• •

王宁1( ), 鲁家荣2, 刘一航2, 温家鹏2, 杜丁2, 闫昊2(

), 鲁家荣2, 刘一航2, 温家鹏2, 杜丁2, 闫昊2( ), 刘熠斌2, 陈小博2, 杨朝合2

), 刘熠斌2, 陈小博2, 杨朝合2

收稿日期:2025-09-02

修回日期:2025-11-11

出版日期:2025-11-18

通讯作者:

闫昊

作者简介:王宁(1992—),男,硕士,工程师,cppewangning@cnpc.com.cn

基金资助:

Ning WANG1( ), Jiarong LU2, Yihang LIU2, Jiapeng WEN2, Ding DU2, Hao YAN2(

), Jiarong LU2, Yihang LIU2, Jiapeng WEN2, Ding DU2, Hao YAN2( ), Yibin LIU2, Xiaobo CHEN2, Chaohe YANG2

), Yibin LIU2, Xiaobo CHEN2, Chaohe YANG2

Received:2025-09-02

Revised:2025-11-11

Online:2025-11-18

Contact:

Hao YAN

摘要:

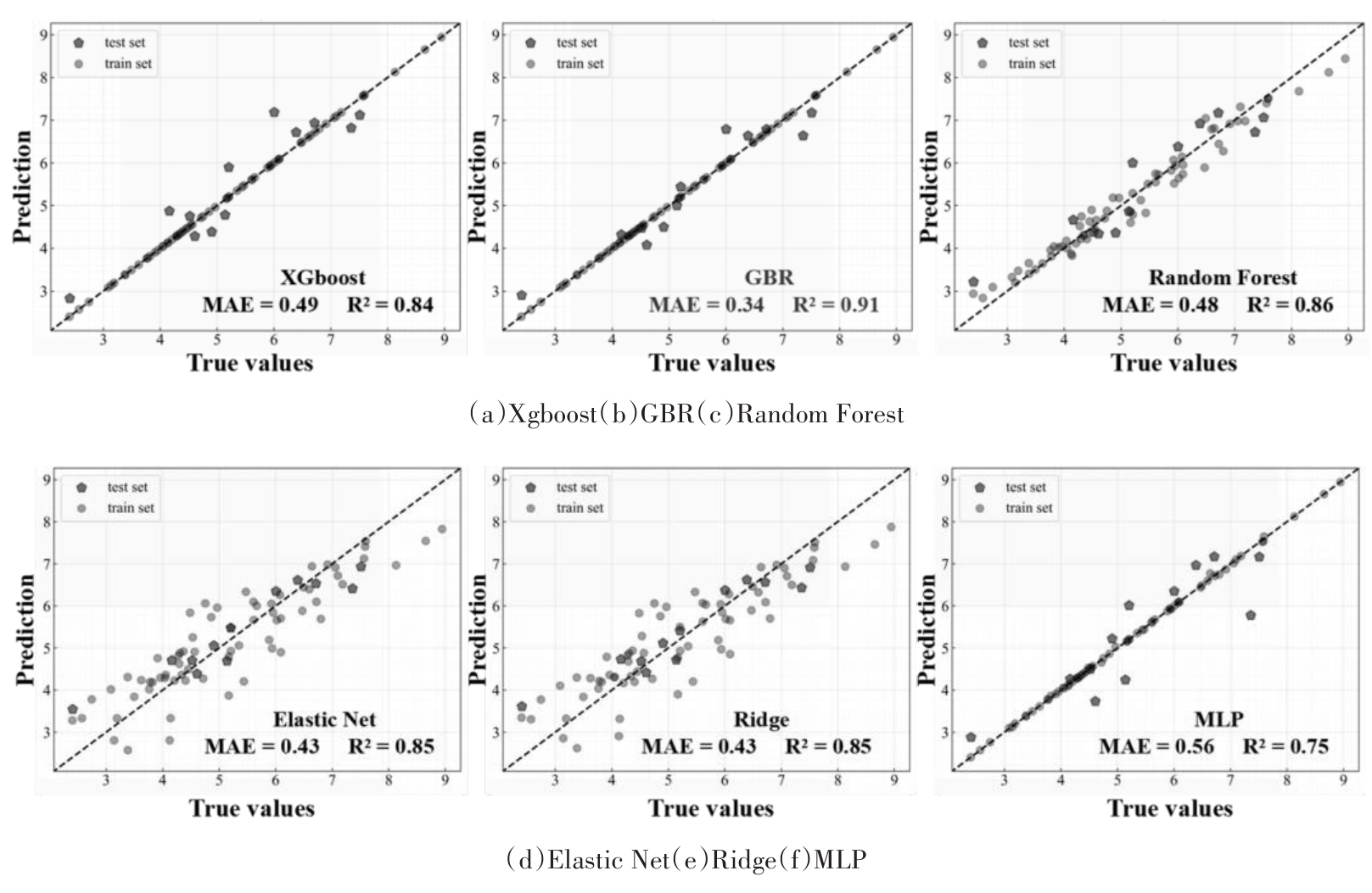

采用巨正则蒙特卡罗方法(GCMC),研究了变压吸附条件下天然气甲烷、二氧化碳组分在80余种分子筛拓扑结构上的纯组分吸附和竞争吸附情况,获得了饱和吸附量、等量吸附热和吸附选择性等衡量CO2吸附性能的数据。其中FAU拓扑结构具有最高的CO2饱和吸附量,WEI拓扑结构具有最高的CO2吸附选择性。综合分子模拟结果与国际分子筛数据库中260种分子筛结构特征构建了1040组数据的数据库,用于CO2饱和吸附量的预测。采用XGboost、GBR等6种机器学习算法对上述数据库进行训练,其中GBR模型在测试集上表现出最高的决定系数(R2=0.91)和最低的均方误差(MAE=0.34)。采用该模型对剩余分子筛的吸附性能进行预测,发现了CLO、IRT等结构,因其较低的框架密度和较大的可及体积表现出媲美FAU的CO2饱和吸附量,且CO2吸附选择性远高于FAU。

中图分类号:

王宁, 鲁家荣, 刘一航, 温家鹏, 杜丁, 闫昊, 刘熠斌, 陈小博, 杨朝合. 机器学习辅助快速筛选高性能CO2吸附分子筛[J]. 化工学报, DOI: 10.11949/0438-1157.20250983.

Ning WANG, Jiarong LU, Yihang LIU, Jiapeng WEN, Ding DU, Hao YAN, Yibin LIU, Xiaobo CHEN, Chaohe YANG. Machine learning-assisted high-throughput screening of high-performance zeolites for CO2 adsorption[J]. CIESC Journal, DOI: 10.11949/0438-1157.20250983.

| 标签 | 来源 | 含义 | 单位 |

|---|---|---|---|

| FD-Si | IZA | 框架密度 | T/1000Å3 |

| TD | IZA | 拓扑密度 | / |

| TD10 | IZA | 配位序列10层拓扑密度 | / |

| Channel | IZA | 沸石孔道维度 | / |

| MSi | IZA | 沸石最大包容球体直径 | Å |

| MSDa | IZA | 沿a轴方向最大球体直径 | Å |

| MSDb | IZA | 沿b轴方向最大球体直径 | Å |

| MSDc | IZA | 沿c轴方向最大球体直径 | Å |

| PSmax | IZA | 沿三维方向最大球体直径 | Å |

| PSmin | IZA | 沿三维方向最小球体直径 | Å |

| AV | IZA | 有效体积 | % |

| CO2ads | MS2018 | 纯组分CO2饱和吸附量 | mmol/g |

| CO2sel | MS2018 | CO2吸附选择性 | / |

表1 天然气脱酸体系高性能CO2吸附拓扑结构机器学习预测特征标签

Table 1 Feature labels for prediction of high-performance CO2 adsorption topologies in natural gas deacidification systems

| 标签 | 来源 | 含义 | 单位 |

|---|---|---|---|

| FD-Si | IZA | 框架密度 | T/1000Å3 |

| TD | IZA | 拓扑密度 | / |

| TD10 | IZA | 配位序列10层拓扑密度 | / |

| Channel | IZA | 沸石孔道维度 | / |

| MSi | IZA | 沸石最大包容球体直径 | Å |

| MSDa | IZA | 沿a轴方向最大球体直径 | Å |

| MSDb | IZA | 沿b轴方向最大球体直径 | Å |

| MSDc | IZA | 沿c轴方向最大球体直径 | Å |

| PSmax | IZA | 沿三维方向最大球体直径 | Å |

| PSmin | IZA | 沿三维方向最小球体直径 | Å |

| AV | IZA | 有效体积 | % |

| CO2ads | MS2018 | 纯组分CO2饱和吸附量 | mmol/g |

| CO2sel | MS2018 | CO2吸附选择性 | / |

图6 六种种机器学习模型对CO2饱和吸附量预测效果,包括平均绝对误差MAE和测试集决定系数R2

Fig.6 Prediction performance of six machine learning models for CO2 saturation uptake: MAE and test set R²

| 机器学习算法 | 最优参数 | 预测效果 |

|---|---|---|

极致梯度提升 (Xgboost) | n_estimators = 300, max_depth = 5 learning_rate = 0.1, subsample = 0.8 colsample_bytree = 0.8 | MAECO2ads = 0.49 R2CO2ads = 0.84 |

梯度提升回归 (Gradient boost) | n_estimators = 200, max_depth = 3 learning_rate = 0.3, subsample = 0.8 | MAECO2ads = 0.34 R2CO2ads = 0.91 |

随机森林回归 (Random forest) | n_estimators = 150, max_depth = 10 min_samples_split = 2, min_samples_leaf = 1 | MAECO2ads = 0.48 R2CO2ads = 0.86 |

弹性网络回归 (Elastic net) | alpha = 0.1, l1_ratio = 0.1, max_iter = 1000 | MAECO2ads = 0.43 R2CO2ads = 0.85 |

岭回归 (Ridge) | alpha = 10, solver = sparse_cg | MAECO2ads = 0.43 R2CO2ads = 0.85 |

多层感知机回归 (MLP) | Activation = relu, alpha = 0.1, hidden_layer_sizes = (50,50,50), learning_rate = constant, solver = lbfgs | MAECO2ads = 0.56 R2CO2ads = 0.75 |

表2 六种机器学习模型预测效果及最优超参数

Table 2 Prediction performance and optimal hyperparameters of six machine learning models

| 机器学习算法 | 最优参数 | 预测效果 |

|---|---|---|

极致梯度提升 (Xgboost) | n_estimators = 300, max_depth = 5 learning_rate = 0.1, subsample = 0.8 colsample_bytree = 0.8 | MAECO2ads = 0.49 R2CO2ads = 0.84 |

梯度提升回归 (Gradient boost) | n_estimators = 200, max_depth = 3 learning_rate = 0.3, subsample = 0.8 | MAECO2ads = 0.34 R2CO2ads = 0.91 |

随机森林回归 (Random forest) | n_estimators = 150, max_depth = 10 min_samples_split = 2, min_samples_leaf = 1 | MAECO2ads = 0.48 R2CO2ads = 0.86 |

弹性网络回归 (Elastic net) | alpha = 0.1, l1_ratio = 0.1, max_iter = 1000 | MAECO2ads = 0.43 R2CO2ads = 0.85 |

岭回归 (Ridge) | alpha = 10, solver = sparse_cg | MAECO2ads = 0.43 R2CO2ads = 0.85 |

多层感知机回归 (MLP) | Activation = relu, alpha = 0.1, hidden_layer_sizes = (50,50,50), learning_rate = constant, solver = lbfgs | MAECO2ads = 0.56 R2CO2ads = 0.75 |

| [1] | 张强. "双碳"背景下我国化石能源的影响分析[J]. 现代工业经济和信息化, 2025, 15(6): 32-33, 40. |

| Zhang Q. Impact analysis of China's fossil energy in the context of "dual carbon"[J]. Modern Industrial Economy and Informationization, 2025, 15(6): 32-33, 40. | |

| [2] | 余晓钟, 杜全燕, 章阐引, 等. 能源转型背景下天然气储运高质量发展路径[J]. 天然气技术与经济, 2024, 18(6): 1-6. |

| Yu X Z, Du Q Y, Zhang C Y, et al. The path to high-quality development of natural-gas storage and transportation in the context of energy transition[J]. Natural Gas Technology and Economy, 2024, 18(6): 1-6. | |

| [3] | 刘帅. "双碳"目标下天然气发电与新能源融合产业碳减排技术路径[J]. 油气与新能源, 2025, 37(4): 83-88. |

| Liu S. Carbon reduction technology pathways for natural gas power generation and new energy integration under the "dual carbon" goals[J]. Petroleum and New Energy, 2025, 37(4): 83-88. | |

| [4] | 田望. 油气储运企业碳管理现状及体系构建[J]. 石油学报(石油加工), 2025, 41(5): 1224-1230. |

| Tian W. Current status and system construction of carbon management in oil and gas storage and transportation enterprises[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2025, 41(5): 1224-1230. | |

| [5] | 李海芹. 天然气处理厂脱酸过程的控制联锁方案设计[J]. 山东化工, 2025, 54(6): 211-214, 217. |

| Li H Q. Design of control interlock scheme for deacidification process in natural gas processing plant[J]. Shandong Chemical Industry, 2025, 54(6): 211-214, 217. | |

| [6] | 刘露, 段振红, 贺高红. 天然气脱除CO2方法的比较与进展[J]. 化工进展, 2009, 28(S1): 290-292. |

| Liu L, Duan Z H, He G H. Comparison and progress of methods for removing CO2 from natural gas[J]. Chemical Industry and Engineering Progress, 2009, 28(S1): 290-292. | |

| [7] | 洪宗平, 叶楚梅, 吴洪, 等. 天然气脱碳技术研究进展[J]. 化工学报, 2021, 72(12): 6030-6048. |

| Hong Z P, Ye C M, Wu H, et al. Research progress in CO2 removal technology of natural gas[J]. CIESC Journal, 2021, 72(12): 6030-6048. | |

| [8] | 王春燕, 杨莉娜, 王念榕, 等. 变压吸附技术在天然气脱除CO2上的应用探讨[J]. 石油规划设计, 2013, 25(1): 52-55. |

| Wang C Y, Yang L N, Wang N R, et al. Discussion on application of pressure swing adsorption technology in CO2 removal from natural gas[J]. Petroleum Planning & Engineering, 2013, 25(1): 52-55. | |

| [9] | 刘宝林. 低温变压吸附脱除天然气中二氧化碳实验研究[D]. 大连: 大连理工大学, 2015. |

| Liu B L. Experimental study of low-temperature and pressure swing adsorption removal carbon dioxide gas from natural gas[D]. Dalian: Dalian University of Technology, 2015. | |

| [10] | 赖丹. 一维超微孔MOFs材料孔径调控与CO2/CH4吸附动力学研究[D]. 杭州: 浙江大学, 2021. |

| Lai D. Engineering the pore size of ultra-microporous MOFs for kinetical separation of CO2/CH4 [D]. Hangzhou: Zhejiang University, 2021. | |

| [11] | Pérez-Botella E, Valencia S, Rey F. Zeolites in adsorption processes: state of the art and future prospects[J]. Chemical Reviews, 2022, 122(24): 17647-17695. |

| [12] | Li Y, Yu J H. Emerging applications of zeolites in catalysis, separation and host–guest assembly[J]. Nature Reviews Materials, 2021, 6(12): 1156-1174. |

| [13] | 赵新红, 王浩, 丁梦琦, 等. 不同合成路线耦合制备沸石分子筛[J]. 化学进展, 2024, 36(4): 525-536. |

| Zhao X H, Wang H, Ding M Q, et al. Coupling different synthesis routes to prepare zeolite molecular sieves[J]. Progress in Chemistry, 2024, 36(4): 525-536. | |

| [14] | 郭彭涛, 王婷, 薛波, 等. 用于CH4/N2分离的多吸附位点超微孔MOF[J]. 化工学报, 2025, 76(5): 2304-2312. |

| Guo P T, Wang T, Xue B, et al. Ultramicroporous MOF with multiple adsorption sites for CH4/N2 separation[J]. CIESC Journal, 2025, 76(5): 2304-2312. | |

| [15] | 张霄, 董毅, 林赛赛, 等. 机器学习加速能源环境催化材料的创新研究[J]. 能源环境保护, 2023, 37(3): 1-12. |

| Zhang X, Dong Y, Lin S S, et al. Machine learning accelerating innovative researches on energy and environmental catalysts[J]. Energy Environmental Protection, 2023, 37(3): 1-12. | |

| [16] | 周印洁, 吉思蓓, 何松阳, 等. 机器学习辅助高通量筛选金属有机骨架用于富碳天然气中分离CO2 [J]. 化工学报, 2025, 76(3): 1093-1101. |

| Zhou Y J, Ji S B, He S Y, et al. Machine learning-assisted high-throughput screening approach for CO2 separation from CO2-rich natural gas using metal-organic frameworks[J]. CIESC Journal, 2025, 76(3): 1093-1101. | |

| [17] | 黄晓珊, 关雅芳, 李惠琳, 等. 机器学习辅助筛选MOFs缓蚀剂载体及其吸附性能预测[J]. 电镀与涂饰, 2025, 44(6): 110-117. |

| Huang X S, Guan Y F, Li H L, et al. Machine learning-assisted screening of MOF carriers for corrosion inhibitors and their adsorption performance prediction[J]. Electroplating & Finishing, 2025, 44(6): 110-117. | |

| [18] | Wanyonyi F S, Fidelis T T, Mutua G K, et al. Role of pore chemistry and topology in the heavy metal sorption by zeolites: From molecular simulation to machine learning[J]. Computational Materials Science, 2021, 195: 110519. |

| [19] | 陈佳丽, 赵国祥, 颜亚玉, 等. 机器学习探究电子气体在沸石分子筛上的吸附[J]. 无机化学学报, 2025, 41(1): 155-164. |

| Chen J L, Zhao G X, Yan Y Y, et al. Machine learning exploring the adsorption of electronic gases on zeolite molecular sieves[J]. Chinese Journal of Inorganic Chemistry, 2025, 41(1): 155-164. | |

| [20] | Chen Y L, Hu W D, Li X, et al. Machine learning prediction of transition-state energies in small-pore zeolites combining acidity and topology descriptors[J]. The Journal of Physical Chemistry C, 2024, 128(9): 3770-3779. |

| [21] | Wang Y, Jiang Z J, Lu W G, et al. Machine learning-assisted exploration of chemical space of MOF-5 analogs for enhanced C2H6/C2H4 separation[J]. Angewandte Chemie International Edition, 2025, 64(21): e202500783. |

| [22] | 汤赛. 沸石分子筛吸附大气中有毒污染物的分子模拟研究[D]. 武汉: 武汉工程大学, 2018. |

| Tang S. Molecular simulation of the adsorption of toxic pollutant in the atmosphere in zeolites[D]. Wuhan: Wuhan Institute of Technology, 2018. | |

| [23] | 王翀, 鲁家荣, 闫昊, 等. NaX分子筛吸附天然气中酸性气的分子模拟[J]. 石油炼制与化工, 2023, 54(9): 41-50. |

| Wang C, Lu J R, Yan H, et al. Molecular simulation of adsorption of acid gas from natural gas in NaX zeolite[J]. Petroleum Processing and Petrochemicals, 2023, 54(9): 41-50. | |

| [24] | Sun H, Jin Z, Yang C W, et al. COMPASS II: extended coverage for polymer and drug-like molecule databases[J]. Journal of Molecular Modeling, 2016, 22(2): 47. |

| [25] | Perdew J, Burke K, Ernzerhof M. Generalized gradient approximation made simple[J]. Physical Review Letters, 1996, 77(18): 3865-3868. |

| [26] | Karimi M, Rodrigues A E, Silva J A C. Designing a simple volumetric apparatus for measuring gas adsorption equilibria and kinetics of sorption. Application and validation for CO2, CH4 and N2 adsorption in binder-free beads of 4A zeolite[J]. Chemical Engineering Journal, 2021, 425: 130538. |

| [27] | Cavenati S, Grande C A, Rodrigues A E. Adsorption equilibrium of methane, carbon dioxide, and nitrogen on zeolite 13X at high pressures[J]. Journal of Chemical & Engineering Data, 2004, 49(4): 1095-1101. |

| [28] | Jedli H, Almoneef M M, Mbarek M, et al. Adsorption of CO2 onto zeolite ZSM-5: Kinetic, equilibrium and thermodynamic studies[J]. Fuel, 2022, 321: 124097. |

| [29] | Sastre G, Corma A. The confinement effect in zeolites[J]. Journal of Molecular Catalysis A: Chemical, 2009, 305(1/2): 3-7. |

| [30] | 郭强, 肇启东, 肖永厚. 双回流变压吸附高效分离CO/H2制备高纯H2和CO[J]. 化工学报, 2024, 75(11): 4298-4308. |

| Guo Q, Zhao Q D, Xiao Y H. Preparation of high-purity H2 and CO by efficient separation of CO/H2 using dual-reflux pressure swing adsorption process[J]. CIESC Journal, 2024, 75(11): 4298-4308. | |

| [31] | 彭晨曦. NaY型分子筛脱除高炉煤气中H2S时COS的生成行为研究[D]. 太原: 太原理工大学, 2024. |

| Peng C X. Study on COS formation behavior in removal of H2S from blast furnace gas by NaY molecular sieve[D]. Taiyuan: Taiyuan University of Technology, 2024. | |

| [32] | Lin Q F, Gao Z R, Lin C, et al. A stable aluminosilicate zeolite with intersecting three-dimensional extra-large pores[J]. Science, 2021, 374(6575): 1605-1608. |

| [33] | Ma C, Zhang Z H, Zhang M D, et al. Accelerated discovery of stable, extra-large-pore nano zeolites with micro-electron diffraction[J]. Science, 2025, 388(6754): 1417-1421. |

| [34] | Wang N N, Dang G L, Bai Z W, et al. In situ synthesis of cation-free zirconia-supported zeolite CHA membranes for efficient CO2/CH4 separation[J]. ACS Applied Materials & Interfaces, 2023, 15(13): 16853-16864. |

| [35] | 孙永彪, 唐建峰, 刘鑫博, 等. 基于动态吸附的X型沸石对CO2/CH4分离性能实验[J]. 中国石油大学学报(自然科学版), 2022, 46(4): 160-167. |

| Sun Y B, Tang J F, Liu X B, et al. Experiment on effect of X type zeolites on separation of CO2/CH4 mixture based on dynamic adsorption[J]. Journal of China University of Petroleum (Edition of Natural Science), 2022, 46(4): 160-167. | |

| [36] | Zhang M J, Qian W X, Ma H F, et al. A theoretical study on the separation of CO2/CH4 through MFI zeolite[J]. Computational and Theoretical Chemistry, 2023, 1228: 114272. |

| [37] | 刘明, 徐若涵, 王浩男, 等. 斜发沸石在不同晶化阶段的微观结构和分形特征及其对CO2和CH4的吸附性能[J]. 北京工业大学学报, 2025, 51(11): 1374-1384. |

| Liu M, Xu R H, Wang H N, et al. Microstructures and fractal characteristics of clinoptilolite synthesized at various crystallization stages for adsorption properties for CO2 and CH4 [J]. Journal of Beijing University of Technology, 2025, 51(11): 1374-1384. | |

| [38] | 董晓莹, 周扬, 宁跃文, 等. 生物模板法制备SAPO-34分子筛及其对CO2/CH4吸附分离性能的研究[J]. 现代化工, 2022, 42(8): 128-133. |

| Dong X Y, Zhou Y, Ning Y W, et al. Preparation of SAPO-34 molecular sieve by biological template method and its application in CO2/CH4 adsorption separation[J]. Modern Chemical Industry, 2022, 42(8): 128-133. | |

| [39] | Lei J, Zhong Z L, Yuan W Y, et al. Development of heterometallic annular tetranuclear clusters in metal–organic frameworks for methane purification and storage[J]. Chem & Bio Engineering, 2024, 1(9): 773-782. |

| [40] | Liu X, Wang H, Liu C, et al. Recent advances of multidentate ligand-based anion-pillared MOFs for enhanced separation and purification processes[J]. Chem & Bio Engineering, 2024, 1(6): 469-487. |

| [1] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [2] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [3] | 马爱华, 赵帅, 王林, 常明慧. 太阳能吸收制冷循环动态特性仿真方法研究[J]. 化工学报, 2025, 76(S1): 318-325. |

| [4] | 黄琮琪, 邵双全. 液冷数据中心余热驱动的压缩-吸收式制冷系统特性研究[J]. 化工学报, 2025, 76(S1): 326-335. |

| [5] | 吕龙义, 唐明磊, 郝鹏, 吴旻昊, 高文芳, 张光明. 导电材料强化高固厌氧消化性能及机制研究进展[J]. 化工学报, 2025, 76(9): 4737-4751. |

| [6] | 胡国祥, 朱忆魁, 龙华, 刘晓雯, 熊勤钢. 组分配比影响氯化胆碱-乳酸低共熔溶剂碱木质素溶解度的底层机理研究[J]. 化工学报, 2025, 76(9): 4449-4461. |

| [7] | 李雪雯, 王治红, 高阳, 吴明鸥, 马文皓, 谭仁敏. 基于热泵技术的醇胺法脱硫再生系统多目标优化研究[J]. 化工学报, 2025, 76(9): 4563-4577. |

| [8] | 李相海, 赖德林, 孔纲, 周健. 双仿生表面水下疏油协同机制的分子动力学模拟研究[J]. 化工学报, 2025, 76(9): 4551-4562. |

| [9] | 钱慧慧, 王文婕, 陈文尧, 周兴贵, 张晶, 段学志. 聚丙烯定向转化制芳烃:金属-分子筛协同催化机制[J]. 化工学报, 2025, 76(9): 4838-4849. |

| [10] | 陈治宏, 吴佳伟, 楼小玲, 贠军贤. 化学品生物制造过程机器学习的研究进展[J]. 化工学报, 2025, 76(8): 3789-3804. |

| [11] | 高正, 汪辉, 屈治国. 数据驱动辅助高通量筛选阴离子柱撑金属有机框架储氢[J]. 化工学报, 2025, 76(8): 4259-4272. |

| [12] | 周媚, 曾浩桀, 蒋火炎, 蒲婷, 曾星星, 刘宝玉. 二次晶化法改性合成MTW分子筛及其在苯和环己烯烷基化反应中的催化性能[J]. 化工学报, 2025, 76(8): 4071-4080. |

| [13] | 林嘉豪, 付芳忠, 叶昊辉, 胡金, 姚明灿, 范鹤林, 王旭, 王瑞祥, 徐志峰. NdF3含量对NdF3-LiF熔盐局域结构和输运性质的影响[J]. 化工学报, 2025, 76(8): 3834-3841. |

| [14] | 王小令, 王绍清, 赵云刚, 常方哲, 穆瑞峰. 基于ReaxFF MD模拟的煤加氢热解有机Ca转化机制研究[J]. 化工学报, 2025, 76(8): 4297-4309. |

| [15] | 范夏雨, 孙建辰, 李可莹, 姚馨雅, 商辉. 机器学习驱动液态有机储氢技术的系统优化[J]. 化工学报, 2025, 76(8): 3805-3821. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号