• •

赵日晶1( ), 谢锃1, 许桐瑞1, 吴永帅1, 黄东1(

), 谢锃1, 许桐瑞1, 吴永帅1, 黄东1( ), 姜学斌2

), 姜学斌2

收稿日期:2025-09-09

修回日期:2025-11-09

出版日期:2025-11-27

通讯作者:

黄东

作者简介:赵日晶(1989—),男,博士,副教授,zhaorijing.4@xjtu.edu.cn

基金资助:

Rijing ZHAO1( ), Zeng XIE1, Tongrui XU1, Yongshuai WU1, Dong HUANG1(

), Zeng XIE1, Tongrui XU1, Yongshuai WU1, Dong HUANG1( ), Xuebin JIANG2

), Xuebin JIANG2

Received:2025-09-09

Revised:2025-11-09

Online:2025-11-27

Contact:

Dong HUANG

摘要:

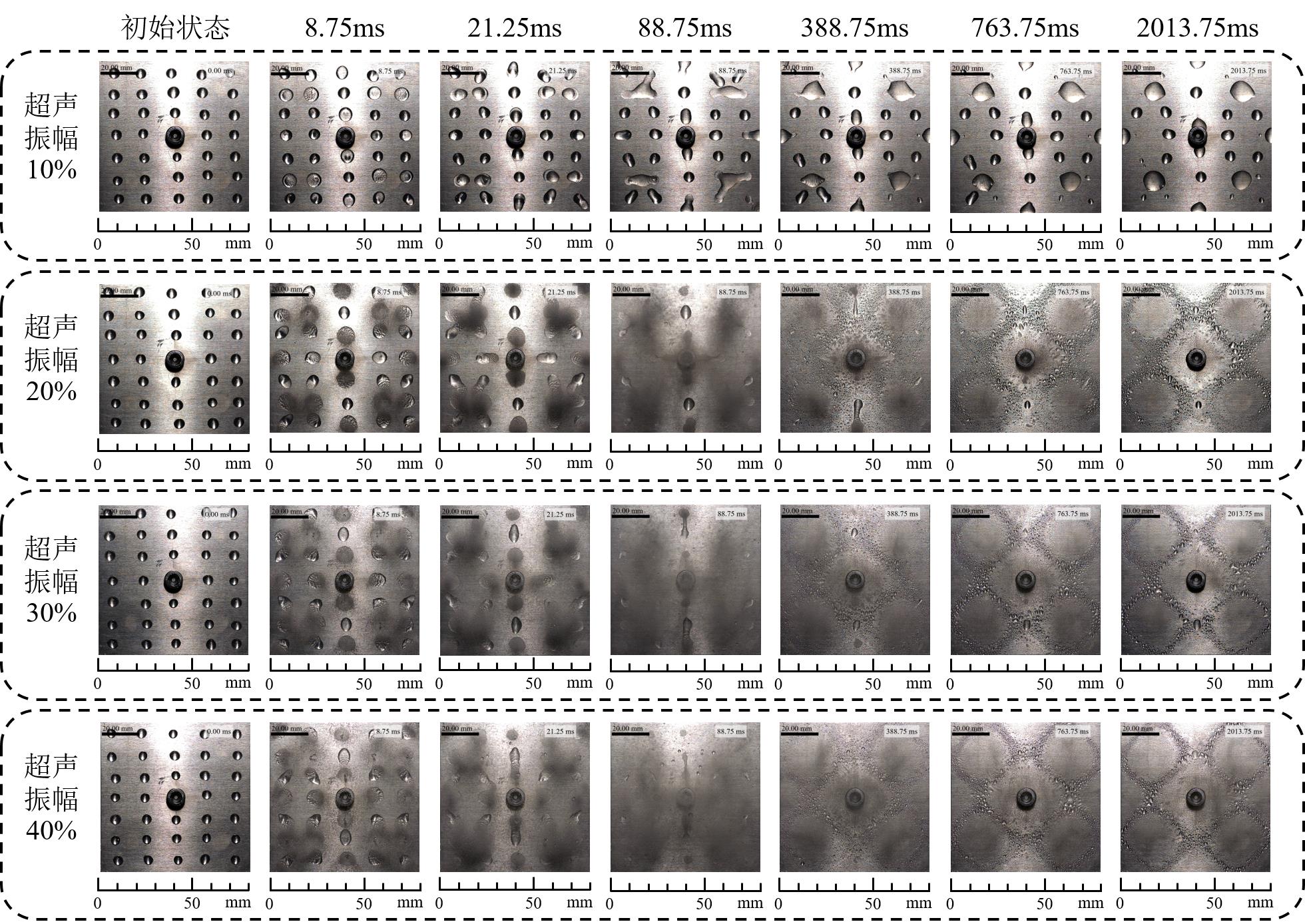

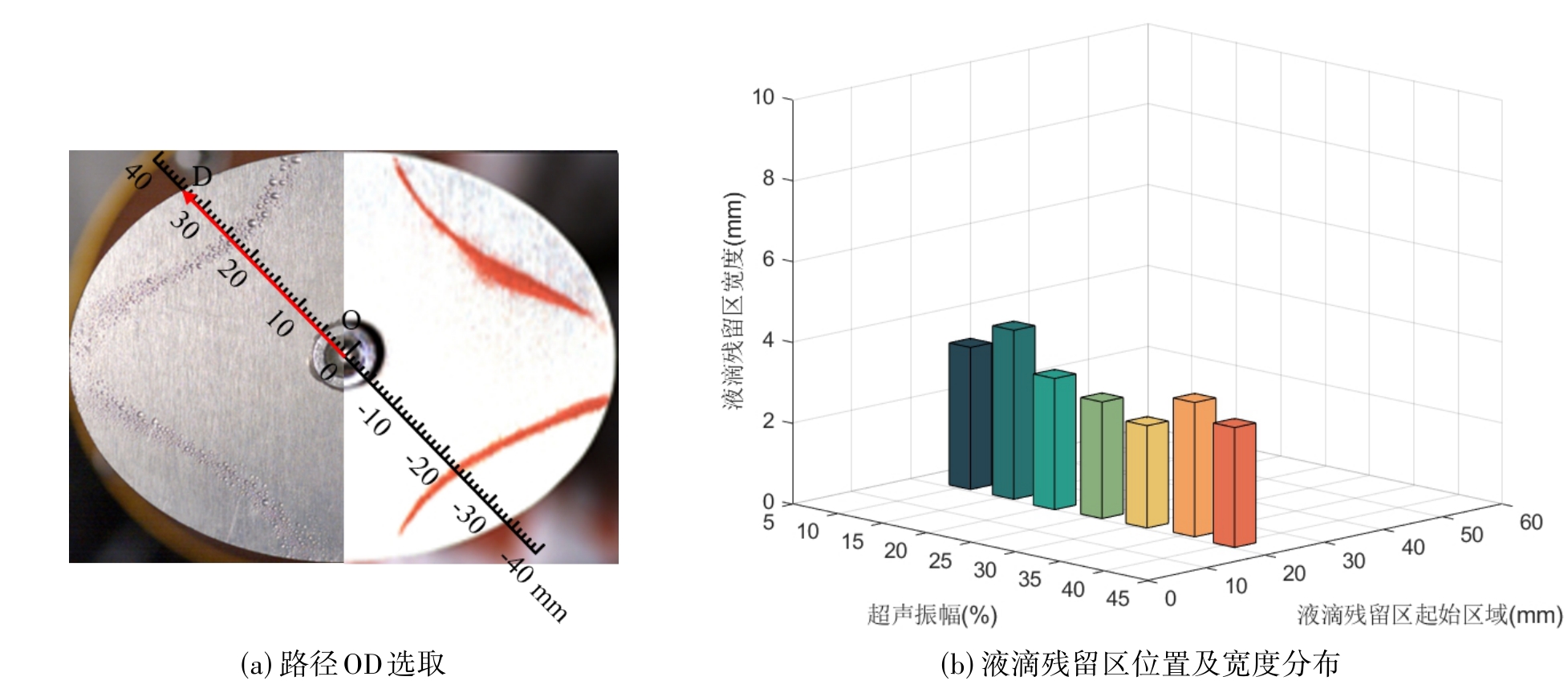

实验研究了超声激励平板振型分布对液滴群去除特性的影响。首先,基于超声扫频的平板表面铜粉分布结果表明,特定频率下各平板表面均会出现高-过渡-低振幅交替的半谐振特征,方、矩、圆、椭四种平板的低振幅区域分别呈中心对称4D型、轴对称4弧型、同心2圆型、中心对称4弧型分布。其次,在特定半谐振频率下针对各平板开展液滴群去除实验,发现液滴群均经历铺展雾化、运动合并、回落凝结、二次雾化四个阶段后,以微液滴形式残留且形状与各平板低振幅区域一致。再次,定量分析了超声振幅对各平板液滴去除特征的影响,结果表明随振幅增大,方、矩、圆三种平板离中心较近的微液滴残留区宽度单调递减,椭圆板液滴残留区则无明显变化规律;各振幅下椭圆板的微液滴残留区面积占比均最小,40%振幅下椭板比方、圆、矩板残留区域占比分别小17.59%、14.32%、6.98%,表明有多个焦点的平板形状可能更利于液滴群去除。预期本文结果将丰富超声波除液滴以及热泵空调增效领域的研究。

中图分类号:

赵日晶, 谢锃, 许桐瑞, 吴永帅, 黄东, 姜学斌. 超声激励平板振型分布对液滴群去除特性影响[J]. 化工学报, DOI: 10.11949/0438-1157.20251016.

Rijing ZHAO, Zeng XIE, Tongrui XU, Yongshuai WU, Dong HUANG, Xuebin JIANG. Effect of ultrasonic excitation vibration mode distribution of plates on droplet group removal characteristics[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251016.

图4 不同超声振幅激励下方形板表面滴定液滴群去除特性

Fig.4 Removal characteristics of titration droplet groups on square plate surface under different ultrasonic amplitude excitations

图9 椭圆形板超声雾化2s后液滴残留区位置及宽度分布

Fig.9 Position and width distribution of the droplet residual area after 2s of ultrasonic atomization on an elliptical plate

| 10% | 20% | 30% | 40% | |

|---|---|---|---|---|

| 方形板 | - | 41.30% | 34.38% | 28.90% |

| 矩形板 | - | 39.34% | 24.14% | 18.28% |

| 圆形板 | - | - | 27.67% | 25.63% |

| 椭圆形板 | 13.30% | 13.33% | 12.27% | 11.30% |

表1 不同振幅下超声激励四种平板后的液滴残留面积占比

Table 1 Residual area fraction after ultrasonic excitation of four types of plates under different amplitudes

| 10% | 20% | 30% | 40% | |

|---|---|---|---|---|

| 方形板 | - | 41.30% | 34.38% | 28.90% |

| 矩形板 | - | 39.34% | 24.14% | 18.28% |

| 圆形板 | - | - | 27.67% | 25.63% |

| 椭圆形板 | 13.30% | 13.33% | 12.27% | 11.30% |

| [1] | 张朝晖, 刘璐璐, 王若楠, 等. "双碳"目标下制冷空调行业技术发展的思考[J]. 制冷与空调, 2022, 22(1): 1-10. |

| Zhang Z H, Liu L L, Wang R N, et al. Thoughts on technical development of refrigeration and air-conditioning industry under carbon peaking and carbon neutrality goals[J]. Refrigeration and Air-Conditioning, 2022, 22(1): 1-10. | |

| [2] | Jiang S, Zhao H, Ni L. Review and prospect of air source heat pump research: a bibliometric insight[J]. International Journal of Refrigeration, 2025, 170: 172-191. |

| [3] | 马强, 吴晓敏. 表面特性对结霜和融霜排液的影响[J]. 化工学报, 2017, 68(S1): 90-95. |

| Ma Q, Wu X M. Effect of surface wettability on frosting, defrosting and drainage[J]. CIESC Journal, 2017, 68(S1): 90-95. | |

| [4] | Huang D, Zhao R J, Liu Y, et al. Effect of fin types of outdoor fan-supplied finned-tube heat exchanger on periodic frosting and defrosting performance of a residential air-source heat pump[J]. Applied Thermal Engineering, 2014, 69(1/2): 251-260. |

| [5] | 李佳星. 翅片管换热器结霜工况流动及换热特性研究[D]. 武汉: 华中科技大学, 2024. |

| Li J X. Research on flow and heat transfer characteristics of finned tube heat exchangers under frosting conditions[D]. Wuhan: Huazhong University of Science and Technology, 2024. | |

| [6] | 苏伟,张小松. 换热器表面抑霜/除霜技术研究进展[J]. 工程热物理学报, 2021, 42(9): 2195-2215. |

| Su W, Zhang X S. Review of anti-frosting and defrosting methods on air source heat pump[J]. Journal of Engineering Thermophysics, 2021, 42(9): 2195-2215. | |

| [7] | 张毅, 张冠敏, 冷学礼, 等. 无霜空气源热泵技术研究进展[J]. 化工学报, 2020, 71(12): 5400-5419. |

| Zhang Y, Zhang G M, Leng X L, et al. Research progress on frost-free air source heat pump technology[J]. CIESC Journal, 2020, 71(12): 5400-5419. | |

| [8] | 张逸翔. 空气源热泵热气旁通抑霜除霜研究[D]. 武汉: 华中科技大学, 2024. |

| Zhang Y X. Research on frost suppression and defrosting of air source heat pump by hot gas bypass[D]. Wuhan: Huazhong University of Science and Technology, 2024. | |

| [9] | Kwak K, Bai C. A study on the performance enhancement of heat pump using electric heater under the frosting condition: Heat pump under frosting condition[J]. Applied Thermal Engineering, 2010, 30(6/7): 539-543. |

| [10] | 薛连政, 鲁大山. 冷库除霜方式分析[J]. 制冷与空调, 2021, 21(10): 35-38. |

| Xue L Z, Lu D S. Analysis on defrosting methods for cold storage[J]. Refrigeration and Air-Conditioning, 2021, 21(10): 35-38. | |

| [11] | Bai X X, Liu S N, Deng S M, et al. An optimal control strategy for ASHP units with a novel dual-fan outdoor coil for evener frosting along airflow direction based on GRNN modelling[J]. Energy and Buildings, 2023, 292: 113136. |

| [12] | Wu S Y, Zhao R J, Wei X H, et al. Air-side thermal-hydraulic analysis and parameter optimization for vertical-fin microchannel heat exchanger[J]. Applied Thermal Engineering, 2023, 226: 120297. |

| [13] | Wang F, Liang C H, Yang W B, et al. Effects of frost thickness on dynamic defrosting on vertical hydrophobic and superhydrophobic fin surfaces[J]. Energy and Buildings, 2020, 223: 110134. |

| [14] | 秋雨豪, 杨维刚. 亲水涂层对翅片管式换热器空气侧性能的影响[J]. 制冷与空调, 2024, 24(3): 46-49. |

| Qiu Y H, Yang W G. Effects of hydrophilic coating on air-side performance of finned-tube heat exchanger[J]. Refrigeration and Air-Conditioning, 2024, 24(3): 46-49. | |

| [15] | Jhee S, Lee K S, Kim W S. Effect of surface treatments on the frosting/defrosting behavior of a fin-tube heat exchanger[J]. International Journal of Refrigeration, 2002, 25(8): 1047-1053. |

| [16] | Li F, Wu S Y, Ma Z H, et al. Effect of surface coating on defrosting water drainage characteristics of vertical-fin microchannel frosting evaporator[J]. Applied Thermal Engineering, 2022, 208: 118220. |

| [17] | 吴俐俊, 汪磊, 陈文政, 等. 换热器表面疏水涂层的制备及性能测试[J]. 同济大学学报(自然科学版). 2023, 51(9): 1479-1488. |

| Wu L J, Wang L, Chen W Z, et al. Preparation and performance test of hydrophobic coating on heat exchanger surface[J]. Journal of Tongji University (Natural Science), 2023, 51(9): 1479-1488. | |

| [18] | 马小魁, 丁国良, 张圆明. 析湿工况下亲水层对波纹翅片管换热器空气侧特性的影响分析[J]. 化工学报, 2007, 58(5): 1121-1126. |

| Ma X K, Ding G L, Zhang Y M. Effect of hydrophilic coating on airside performance of wavy fin-and-tube heat exchangers under dehumidifying conditions[J]. CIESC Journal, 2007, 58(5): 1121-1126. | |

| [19] | 吴永帅, 吴思远, 孙瑜, 等. 超声波抑霜/除霜机理及其实用化研究进展[J]. 工程热物理学报. 2025, 46(5): 1379-1400. |

| Wu Y S, Wu S Y, Sun Y, et al. Research Progress on the mechanism of ultrasound frost retardation/defrosting and its applications[J]. Journal of Engineering Thermophysics, 2025, 46(5): 1379-1400. | |

| [20] | 徐鹏, 赵靖怡, 李朝阳. 空气源热泵除霜技术研究进展[J]. 制冷与空调, 2024, 24(4): 97-104. |

| Xu P, Zhao J Y, Li Z Y. Research progress on defrosting technology of air source heat pump[J]. Refrigeration and Air-Conditioning, 2024, 24(4): 97-104. | |

| [21] | 于超. 超声波对不同润湿性表面霜层脱除的试验研究[D]. 南京: 南京师范大学, 2022. |

| Yu C. Experimental study on ultrasonic removal of frost on surfaces with different wettability[D]. Nanjing: Nanjing Normal University, 2022. | |

| [22] | 谭海辉, 陶唐飞, 徐光华, 等. 翅片管式蒸发器超声波除霜理论与技术研究[J]. 西安交通大学学报, 2015, 49(9): 105-113. |

| Tan H H, Tao T F, Xu G H, et al. Ultrasonic defrosting theory and technology for finned-tube evaporator[J]. Journal of Xi'an Jiaotong University, 2015, 49(9): 105-113. | |

| [23] | Tan H H, Zhang X F, Zhang L, et al. Ultrasonic influence mechanism of a cold surface frosting process and an optimised defrosting technique[J]. Applied Thermal Engineering, 2019, 153: 113-127. |

| [24] | 李栋, 陈振乾. 超声波瞬间雾化结霜初始阶段液滴的可视化[J]. 化工学报, 2013, 64(11): 3910-3916. |

| Li D, Chen Z Q. Visualization of ultrasonic vibration for instantaneously atomizing water droplets in initial frost growth stage[J]. CIESC Journal, 2013, 64(11): 3910-3916. | |

| [25] | 朱琳. 冷表面结/融霜行为及超声波去除表面融霜液滴试验研究[D]. 南京: 南京师范大学, 2017. |

| Zhu L. Experimental study on frosting/defrosting behaviors of cold surfaces and ultrasonic removal of defrosting droplets[D]. Nanjing: Nanjing Normal University, 2017. | |

| [26] | Vukasinovic B, Smith M K, Glezer A. Dynamics of a sessile drop in forced vibration[J]. Journal of Fluid Mechanics, 2007, 587: 395-423. |

| [27] | Zhang Y, Yuan S M, Gao Y. Spatial distribution and transient evolution of sub-droplet velocity and size in ultrasonic atomization[J]. Experimental Thermal and Fluid Science, 2023, 140: 110761. |

| [28] | Zhang H X, Zhang X W, Yi X, et al. Dynamic behaviors of droplets impacting on ultrasonically vibrating surfaces[J]. Experimental Thermal and Fluid Science, 2020, 112: 110019. |

| [29] | 李帅. 超声波去除铝板表面霜层及融霜液滴的试验研究[D]. 南京: 南京师范大学, 2020. |

| Li S. Experimental study on ultrasonic removal of frost and defrosting droplets from aluminum surfaces[D]. Nanjing: Nanjing Normal University, 2020. | |

| [30] | 吴馨, 龚建英, 靳龙, 等. 超声波激励下铝板表面液滴群输运特性的研究[J], 化工学报, 2023, 74(S1): 104-112. |

| Wu X, Gong J Y, Jin L, et al. Study on the transportation characteristics of droplets on the aluminiumsurface under ultrasonic excitation[J]. CIESC Journal, 2023, 74(S1): 104-112. | |

| [31] | 叶振鸿, 王炜, 李新华, 等. 综述: 微通道换热器的防冻技术[J]. 上海交通大学学报(英文版), 2024, 29(2): 161-178. |

| Ye Z, Wang W, Li X, et al. Review on Anti-Frost Technology Based on Microchannel Heat Exchanger[J]. Journal of Shanghai Jiaotong University (Science), 2024, 29(2): 161-178. | |

| [32] | Urai T, Kamai M, Fujii H. Estimation of intrinsic contact angle of various liquids on PTFE by utilizing ultrasonic vibration[J]. Journal of Materials Engineering and Performance, 2016, 25(8): 3384-3389. |

| [33] | Andrade M A B, Marzo A. Numerical and experimental investigation of the stability of a drop in a single-axis acoustic levitator[J]. Physics of Fluids, 2019, 31(11): 117101. |

| [1] | 任现超, 谷雅秀, 段少斌, 贾文竹, 李汉林. 翅片式椭圆套管蒸发式冷凝器传热传质性能实验研究[J]. 化工学报, 2025, 76(S1): 75-83. |

| [2] | 孙浩然, 吴成云, 王艳蒙, 孙静楠, 胡仞与, 段钟弟. 热对流影响下液滴蒸发特性模型与实验研究[J]. 化工学报, 2025, 76(S1): 123-132. |

| [3] | 吴馨, 龚建英, 李祥宇, 王宇涛, 杨小龙, 蒋震. 超声波激励疏水表面液滴运动的实验研究[J]. 化工学报, 2025, 76(S1): 133-139. |

| [4] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [5] | 李文龙, 常程, 吴小林, 姬忠礼. 油水聚结过滤材料中的液体分布特性及过程压降演化研究[J]. 化工学报, 2025, 76(9): 4850-4861. |

| [6] | 刘璐, 杨莹, 杨浩文, 王太, 王腾, 董新宇, 闫润. 星形亲水区组合表面冷凝液滴脱落特性实验研究[J]. 化工学报, 2025, 76(8): 3905-3914. |

| [7] | 周玉祥, 林巧力. 基于振荡座滴测定液滴表面张力的方法[J]. 化工学报, 2025, 76(8): 4185-4193. |

| [8] | 叶鑫煌, 薛嘉豪, 赵玉来. 可聚型Gemini表面活性剂的制备、表征及其稳定高内相乳液的研究[J]. 化工学报, 2025, 76(8): 4331-4340. |

| [9] | 龚路远, 果正龙, 赵登辉, 郭亚丽, 周健, 韩倩倩, 沈胜强. 不同疏水性表面冷凝传热性能及动力学特征研究[J]. 化工学报, 2025, 76(8): 3932-3943. |

| [10] | 彭梦圆, 李家明, 沙敏, 张丁. 季铵盐氟碳表面活性剂复配体系的性能研究[J]. 化工学报, 2025, 76(8): 4177-4184. |

| [11] | 陈科拯, 高蓬辉, 焉富春, 程博. 考虑液滴动态行为的亲-疏水复合结构表面冷凝特性影响因素分析[J]. 化工学报, 2025, 76(8): 3976-3989. |

| [12] | 张海丰, 闫静怡, 岳玉学, 张子龙, 王柏林, 李小年. WO3纳米颗粒定性表面羟基化重构及其改性变压器油机制研究[J]. 化工学报, 2025, 76(7): 3696-3709. |

| [13] | 杨文毅, 由长福, 王海名. 燃煤机组变负荷运行下的脱硫废水零排放流程模拟分析[J]. 化工学报, 2025, 76(7): 3468-3476. |

| [14] | 赵美, 甘雨欣, 赵绍磊, 杨令, 王亭杰. 硅橡胶用纳米二氧化硅表面有机修饰及补强机理研究进展[J]. 化工学报, 2025, 76(7): 3125-3136. |

| [15] | 李同辉, 回天力, 郑涛, 张睿, 刘海燕, 刘植昌, 徐春明, 孟祥海. 氢氧化物协同钯双活性位点用于大电流和pH通用析氢反应[J]. 化工学报, 2025, 76(7): 3671-3685. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号