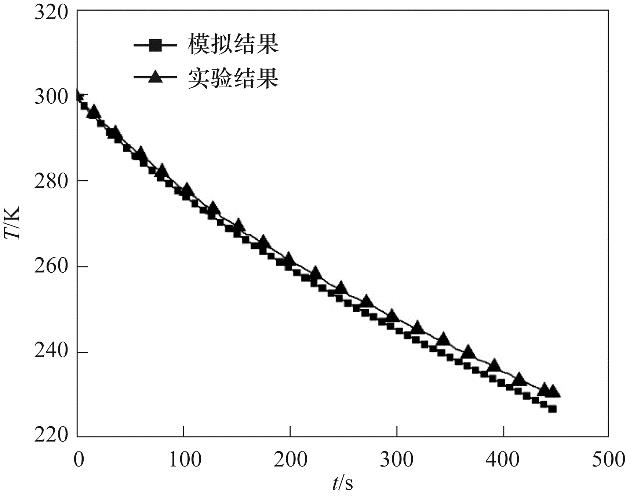

图2 放气过程中压力容器内氢气温度的仿真结果与实验结果对比

Fig.2 Comparison of hydrogen temperature inside the pressure vessel during the venting process by the simulation and the experiment

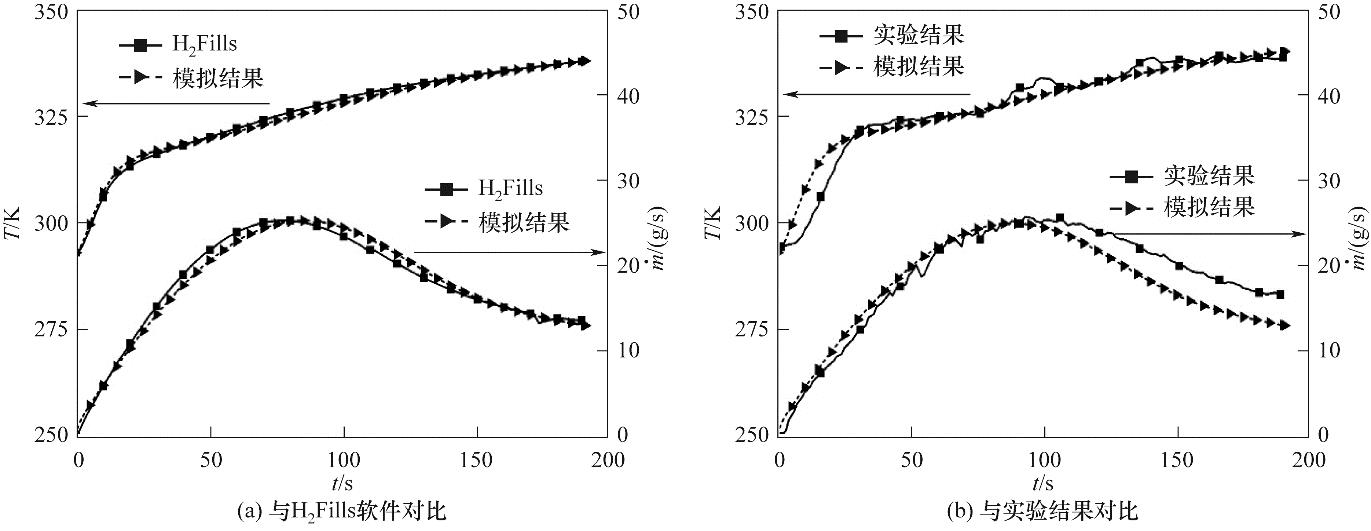

图3 模型与H2Fills软件及实验结果在FCEV储氢罐温升与质量流量的对比

Fig.3 Comparison of temperature rise in the FCEV tank and mass flow rate by the present model with H2Fills software and experimental results

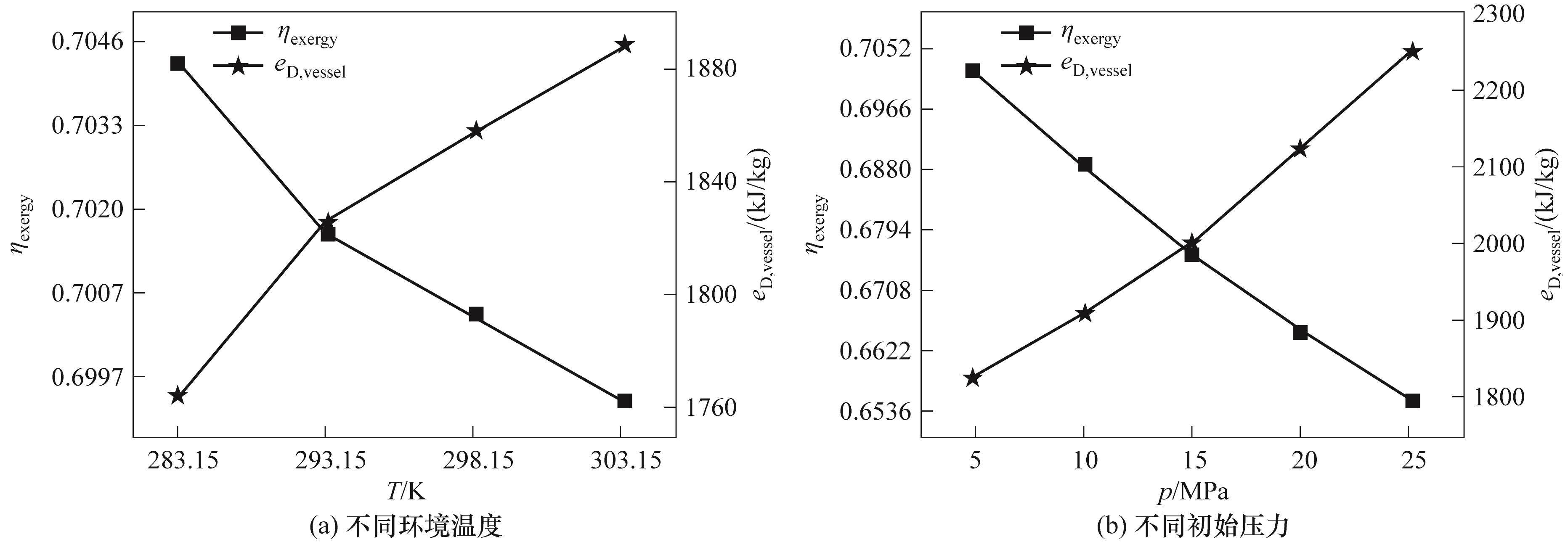

图5 泵-热协同增压过程在不同压力容器参数下的㶲损及㶲效率变化

Fig.5 Variations of exergy destruction and exergy efficiency during the pump-thermal synergistic pressurization process under different pressure vessel parameters

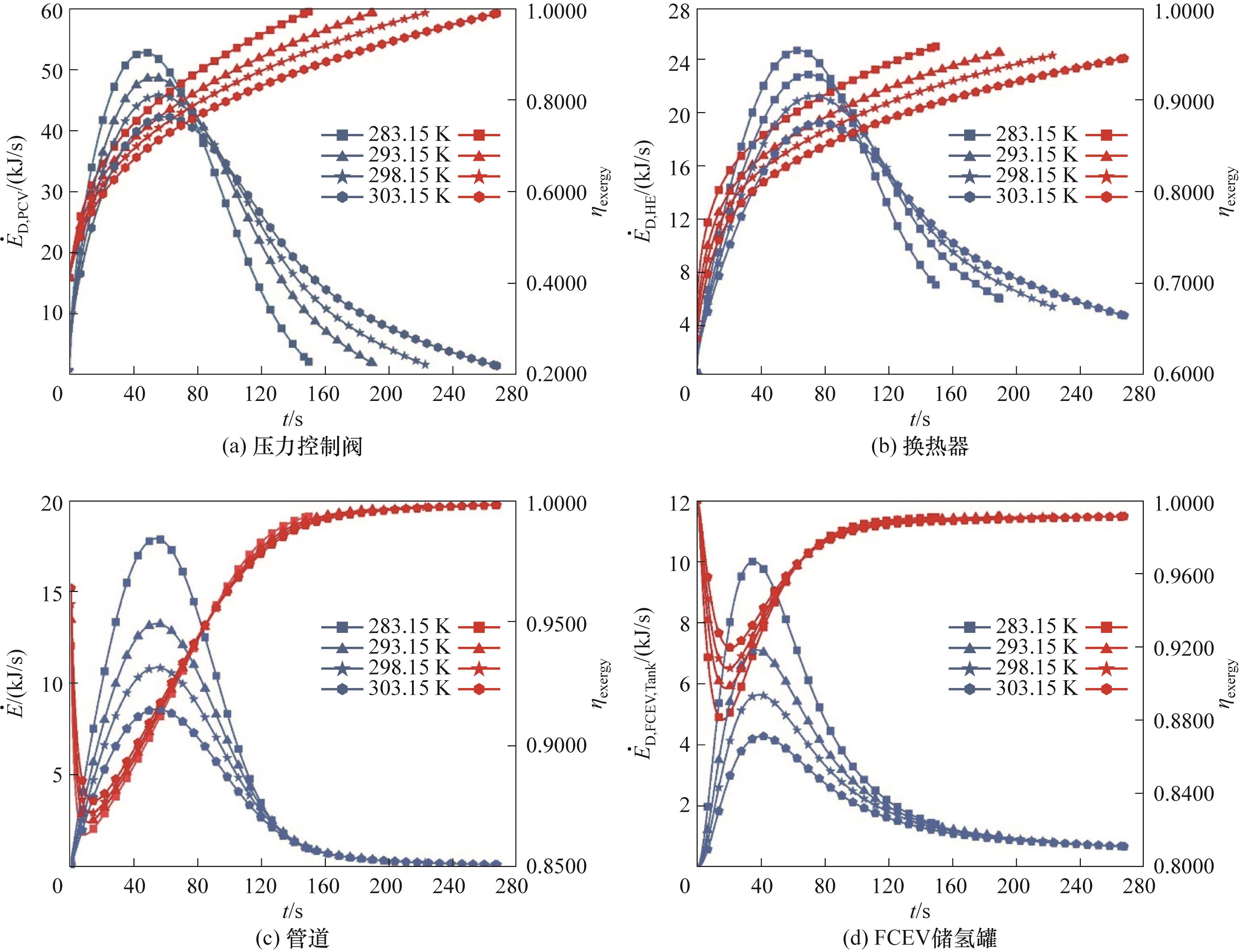

图6 不同环境温度下氢气加注过程中核心组件的㶲损失和㶲效率变化

Fig.6 Variations of exergy destruction and exergy efficiency of key components during the hydrogen refueling process under different ambient temperatures

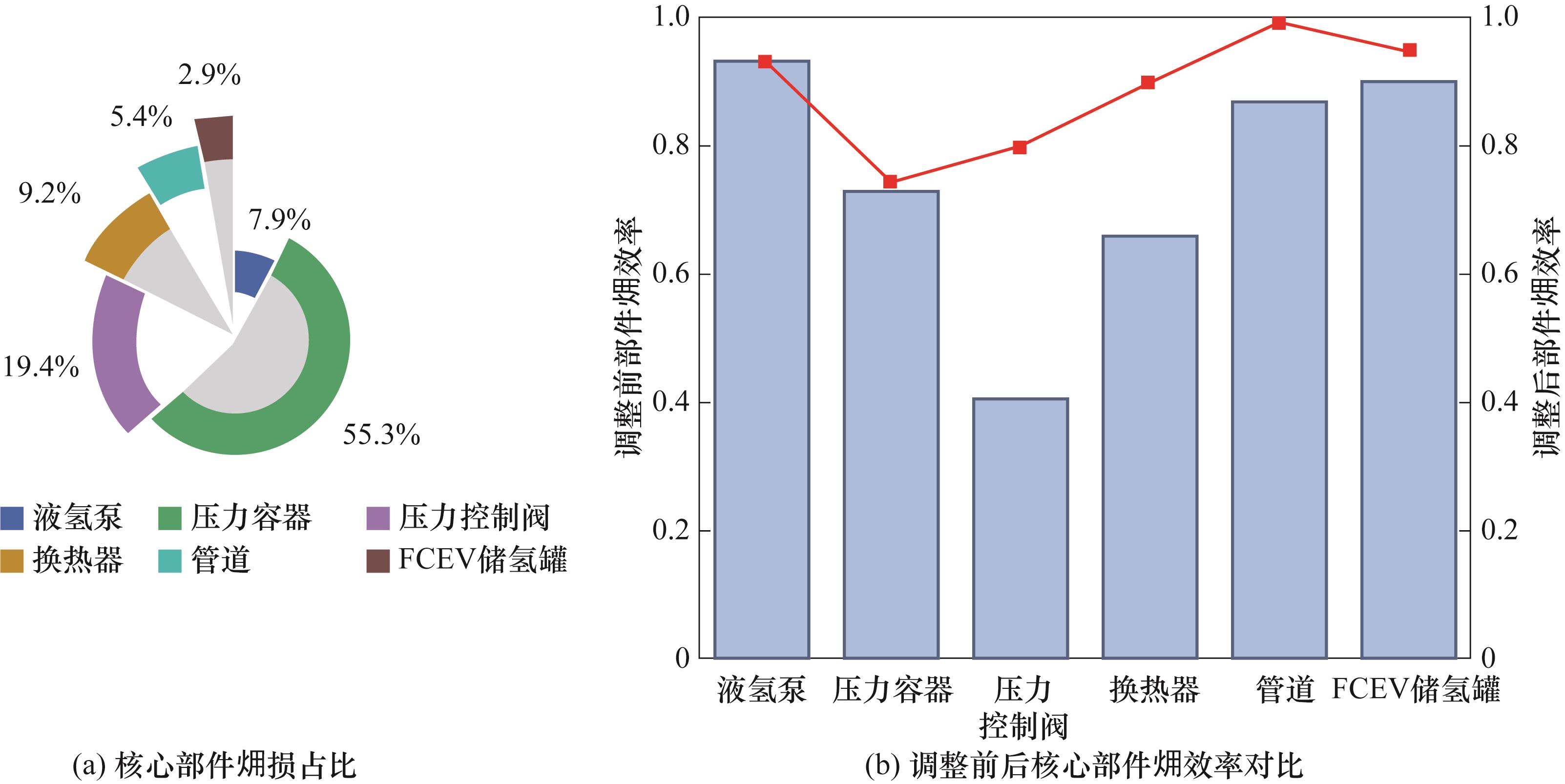

图7 全系统运行过程中核心部件㶲损所占比例及优化调整前后㶲效率

Fig.7 Proportions of exergy loss in key components during full system operation and comparison of exergy efficiency before and after optimization

| [1] | 殷朝辉, 蒋利军, 刘蔚, 等. 氢能利用关键技术及发展现状[J]. 太阳能, 2024(7): 62-69. |

| Yin Z H, Jiang L J, Liu Y, et al. Key technologies and current situation of hydrogen energy utilization[J]. Solar Energy, 2024(7): 62-69. | |

| [2] | 顾晗, 孙鸣, 初丽娜. 氢能利用技术发展与现状[J]. 广东化工, 2024, 51(20): 64-66. |

| Gu H, Sun M, Chu L N. Development and current situation of hydrogen energy utilization technology[J]. Guangdong Chemical Industry, 2024, 51(20): 64-66. | |

| [3] | 王鑫, 陈叔平, 朱鸣. 液氢储运技术发展现状与展望[J]. 太阳能学报, 2024, 45(1): 500-514. |

| Wang X, Chen S P, Zhu M. Development status and prospect of liquid hydrogen storage and transportation technology[J]. Acta Energiae Solaris Sinica, 2024, 45(1): 500-514. | |

| [4] | 崔振莹. 氢能储运技术现状及发展分析[J]. 中外能源, 2024, 29(7): 31-39. |

| Cui Z Y. Current status and development of hydrogen storage and transportation technologies[J]. Sino-Global Energy, 2024, 29(7): 31-39. | |

| [5] | 薛明喆, 师存阳, 刘家宁, 等. 液氢加氢站及其关键装备的发展现状及展望[J]. 同济大学学报(自然科学版), 2023, 51(12): 1959-1971. |

| Xue M Z, Shi C Y, Liu J N, et al. Development status and prospects of liquid hydrogen refueling station and its key equipment[J]. Journal of Tongji University (Natural Science), 2023, 51(12): 1959-1971. | |

| [6] | 周昌祥. 加氢站关键技术及系统集成分析[J]. 上海节能, 2024(7): 1138-1141. |

| Zhou C X. Key technologies and system integration analysis of hydrogen refueling stations[J]. Shanghai Energy Saving, 2024(7): 1138-1141. | |

| [7] | Reddi K, Elgowainy A, Rustagi N, et al. Impact of hydrogen refueling configurations and market parameters on the refueling cost of hydrogen[J]. International Journal of Hydrogen Energy, 2017, 42(34): 21855-21865. |

| [8] | Genovese M, Fragiacomo P. Hydrogen refueling station: overview of the technological status and research enhancement[J]. Journal of Energy Storage, 2023, 61: 106758. |

| [9] | Petitpas G, Aceves S M, Gupta N. Vehicle refueling with liquid hydrogen thermal compression[J]. International Journal of Hydrogen Energy, 2012, 37(15): 11448-11457. |

| [10] | Schäfer S, Klein H. Thermodynamical analysis of a hydrogen fueling station via dynamic simulation[J]. International Journal of Hydrogen Energy, 2019, 44(33): 18240-18254. |

| [11] | Wu Y M, Chen J Y, Shao S Q. Analysis of energy saving potential of an asynchronous refueling process for liquid hydrogen station[J]. International Journal of Hydrogen Energy, 2024, 49: 373-384. |

| [12] | 高浩华, 顾素平, 王琛, 等. 高压液氢泵行业研究现状及关键技术问题[J]. 天然气工业, 2024, 44(8): 166-177. |

| Gao H H, Gu S P, Wang C, et al. Research status and key technical issues of high pressure liquid hydrogen pump industry[J]. Natural Gas Industry, 2024, 44(8): 166-177. | |

| [13] | Zhai Q W, Han D X, Wang Q, et al. A novel pump-thermal synergistic pressurization process for an efficient liquid hydrogen refueling station system[J]. International Journal of Hydrogen Energy, 2024, 83: 1087-1098. |

| [14] | Kuroki T, Nagasawa K, Peters M, et al. Thermodynamic modeling of hydrogen fueling process from high-pressure storage tank to vehicle tank[J]. International Journal of Hydrogen Energy, 2021, 46(42): 22004-22017. |

| [15] | Ren S D, Jia X H, Wang S J, et al. Creation and validation of a dynamic simulation method for the whole process of a hydrogen refueling station[J]. Journal of Energy Storage, 2024, 82: 110508. |

| [16] | Hu H W, Di J J, Lang Z R, et al. Thermodynamic modeling and analysis of hydrogen storage systems in hydrogen refueling stations[J]. International Journal of Hydrogen Energy, 2024, 57: 1101-1110. |

| [17] | Park B H, Joe C H. Investigation of configuration on multi-tank cascade system at hydrogen refueling stations with mass flow rate[J]. International Journal of Hydrogen Energy, 2024, 49: 1140-1153. |

| [18] | Poudel S, Tun H, Reddi K, et al. Investigation of precooling unit design options in hydrogen refueling station for heavy-duty fuel-cell electric vehicles[J]. International Journal of Hydrogen Energy, 2024, 61: 493-502. |

| [19] | Yang X, Wang W, Wang Z, et al. Simulation of pre-cooling in a high pressure hydrogen refueling station for operation optimization[J]. International Journal of Hydrogen Energy, 2024, 86: 434-444. |

| [20] | Wang C, Wang J B, Wu T, et al. A numerical analysis on the thermal characteristics by filling parameters of high-pressure valve for hydrogen refueling station[J]. Results in Engineering, 2024, 21: 101943. |

| [21] | Cui W Y, Yuan Y P, Wang H Y, et al. Numerical investigation on the influence of geometrical parameters on the temperature distribution in marine hydrogen storage tanks during filling[J]. International Journal of Hydrogen Energy, 2024, 51: 61-71. |

| [22] | 吴一梅, 邵双全, 陈建业, 等. 车辆配置对气态加氢站预冷负荷的影响[J]. 工程热物理学报, 2023, 44(9): 2347-2354. |

| Wu Y M, Shao S Q, Chen J Y, et al. Effect of vehicle configurations on the precooling load of a hydrogen station[J]. Journal of Engineering Thermophysics, 2023, 44(9): 2347-2354. | |

| [23] | 冯一宁, 朱绍伟, 薛明喆, 等. 液氢加氢站加注过程㶲分析[J]. 真空与低温, 2024, 30(4): 417-423. |

| Feng Y N, Zhu S W, Xue M Z, et al. Exergy analysis of filling process of liquid hydrogen fueling station[J]. Vacuum and Cryogenics, 2024, 30(4): 417-423. | |

| [24] | Kim H S. 4E analysis of novel direct expansion cycle-organic Rankine cycle-integrated hydrogen refueling station system using liquid hydrogen cold energy[J]. Journal of Cleaner Production, 2024, 462: 142682. |

| [25] | Salimi Delshad M, Momenimovahed A, Mazidi M S, et al. Energy, exergy, exergoenvironmental, and exergoeconomic (4E) analyses of a gas boosting station[J]. Energy Science & Engineering, 2021, 9(11): 2044-2063. |

| [26] | Li J, Ramteke A, Youn E, et al. Liquid pump-enabled hydrogen refueling system for heavy duty fuel cell vehicles: pump performance and J2601-compliant fills with precooling[J]. International Journal of Hydrogen Energy, 2021, 46(42): 22018-22029. |

| [27] | Petitpas G, Moreno-Blanco J, Espinosa-Loza F, et al. Rapid high density cryogenic pressure vessel filling to 345 bar with a liquid hydrogen pump[J]. International Journal of Hydrogen Energy, 2018, 43(42): 19547-19558. |

| [28] | Qiu G Y, Zhu S L, Wang K, et al. Numerical study on the dynamic process of reciprocating liquid hydrogen pumps for hydrogen refueling stations[J]. Energy, 2023, 281: 128303. |

| [29] | Petitpas G, Aceves S M. Liquid hydrogen pump performance and durability testing through repeated cryogenic vessel filling to 700 bar[J]. International Journal of Hydrogen Energy, 2018, 43(39): 18403-18420. |

| [30] | Aceves S M, Espinosa-Loza F, Ledesma-Orozco E, et al. High-density automotive hydrogen storage with cryogenic capable pressure vessels[J]. International Journal of Hydrogen Energy, 2010, 35(3): 1219-1226. |

| [31] | Rothuizen E D. Hydrogen fuelling stations: a thermodynamic analysis of fuelling hydrogen vehicles for personal transportation[D]. Denmark: Technical University of Denmark, 2013. |

| [32] | Klopčič N, Regenfelder R, Hafner T, et al. Refuelling tests of a hydrogen tank for heavy-duty applications[J]. International Journal of Hydrogen Energy, 2024, 49: 1237-1249. |

| [33] | Oh S J, Yoon J H, Jeon K S, et al. A numerical study on characteristics of heat transfer in hydrogen filling storage vessel by charging conditions[J]. International Journal of Hydrogen Energy, 2022, 47(61): 25679-25695. |

| [34] | Olmos F, Manousiouthakis V I. Gas tank fill-up in globally minimum time: theory and application to hydrogen[J]. International Journal of Hydrogen Energy, 2014, 39(23): 12138-12157. |

| [35] | Yu Y H, Lu C, Ye S, et al. Optimization on volume ratio of three-stage cascade storage system in hydrogen refueling stations[J]. International Journal of Hydrogen Energy, 2022, 47(27): 13430-13441. |

| [36] | Kuroki T, Sakoda N, Shinzato K, et al. Prediction of transient temperature of hydrogen flowing from pre-cooler of refueling station to inlet of vehicle tank[J]. International Journal of Hydrogen Energy, 2018, 43(3): 1846-1854. |

| [37] | Chae C K, Park B H, Huh Y S, et al. Development of a new real time responding hydrogen fueling protocol[J]. International Journal of Hydrogen Energy, 2020, 45(30): 15390-15401. |

| [38] | Li J Q, Chen Y, Ma Y B, et al. A study on the Joule-Thomson effect of during filling hydrogen in high pressure tank[J]. Case Studies in Thermal Engineering, 2023, 41: 102678. |

| [39] | Maurer W, Justl M, Keuschnigg R. Improving hydrogen refueling stations to achieve minimum refueling costs for small bus fleets[J]. International Journal of Hydrogen Energy, 2023, 48(77): 29821-29834. |

| [40] | Schneider J, Meadows G, Mathison S R, et al. Validation and sensitivity studies for SAE J2601, the light duty vehicle hydrogen fueling standard[J]. SAE International Journal of Alternative Powertrains, 2014, 3(2): 257-309. |

| [41] | Bell I H, Wronski J, Quoilin S, et al. Pure and pseudo-pure fluid thermophysical property evaluation and the open-source thermophysical property library CoolProp[J]. Industrial & Engineering Chemistry Research, 2014, 53(6): 2498-2508. |

| [42] | de Miguel N, Acosta B, Moretto P, et al. The effect of defueling rate on the temperature evolution of on-board hydrogen tanks[J]. International Journal of Hydrogen Energy, 2015, 40(42): 14768-14774. |

| [1] | 周有苗, 刘晔, 余锋, 罗小钰, 王斌辉. 双源压缩-喷射复合热泵系统构建及特性分析[J]. 化工学报, 2025, 76(S1): 36-42. |

| [2] | 杨语晴, 李银龙, 晏刚. 采用低GWP制冷剂的级联加热自复叠高温热泵循环热力学分析[J]. 化工学报, 2025, 76(S1): 43-53. |

| [3] | 刘璐, 王文玥, 王腾, 王太, 董新宇, 汤建成, 王少恒. 基于双混合工质深冷的氢液化工艺优化与分析[J]. 化工学报, 2025, 76(9): 4933-4943. |

| [4] | 王偲凡, 栗一帆, 陈江波, 周桓. 碳酸盐型卤水Li+, Na+, K+, CO |

| [5] | 丁叶薇, 康文博, 宋昱潼, 樊钦习, 吉远辉. 吲哚美辛纳米药物筛选及自组装机制的理论研究[J]. 化工学报, 2024, 75(11): 4141-4151. |

| [6] | 汤涵, 蔡进, 覃海航, 陈光进, 孙长宇. 水合物共存体系中气体溶解度预测模型[J]. 化工学报, 2024, 75(11): 4348-4358. |

| [7] | 门文欣, 彭庆收, 桂霞. 不同季铵盐作用下的CO2水合物相平衡[J]. 化工学报, 2022, 73(4): 1472-1482. |

| [8] | 李丹, 孙帅琦, 张涛, 赵一慧, 孟令宗, 郭亚飞, 邓天龙. 五元体系HCl-NaCl-CaCl2-H3BO3-H2O在298.15 K的Pitzer模型及其应用研究[J]. 化工学报, 2021, 72(6): 3160-3169. |

| [9] | 陈博亚, 李明宴, 朱雨航, 彭昌军, 刘洪来. 利用二维流体分子热力学模型计算气体混合物在固体界面的吸附等温线[J]. 化工学报, 2021, 72(2): 913-920. |

| [10] | 李攀, 孔慧, 宋卓栋, 张作毅, 王云芳. 甲醇-甲醛-聚甲氧基二甲醚三元体系汽液平衡[J]. 化工学报, 2020, 71(S1): 7-14. |

| [11] | 范凯, 陈长旭, 周峰, 郑晖, 许春建. 正丁醇-氯苯-苯乙酮三元体系等压汽液平衡的测定与关联[J]. 化工学报, 2018, 69(2): 578-585. |

| [12] | 宗杰, 马庆兰, 陈光进, 孙长宇. ZIF-8/乙二醇体系分离捕集CO2溶解度的模拟计算[J]. 化工学报, 2018, 69(10): 4276-4283. |

| [13] | 陆小华, 蒋管聪, 朱育丹, 冯新, 吕玲红. 受限界面处流体分子行为的调控及相关分子热力学模型初探:基于高比表面氧化钛的研究进展[J]. 化工学报, 2018, 69(1): 1-8. |

| [14] | 周峰, 陈长旭, 许春建. 乙酸异戊酯+异戊醇和乙酸异戊酯+正己醇体系汽液平衡[J]. 化工学报, 2017, 68(2): 560-566. |

| [15] | 王丰阳, 梁欢欢, 周彩荣. 常压下甲醇-聚甲氧基二甲醚二元体系汽液平衡[J]. 化工学报, 2016, 67(7): 2685-2691. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号