化工学报 ›› 2025, Vol. 76 ›› Issue (7): 3446-3458.DOI: 10.11949/0438-1157.20241297

李晋1( ), 胡水清1, 翁艺斌2, 姜峻韬1, 王庆宏1(

), 胡水清1, 翁艺斌2, 姜峻韬1, 王庆宏1( ), 陈春茂1

), 陈春茂1

收稿日期:2024-11-13

修回日期:2024-12-23

出版日期:2025-07-25

发布日期:2025-08-13

通讯作者:

王庆宏

作者简介:李晋(1993—),男,博士,讲师,lijincup@163.com

基金资助:

Jin LI1( ), Shuiqing HU1, Yibin WENG2, Juntao JIANG1, Qinghong WANG1(

), Shuiqing HU1, Yibin WENG2, Juntao JIANG1, Qinghong WANG1( ), Chunmao CHEN1

), Chunmao CHEN1

Received:2024-11-13

Revised:2024-12-23

Online:2025-07-25

Published:2025-08-13

Contact:

Qinghong WANG

摘要:

针对炼厂剩余活性污泥(WAS)资源属性,并结合碱渣高碱度特性,提出碱渣预处理及热-碱渣、电解-碱渣和碱性发酵联合预处理策略,旨在提升WAS厌氧消化的甲烷产率。结果表明,碱渣能显著促进胞内有机物溶出,SCOD浓度从128 mg·L-1增至2932 mg·L-1。热-碱渣、电解-碱渣和碱性发酵联合预处理可进一步促进蛋白质、多糖和挥发性脂肪酸释放,改善了溶解性有机物可生化性,提升了单宁、芳香类和富含羧基脂环族化合物等难降解物质的生物转化效率,使得甲烷产率较单独碱渣预处理(58.3 ml·g-1-VS)分别提高了62%、80%和97%。共现网络分析显示,Clostridium_sensu_stricto_5、Clostridium_sensu_stricto_1和Raineyella在分解富含羧基脂环族化合物中起到关键作用。通过经济效益评估,碱性发酵预处理方式净收益最大,可节省处理成本58.5 CNY·t-1,并基于此方法提出了一条WAS与碱渣协同处理的新策略。

中图分类号:

李晋, 胡水清, 翁艺斌, 姜峻韬, 王庆宏, 陈春茂. 基于碱渣预处理策略强化炼厂污泥厌氧消化效能[J]. 化工学报, 2025, 76(7): 3446-3458.

Jin LI, Shuiqing HU, Yibin WENG, Juntao JIANG, Qinghong WANG, Chunmao CHEN. Enhanced anaerobic digestion of refinery waste activated sludge based on pretreatment strategy by spend caustic[J]. CIESC Journal, 2025, 76(7): 3446-3458.

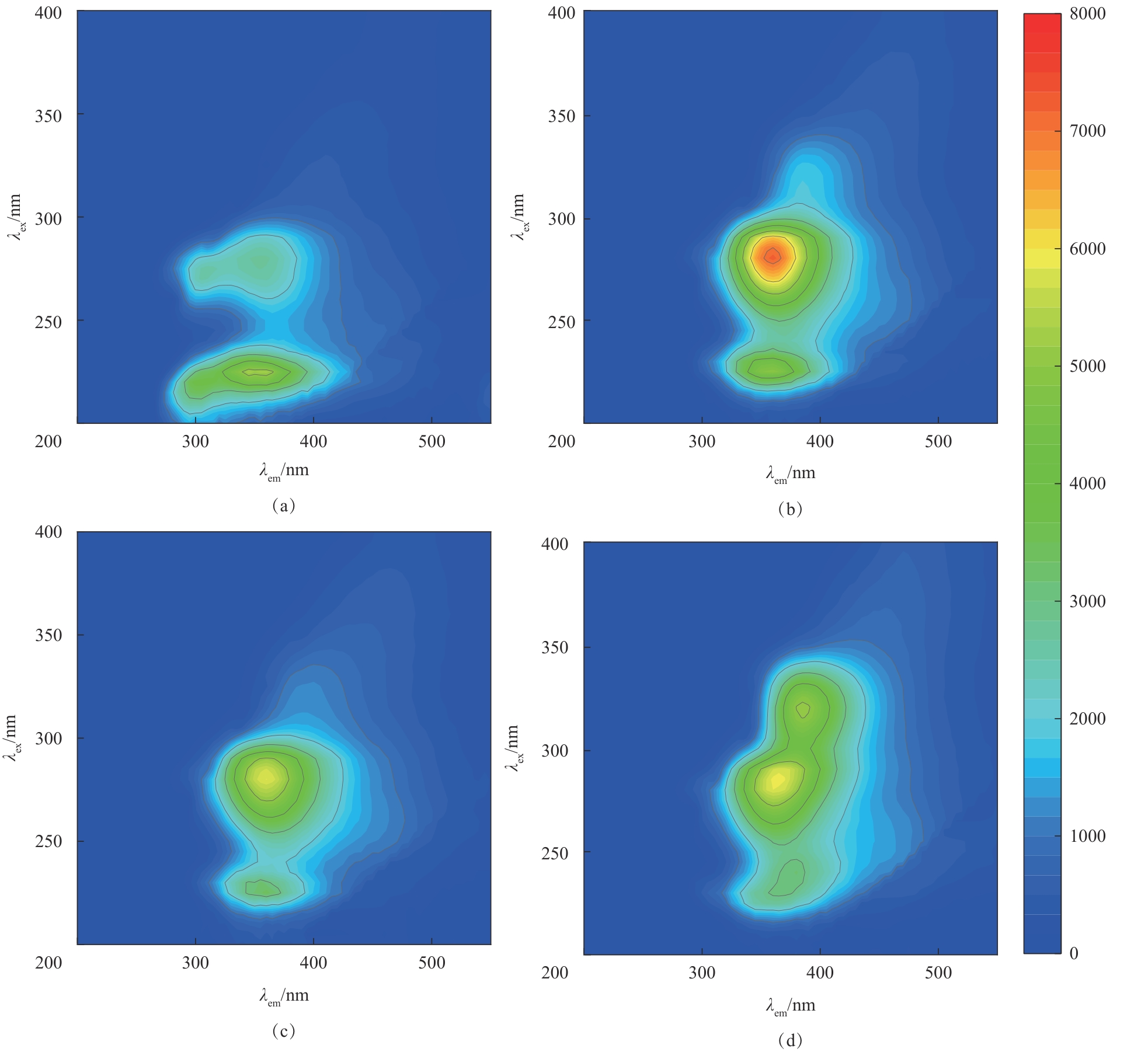

图2 碱渣(a)、热-碱渣(b)、电解-碱渣(c)、碱性发酵(d)预处理后溶出有机物的三维荧光谱图

Fig.2 Three-dimensional fluorescence spectra of dissolved organic matters after RSC pretreatments (a), thermal-RSC (b), electrolysis-RSC (c) and alkaline fermentation (d)

图4 厌氧消化过程残留、降解和生成的溶解性有机物在van Krevelen图中的分布

Fig.4 van Krevelen diagram of the comparing decomposed, resistant, and produced dissolved organic matters during anaerobic digestion

| 项目 | 空白组 | 碱渣组 | 热-碱渣组 | 电解-碱渣组 | 碱性发酵组 |

|---|---|---|---|---|---|

| 进料TS含量/(g·L-1) | 19.24 | 19.24 | 19.24 | 19.24 | 19.24 |

| 预处理费用/(CNY·t-1) | 0 | 0 | 59.21 | 19.67 | 14.38 |

| 中和费用/(CNY·t-1) | 0 | 5.86 | 2.43 | 4.24 | 2.98 |

| 厌氧消化费用/(CNY·t-1) | 14.38 | 14.38 | 0 | 14.38 | 0 |

| TS去除率/% | 13.52 | 18.75 | 25.48 | 26.23 | 24.78 |

| 委外处置费用/(CNY·t-1) | 294.03 | 276.25 | 253.37 | 250.82 | 255.75 |

| 氢气产率/(dm3·t-1) | 48.00 | 251.32 | 142.04 | 407.80 | 313.32 |

| 甲烷产率/(dm3·t-1) | 233.54 | 719.63 | 1176.34 | 1295.15 | 1423.46 |

| 能源收益/ CNY | -1.81 | -5.84 | -8.85 | -10.39 | -11.07 |

| 碱渣投加量/(L·t-1) | 0 | 30 | 10 | 27.5 | 20 |

| 减少的碱渣处理费用/(CNY·t-1) | 0 | -6 | -2 | -5.5 | -4 |

| 总处理费用/(CNY·t-1) | 306.60 | 284.65 | 304.36 | 273.22 | 258.04 |

表1 不同预处理方法促进WAS厌氧消化的经济成本评估

Table 1 Economic evaluation of WAS anaerobic digestion by different pretreatment methods

| 项目 | 空白组 | 碱渣组 | 热-碱渣组 | 电解-碱渣组 | 碱性发酵组 |

|---|---|---|---|---|---|

| 进料TS含量/(g·L-1) | 19.24 | 19.24 | 19.24 | 19.24 | 19.24 |

| 预处理费用/(CNY·t-1) | 0 | 0 | 59.21 | 19.67 | 14.38 |

| 中和费用/(CNY·t-1) | 0 | 5.86 | 2.43 | 4.24 | 2.98 |

| 厌氧消化费用/(CNY·t-1) | 14.38 | 14.38 | 0 | 14.38 | 0 |

| TS去除率/% | 13.52 | 18.75 | 25.48 | 26.23 | 24.78 |

| 委外处置费用/(CNY·t-1) | 294.03 | 276.25 | 253.37 | 250.82 | 255.75 |

| 氢气产率/(dm3·t-1) | 48.00 | 251.32 | 142.04 | 407.80 | 313.32 |

| 甲烷产率/(dm3·t-1) | 233.54 | 719.63 | 1176.34 | 1295.15 | 1423.46 |

| 能源收益/ CNY | -1.81 | -5.84 | -8.85 | -10.39 | -11.07 |

| 碱渣投加量/(L·t-1) | 0 | 30 | 10 | 27.5 | 20 |

| 减少的碱渣处理费用/(CNY·t-1) | 0 | -6 | -2 | -5.5 | -4 |

| 总处理费用/(CNY·t-1) | 306.60 | 284.65 | 304.36 | 273.22 | 258.04 |

| [1] | 李晋, 谢萍, 陈平, 等. 废白土热解残渣强化炼化剩余污泥水热液厌氧产能[J]. 工业水处理, 2022, 42(12): 65-71, 77. |

| Li J, Xie P, Chen P, et al. Enhancement of anaerobic digestion of refinery excess sludge hydrothermal liquid by pyrolytic residue of spent bleaching earth[J]. Industrial Water Treatment, 2022, 42(12): 65-71, 77. | |

| [2] | 罗进财, 王欣芸, 孙鸿, 等. 改善剩余污泥厌氧消化产甲烷性能的新策略:导电材料介导微生物种间直接电子传递[J]. 应用化工, 2024, 53(4): 918-924. |

| Luo J C, Wang X Y, Sun H, et al. A new strategy to improve methanogenesis from anaerobic digestion of waste activated sludge: conductive materials mediate direct interspecies electron transfer of microorganisms[J]. Applied Chemical Industry, 2024, 53(4): 918-924. | |

| [3] | 杨丽丽, 张勇, 胡定成, 等. 利用物理法-热水解预处理剩余污泥技术的研究进展[J]. 应用化工, 2024, 53(8): 1975-1979, 1988. |

| Yang L L, Zhang Y, Hu D C, et al. Research progress of pretreatment of residual sludge by physical thermal hydrolysis[J]. Applied Chemical Industry, 2024, 53(8): 1975-1979, 1988. | |

| [4] | Dasgupta A, Chandel M K. Enhancement of biogas production from organic fraction of municipal solid waste using hydrothermal pretreatment[J]. Bioresource Technology Reports, 2019, 7: 100281. |

| [5] | Lizama A C, Figueiras C C, Herrera R R, et al. Effects of ultrasonic pretreatment on the solubilization and kinetic study of biogas production from anaerobic digestion of waste activated sludge[J]. International Biodeterioration & Biodegradation, 2017, 123: 1-9. |

| [6] | 王海东, 张文存, 王丽莉, 等. 污泥厌氧消化预处理技术综述[J]. 应用化工, 2021, 50(7): 1973-1977. |

| Wang H D, Zhang W C, Wang L L, et al. Review of pretreatment process of sludge anaerobic digestion[J]. Applied Chemical Industry, 2021, 50(7): 1973-1977. | |

| [7] | 侯银萍, 蔡斌斌, 张安龙, 等. 不同预处理方法促进剩余污泥破胞及厌氧消化产气效率的研究[J]. 陕西科技大学学报, 2022, 40(2): 13-19, 27. |

| Hou Y P, Cai B B, Zhang A L, et al. Research on promoting sludge cracking and the biogas production efficiency of anaerobic digestion by different pretreatment methods[J]. Journal of Shaanxi University of Science & Technology, 2022, 40(2): 13-19, 27. | |

| [8] | 沈嘉辉, 王侃宏, 梁玉帅, 等. 游离氨预处理污泥促进有机物释放过程研究[J]. 现代化工, 2023, 43(7): 104-112. |

| [29] | Yao B, Liu M, Yu L Q, et al. Mechanism of biochar in alleviating the inhibition of anaerobic digestion under ciprofloxacin press[J]. Journal of Hazardous Materials, 2024, 480: 135949. |

| [30] | Zhu D M, Wang Z X, Liu K Q, et al. Multi-cycle anaerobic digestion of hydrothermal liquefaction aqueous phase: role of carbon and iron based conductive materials in inhibitory compounds degradation, microbial structure shaping, and interspecies electron transfer regulation[J]. Chemical Engineering Journal, 2023, 454: 140019. |

| [31] | Ma X Z, Li S L, Pan R K, et al. Effect of biochar on the mitigation of organic volatile fatty acid emission during aerobic biostabilization of biosolids and the underlying mechanism[J]. Journal of Cleaner Production, 2023, 390: 136213. |

| [32] | 陈烨, 孙治雷, 吴能友, 等. 海洋沉积物中甲烷代谢微生物的研究进展[J]. 海洋地质与第四纪地质, 2022, 42(6): 82-92. |

| Chen Y, Sun Z L, Wu N Y, et al. Advances in the study of methane-metabolizing microbial communities in marine sediments[J]. Marine Geology & Quaternary Geology, 2022, 42(6): 82-92. | |

| [33] | 于亚梅, 沈雁文, 朱南文, 等. 生物炭和石墨的电化学性质对剩余污泥厌氧消化产甲烷的影响[J]. 环境工程学报, 2020, 14(3): 807-820. |

| Yu Y M, Shen Y W, Zhu N W, et al. Effect of electrochemical properties of biochar and graphite on methane production in anaerobic digestion of excess activated sludge[J]. Chinese Journal of Environmental Engineering, 2020, 14(3): 807-820. | |

| [34] | 尹若愚, 李乃玉, 全向春, 等. 负载纳米零价铁及Fe3O4颗粒对厌氧颗粒污泥长期运行性能及微生物群落结构影响[J]. 环境科学学报, 2023, 43(11): 24-32. |

| Yin R Y, Li N Y, Quan X C, et al. Effects of zero valent iron and ferriferrous oxide loading on methanogenesis performance of anaerobic granular sludge and microbial community under a long-term operation[J]. Acta Scientiae Circumstantiae, 2023, 43(11): 24-32. | |

| [35] | 尚欣宇, 孙晓娇, 徐艳, 等. 纳米铁氧化物对Pelotomaculum schinkii培养系丙酸厌氧降解产甲烷的影响[J]. 微生物学杂志, 2024, 44(1): 32-39. |

| Shang X Y, Sun X J, Xu Y, et al. Influence of iron oxides nanoparticles on anaerobic degradation of propionic acid in Pelotomaculum schinkii cultivation system to produce mathane[J]. Journal of Microbiology, 2024, 44(1): 32-39. | |

| [36] | 许晓晴, 陈烨, 甄毓, 等. 渤海沉积物中产甲烷途径及产甲烷菌群落特征[J]. 海洋地质与第四纪地质, 2022, 42(3): 50-61. |

| [8] | Shen J H, Wang K H, Liang Y S, et al. Study on promotion of organic matters release through pretreatment of sludge by free ammonia[J]. Modern Chemical Industry, 2023, 43(7): 104-112. |

| [9] | 王晨路, 刘吉宝, 解立平, 等. 铁(Ⅱ)-炭活化过硫酸盐对剩余污泥中溶解性有机物释放的影响[J]. 环境工程学报, 2021, 15(12): 4009-4017. |

| Wang C L, Liu J B, Xie L P, et al. Influence on DOM release from sewage sludge by Fe(Ⅱ)-AC activating persulfate[J]. Chinese Journal of Environmental Engineering, 2021, 15(12): 4009-4017. | |

| [10] | Li H, Li C C, Liu W J, et al. Optimized alkaline pretreatment of sludge before anaerobic digestion[J]. Bioresource Technology, 2012, 123: 189-194. |

| [11] | Ye J, Hu A D, Ren G P, et al. Red mud enhances methanogenesis with the simultaneous improvement of hydrolysis-acidification and electrical conductivity[J]. Bioresource Technology, 2018, 247: 131-137. |

| [12] | Li J, Wang Q H, Liang J H, et al. An enhanced disintegration using refinery spent caustic for anaerobic digestion of refinery waste activated sludge[J]. Journal of Environmental Management, 2021, 284: 112022. |

| [13] | 蔡美辰, 戚丹丹, 刘林林, 等. 碱预处理提高剩余污泥厌氧产甲烷性能研究[J]. 中国沼气, 2020, 38(4): 3-8. |

| Cai M C, Qi D D, Liu L L, et al. Enhancing anaerobic methane production of sewage sludge by alkaline pretreatment[J]. China Biogas, 2020, 38(4): 3-8. | |

| [14] | Pratap V, Kumar S, Yadav B R. Effect of low-temperature thermal-alkali pre-treatment on waste activated sludge solubilisation[J]. Process Safety and Environmental Protection, 2024, 189: 530-540. |

| [15] | Zhen G Y, Lu X Q, Li Y Y, et al. Combined electrical-alkali pretreatment to increase the anaerobic hydrolysis rate of waste activated sludge during anaerobic digestion[J]. Applied Energy, 2014, 128: 93-102. |

| [16] | Ramos-Suarez M, Zhang Y, Heaven S. Acidogenic fermentation of organic residual solids: effect of different alkaline sources on pH, alkalinity, and fermentation performance[J]. Fermentation, 2024, 10(11): 571. |

| [17] | 李晋, 梁家豪, 马文峰, 等. 热-碱渣预处理强化炼厂剩余活性污泥厌氧消化性能[J]. 化工进展, 2023, 42(12): 6609-6619. |

| Li J, Liang J H, Ma W F, et al. Enhanced anaerobic digestion of refinery waste activated sludge using thermal-refinery spend caustic pretreatment[J]. Chemical Industry and Engineering Progress, 2023, 42(12): 6609-6619. | |

| [18] | Li J, Xin W Z, Liang J H, et al. Alkaline fermentation of refinery waste activated sludge mediated by refinery spent caustic for volatile fatty acids production[J]. Journal of Environmental Management. 2022, 324: 116317. |

| [19] | Wang D B, Huang Y X, Xu Q X, et al. Free ammonia aids ultrasound pretreatment to enhance short-chain fatty acids production from waste activated sludge[J]. Bioresource Technology, 2019, 275: 163-171. |

| [20] | Zeng Q, Zan F X, Hao T W, et al. Electrochemical pretreatment for stabilization of waste activated sludge: simultaneously enhancing dewaterability, inactivating pathogens and mitigating hydrogen sulfide[J]. Water Research, 2019, 166: 115035. |

| [21] | Yukesh Kannah R, Kavitha S, Rajesh Banu J, et al. Synergetic effect of combined pretreatment for energy efficient biogas generation[J]. Bioresource Technology, 2017, 232: 235-246. |

| [22] | 郭送军, 韦进毅, 王晨路, 等. 基于FT-ICR MS的蒸汽爆破预处理强化污泥厌氧消化的有机物分子解析[J]. 环境工程学报, 2023, 17(4): 1337-1345. |

| Guo S J, Wei J Y, Wang C L, et al. Molecular analysis of organic compounds in anaerobic digestion of sludge enhanced by steam explosion pretreatment based on FT-ICR MS[J]. Chinese Journal of Environmental Engineering, 2023, 17(4): 1337-1345. | |

| [23] | 郝晓地, 唐兴, 李季, 等. 腐殖酸影响剩余污泥厌氧消化过程实验研究[J]. 环境科学学报, 2018, 38(8): 3061-3068. |

| Hao X D, Tang X, Li J, et al. Experimental study on the effect of humic acid on the process of anaerobic digestion of excess sludge[J]. Acta Scientiae Circumstantiae, 2018, 38(8): 3061-3068. | |

| [24] | Muenmee S, Theepharaksapan S, Boonnorat J. Effect of food to microbe (F/M) ratio on anaerobic digestion of refinery waste sludge under mesophilic conditions: biogas potential and phytotoxicity[J]. Current Applied Science and Technology, 2022, 1: 1-11. |

| [25] | Wang J S, Zhang Z J, Ye X, et al. Enhanced solubilization and biochemical methane potential of waste activated sludge by combined free nitrous acid and potassium ferrate pretreatment[J]. Bioresource Technology, 2020, 297: 122376. |

| [26] | He H Y, Liu Y L, Wang X S, et al. Effects of newly prepared alkaline ferrate on sludge disintegration and methane production: reaction mechanism and model simulation[J]. Chemical Engineering Journal, 2018, 343: 520-529. |

| [36] | Xu X Q, Chen Y, Zhen Y, et al. Methanogenic pathways and methanogen communities in the sediments from Bohai Sea[J]. Marine Geology & Quaternary Geology, 2022, 42(3): 50-61. |

| [37] | 阮敏, 孙宇桐, 黄忠良, 等. 污泥预处理-厌氧消化体系的能源经济性评价[J]. 化工进展, 2022, 41(3): 1503-1516. |

| Ruan M, Sun Y T, Huang Z L, et al. Energy economy evaluation of sludge pretreatment-anaerobic digestion system[J]. Chemical Industry and Engineering Progress, 2022, 41(3): 1503-1516. | |

| [27] | Yuan Z W, He C, Shi Q, et al. Molecular insights into the transformation of dissolved organic matter in landfill leachate concentrate during biodegradation and coagulation processes using ESI FT-ICR MS[J]. Environmental Science & Technology, 2017, 51(14): 8110-8118. |

| [28] | Harirchi S, Wainaina S, Sar T, et al. Microbiological insights into anaerobic digestion for biogas, hydrogen or volatile fatty acids (VFAs): a review[J]. Bioengineered, 2022, 13(3): 6521-6557. |

| [1] | 何婷, 张开, 林文胜, 陈利琼, 陈家富. 沼气超临界压力低温脱碳-液化耦合流程研究[J]. 化工学报, 2025, 76(S1): 418-425. |

| [2] | 陆学瑞, 周帼彦, 方琦, 俞孟正, 张秀成, 涂善东. 固体氧化物燃料电池外重整器积炭效应数值模拟研究[J]. 化工学报, 2025, 76(7): 3295-3304. |

| [3] | 周臣儒, 刘陈伟, 王志远, 綦民辉, 董三宝, 王翔宇, 李明忠. 甲醇和乙二醇对甲烷水合物黏附强度的影响[J]. 化工学报, 2025, 76(7): 3596-3604. |

| [4] | 麦棹铭, 武颖韬, 王维, 穆海宝, 黄佐华, 汤成龙. 正十二烷-甲烷双燃料非线性着火特性及稀释气体效应研究[J]. 化工学报, 2025, 76(6): 3115-3124. |

| [5] | 马瑞洁, 黄子轩, 关雪倩, 陈光进, 刘蓓. ZIF-8/DMPU浆液分离C2H6/ CH4混合气研究[J]. 化工学报, 2025, 76(5): 2262-2269. |

| [6] | 张玮杰, 何甲文, 张一鸣, 李德立, 胡光亚, 蔡骁, 王金华, 黄佐华. 燃料分层对多级旋流甲烷燃烧流场和火焰结构影响研究[J]. 化工学报, 2025, 76(4): 1754-1764. |

| [7] | 石美琳, 赵连达, 邓行健, 王静松, 左海滨, 薛庆国. 催化甲烷重整工艺的研究进展[J]. 化工学报, 2024, 75(S1): 25-39. |

| [8] | 赵焕娟, 包颖昕, 于康, 刘婧, 钱新明. 多元组分爆轰不稳定性定量实验研究[J]. 化工学报, 2024, 75(S1): 339-348. |

| [9] | 徐宏标, 杨亮, 李子栋, 刘道平. 盐水微滴/泡沫铜复合体系中甲烷水合物生成动力学研究[J]. 化工学报, 2024, 75(9): 3287-3296. |

| [10] | 张祎琪, 谭雪松, 李吾环, 张权, 苗长林, 庄新姝. 温和条件下乙二醇苯醚高效分离回收甘蔗渣组分[J]. 化工学报, 2024, 75(6): 2274-2282. |

| [11] | 刘礼豪, 黄婷, 雍宇, 罗昕浩, 赵泽明, 宋尚飞, 史博会, 陈光进, 宫敬. 含粉砂盐水体系甲烷水合物生成与固相沉积规律[J]. 化工学报, 2024, 75(5): 1987-2000. |

| [12] | 王沛, 段睿明, 张广儒, 金万勤. 光热驱动的膜分离生物甲烷制氢过程建模与仿真分析[J]. 化工学报, 2024, 75(3): 967-973. |

| [13] | 马浩天, 荆体瑞, 刘程程, 玉散·吐拉甫, 张喆, 王一迪, 王庆宏, 陈春茂, 徐春明. Sr改性LaFeO3用于甲烷化学链重整的还原性能与动力学研究[J]. 化工学报, 2024, 75(12): 4532-4546. |

| [14] | 梁爽, 李兴洵, 高龙燕, 郭绪强, 陈光进, 孙长宇. 油相中水滴表面甲烷水合物膜生长动力学研究[J]. 化工学报, 2024, 75(11): 4369-4377. |

| [15] | 杨百玉, 寇悦, 姜峻韬, 詹亚力, 王庆宏, 陈春茂. 炼化碱渣湿式氧化预处理过程DOM的化学转化特征[J]. 化工学报, 2023, 74(9): 3912-3920. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号