化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6696-6707.DOI: 10.11949/0438-1157.20250619

收稿日期:2025-06-09

修回日期:2025-08-13

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

李浩然

作者简介:张雷(1996—),女,博士,讲师,arctanty@neepu.edu.cn

基金资助:

Lei ZHANG( ), Jiawei KANG, Haoran LI(

), Jiawei KANG, Haoran LI( ), Wenpeng HONG

), Wenpeng HONG

Received:2025-06-09

Revised:2025-08-13

Online:2025-12-31

Published:2026-01-23

Contact:

Haoran LI

摘要:

生物炭还原NO作为生物质再燃脱硝技术的核心,其效率的提升对实现NO的快速减排至关重要。针对现有脱硝生物炭定向设计缺乏理论支撑这一问题,分别构建原始与贫氧预处理生物炭模型(BCraw和BCoxy),从微观角度解析贫氧预处理对生物炭还原NO的影响机制。研究发现,BCraw对NO的还原主要由NO吸附及裂解、氢原子迁移、芳香环裂解重组以及氮气脱附四个过程组成。与BCraw相比,BCoxy中酚羟基的共轭效应优化了NO的还原路径,氮气脱附能量Gap值由546.65 kJ/mol降为409.40 kJ/mol。生物炭的程序升温还原实验(TPR)结果表明,BCoxy对NO的还原能力是BCraw的1.04倍,进一步验证了模拟结果的可靠性。上述结果阐明了贫氧预处理对生物炭还原NO的影响机理,为生物炭基高效脱硝材料设计提供了理论基础。

中图分类号:

张雷, 康嘉伟, 李浩然, 洪文鹏. 贫氧预处理对生物炭还原NO的影响机制研究[J]. 化工学报, 2025, 76(12): 6696-6707.

Lei ZHANG, Jiawei KANG, Haoran LI, Wenpeng HONG. Affected mechanisms of oxygen-deficient pretreatment on reduction of NO by biochar[J]. CIESC Journal, 2025, 76(12): 6696-6707.

| 元素分析/%(质量分数,daf) | 工业分析/%(质量分数,ar) | |||||||

|---|---|---|---|---|---|---|---|---|

| C | H | N | S | O① | 水分 | 挥发分 | 固定碳 | 灰分 |

| 66.70 | 3.34 | 1.16 | 0.38 | 28.42 | 7.35 | 60.41 | 19.10 | 13.14 |

表1 生物质样品的元素分析和工业分析

Table 1 Ultimate and proximate analyses of rice husk

| 元素分析/%(质量分数,daf) | 工业分析/%(质量分数,ar) | |||||||

|---|---|---|---|---|---|---|---|---|

| C | H | N | S | O① | 水分 | 挥发分 | 固定碳 | 灰分 |

| 66.70 | 3.34 | 1.16 | 0.38 | 28.42 | 7.35 | 60.41 | 19.10 | 13.14 |

| 反应 | LUMO-HOMO能量差值/eV |

|---|---|

| BCraw-NO | |

| 反应Ⅰ | Gap Ⅰ = BCraw (LUMO) - NO (HOMO) = 0.83 |

| 反应Ⅱ | Gap Ⅱ = NO (LUMO) - BCraw (HOMO) = 3.51 |

| BCoxy-NO | |

| 反应Ⅲ | Gap Ⅲ= BCoxy (LUMO) - NO (HOMO) = 0.87 |

| 反应Ⅳ | Gap Ⅳ= NO (LUMO) - BCoxy (HOMO) = 3.28 |

表2 BCraw和BCoxy异相还原NO过程中的LUMO-HOMO能量差值

Table 2 The LUMO-HOMO gaps during the reduction of NO by BCraw and BCoxy

| 反应 | LUMO-HOMO能量差值/eV |

|---|---|

| BCraw-NO | |

| 反应Ⅰ | Gap Ⅰ = BCraw (LUMO) - NO (HOMO) = 0.83 |

| 反应Ⅱ | Gap Ⅱ = NO (LUMO) - BCraw (HOMO) = 3.51 |

| BCoxy-NO | |

| 反应Ⅲ | Gap Ⅲ= BCoxy (LUMO) - NO (HOMO) = 0.87 |

| 反应Ⅳ | Gap Ⅳ= NO (LUMO) - BCoxy (HOMO) = 3.28 |

| 模型 | CLEI/(e·eV) | ||||

|---|---|---|---|---|---|

| C1 | N2 | C3 | C4 | C5 | |

| BCraw | 0.05620 | 0.06942 | 0.01546 | 0.06249 | 0.03673 |

| BCoxy | 0.06183 | 0.06233 | 0.01628 | 0.05067 | 0.02498 |

表3 BCraw和BCoxy中重要原子的CLEI值

Table 3 The CLEI values of primary atoms in BCraw and BCoxy structures

| 模型 | CLEI/(e·eV) | ||||

|---|---|---|---|---|---|

| C1 | N2 | C3 | C4 | C5 | |

| BCraw | 0.05620 | 0.06942 | 0.01546 | 0.06249 | 0.03673 |

| BCoxy | 0.06183 | 0.06233 | 0.01628 | 0.05067 | 0.02498 |

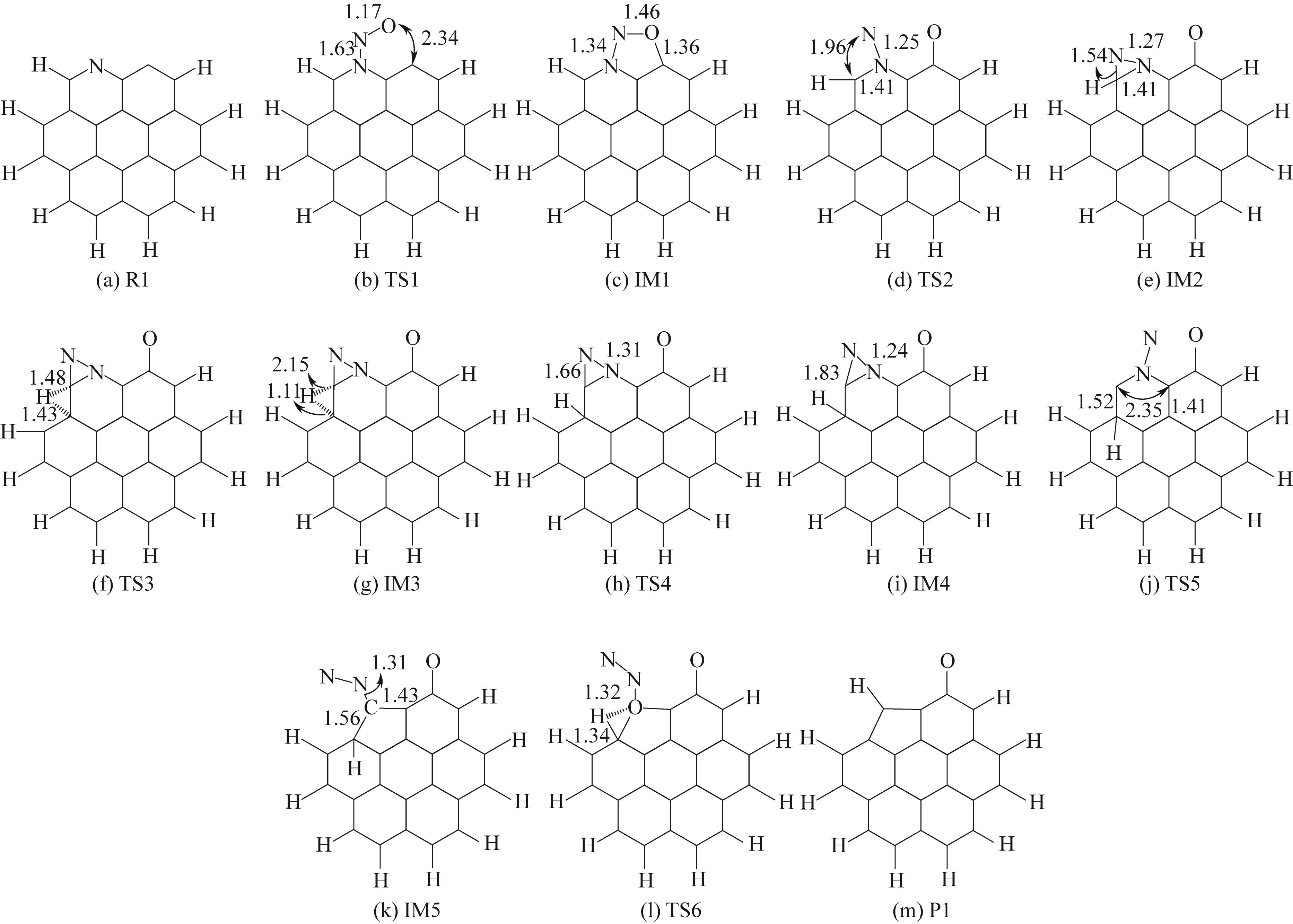

图5 BCraw-NO反应过程中反应物、中间体、过渡态和产物的几何优化结构示意图

Fig.5 The diagrams of geometric optimization of intermediates and transition states in the reaction of BCraw-NO

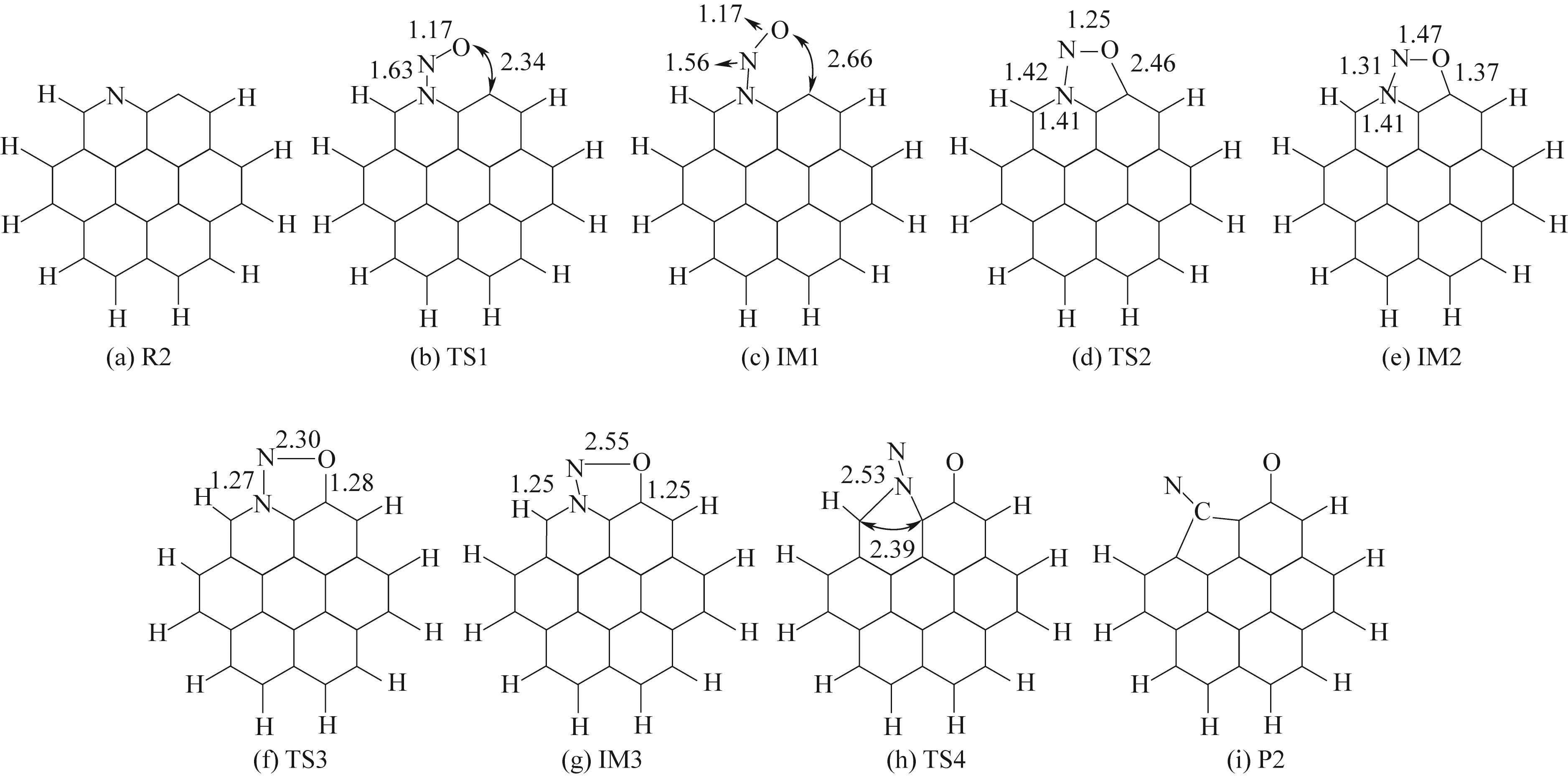

图7 BCoxy-NO反应过程中反应物、中间体、过渡态和产物的几何优化结构示意图

Fig.7 The diagrams of geometric optimization of reactants, intermediates, transition states and products in the reaction of BCoxy-NO

| 模型 | (dcNO/dt)max/(μmol/(mol·℃)) | t0/s | tmax/s | Ti/℃ | Tmax/℃ |

|---|---|---|---|---|---|

| BCraw | -3.70 | 4206 | 4419 | 701 | 736.5 |

| BCoxy | -3.33 | 4512 | 4626 | 752 | 771 |

表4 生物炭异相还原NO过程中的特性参数

Table 4 The reduction characteristic parameters during the reaction between biochar and NO

| 模型 | (dcNO/dt)max/(μmol/(mol·℃)) | t0/s | tmax/s | Ti/℃ | Tmax/℃ |

|---|---|---|---|---|---|

| BCraw | -3.70 | 4206 | 4419 | 701 | 736.5 |

| BCoxy | -3.33 | 4512 | 4626 | 752 | 771 |

| [4] | Council State. The 13th Five-Year Plan for the protection of the ecological environment[EB/OL]. (2016-11-24) [2025-06-07]. . |

| [5] | 生态环境部, 国家发展和改革委员会, 工业和信息化部, 住房和城乡建设部, 交通运输部, 农业农村部, 国家能源局. 减污降碳协同增效实施方案[EB/OL].(2022-06-10)[2025-06-07]. . |

| Ministry of Ecology and Environment of the People's Republic of China, National Development and Reform Commission, Ministry of Industry and Information Technology of the People's Republic of China, Ministry of Housing and Urban-Rural Development of the People's Republic of China, Ministry of Transport of the People's Republic of China, Ministry of Agriculture and Rural Affairs of the People's Republic of China, National Energy Administration. Implementation plan for synergistic efficiency of pollution reduction and carbon reduction[EB/OL]. (2022-06-10) [2025-06-07]. . | |

| [6] | 国务院. 空气质量持续改善行动计划[EB/OL].(2023-11-30)[2025-06-07]. |

| Council State. The action plan for continuous improvement of air quality[EB/OL]. (2023-11-30) [2025-06-07]. . | |

| [7] | 赵杰. 生物质气再燃还原NO x 的实验研究[D]. 上海: 上海应用技术大学, 2016: 5-11. |

| Zhao J. Experimental study on NO x emissions reduction by biogas reburning[D]. Shanghai: Shanghai Institute of Technology, 2016: 5-11. | |

| [8] | 王鹏涛, 王乃继, 梁兴, 等. 气体燃料再燃脱硝机理及工程应用进展[J]. 洁净煤技术, 2019, 25(6): 51-60. |

| Wang P T, Wang N J, Liang X, et al. Denitration mechanism and engineering application progress of gas fuel reburning[J]. Clean Coal Technology, 2019, 25(6): 51-60. | |

| [9] | Verdía Barbará P, Choudhary H, Nakasu P S, et al. Recent advances in the use of ionic liquids and deep eutectic solvents for lignocellulosic biorefineries and biobased chemical and material production[J]. Chemical Reviews, 2025, 125(12): 5461-5583. |

| [10] | Ai Z J, Cao C K, Zhang W J, et al. Machine learning-aided engineering of biochar from biomass pyrolysis and activation processes for enhanced CO2 adsorption[J]. Separation and Purification Technology, 2025, 376: 133882. |

| [11] | Buss W, Hilber I, Graham M C, et al. Composition of PAHs in biochar and implications for biochar production[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(20): 6755-6765. |

| [12] | Wen C, Liu T Y, Wang D P, et al. Biochar as the effective adsorbent to combustion gaseous pollutants: preparation, activation, functionalization and the adsorption mechanisms[J]. Progress in Energy and Combustion Science, 2023, 99: 101098. |

| [13] | Marcińczyk M, Oleszczuk P. Biochar and engineered biochar as slow- and controlled-release fertilizers[J]. Journal of Cleaner Production, 2022, 339: 130685. |

| [14] | Shu Y, Wang H C, Zhu J W, et al. An experimental study of heterogeneous NO reduction by biomass reburning[J]. Fuel Processing Technology, 2015, 132: 111-117. |

| [15] | Karlström O, Perander M, DeMartini N, et al. Role of ash on the NO formation during char oxidation of biomass[J]. Fuel, 2017, 190: 274-280. |

| [16] | Cao S S, Duan F, Wang P, et al. Biochar contribution in biomass reburning technology and transformation mechanism of its nitrogen foundational groups at different oxygen contents[J]. Energy, 2018, 155: 272-280. |

| [17] | 赵宗彬, 李文, 李保庆. 氧气对半焦还原NO反应的作用机理研究[J]. 中国矿业大学学报, 2001, 30(5): 484-487. |

| Zhao Z B, Li W, Li B Q. Influence mechanism of O2 on NO-char reaction[J]. Journal of China University of Mining & Technology, 2001, 30(5): 484-487. | |

| [18] | Figueiredo J L, Pereira M F R, Freitas M M A, et al. Modification of the surface chemistry of activated carbons[J]. Carbon, 1999, 37(9): 1379-1389. |

| [19] | Moulijn J A, Kapteijn F. Towards a unified theory of reactions of carbon with oxygen-containing molecules[J]. Carbon, 1995, 33(8): 1155-1165. |

| [20] | Yang J, Mestl G, Herein D, et al. Reaction of NO with carbonaceous materials(2): Effect of oxygen on the reaction of NO with ashless carbon black[J]. Carbon, 2000, 38(5): 729-740. |

| [21] | Wang Z Z, Sun R, Ismail T M, et al. Characterization of coal char surface behavior after a heterogeneous oxidative treatment[J]. Fuel, 2017, 210: 154-164. |

| [22] | Liu J, Xia Y G, Sun H D, et al. Theoretical insight into NO formation and reduction at biochar N-sites: influence of different oxygen-containing functional groups[J]. Journal of Environmental Chemical Engineering, 2024, 12(4): 113147. |

| [1] | Cliff S J, Drysdale W, Lewis A C, et al. Evidence of heating-dominated urban NO x emissions[J]. Environmental Science & Technology, 2025, 59(9): 4399-4408. |

| [2] | 中华人民共和国国家发展和改革委员会. 中华人民共和国国民经济和社会发展第十二个五年规划纲要[EB/OL].(2011-09-20)[2025-06-07]. . |

| National Development and Reform Commission. The twelfth Five-Year Plan for national economic and social develop-ment of the People's Republic of China[EB/OL]. (2011-09-20) [2025-06-07]. . | |

| [3] | 国务院.大气污染防治行动计划[EB/OL]. (2013-09-10)[2025-06-07]. . |

| Council State. Air pollution prevention and control action plan[EB/OL]. (2013-09-10) [2025-06-07]. . | |

| [4] | 国务院.“十三五”生态环境保护规划[EB/OL].(2016-11-24)[2025-06-07]. . |

| [23] | Chen P, Gu M Y, Wang D F, et al. Experimental and density functional theory study of the influence mechanism of oxygen on NO heterogeneous reduction in deep air-staged combustion[J]. Combustion and Flame, 2021, 223: 127-141. |

| [24] | Chen P, Gu M Y, Chen X, et al. Study of the reaction mechanism of oxygen to heterogeneous reduction of NO by char[J]. Fuel, 2019, 236: 1213-1225. |

| [25] | Zhang H, Liu J X, Wang X Y, et al. Density functional theory study on two different oxygen enhancement mechanisms during NO-char interaction[J]. Combustion and Flame, 2016, 169: 11-18. |

| [26] | Lu S, Rand B, Bartle K D, et al. Novel oxidation resistant carbon-silicon alloy fibres[J]. Carbon, 1997, 35(10/11): 1485-1493. |

| [27] | Huang Q L, Zhang Q R, Zhao S W, et al. Efficient recovery of rare metal lanthanum from water by MOF-modified biochar: DFT calculation and dynamic adsorption[J]. Biochar, 2025, 7: 29. |

| [28] | Li H X, Tang M H, Wang L, et al. Molecular simulation combined with DFT calculation guided heteroatom-doped biochar rational design for highly selective and efficient CO2 capture[J]. Chemical Engineering Journal, 2024, 481: 148362. |

| [29] | Zhang J J, Huang D R, Shao J G, et al. Activation-free synthesis of nitrogen-doped biochar for enhanced adsorption of CO2 [J]. Journal of Cleaner Production, 2022, 355: 131642. |

| [30] | Maklavany D M, Rouzitalab Z, Amini A M, et al. One-step approach to quaternary (B, N, P, S)-doped hierarchical porous carbon derived from Quercus Brantii for highly selective and efficient CO2 capture: a combined experimental and extensive DFT study[J]. Chemical Engineering Journal, 2023, 453: 139950. |

| [31] | Long Y X, Tian H, Lee C H, et al. Competitive adsorption of H2O and CO2 on nitrogen-doped biochar with rich-oxygen functional groups[J]. Separation and Purification Technology, 2025, 359: 130476. |

| [32] | Yang X P, Jiang D, Cheng X X, et al. Adsorption properties of seaweed-based biochar with the greenhouse gases (CO2, CH4, N2O) through density functional theory (DFT)[J]. Biomass and Bioenergy, 2022, 163: 106519. |

| [33] | Lu T, Chen F W. Multiwfn: a multifunctional wavefunction analyzer[J]. Journal of Computational Chemistry, 2012, 33(5): 580-592. |

| [34] | Lu T, Chen F W. Atomic dipole moment corrected Hirshfeld population method[J]. Journal of Theoretical and Computational Chemistry, 2012, 11(1): 163-183. |

| [35] | Lu T, Chen Q X. Interaction region indicator: a simple real space function clearly revealing both chemical bonds and weak interactions[J]. Chemistry-Methods, 2021, 1(5): 231-239. |

| [36] | Kim B G, Ma X, Chen C, et al. Energy level modulation of HOMO, LUMO, and band-gap in conjugated polymers for organic photovoltaic applications[J]. Advanced Functional Materials, 2013, 23(4): 439-445. |

| [37] | Ye Z L, Xie S J, Cao Z Y, et al. High-rate aqueous zinc-organic battery achieved by lowering HOMO/LUMO of organic cathode[J]. Energy Storage Materials, 2021, 37: 378-386. |

| [38] | Yapp E K Y, Patterson R I A, Akroyd J, et al. Numerical simulation and parametric sensitivity study of optical band gap in a laminar co-flow ethylene diffusion flame[J]. Combustion and Flame, 2016, 167: 320-334. |

| [39] | Zhang L, Zhu W K, Wang Z Z, et al. Investigation of the synergetic regulation of O2/Ar preheating treatment and sodium salt addition on semichar combustion characteristics[J]. Fuel, 2023, 338: 127269. |

| [40] | Dueso C, Mayoral M C, Andrés J M, et al. Towards oxy-steam combustion: the effect of increasing the steam concentration on coal reactivity[J]. Fuel, 2019, 239: 534-546. |

| [41] | Zhang L, Sun R, Wang X Y, et al. Experimental and density functional theory investigation of the NO reduction mechanism by semichars preheated in Ar and CO2/Ar atmospheres[J]. Fuel, 2022, 326: 125080. |

| [42] | Wang Z Z, Xu J, Sun R, et al. Investigation of the NO reduction characteristics of coal char at different conversion degrees under an NO atmosphere[J]. Energy & Fuels, 2017, 31(8): 8722-8732. |

| [1] | 孙云龙, 徐肖肖, 黄永方, 郭纪超, 陈卫卫. 水平光滑管内CO2流动沸腾的非绝热可视化研究[J]. 化工学报, 2025, 76(S1): 230-236. |

| [2] | 郭纪超, 徐肖肖, 孙云龙. 基于植物工厂中的CO2浓度气流模拟及优化研究[J]. 化工学报, 2025, 76(S1): 237-245. |

| [3] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [4] | 何婷, 张开, 林文胜, 陈利琼, 陈家富. 沼气超临界压力低温脱碳-液化耦合流程研究[J]. 化工学报, 2025, 76(S1): 418-425. |

| [5] | 胡国祥, 朱忆魁, 龙华, 刘晓雯, 熊勤钢. 组分配比影响氯化胆碱-乳酸低共熔溶剂碱木质素溶解度的底层机理研究[J]. 化工学报, 2025, 76(9): 4449-4461. |

| [6] | 王偲凡, 栗一帆, 陈江波, 周桓. 碳酸盐型卤水Li+, Na+, K+, CO |

| [7] | 周怀荣, 伊嘉伟, 曹阿波, 郭奥雪, 王东亮, 杨勇, 杨思宇. 共电解耦合CO2间接加氢制甲醇工艺集成设计与性能评价[J]. 化工学报, 2025, 76(9): 4586-4600. |

| [8] | 张建民, 何美贵, 贾万鑫, 赵静, 金万勤. 聚氧化乙烯/冠醚共混膜及其二氧化碳分离性能[J]. 化工学报, 2025, 76(9): 4862-4871. |

| [9] | 王一飞, 李玉星, 欧阳欣, 赵雪峰, 孟岚, 胡其会, 殷布泽, 郭雅琦. 基于裂尖减压特性的CO2管道断裂扩展数值计算[J]. 化工学报, 2025, 76(9): 4683-4693. |

| [10] | 张彬怡, 孙少东, 姚谦, 蔡文河, 张惠宇, 李成新. 煤制甲醇耦合固体氧化物燃料电池混合系统研究[J]. 化工学报, 2025, 76(9): 4658-4669. |

| [11] | 何晨, 陆明飞, 王令金, 许晓颖, 董鹏博, 赵文涛, 隆武强. 氨-甲醇高压混合气稀燃层流实验与模拟研究[J]. 化工学报, 2025, 76(8): 4248-4258. |

| [12] | 廖兵, 祝鑫宇, 黄倩倩, 胥雯, 寇梦瑶, 郭娜. 盐酸羟胺强化芬顿体系在近中性条件下去除2,4-DCP的性能及机理研究[J]. 化工学报, 2025, 76(8): 4273-4283. |

| [13] | 周运桃, 崔丽凤, 张杰, 于富红, 李新刚, 田野. Ga2O3调控CuCeO催化CO2加氢制甲醇的研究[J]. 化工学报, 2025, 76(8): 4042-4051. |

| [14] | 刘沁雯, 叶恒冰, 张逸伟, 朱法华, 钟文琪. 煤与禽类粪便混合燃料的加压富氧燃烧特性研究[J]. 化工学报, 2025, 76(7): 3487-3497. |

| [15] | 李晋, 胡水清, 翁艺斌, 姜峻韬, 王庆宏, 陈春茂. 基于碱渣预处理策略强化炼厂污泥厌氧消化效能[J]. 化工学报, 2025, 76(7): 3446-3458. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号