• •

高龙飞1,2( ), 白进1,2(

), 白进1,2( ), 刘星辰1,2, 孔令学1,2, 李怀柱1, 白宗庆1,2, 李文1,2

), 刘星辰1,2, 孔令学1,2, 李怀柱1, 白宗庆1,2, 李文1,2

收稿日期:2025-08-04

修回日期:2025-11-10

出版日期:2025-11-11

通讯作者:

白进

作者简介:高龙飞(1995—),男,博士,助理研究员,gaolongfei@sxicc.ac.cn

基金资助:

Longfei GAO1,2( ), Jin BAI1,2(

), Jin BAI1,2( ), Xingchen LIU1,2, Lingxue KONG1,2, Huaizhu LI1, Zongqing BAI1,2, Wen LI1,2

), Xingchen LIU1,2, Lingxue KONG1,2, Huaizhu LI1, Zongqing BAI1,2, Wen LI1,2

Received:2025-08-04

Revised:2025-11-10

Online:2025-11-11

Contact:

Jin BAI

摘要:

煤炭清洁高效利用是我国能源转型的关键路径,气流床气化作为现代煤化工的核心工艺,熔渣流动性决定着气化炉运行稳定性。气化熔渣的结构特征决定了其黏度、熔点等关键物化性质,本文系统综述了熔渣从宏观、介观到微观的多尺度结构研究进展,论述了其多维结构特征,总结了各尺度结构参数的计算原理及分析方法,回顾了硅酸盐熔体领域的理论发展概况。论述了实验表征、分子模拟技术以及人工智能等方法在熔渣研究中的关键进展,以及各类方法的优势与局限。通过对聚合度理论、电荷补偿理论到氧键结构、环分布以及动态演化理论的梳理,论述了熔渣体系从静态统计描述到动态演化机制认知的范式转变。研究发现熔渣结构的动态演化主导流变行为,未来需发展原位表征技术耦合机器学习和多尺度模拟,构建高质量、标准化的物性与结构数据库,并发展融合物理机理的可解释机器学习模型,为熔渣性质的精准调控与气化工艺的优化提供坚实的理论基石。

中图分类号:

高龙飞, 白进, 刘星辰, 孔令学, 李怀柱, 白宗庆, 李文. 煤气化熔渣结构的多尺度研究进展[J]. 化工学报, DOI: 10.11949/0438-1157.20250864.

Longfei GAO, Jin BAI, Xingchen LIU, Lingxue KONG, Huaizhu LI, Zongqing BAI, Wen LI. Advances in multiscale study of coal gasification slag structure[J]. CIESC Journal, DOI: 10.11949/0438-1157.20250864.

| 离子 | 半径Å | 离子势 | 电负性 | 主配位数 | 类型 |

|---|---|---|---|---|---|

| Si4+ | 0.41 | 9.76 | 1.90 | 4 | 造网组分 |

| Al3+ | 0.50 | 6.00 | 1.50 | 4 | |

| Ti4+ | 0.68 | 5.88 | 1.54 | 4 | |

| P5+ | 0.34 | 14.71 | 2.15 | 4 | |

| Ca2+ | 1.06 | 1.89 | 1.00 | 6 | 修饰组分 |

| Na+ | 0.95 | 1.05 | 0.90 | 6 | |

| K+ | 1.39 | 0.72 | 0.80 | 6 | |

| Mn2+ | 0.91 | 2.20 | 1.50 | 6 | |

| Fe2+ | 0.75 | 2.67 | 1.80 | 6 | |

| Mg2+ | 0.65 | 3.08 | 1.20 | 6 |

表1 硅酸盐熔体中常见离子的主要参数[31-34]

Table 1 Main parameters of ions in silicate melts[31-34]

| 离子 | 半径Å | 离子势 | 电负性 | 主配位数 | 类型 |

|---|---|---|---|---|---|

| Si4+ | 0.41 | 9.76 | 1.90 | 4 | 造网组分 |

| Al3+ | 0.50 | 6.00 | 1.50 | 4 | |

| Ti4+ | 0.68 | 5.88 | 1.54 | 4 | |

| P5+ | 0.34 | 14.71 | 2.15 | 4 | |

| Ca2+ | 1.06 | 1.89 | 1.00 | 6 | 修饰组分 |

| Na+ | 0.95 | 1.05 | 0.90 | 6 | |

| K+ | 1.39 | 0.72 | 0.80 | 6 | |

| Mn2+ | 0.91 | 2.20 | 1.50 | 6 | |

| Fe2+ | 0.75 | 2.67 | 1.80 | 6 | |

| Mg2+ | 0.65 | 3.08 | 1.20 | 6 |

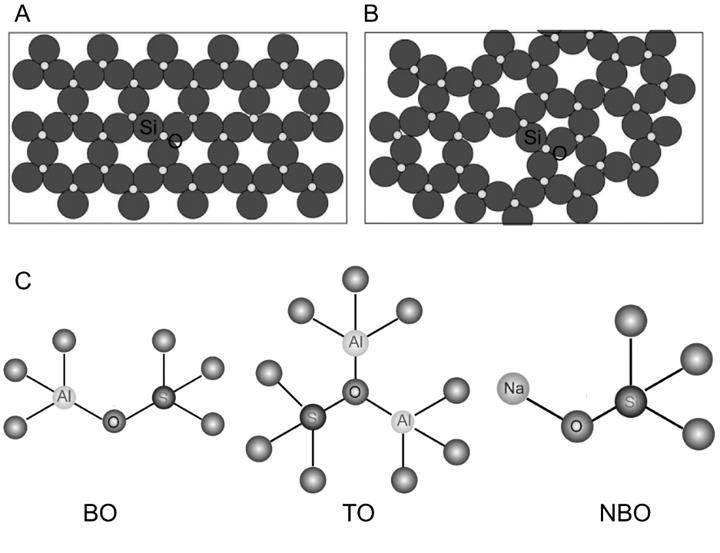

图2 硅酸盐熔体结构示意图:(A) 结晶态[37]; (B) 非晶态[37]; (C) 氧键结构注:(B) Amorphous state[37]; (C) Oxygen bond structure

Fig. 2 Schematic structure of silicate melts: (A) Crystalline state[37];

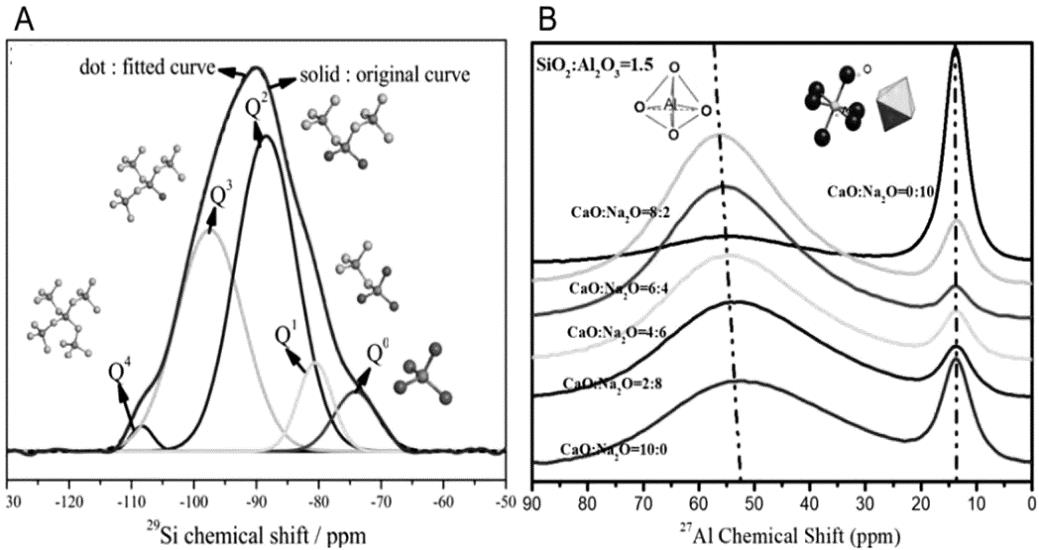

图4 核磁分析结果示意图:(A) 熔渣29Si-NMR谱图[54]; (B) 不同CaO/Na2O下熔渣27Al-NMR谱图[55]

Fig. 4 Schematic of NMR analysis results: (A) ²⁹Si-NMR spectrum of molten slag [54]; (B) ²⁷Al-NMR spectra of molten slag under different CaO/Na₂O ratios [55]

| Atom | z (e) | B (kJ/mol) | ρ (A) | C (A6 kJ/mol) |

|---|---|---|---|---|

| O | -0.945 (-1.20) | 870570.0 (889916.0) | 0.265 (0.265) | 8210.17 (8210.17) |

| Si | 1.89 (2.40) | 4853815.5 (5900530.0) | 0.161 (0.161) | 4467.07 (4467.07) |

| Ti | 1.89 | 4836495 | 0.178 | 4467.07 |

| Al | 1.4175 | 2753544.3 | 0.172 | 3336.26 |

| Fe3+ | 1.4175 | 773840 | 0.19 | 0 |

| Fe2+ | 0.945 (1.20) | 1257488.6 (1450950.0) | 0.190 (0.190) | 0.0 (0.0) |

| Mg | 0.945 | 3150507.4 | 0.178 | 2632.22 |

| Ca | 0.945 | 15019679.1 | 0.178 | 4077.45 |

| Na | 0.4725 | 11607587.5 | 0.17 | 0 |

| K | 0.4725 | 220447.4 | 0.29 | 0 |

| Mg | 0.945 | 870570.0 (889916.0) | 0.178 | 2632.22 |

表2 熔渣体系原子势参数[69]

Table 2 Parameter of potential function[69]

| Atom | z (e) | B (kJ/mol) | ρ (A) | C (A6 kJ/mol) |

|---|---|---|---|---|

| O | -0.945 (-1.20) | 870570.0 (889916.0) | 0.265 (0.265) | 8210.17 (8210.17) |

| Si | 1.89 (2.40) | 4853815.5 (5900530.0) | 0.161 (0.161) | 4467.07 (4467.07) |

| Ti | 1.89 | 4836495 | 0.178 | 4467.07 |

| Al | 1.4175 | 2753544.3 | 0.172 | 3336.26 |

| Fe3+ | 1.4175 | 773840 | 0.19 | 0 |

| Fe2+ | 0.945 (1.20) | 1257488.6 (1450950.0) | 0.190 (0.190) | 0.0 (0.0) |

| Mg | 0.945 | 3150507.4 | 0.178 | 2632.22 |

| Ca | 0.945 | 15019679.1 | 0.178 | 4077.45 |

| Na | 0.4725 | 11607587.5 | 0.17 | 0 |

| K | 0.4725 | 220447.4 | 0.29 | 0 |

| Mg | 0.945 | 870570.0 (889916.0) | 0.178 | 2632.22 |

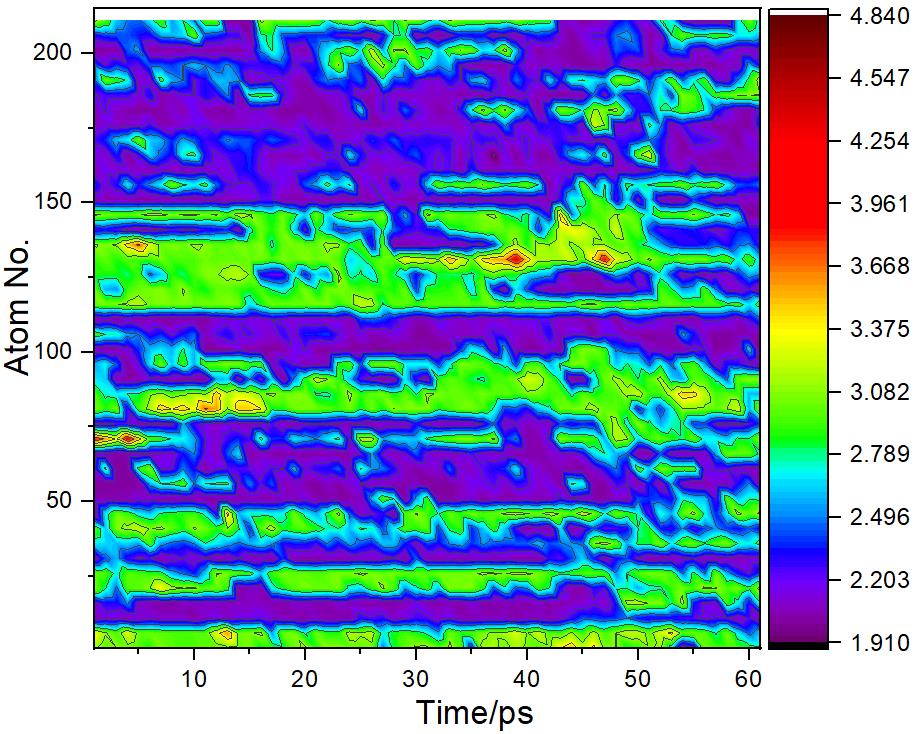

图17 瞬态配位分析示意图[12](X轴为时间轴,Y轴数字代表分子原子序号,颜色代表原子配位数)

Fig. 17 Schematic diagram of transient coordination analysis [12] (X-axis: time; Y-axis: atomic Number; Color: atomic Coordination Number)

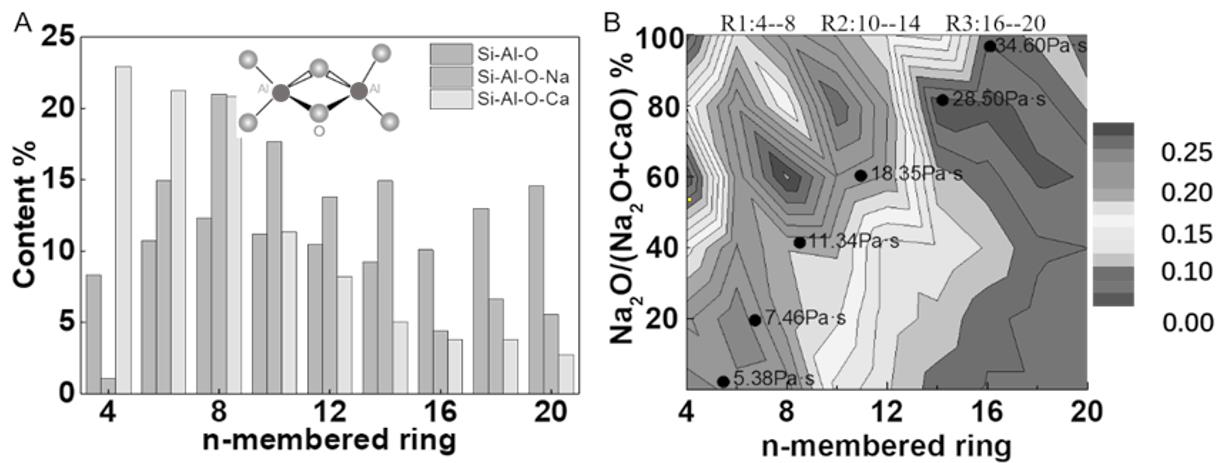

图22 熔渣环结构分布:(A)不同体系环分布结果; (B)环分布-组成-黏度关联结果[11]

Fig. 22 Ring structure distribution in slag: (A) Ring statistics across systems; (B) Ring-viscosity-composition correlation[11]

| [1] | 谢克昌. 新型能源体系发展思考与建议[J]. 中国工程科学, 2024, 26(4): 1-8. |

| Xie K C. Strategic thinking and suggestions on new energy system[J]. Strategic Study of Chinese Academy of Engineering, 2024, 26(4): 1-8. | |

| [2] | 谢克昌. 新型能源体系发展背景下煤炭清洁高效转化的挑战及途径[J]. 煤炭学报, 2024, 49(1): 47-56. |

| Xie K C. Develop new energy system and promote clean and efficient conversion of coal[J]. Journal of China Coal Society, 2024, 49(1): 47-56. | |

| [3] | 王辅臣. 煤气化技术在中国: 回顾与展望[J]. 洁净煤技术, 2021, 27(1): 1-33. |

| Wang F C. Coal gasification technologies in China: Review and prospect[J]. Clean Coal Technology, 2021, 27(1): 1-33. | |

| [4] | 吕清刚, 柴祯. "双碳"目标下的化石能源高效清洁利用[J]. 中国科学院院刊, 2022, 37(4): 541-548. |

| Lyu Q G, Chai Z. Highly efficient and clean utilization of fossil energy under carbon peak and neutrality targets[J]. Bulletin of Chinese Academy of Sciences, 2022, 37(4): 541-548. | |

| [5] | 李文, 白进. 煤的灰化学[M]. 北京: 科学出版社, 2013. |

| Li W, Bai J. Coal Ash Chemistry [M]. Beijing: Science Press, 2013. | |

| [6] | Zhang L M, Song X D, Wei J T, et al. Effect of iron on crystallization and flow properties of coal ash slag: a combined computational-experimental study[J]. Fuel, 2023, 334: 126751. |

| [7] | 王鑫, 李晓东, 李臣威, 等. 煤气化渣资源化利用现状及碳-灰分离技术研究进展[J/OL]. 煤炭学报, 2025: 1-21. (2025-04-30). . |

| Wang X, Li X D, Li C W, et al. Advances in the resource utilization of coal gasification slag and carbon-ash separation technology [J/OL]. Journal of China Coal Society, 2025: 1-21. (2025-04-30). . | |

| [8] | 袁刚, 孙宇, 苏梓慧, 等. 煤气化渣资源化利用研究进展、挑战与创新[J/OL]. 化工进展, 2025: 1-26. (2025-07-03). . |

| Yuan G, Sun Y, Su Z H, et al. Advances, challenges and innovations in resource utilization of coal gasification slag [J/OL]. Chemical Industry and Engineering Progress, 2025: 1-26. (2025-07-03). . | |

| [9] | Dai X, Bai J, Huang Q, et al. Coal ash fusion properties from molecular dynamics simulation: the role of calcium oxide[J]. Fuel, 2018, 216: 760-767. |

| [10] | Dai X, Bai J, Huang Q, et al. Viscosity temperature properties from molecular dynamics simulation: The role of calcium oxide, sodium oxide and ferrous oxide[J]. Fuel, 2019, 237: 163-169. |

| [11] | Gao L F, Liu X C, Bai J, et al. Structure and flow properties of coal ash slag using ring statistics and molecular dynamics simulation: Role of CaO/Na2O in SiO2–Al2O3–CaO–Na2O[J]. Chemical Engineering Science, 2021, 231: 116285. |

| [12] | Gao L F, Liu X C, Bai J, et al. The crucial role of transient tri-coordinated oxygen in the flow of silicate melts[J]. Physical Chemistry Chemical Physics, 2024, 26(9): 7920-7930. |

| [13] | Ni H W. Advances and application in physicochemical properties of silicate melts[J]. Chinese Science Bulletin, 2013, 58(10): 865-890. |

| [14] | An H Q, Liu Z, Tian F C. A machine learning framework for coal gasification process simulation and operation optimization[J]. Fuel, 2025, 401: 135934. |

| [15] | 刘东飞, 张帆, 刘铮, 等. 机器学习势及其在分子模拟中的应用综述[J]. 化工学报, 2024, 75(4): 1241-1255. |

| Liu D F, Zhang F, Liu Z, et al. A review of machine learning potentials and their applications to molecular simulation[J]. CIESC Journal, 2024, 75(4): 1241-1255. | |

| [16] | Sun Y Z, Sun K D, Liu Z, et al. Ash fusion temperature prediction based on a Bayesian-optimized ensemble learning algorithm[J]. Clean Energy, 2025, 9(5): 104-113. |

| [17] | Abdelrahim A I M, Yücel Ö. A machine learning based regression methods to predicting syngas composition for plasma gasification system[J]. Fuel, 2025, 381: 133575. |

| [18] | Chen J H, Feng Y F, Zhang Y X, Luan X, Lu X G, Yu Z G, Chou K. Viscosity prediction of refining slag based on machine learning with domain knowledge[J/OL]. International Journal of Minerals, Metallurgy and Materials 2025. (2025-5-30). . |

| [19] | 廖昌建, 王晶, 金平, 等. 煤气化渣理化特性及其所含重金属迁移规律综述[J]. 煤炭科学技术, 2025, 53(2): 426-443. |

| Liao C J, Wang J, Jin P, et al. Review of physical and chemical characteristics and heavy metal migration rules of coal gasification slag[J]. Coal Science and Technology, 2025, 53(2): 426-443. | |

| [20] | 钟巍, 鲍光达, 王海川, 等. 基于机器学习算法的熔渣液相线温度预测[J]. 炼钢, 2022, 38(3): 12-19. |

| Zhong W, Bao G D, Wang H C, et al. Prediction of slag liquidus temperature based on machine learning algorithm[J]. Steelmaking, 2022, 38(3): 12-19. | |

| [21] | Wang R Q, Rong B, Ma S, et al. Prediction of ash fusion temperatures of municipal solid waste incinerator ash based on support vector regression[J]. Journal of the Energy Institute, 2023, 111: 101438. |

| [22] | 吴永全. 硅酸盐熔体微观结构及其与宏观性质关系的理论研究[D]. 上海: 上海大学, 2004. |

| Wu Y Q. Theoretical studies on the micro-structure of molten silicates and its relation with the macro-properties[D]. Shanghai: Shanghai University, 2004. | |

| [23] | 陈晓东. 煤中碱金属钠对煤灰高温流动性的影响及机理[D]. 北京: 中国科学院大学, 2018. |

| Chen X D. Effect and mechanism of alkali metal sodium in coal on high temperature fluidity of coal ash[D]. Beijing: University of Chinese Academy of Sciences, 2018. | |

| [24] | 曲江山, 张建波, 孙志刚, 等. 煤气化渣综合利用研究进展[J]. 洁净煤技术, 2020, 26(1): 184-193. |

| Qu J S, Zhang J B, Sun Z G, et al. Research progress on comprehensive utilization of coal gasification slag[J]. Clean Coal Technology, 2020, 26(1): 184-193. | |

| [25] | Vorres K S. Prediction of ash melting behavior from coal ash composition[J]. Analytical Methods for Coal and Coal Products, 1979, Ⅲ: 481-487. |

| [26] | 鲁浩, 白进, 孔令学, 等. 气流床气化炉中煤气化熔渣的结晶行为研究进展[J]. 洁净煤技术, 2024, 30(6): 47-67. |

| Lu H, Bai J, Kong L X, et al. Research progress on the crystallization behavior of coal slag in entrained-flow gasifiers[J]. Clean Coal Technology, 2024, 30(6): 47-67. | |

| [27] | 李丽霞, 贾茹. 硅酸盐物理化学[M]. 天津: 天津大学出版社, 2010. |

| Li L X, Jia R. Physical chemistry of silicate[M]. Tianjin: Tianjin University Press, 2010. | |

| [28] | Toplis M J, Dingwell D B, Hess K U, et al. Viscosity, fragility, and configurational entropy of melts along the join SiO2-NaAlSiO4 [J]. American Mineralogist, 1997, 82(9/10): 979-990. |

| [29] | Majumdar A, Wu M, Pan Y M, et al. Structural dynamics of basaltic melt at mantle conditions with implications for magma oceans and superplumes[J]. Nature Communications, 2020, 11: 4815. |

| [30] | 代鑫. 煤灰结构及流动性关系的实验和理论研究[D]. 北京: 中国科学院大学, 2018. |

| Dai X. Experimental and theoretical study on the relationship between coal ash structure and fluidity[D]. Beijing: University of Chinese Academy of Sciences, 2018. | |

| [31] | Stebbins J F, Kroeker S, Lee S K, et al. Quantification of five- and six-coordinated aluminum ions in aluminosilicate and fluoride-containing glasses by high-field, high-resolution 27Al NMR[J]. Journal of Non-Crystalline Solids, 2000, 275(1/2): 1-6. |

| [32] | Neuville D R, Henderson G S, Cormier L, et al. The structure of crystals, glasses, and melts along the CaO-Al2O3 join: Results from Raman, Al L- and K-edge X-ray absorption, and 27Al NMR spectroscopy[J]. American Mineralogist, 2010, 95(10): 1580-1589. |

| [33] | Fang J L, Pang Z G, Xing X D, et al. Thermodynamic properties, viscosity, and structure of CaO–SiO2–MgO–Al2O3–TiO2-based slag[J]. Materials, 2021, 14(1): 124. |

| [34] | McMillan P, Piriou B, Navrotsky A. A Raman spectroscopic study of glasses along the joins silica-calcium aluminate, silica-sodium aluminate, and silica-potassium aluminate[J]. Geochimica et Cosmochimica Acta, 1982, 46(11): 2021-2037. |

| [35] | 严志明. 铝硅酸盐基高炉渣结构和性能基础研究[D]. 重庆: 重庆大学, 2019. |

| Yan Z M. Fundamental research on the structure and physicochemical properties of aluminosilicate based blast furnace slag[D]. Chongqing: Chongqing University, 2019. | |

| [36] | 刘吉辉. 高炉渣冶金性能与微观结构演变规律分析[D]. 鞍山: 辽宁科技大学, 2022. |

| Liu J H. Analysis on metallurgical properties and microstructure evolution behavior of blast furnace slag[D]. Anshan: University of Science and Technology Liaoning, 2022. | |

| [37] | Stebbins J F. Glass structure, melt structure, and dynamics: Some concepts for petrology[J]. American Mineralogist, 2016, 101(4): 753-768. |

| [38] | Qiu J R, L F, Zheng C G. Mineral transformation during combustion of coal blends[J]. International Journal of Energy Research, 1999, 23(5): 453-463. |

| [39] | Wu X J, Zhang Z X, Chen Y S, et al. Main mineral melting behavior and mineral reaction mechanism at molecular level of blended coal ash under gasification condition[J]. Fuel Processing Technology, 2010, 91(11): 1591-1600. |

| [40] | Stebbins J F, Farnan I. Effects of high temperature on silicate liquid structure: a multinuclear NMR study[J]. Science, 1992, 255(5044): 586-589. |

| [41] | Stebbins J F. NMR evidence for five-coordinated silicon in a silicate glass at atmospheric pressure[J]. Nature, 1991, 351(6328): 638-639. |

| [42] | Liu S B, Stebbins J F, Schneider E, et al. Diffusive motion in alkali silicate melts: an NMR study at high temperature[J]. Geochimica et Cosmochimica Acta, 1988, 52(2): 527-538. |

| [43] | 常翱飞, 丁兴. 热扩散驱动的元素分异和同位素分馏: 一种不容忽视的硅酸盐成分分异机制[J]. 岩石学报, 2020, 36(1): 99-112. |

| Chang A F, Ding X. Thermodiffusion driven element and isotope fractionations: a remarkable differentiation mechanism in silicate systems[J]. Acta Petrologica Sinica, 2020, 36(1): 99-112. | |

| [44] | Feng Z X, Bai J, Vassilev S V, et al. The insight into the fusion process and sintering behaviour of blended ash from co-gasification of coal and biomass feedstock[J]. Fuel, 2025, 388: 134462. |

| [45] | Shi W J, Laabs M, Reinmöller M, et al. In-situ analysis of the effect of CaO/Fe2O3 addition on ash melting and sintering behavior for slagging-type applications[J]. Fuel, 2021, 285: 119090. |

| [46] | 陈江明, 王学云, 张波涛. 固定床液态熔渣气化炉渣池液位控制方法探究[J]. 煤质技术, 2023, 35(8) 43-50. |

| Chen J M, Wang X Y, Zhang B T. Discussion of liquid level control method of slag pool in fixed-bed liquid slagging gasifier[J]. Coal Quality Technology, 2023, 35(8): 43-50. | |

| [47] | 曹欢欢, 赵思远, 张钢强. 煤气化粗渣中残碳对结晶固化特性的影响研究[J]. 化工设计通讯, 2025, 51(7): 1-3. |

| Cao H H, Zhao S Y, Zhang G Q. Research on the impact of residual carbon in coal gasification slag on crystallization and solidification characteristics[J]. Chemical Engineering Design Communications, 2025, 51(7): 1-3. | |

| [48] | 张林民, 宋旭东, 卫俊涛, 等. 气化渣中残炭形成机理及其对灰渣流动性影响[J]. 洁净煤技术, 2025, 31(7): 11-23. |

| Zhang L M, Song X D, Wei J T, et al. Formation mechanism of residual carbon in gasification slag and its effect on ash slag fluidity[J]. Clean Coal Technology, 2025, 31(7): 11-23. | |

| [49] | Wang J, Yuan Z S, Kong L X, et al. The critical condition and kinetics of interaction between residual char and slag in the coal slagging gasifier[J]. Fuel, 2023, 341: 127644. |

| [50] | Han Y L. Seeing crystal formation one particle at a time[J]. Nature Materials, 2020, 19(4): 377-378. |

| [51] | Hu Y C, Tanaka H. Revealing the role of liquid preordering in crystallisation of supercooled liquids[J]. Nature Communications, 2022, 13: 4519. |

| [52] | Lu H, Bai J, Wu G X, et al. The dissolution behavior of anorthite in partly crystallized slag of solid fuel at increasing temperature[J]. Chemical Engineering Journal, 2025, 505: 159668. |

| [53] | 吴永全, 蒋国昌, 尤静林, 等. 非晶态硅酸盐微观结构的研究进展[J]. 硅酸盐学报, 2004, 32(1): 57-62. |

| Wu Y Q, Jiang G C, You J L, et al. Progress of research on microstructure of amorphous silicate[J]. Journal of the Chinese Ceramic Society, 2004, 32(1): 57-62. | |

| [54] | 葛泽峰. 二元复合助剂对煤灰黏温特性和结晶的影响及机理研究[D]. 北京: 中国科学院大学, 2020. |

| Ge Z F. Influence and mechanism of binary fluxes on viscosity and crystallization of coal ash slag [D]. Beijing: University of Chinese Academy of Sciences, 2020. | |

| [55] | Ge Z F, Kong L X, Bai J, et al. Effect of CaO/Na2O on slag viscosity behavior under entrained flow gasification conditions[J]. Fuel Processing Technology, 2018, 181: 352-360. |

| [56] | Stebbins J F, Xu Z. NMR evidence for excess non-bridging oxygen in an aluminosilicate glass[J]. Nature, 1997, 390: 60-62. |

| [57] | Stebbins J F, Dubinsky E V, Kanehashi K, et al. Temperature effects on non-bridging oxygen and aluminum coordination number in calcium aluminosilicate glasses and melts[J]. Geochimica et Cosmochimica Acta, 2008, 72(3): 910-925. |

| [58] | Stebbins J F, Oglesby J V, Kroeker S, et al. Oxygen triclusters, non-bridging oxygens, and the properties of silicate melts: the view from 17O NMR[C]. Eleventh Annual V M Goldschmidt Conference 2001, 5: 3205. |

| [59] | Liao K, Haruta M, Masuno A, et al. Real-space mapping of oxygen coordination in phase-separated aluminosilicate glass: implication for glass stability[J]. ACS Applied Nano Materials, 2020, 3(6): 5053-5060. |

| [60] | Zhou Q, Shi Y, Deng B H, et al. Experimental method to quantify the ring size distribution in silicate glasses and simulation validation thereof[J]. Science Advances, 2021, 7(28): eabh1761. |

| [61] | Mysen B O. The structure of silicate melts[J]. Annual Review of Earth and Planetary Sciences, 1983, 11: 75-97. |

| [62] | Jones J E. On the determination of molecular fields—I. From the variation for molecular simulation[J]. Proc. Roy. Soc. Lond. A, 1924, 738(106): 441-462. |

| [63] | Buckingham R A. The classical equation of state of gaseous helium, neon and argon[J]. Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences, 1938, 168(933): 264-283. |

| [64] | Morse P M. Diatomic molecules according to the wave mechanics. II. vibrational levels[J]. Physical Review, 1929, 34(1): 57-64. |

| [65] | Royce B S H. The creation of point point defects in alkali halides[J]. Progress in Solid State Chemistry, 1967,4: 213-243. |

| [66] | Zhang X B, Liu C J, Jiang M F. Molecular dynamics simulations of melt structure properties of CaO–Al2O3–Na2O slag[J]. Metallurgical and Materials Transactions B, 2021, 52(4): 2604-2611. |

| [67] | Jiang C H, Li K J, Zhang J L, et al. The effect of CaO and MgO on the structure and properties of coal ash in the blast furnace: a molecular dynamics simulation and thermodynamic calculation[J]. Chemical Engineering Science, 2019, 210: 115226. |

| [68] | Dai X, He J, Bai J, et al. Ash fusion properties from molecular dynamics simulation: role of the ratio of silicon and aluminum[J]. Energy & Fuels, 2016, 30(3): 2407-2413. |

| [69] | Matsui M. Computational modeling of crystals and liquids in the system Na2O–CaO–MgO–Al2O3–SiO2, Properties of Earth and Planetary Materials at High Pressure and Temperature[M]. United States of America: AGU Pbulications, 1998. |

| [70] | 李欣欣. Fe基合金液态中程有序结构演变及结构-磁性相关性的第一性原理研究[D]. 济南: 山东大学, 2019. |

| Li X X. Liquid structural evolution on medium-range scale and the correlation between structure and magnetic properties in Fe-based alloys by first principles simulations [D]. Jinan: Shandong University, 2019. | |

| [71] | Solomatova N V, Caracas R. Pressure-induced coordination changes in a pyrolitic silicate melt from ab initio molecular dynamics simulations[J]. Journal of Geophysical Research: Solid Earth, 2019, 124(11): 11232-11250. |

| [72] | Bajgain S K, Ashley A W, Mookherjee M, et al. Insights into magma ocean dynamics from the transport properties of basaltic melt[J]. Nature Communications, 2022, 13(1): 7590. |

| [73] | 张世良, 戚力, 高伟, 等. 分子模拟中常用的结构分析与表征方法综述[J]. 燕山大学学报, 2015, 39(3): 213-220. |

| Zhang S L, Qi L, Gao W, et al. Summary of methods for structural analysis and characterization in molecular modeling[J]. Journal of Yanshan University, 2015, 39(3): 213-220. | |

| [74] | Kim T H, Kelton K F. Structural study of supercooled liquid transition metals[J]. The Journal of Chemical Physics, 2007, 126(5): 054513. |

| [75] | Xuan W W, Wang H N, Xia D H. Deep structure analysis on coal slags with increasing silicon content and correlation with melt viscosity[J]. Fuel, 2019, 242: 362-367. |

| [76] | Jiang C H, Zhang H X, Xiong Z X, et al. Molecular dynamics investigations on the effect of Na2O on the structure and properties of blast furnace slag under different basicity conditions[J]. Journal of Molecular Liquids, 2020, 299: 112195. |

| [77] | Lodesani F, Menziani M C, Hijiya H, et al. Structural origins of the mixed alkali effect in alkali aluminosilicate glasses: molecular dynamics study and its assessment[J]. Scientific Reports, 2020, 10: 2906. |

| [78] | 王辅臣, 代正华. 煤气化-煤炭高效清洁利用的核心技术[J]. 化学世界, 2015, 56(1): 51-55. |

| Wang F C, Dai Z H. Coal gasification-core technology of the efficient and clean utilization of coal[J]. Chemical World, 2015, 56(1): 51-55. | |

| [79] | King S V. Ring configurations in a random network model of vitreous silica[J]. Nature, 1967, 213: 1112-1113. |

| [80] | Ebrahem F, Bamer F, Markert B. The influence of the network topology on the deformation and fracture behaviour of silica glass: a molecular dynamics study[J]. Computational Materials Science, 2018, 149: 162-169. |

| [81] | Goetzke K, Klein H J. Properties and efficient algorithmic determination of different classes of rings in finite and infinite polyhedral networks[J]. Journal of Non-Crystalline Solids, 1991, 127(2): 215-220. |

| [82] | Yuan X L, Cormack A N. Efficient algorithm for primitive ring statistics in topological networks[J]. Computational Materials Science, 2002, 24(3): 343-360. |

| [83] | Le Roux S, Jund P. Ring statistics analysis of topological networks: New approach and application to amorphous GeS2 and SiO2 systems[J]. Computational Materials Science, 2010, 49(1): 70-83. |

| [84] | Gao L F, Liu X C, Bai J, et al. Unveiling charge compensation effects in Na2O–Al2O3–SiO2 melts: atomic-scale mechanisms and implications for fluidity from AIMD simulations[J]. The Journal of Physical Chemistry C, 2024, 128(41): 17756-17766. |

| [85] | Vargas S, Frandsen F J, Dam-Johansen K. Rheological properties of high-temperature melts of coal ashes and other silicates[J]. Progress in Energy and Combustion Science, 2001, 27(3): 237-429. |

| [86] | Ni H W, Keppler H, Behrens H. Electrical conductivity of hydrous basaltic melts: implications for partial melting in the upper mantle[J]. Contributions to Mineralogy and Petrology, 2011, 162(3): 637-650. |

| [87] | Lee S K Stebbins J F. Nature of cation mixing and ordering in Na-Ca silicate glasses and melts[J]. The Journal of Physical Chemistry B, 2003, 107(14): 3141-3148. |

| [88] | Bi Z S, Li K J, Jiang C H, et al. New insights into the traditional charge compensation theory: amphoteric behavior of TiO2 under the guidance of supply–demand relationship[J]. ACS Omega, 2022, 7(24): 21225-21232. |

| [89] | Zachariasen W H. The atomic arrangement in glass[J]. Journal of the American Chemical Society, 1932, 54(10): 3841-3851. |

| [90] | Senior C L, Srinivasachar S. Viscosity of ash particles in combustion systems for prediction of particle sticking[J]. Energy & Fuels, 1995, 9(2): 277-283. |

| [91] | Machin J S, Hanna D L. Viscosity studies of system CaO–MgO–Al2O3–SiO2: 1, 40% SiO2[J]. Journal of the American Ceramic Society, 1945, 28(11): 310-316. |

| [92] | Mills K. the structure and properties of silicate slags, Treatise on Process Metallurgy[M]. Elsevier, 2014, 223-263. |

| [93] | Maekawa H., Nakao T., Shimokawa S.et al. Coordination of sodium ions in NaAlO2–SiO2 melts: a high temperature 23NaNMR study[J]. Physics and Chemistry of Minerals, 1997, 24: 53–65. |

| [94] | Wu G X, Yazhenskikh E, Hack K, et al. Viscosity model for oxide melts relevant to fuel slags. Part 2: the system SiO2–Al2O3–CaO–MgO–Na2O–K2O[J]. Fuel Processing Technology, 2015, 138: 520-533. |

| [95] | Wu G X, Yazhenskikh E, Hack K, et al. Viscosity model for oxide melts relevant to fuel slags. Part 1: Pure oxides and binary systems in the system SiO2–Al2O3–CaO–MgO–Na2O–K2O[J]. Fuel Processing Technology, 2015, 137: 93-103. |

| [96] | Toplis M J, Dingwell D B, Lenci T. Peraluminous viscosity maxima in Na2O–Al2O3–SiO2 liquids: The role of triclusters in tectosilicate melts[J]. Geochimica et Cosmochimica Acta, 1997, 61(13): 2605-2612. |

| [97] | Chartrand P, Pelton A D. Modeling the charge compensation effect in silica-rich Na2O-K2O-Al2O3-SiO2 melts[J]. Calphad, 1999, 23(2): 219-230. |

| [98] | Sreenivasan H, Kinnunen P, Adesanya E, et al. Field strength of network-modifying cation dictates the structure of (Na-Mg) aluminosilicate glasses[J]. Frontiers in Materials, 2020, 7: 267. |

| [99] | Bødker M S, Sørensen S S, Mauro J C, et al. Predicting composition-structure relations in alkali borosilicate glasses using statistical mechanics[J]. Frontiers in Materials, 2019, 6: 175. |

| [100] | Ge Z F, Kong L X, Bai J, et al. Effect of CaO/Fe2O3 ratio on slag viscosity behavior under entrained flow gasification conditions[J]. Fuel, 2019, 258: 116129. |

| [101] | Masson C R, Smith I B, Whiteway S G. Activities and ionic distributions in liquid silicates: application of polymer theory[J]. Canadian Journal of Chemistry, 1970, 48(9): 1456-1464. |

| [102] | Lee S K, Ryu S. Probing of triply coordinated oxygen in amorphous Al2O3 [J]. The Journal of Physical Chemistry Letters, 2018, 9(1): 150-156. |

| [103] | Welch R S, Lee K H, Wilkinson C J, et al. Topological hardening through oxygen triclusters in calcium aluminosilicate glasses[J]. Journal of the American Ceramic Society, 2021, 104(12): 6183-6193. |

| [104] | Bucher D, Guidoni L, Carloni P, et al. Coordination numbers of K+ and Na+ ions inside the selectivity filter of the KcsA potassium channel: insights from first principles molecular dynamics[J]. Biophysical Journal, 2010, 98(10): L47-L49. |

| [105] | Maekawa H, Nakao T, Shimokawa S, et al. Coordination of sodium ions in NaAlO2–SiO2 melts: a high temperature 23Na NMR study[J]. Physics and Chemistry of Minerals, 1997, 24(1): 53-65. |

| [106] | Wang Z, Yu L, Wen G H, et al. A combined computational-experimental study on the effect of Na2O on the fluoride volatilization in molten slags[J]. Journal of Molecular Liquids, 2021, 342: 117499. |

| [107] | Li K J, Khanna R, Zhang J L, et al. Determination of the accuracy and reliability of molecular dynamics simulations in estimating the melting point of iron: Roles of interaction potentials and initial system configurations[J]. Journal of Molecular Liquids, 2019, 290: 111204. |

| [108] | Xuan W W, Wang H N, Xia D H. Depolymerization mechanism of CaO on network structure of synthetic coal slags[J]. Fuel Processing Technology, 2019, 187: 21-27. |

| [109] | Bamer F, Ebrahem F, Markert B. Plasticity in vitreous silica induced by cyclic tension considering rate-dependence: Role of the network topology[J]. Journal of Non-Crystalline Solids, 2019, 503: 176-181. |

| [110] | Liu Q S, Wu J J, Shao Y C, et al. ANN-based model to predict the viscosity of molten blast furnace slag at high temperatures of > 1600 K[J]. Journal of Sustainable Metallurgy, 2023, 9(3): 1020-1032. |

| [1] | 张帅, 徐嘉宇, 华蕾娜, 葛蔚. 气固系统的CG-DPM与MP-PIC耦合模拟方法[J]. 化工学报, 2025, 76(9): 4412-4424. |

| [2] | 胡国祥, 朱忆魁, 龙华, 刘晓雯, 熊勤钢. 组分配比影响氯化胆碱-乳酸低共熔溶剂碱木质素溶解度的底层机理研究[J]. 化工学报, 2025, 76(9): 4449-4461. |

| [3] | 李相海, 赖德林, 孔纲, 周健. 双仿生表面水下疏油协同机制的分子动力学模拟研究[J]. 化工学报, 2025, 76(9): 4551-4562. |

| [4] | 高正, 汪辉, 屈治国. 数据驱动辅助高通量筛选阴离子柱撑金属有机框架储氢[J]. 化工学报, 2025, 76(8): 4259-4272. |

| [5] | 林嘉豪, 付芳忠, 叶昊辉, 胡金, 姚明灿, 范鹤林, 王旭, 王瑞祥, 徐志峰. NdF3含量对NdF3-LiF熔盐局域结构和输运性质的影响[J]. 化工学报, 2025, 76(8): 3834-3841. |

| [6] | 王小令, 王绍清, 赵云刚, 常方哲, 穆瑞峰. 基于ReaxFF MD模拟的煤加氢热解有机Ca转化机制研究[J]. 化工学报, 2025, 76(8): 4297-4309. |

| [7] | 郭铮铮, 赵一丹, 王辅强, 裴璐, 靳彦岭, 任芳, 任鹏刚. 异质结构MoS2/RGO/NiFe2O4复合材料的构筑及电磁波吸收性能研究[J]. 化工学报, 2025, 76(7): 3719-3732. |

| [8] | 乔亮, 李尚, 刘新亮, 王明, 张沛, 侯影飞. 三元共聚物稠油降黏剂的合成及分子模拟研究[J]. 化工学报, 2025, 76(7): 3686-3695. |

| [9] | 李姿睿, 齐凯, 王军, 夏国栋. 基于Janus纳米通道的脱盐过程分子动力学模拟研究[J]. 化工学报, 2025, 76(7): 3531-3538. |

| [10] | 李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357. |

| [11] | 齐昊, 王玉杰, 李申辉, 邹琦, 刘轶群, 赵之平. 双金属Co/Zn-ZIFs中C3H6和C3H8吸附和扩散行为分子模拟研究[J]. 化工学报, 2025, 76(5): 2313-2326. |

| [12] | 陈建兵, 常昊, 高明, 邢兵, 张磊, 刘奇磊. 基于反应模板与分子动力学的胺基相变吸收剂分相预测方法[J]. 化工学报, 2025, 76(5): 2387-2396. |

| [13] | 胡嘉朗, 姜明源, 金律铭, 张永刚, 胡鹏, 纪红兵. 机器学习辅助MOFs高通量计算筛选及气体分离研究进展[J]. 化工学报, 2025, 76(5): 1973-1996. |

| [14] | 朱峰, 赵跃, 马凤翔, 刘伟. 改性UIO-66对SF6/N2混合气体及其分解产物的吸附特性[J]. 化工学报, 2025, 76(4): 1604-1616. |

| [15] | 彭德其, 刘奎霖, 武洋, 俞天兰, 谭卓伟, 吴淑英, 陈莹, 唐明成, 彭建国. 振动往复螺旋强化传热性能及结晶垢微观形貌分析研究[J]. 化工学报, 2025, 76(4): 1559-1568. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号