化工学报 ›› 2025, Vol. 76 ›› Issue (8): 4185-4193.DOI: 10.11949/0438-1157.20250018

收稿日期:2025-01-04

修回日期:2025-02-27

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

林巧力

作者简介:周玉祥(1999—),男,硕士研究生,zhouyuxiang_1127@163.com

基金资助:Received:2025-01-04

Revised:2025-02-27

Online:2025-08-25

Published:2025-09-17

Contact:

Qiaoli LIN

摘要:

表面张力是液体重要的物性参数,是影响各种化学反应和生物反应的关键因素之一,也是化学工程计算中必不可少的基础物性参数。振荡座滴法是一种高精度、高灵敏度地测量液体表面张力的方法。为了探讨基于振荡座滴法测量液体表面张力的有效性和影响因素,本研究在20℃下以蒸馏水、乙醇和乙二醇为实验对象,采用外径不同的不锈钢针头滴落液滴至聚对苯二甲酸乙二醇酯(PET)基板上,通过高速摄像记录液滴的振荡行为,并进行频谱分析。实验结果显示,虽然基于Rayleigh公式计算出的表面张力值普遍高于传统的悬滴法测量值,但振荡频率与液滴体积间存在线性关系。此外,实验还验证了不同图像采集帧率对频谱分析结果的影响。研究表明,振荡座滴法是一种有潜力的测量方法,尤其适用于高温条件下冶金熔体的表面张力测量。然而,目前该方法计算得到的表面张力值仍高于标准值,需要进一步优化模型以提高测量精度。

中图分类号:

周玉祥, 林巧力. 基于振荡座滴测定液滴表面张力的方法[J]. 化工学报, 2025, 76(8): 4185-4193.

Yuxiang ZHOU, Qiaoli LIN. Determination of surface tension via oscillating sessile drop method[J]. CIESC Journal, 2025, 76(8): 4185-4193.

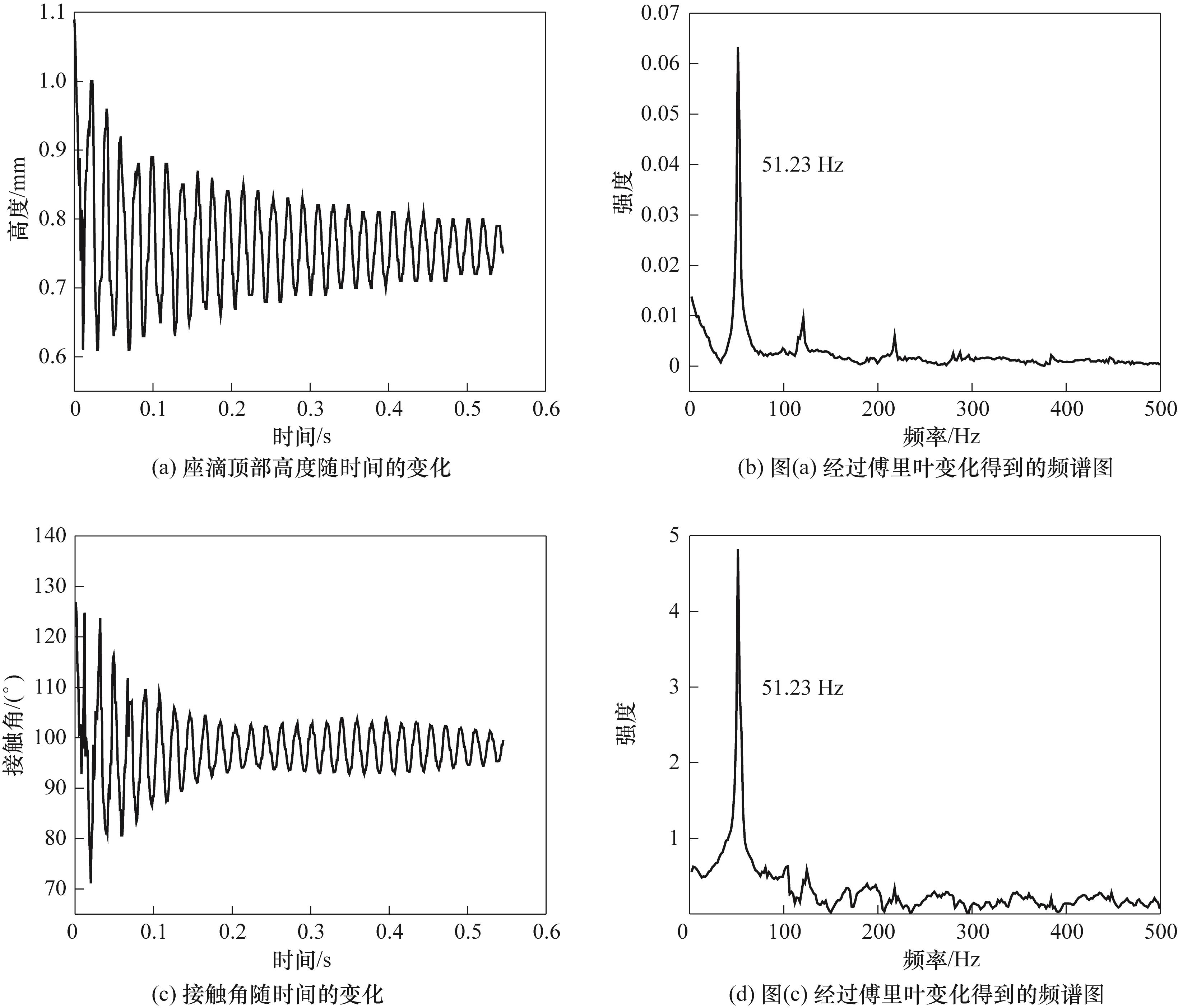

图4 软件测量得到的液滴高度的时域数据、接触角及对其进行傅里叶变换后得到的频域数据

Fig.4 The time domain data of droplet height, contact angle and frequency domain data obtained by Fourier transform measured by the software

| 特征频率/Hz | 液滴体积/μl | 表面张力/(mN/m) |

|---|---|---|

| 87.682 | 9.73 | 88.083 |

| 96.841 | 9.26 | 102.256 |

| 91.511 | 9.12 | 89.929 |

| 92.316 | 10.18 | 102.155 |

| 96.032 | 10.06 | 109.242 |

| 94.032 | 9.60 | 99.950 |

| 88.147 | 9.66 | 88.379 |

表1 0.45 mm外径针头提取的座滴振荡特征频率的表面张力值

Table 1 Surface tension values from oscillatory drop frequencies extracted using 0.45 mm outer diameter needle

| 特征频率/Hz | 液滴体积/μl | 表面张力/(mN/m) |

|---|---|---|

| 87.682 | 9.73 | 88.083 |

| 96.841 | 9.26 | 102.256 |

| 91.511 | 9.12 | 89.929 |

| 92.316 | 10.18 | 102.155 |

| 96.032 | 10.06 | 109.242 |

| 94.032 | 9.60 | 99.950 |

| 88.147 | 9.66 | 88.379 |

| 针头外径/mm | 特征频率/Hz | 液滴体积/μl | 表面张力/(mN/m) |

|---|---|---|---|

| 0.45 | 87.682 | 9.7302 | 88.083 |

| 0.80 | 71.753 | 15.274 | 92.596 |

| 1.26 | 60.133 | 22.461 | 95.635 |

| 1.26 | 63.611 | 19.620 | 93.481 |

| 4.03 | 43.262 | 40.495 | 89.243 |

表2 不同液滴大小、特征频率计算的表面张力值

Table 2 Surface tension values calculated from different drop sizes and characteristic frequencies

| 针头外径/mm | 特征频率/Hz | 液滴体积/μl | 表面张力/(mN/m) |

|---|---|---|---|

| 0.45 | 87.682 | 9.7302 | 88.083 |

| 0.80 | 71.753 | 15.274 | 92.596 |

| 1.26 | 60.133 | 22.461 | 95.635 |

| 1.26 | 63.611 | 19.620 | 93.481 |

| 4.03 | 43.262 | 40.495 | 89.243 |

| 采集帧率/(帧/s) | 特征频率/Hz | 液滴体积/μl | 表面张力/(mN/m) |

|---|---|---|---|

| 1500 | 62.271 | 22.521 | 102.830 |

| 1500 | 60.065 | 22.674 | 96.323 |

| 1000 | 59.851 | 23.355 | 98.511 |

| 260 | 56.304 | 23.058 | 86.072 |

表3 不同采集帧率的特征频率计算的表面张力值(针头外径1.26 mm)

Table 3 Surface tension values calculated from characteristic frequencies at different frame rates (needle outer diameter 1.26 mm)

| 采集帧率/(帧/s) | 特征频率/Hz | 液滴体积/μl | 表面张力/(mN/m) |

|---|---|---|---|

| 1500 | 62.271 | 22.521 | 102.830 |

| 1500 | 60.065 | 22.674 | 96.323 |

| 1000 | 59.851 | 23.355 | 98.511 |

| 260 | 56.304 | 23.058 | 86.072 |

| 特征频率/Hz | 密度/(g/cm3) | 液滴体积/μl | 表面张力/(mN/m) | |

|---|---|---|---|---|

| 振荡座滴法 | 悬滴法 | |||

| 乙醇 | ||||

| 104.063 | 0.789 | 3.52 | 35.441 | 22.3 |

| 89.462 | 0.789 | 3.67 | 27.289 | 22.3 |

| 乙二醇 | ||||

| 89.761 | 1.113 | 5.10 | 53.852 | 44.7 |

表4 乙醇与乙二醇表面张力的振荡座滴法与悬滴法测定值对比

Table 4 Surface tension measurement of ethanol and ethylene glycol: oscillating sessile drop versus pendant-drop method

| 特征频率/Hz | 密度/(g/cm3) | 液滴体积/μl | 表面张力/(mN/m) | |

|---|---|---|---|---|

| 振荡座滴法 | 悬滴法 | |||

| 乙醇 | ||||

| 104.063 | 0.789 | 3.52 | 35.441 | 22.3 |

| 89.462 | 0.789 | 3.67 | 27.289 | 22.3 |

| 乙二醇 | ||||

| 89.761 | 1.113 | 5.10 | 53.852 | 44.7 |

| 特征频率/Hz | 密度/(g/cm3) | 液滴体积/μl | 表面张力/(mN/m) | α | ||

|---|---|---|---|---|---|---|

| 式(5) | 式(6) | 式(7) | ||||

| 95.314 | 0.998 | 11.278 | 120.282 | 190.005 | 195.779 | 1.621 |

| 96.841 | 0.998 | 9.261 | 101.955 | 196.142 | 165.949 | 1.648 |

| 91.511 | 0.998 | 9.124 | 89.701 | 175.145 | 146.003 | 1.557 |

| 92.316 | 0.998 | 10.184 | 101.893 | 178.240 | 165.848 | 1.571 |

| 87.682 | 0.998 | 9.730 | 87.821 | 160.795 | 142.944 | 1.492 |

| 71.753 | 0.998 | 15.274 | 92.319 | 172.554 | 150.264 | 1.221 |

| 60.133 | 0.998 | 22.461 | 95.348 | 215.829 | 155.195 | 1.729 |

| 63.611 | 0.998 | 17.825 | 84.674 | 135.616 | 137.821 | 1.370 |

| 43.262 | 0.998 | 40.495 | 88.976 | 218.186 | 144.823 | 1.738 |

| 104.063 | 0.789① | 3.520 | 35.414 | 30.660 | 57.469 | 1.173 |

| 89.462 | 0.789① | 3.670 | 27.289 | 28.607 | 44.283 | 1.133 |

| 89.761 | 1.113② | 5.100 | 53.842 | 126.313 | 87.374 | 1.683 |

表5 应用式(5)~式(7)计算得到的表面张力和式(9)中的α

Table 5 Surface tension calculated by Eqs. (5)—(7) and α in Eq. (9)

| 特征频率/Hz | 密度/(g/cm3) | 液滴体积/μl | 表面张力/(mN/m) | α | ||

|---|---|---|---|---|---|---|

| 式(5) | 式(6) | 式(7) | ||||

| 95.314 | 0.998 | 11.278 | 120.282 | 190.005 | 195.779 | 1.621 |

| 96.841 | 0.998 | 9.261 | 101.955 | 196.142 | 165.949 | 1.648 |

| 91.511 | 0.998 | 9.124 | 89.701 | 175.145 | 146.003 | 1.557 |

| 92.316 | 0.998 | 10.184 | 101.893 | 178.240 | 165.848 | 1.571 |

| 87.682 | 0.998 | 9.730 | 87.821 | 160.795 | 142.944 | 1.492 |

| 71.753 | 0.998 | 15.274 | 92.319 | 172.554 | 150.264 | 1.221 |

| 60.133 | 0.998 | 22.461 | 95.348 | 215.829 | 155.195 | 1.729 |

| 63.611 | 0.998 | 17.825 | 84.674 | 135.616 | 137.821 | 1.370 |

| 43.262 | 0.998 | 40.495 | 88.976 | 218.186 | 144.823 | 1.738 |

| 104.063 | 0.789① | 3.520 | 35.414 | 30.660 | 57.469 | 1.173 |

| 89.462 | 0.789① | 3.670 | 27.289 | 28.607 | 44.283 | 1.133 |

| 89.761 | 1.113② | 5.100 | 53.842 | 126.313 | 87.374 | 1.683 |

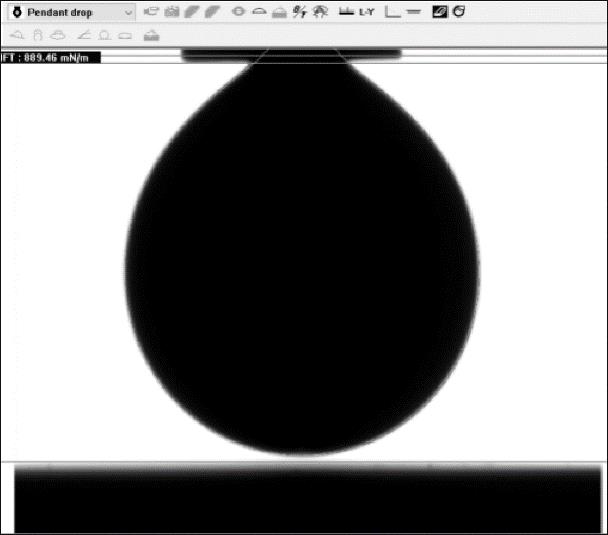

图6 悬滴法验证文献[30]中纯铝在750℃的表面张力

Fig.6 Surface tension of pure aluminum verified by pendant-drop method at 750℃ (the original pendant-drop image is from Ref.[30])

| [1] | Wijshoff H. Drop dynamics in the inkjet printing process[J]. Current Opinion in Colloid & Interface Science, 2018, 36: 20-27. |

| [2] | Basilio P A, Torres Rojas A M, Corvera Poiré E, et al. Stream of droplets as an actuator for oscillatory flows in microfluidics[J]. Microfluidics and Nanofluidics, 2019, 23(5): 64. |

| [3] | Haber E, Douvidzon M, Maayani S, et al. A liquid mirror resonator[J]. Micromachines (Basel), 2023, 14(3): 624. |

| [4] | Wu N, Dai J L, Micale F J. Dynamic surface tension measurement with a dynamic wilhelmy plate technique[J]. Journal of Colloid and Interface Science, 1999, 215(2): 258-269. |

| [5] | Kim D, Jeong M A, Kang K, et al. Gravitational effect on the advancing and receding angle of a 2D Cassie-Baxter droplet on a textured surface[J]. Langmuir, 2020, 36(21): 6061-6069. |

| [6] | Mills K C, Brooks R F. Measurements of thermophysical properties in high temperature melts[J]. Materials Science and Engineering: A, 1994, 178(1/2): 77-81. |

| [7] | Kitahata H, Tanaka R, Koyano Y, et al. Oscillation of a rotating levitated droplet: analysis with a mechanical model[J]. Physical Review. E, Statistical, Nonlinear, and Soft Matter Physics, 2015, 92(6): 062904. |

| [8] | Xiao X, Hyers R W, Wunderlich R K, et al. Deformation induced frequency shifts of oscillating droplets during molten metal surface tension measurement[J]. Applied Physics Letters, 2018, 113(1): 011903. |

| [9] | Fahimi K, Mädler L, Ellendt N. Measurement of surface tension with free-falling oscillating molten metal droplets: a numerical and experimental investigation[J]. Experiments in Fluids, 2023, 64(7): 133. |

| [10] | Strutt J W. Ⅵ. On the capillary phenomena of jets[J]. Proceedings of the Royal Society of London, 1879, 29(196/197/198/199): 71-97. |

| [11] | Lamb H. Hydrodynamics[M]. 6th ed. Cambridge: Cambridge University Press, 1932. |

| [12] | Milne A J B, Defez B, Cabrerizo-Vílchez M, et al. Understanding (sessile/constrained) bubble and drop oscillations[J]. Advances in Colloid and Interface Science, 2014, 203: 22-36. |

| [13] | Liang G T, Yu H B, Chen L Z, et al. Spreading and oscillation induced by liquid drop impacting onto sessile drop[J]. European Journal of Mechanics-B/Fluids, 2020, 79: 247-254. |

| [14] | Deepu P, Chowdhuri S, Basu S. Oscillation dynamics of sessile droplets subjected to substrate vibration[J]. Chemical Engineering Science, 2014, 118: 9-19. |

| [15] | Ding D, Bostwick J B. Pressure modes of the oscillating sessile drop[J]. Journal of Fluid Mechanics, 2022, 944: R1. |

| [16] | Korenchenko A E, Malkova J P. Numerical investigation of phase relationships in an oscillating sessile drop[J]. 2015, 27(10): 102104. |

| [17] | Singha P, Nguyen N K, Zhang J, et al. Oscillating sessile liquid marble — a tool to assess effective surface tension[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 627: 127176. |

| [18] | Mettu S, Chaudhury M K. Motion of drops on a surface induced by thermal gradient and vibration[J]. Langmuir, 2008, 24(19): 10833-10837. |

| [19] | Bashforth F, Adams J C. An Attempt to Test the Theories of Capillary Action by Comparing the Theoretical and Measured Forms of Drops of Fluid[M]. Cambridge: Cambridge University Press, 1883. |

| [20] | 张禹负, 刘华. 一种水平旋转滴法测定接触角的方法及装置: 100380111C[P]. 2008-04-09. |

| Zhang Y F, Liu H. A method and device for measuring contact angle using horizontal rotating droplet method: 100380111C[P]. 2008-04-09. | |

| [21] | 周斌, 李思维, 陈志勇, 等. 完全轮廓法计算液体表面张力的改进[J]. 清华大学学报(自然科学版), 2016, 56(12): 1352-1356. |

| Zhou B, Li S W, Chen Z Y, et al. Full-profile fit pendent drop method for surface tension measurements[J]. Journal of Tsinghua University (Science and Technology), 2016, 56(12): 1352-1356. | |

| [22] | de Ruiter J, Lagraauw R, van den Ende D, et al. Wettability-independent bouncing on flat surfaces mediated by thin air films[J]. Nature Physics, 2015, 11: 48-53. |

| [23] | Birdi K S. Handbook of Surface and Colloid Chemistry[M]. 2nd ed. Boca Raton, Fla.: CRC Press, 2003. |

| [24] | Costalonga M, Brunet P. Directional motion of vibrated sessile drops: a quantitative study[J]. Physical Review Fluids, 2020, 5(2): 023601. |

| [25] | McHale G, Elliott S J, Newton M I, et al. Levitation-free vibrated droplets: resonant oscillations of liquid marbles[J]. Langmuir, 2009, 25(1): 529-533. |

| [26] | Lim T, Han S, Chung J, et al. Experimental study on spreading and evaporation of inkjet printed pico-liter droplet on a heated substrate[J]. International Journal of Heat and Mass Transfer, 2009, 52(1/2): 431-441. |

| [27] | Sangiorgi R, Caracciolo G, Passerone A. Factors limiting the accuracy of measurements of surface tension by the sessile drop method[J]. Journal of Materials Science, 1982, 17(10): 2895-2901. |

| [28] | Sharp J S. Resonant properties of sessile droplets; contact angle dependence of the resonant frequency and width in glycerol/water mixtures[J]. Soft Matter, 2012, 8(2): 399-407. |

| [29] | Korenchenko A E, Beskachko V P. Oscillations of a sessile droplet in open air[J]. Physics of Fluids, 2013, 25(11): 112106. |

| [30] | Sun Y Q, Yousefi E, Kunwar A, et al. Study of the interfacial reactions controlling the spreading of Al on Ni[J]. Applied Surface Science, 2022, 571: 151272. |

| [31] | Gale W F, Totemeier T C.Smithells Metals Reference Book[M]. 8th ed. Amsterdam: Elsevier, 2004. |

| [1] | 彭梦圆, 李家明, 沙敏, 张丁. 季铵盐氟碳表面活性剂复配体系的性能研究[J]. 化工学报, 2025, 76(8): 4177-4184. |

| [2] | 叶鑫煌, 薛嘉豪, 赵玉来. 可聚型Gemini表面活性剂的制备、表征及其稳定高内相乳液的研究[J]. 化工学报, 2025, 76(8): 4331-4340. |

| [3] | 李超, 陈浩文, 胡真, 王成行, 吕昊子, 邱显扬. 脉冲气流-柔性孔耦合成泡机制[J]. 化工学报, 2024, 75(12): 4761-4769. |

| [4] | 赵佳佳, 田世祥, 李鹏, 谢洪高. SiO2-H2O纳米流体强化煤尘润湿性的微观机理研究[J]. 化工学报, 2023, 74(9): 3931-3945. |

| [5] | 赵文一, 匡以武, 王文, 张红星, 苗建印. 水平管内冷凝流动的稳定性[J]. 化工学报, 2021, 72(S1): 257-265. |

| [6] | 朱业铭, 刘金平, 许雄文, 朱丹丹. 竖直多孔平板上液膜流动特性的研究[J]. 化工学报, 2021, 72(8): 4081-4092. |

| [7] | 朱丹丹, 许雄文, 刘金平, 卢炯. 混合润湿性图案化铜基表面冷凝换热性能研究[J]. 化工学报, 2021, 72(5): 2528-2546. |

| [8] | 宇高义郎, 许竞莹, 王国卓, 陈志豪. 质子交换膜燃料电池内含水气体扩散层的冻结特性研究[J]. 化工学报, 2021, 72(4): 2276-2282. |

| [9] | 曹燕,丁延,郭义仓,汪城,刘英杰,陶磊,李进龙. 溴化锂及离子液体水溶液密度、黏度和表面张力测定与计算[J]. 化工学报, 2021, 72(4): 1874-1884. |

| [10] | 别海燕, 黄晨, 安维中, 李玉龙, 林子昕. 正反馈式流体振荡器内部流动特性的数值模拟[J]. 化工学报, 2021, 72(3): 1504-1511. |

| [11] | 吴兆伟, 施浙杭, 赵辉, 周骛, 蔡小舒, 刘海峰. 表面张力变化对含气泡液体射流破裂的影响[J]. 化工学报, 2021, 72(3): 1283-1294. |

| [12] | 张华海, 王悦琳, 王铁峰. 全浓度范围下醇类表面活性剂对气泡聚并影响的实验研究[J]. 化工学报, 2020, 71(9): 4161-4167. |

| [13] | 李睿, 张以任, 陈杭, 路贵民, 于建国. 二元液滴自由碰撞聚并后的振荡行为研究[J]. 化工学报, 2020, 71(4): 1482-1490. |

| [14] | 龚志明, 王瑞祥, 邢美波. 全氟烷基表面活性剂吸附特性研究[J]. 化工学报, 2020, 71(4): 1754-1761. |

| [15] | 刘雷, 张粤, 李霞, 雷惊雷, 李凌杰. 铝合金表面耐久性超疏水防护膜的制备与表征[J]. 化工学报, 2020, 71(10): 4750-4759. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号